Today, I took a 1/2 day off from work and worked on the car. I was able to get the driveshaft measured properly. I will be sending it off tomorrow for shortening and balancing.

I installed the Pertronix electronic ignition. I didn't take pictures, but I ended up modifying the distributor cap a bit to allow the wires to exit the distributor. I just drilled a hole and used a dremel a bit to get the boot that came with the kit to fit snugly.

Next, I did a modification to the new interior panels I bought. I purchased the whole set of new, black panels (roof bar, quarter window, rear hatch, and tail light) from Z Car Depot. I also was able to source new SU nozzles from them.

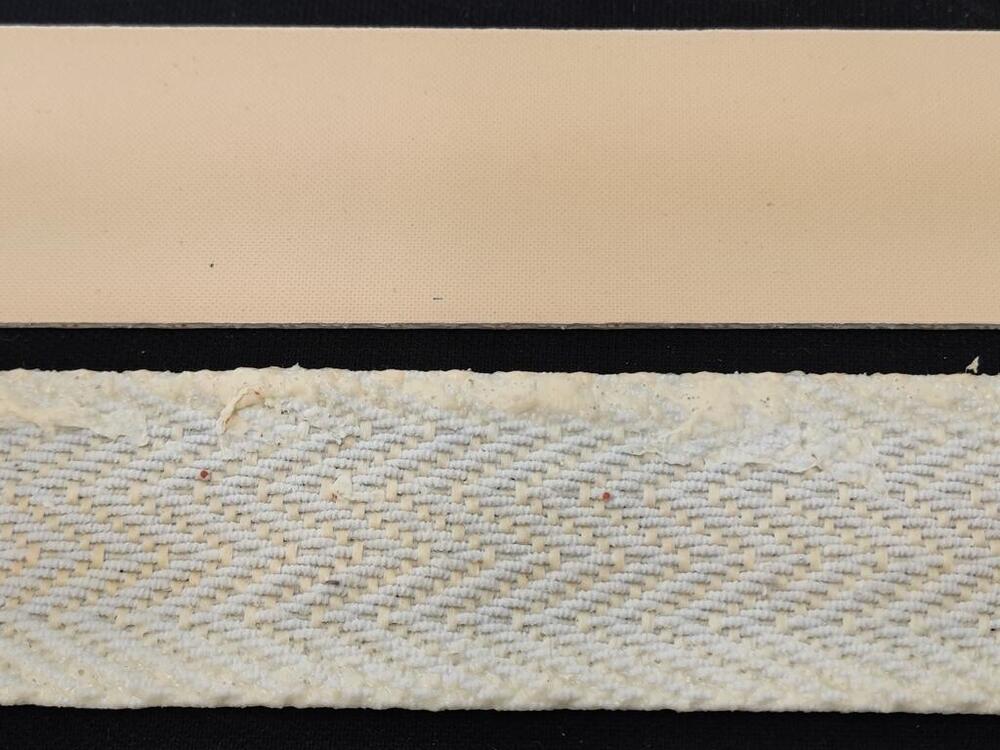

First, a comparison of the grain finish:

Original and reproduction, in that order:

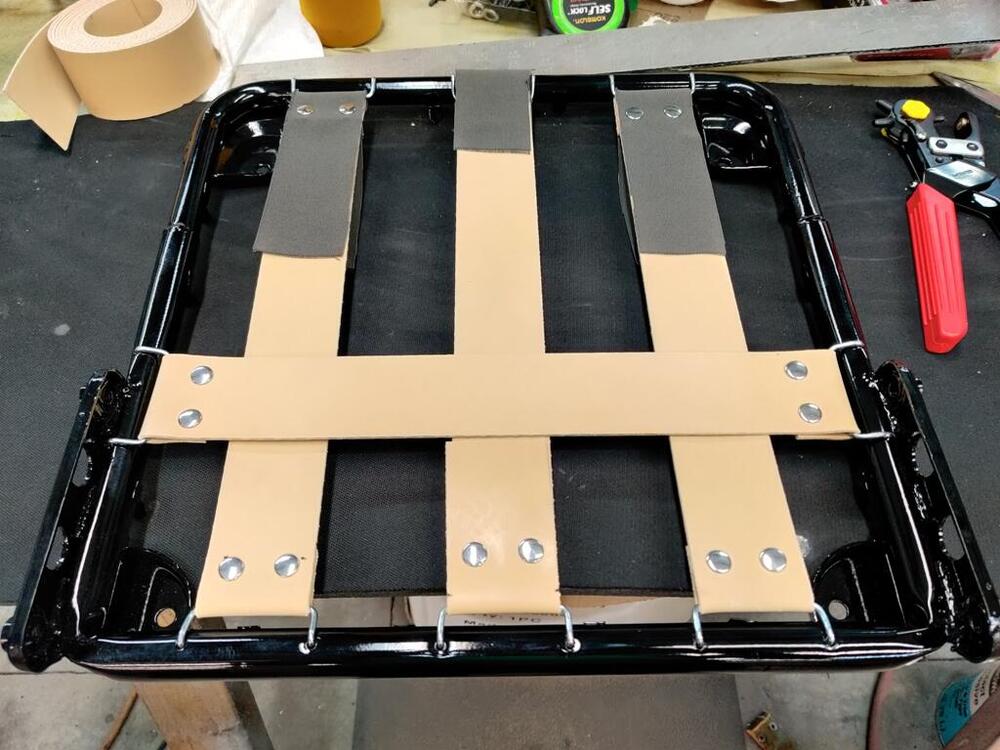

The reproduction panels are nice. They are thicker and heavier than the originals. Instead of the hard plastic they seem to be made out of a slightly softer material. They only come in the early 1970/71 configuration. So, I drilled holes for the side pillar vent.

