With the assistance of a helper, I was able to install the hatch glass again last night, this time with the stainless trim already installed in the gasket. The hardest part was getting the outer edge of the seal to seat against the outside of the hatch surface, when pulling the cord to start bringing the seal lip over and to the inside surface of the pinch weld flange. I started pulling the cord in the middle of the bottom side. With the stainless trim installed, the outside edge of the seal wants to tuck down inside the hatch glass opening instead of being pushed outward to lay flat on the outer surface. To solve, you need to push/pull the hatch glass/weather strip assembly downward toward and against the bottom of the opening. If you do not, the glass will want to move away from the bottom side and as you pull the rope, the outside edge of the weather strip will tuck inside outer edge of the opening (the part where the outside surface of the hatch turns 90 degree downwards to create the flange for the hatch glass.

After a couple of false starts, where I had to put the glass back on a work surface and put the rope back into the groove, we understood that we needed to keep the glass tightly against the bottom edge as I pulled the rope to bring the inner lip of the seal into the inside of the weld flange. Pulling the rope around to each side and up each side equally, and then across the top, there were no issues. We found that for the top edge, pushing on the outside of the glass (to press it into the window opening) worked better as I pulled the rope for that side (fourth, and last, in the order that I went in).

This time, there are no cuts or nicks in the rubber seal at all. For some reason, this factory seal had a bunch of gummy stuff all over it, perhaps to assist with installation, if I am guessing. It seemed a lot more flexible that the other one that I destroyed. Perhaps it was much newer than the previous one I used. I still need to remove that with adhesive remover, and when I do so, the stainless trim won't look dull like it does now.

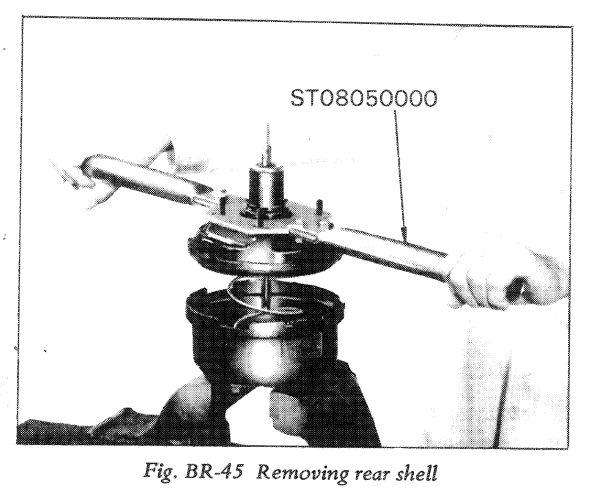

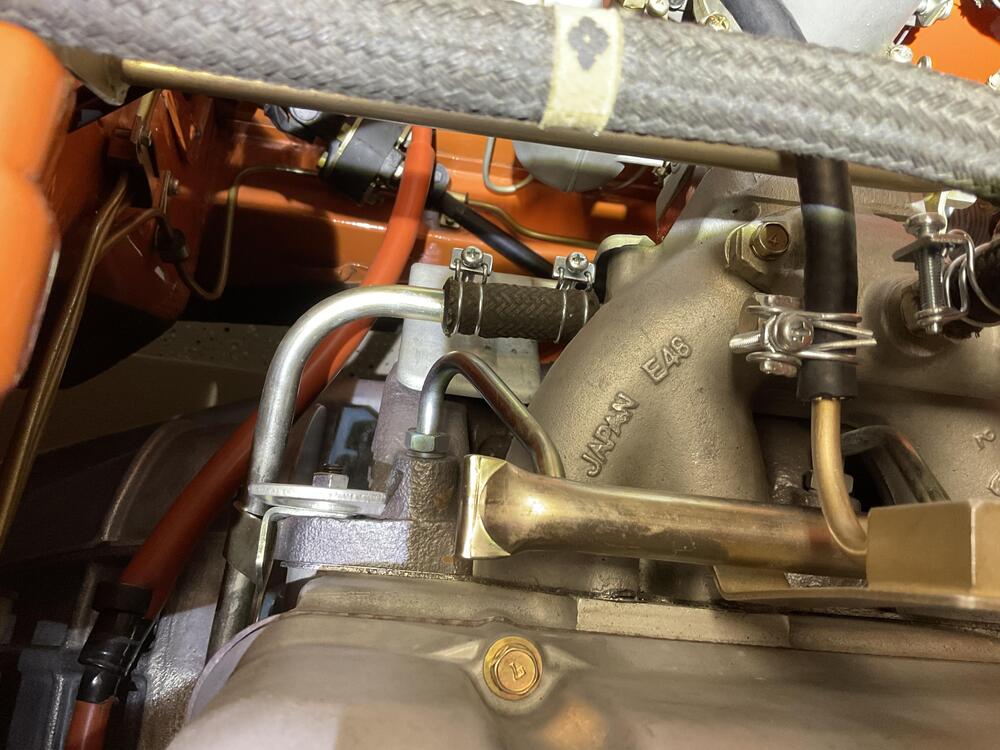

Today, I plan to work on making a copy of brake booster tool ST08050000 so I can get my brake booster apart to start rebuilding it.

Subscriber

Subscriber 4Points1,282Posts

4Points1,282Posts Subscriber

Subscriber 4Points11,142Posts

4Points11,142Posts Subscriber

Subscriber 3Points2,733Posts

3Points2,733Posts Subscriber

Subscriber 3Points2,228Posts

3Points2,228Posts