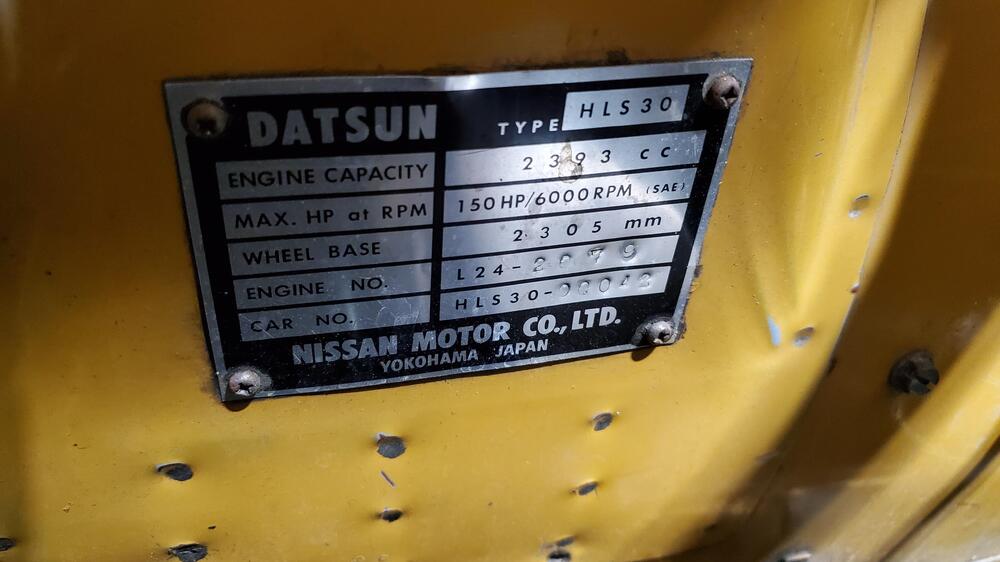

HLS30-00042 arrived this afternoon for a complete restoration. Boy, this an early one, complete with the original clear rear window. It's a little beat up, but most of the parts are there. I own HLS30-02614 in the same color, so by the time I am finished they should be looking like twins.

The motor runs, which is great, but it will undergo a complete rebuild. Amazingly, the head still has the overspray on the lower portion, which is pretty rare to see. I will see if the machine shop can leave that intact. There are still a few wire clamps in there and the owner has a metal fan (and a number of other key parts), so we should be able to get the engine bay looking like the original.

Looks like the hood has been replaced by a later series that was orange. The drivers side door may have been replaced as well, as there appears to be blue paint under the Safari Gold re-spray. Also, the rear panel under the rear bumper is pretty beat up and front bumper is missing. We will need to get one of those. Rear bumper looks to be in pretty good shape. Both headlight buckets are fiberglass and cracked. Both fenders are pretty rusted out in the standard places. Rear hatch panel is also rusted out (as usual) and will need to be replaced by the body shop.

The interior will need to be completely restored as most items are severely cracked or worn. The original dash has just one crack in the middle unfortunately. Not sure if that is repairable, I will have to look into that as the single crack is about 2 inches long. The seats have the original vinyl material which is cool, but not usable obviously (from the pics).

So the plan here is to completely strip the car over the next two weeks and get the body to the body shop ASAP as that is typically the long pole in the process. I am estimating about 6 months for the body shop to complete all its work. While the body is out, I will send the block and head to the machine shop to get that all in order for me to re-build. All the undercarriage parts will be sent to the powder coater, and all of the nuts and bolts will go out for re-plating. I will re-upholster the seats, clean up the wiring harnesses and replace the connector housings, and then start re-assembling items as they return from the shops so that once the body arrives, everything will be ready to assemble.

I will post progress on here and pics as things move along. As always, feel free to comment.

Subscriber

Subscriber 7Points2,228Posts

7Points2,228Posts Subscriber

Subscriber 2Points11,142Posts

2Points11,142Posts

.thumb.jpg.ec8a5efa93ff12430f99926668938dac.jpg)

.thumb.jpg.f70075449a254e1f05b51897c14e5f0e.jpg)