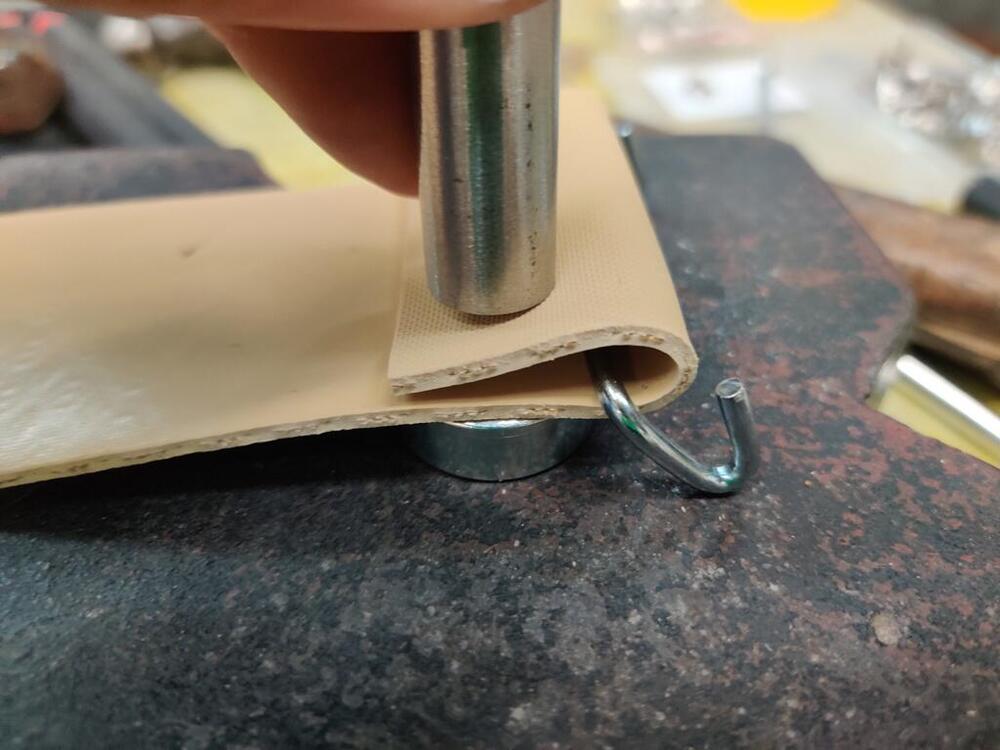

New reproduction panel as received -- factory original panel -- and reproduction panel with holes drilled. I was able to clamp the original on top of the reproduction panel and use the original holes as a template.

It came out nicely:

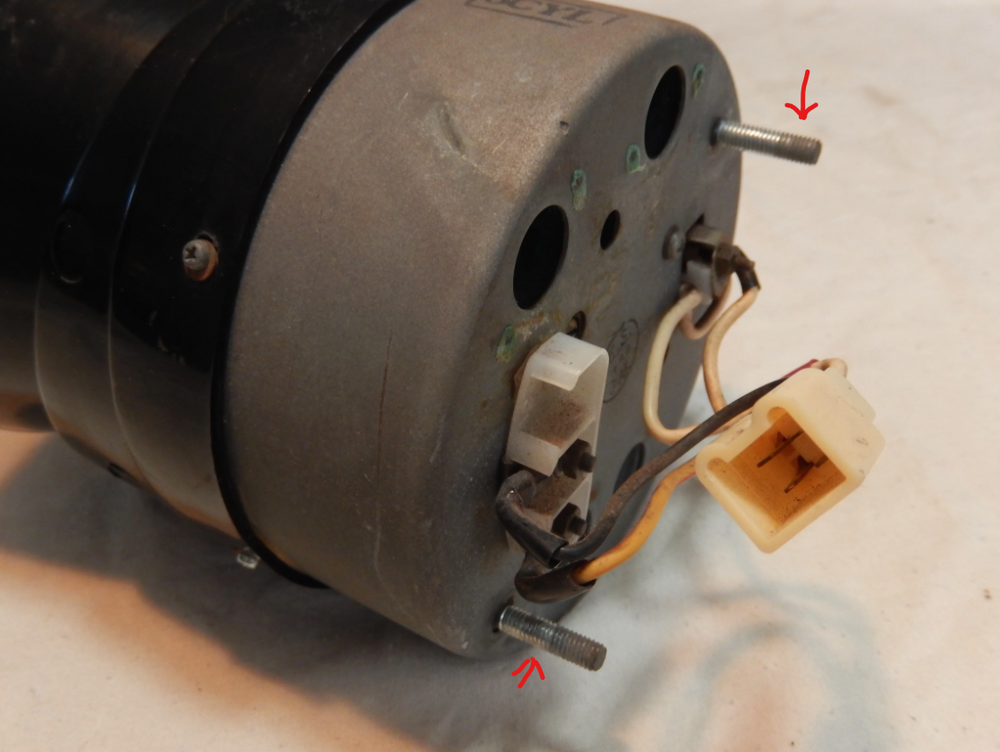

Lastly today, I swapped out the new SU nozzles. While I was there I checked proper throttle plate opening when using the starter lever. When you pull the starter lever all the way open, the throttle plate to carb body clearance should be about .023" to .027". I also made sure to secure the cables at precise locations so that the nozzles both activate and move the same distance when the starter lever is pulled.

I am getting closer to being able to start it up.

Subscriber

Subscriber 5Points1,282Posts

5Points1,282Posts