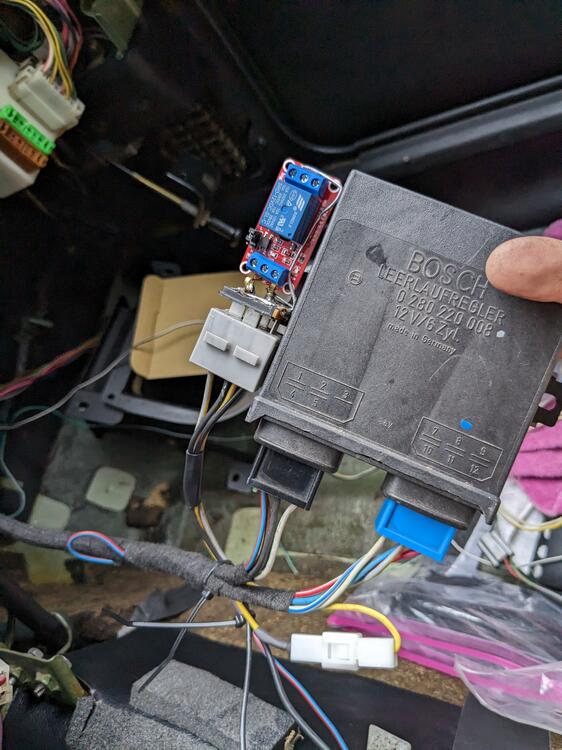

The thing is, the ECU for this is not readily available, and typically expensive if you can locate one. I'm doing it because I have the components, and my stock AAV is dead anyway. This will all only be used for a year or so, then I'm putting in a 350Z drivetrain 😁

Weather has been terrible here, so not getting much done. Did a little work on the wiring inside the cabin while it was raining

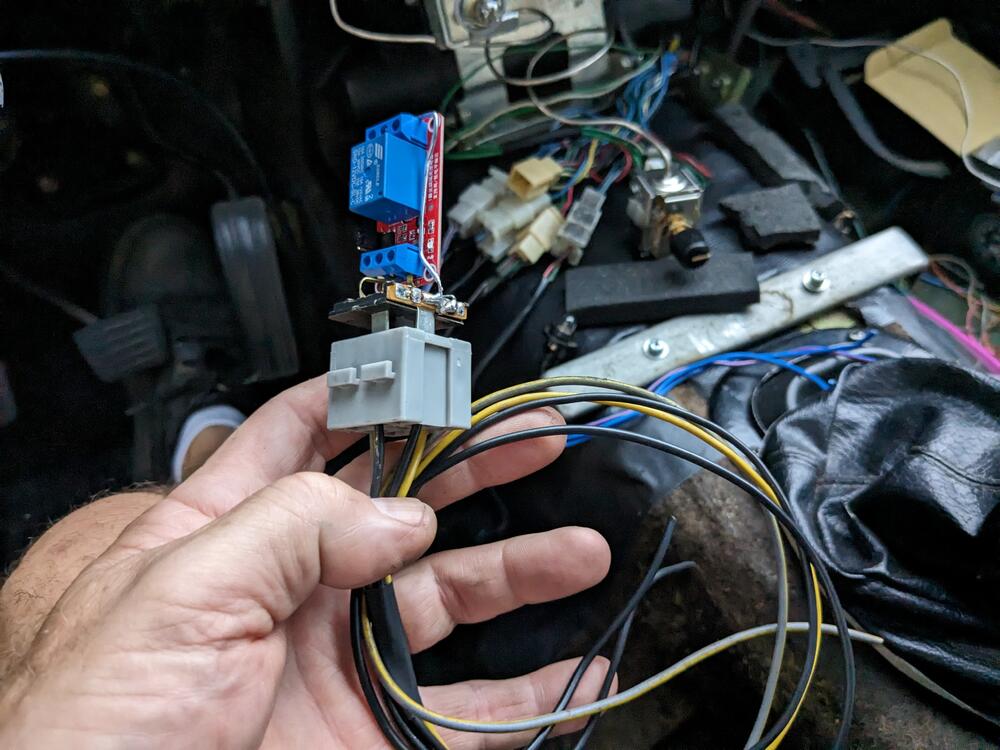

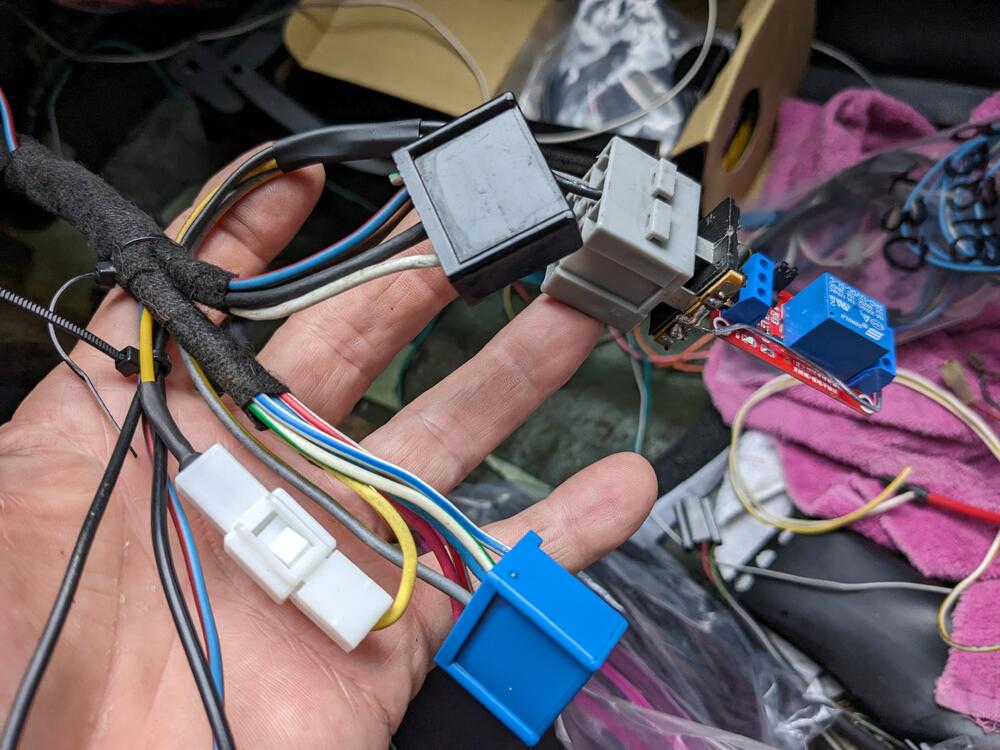

harness for transistor relay for switching the stock TPS signal to the CIS module to open at idle, ground off idle.

yellow wire is the signal from the TPS, so it needs to go to the relay first, then the switched leg goes back to the module

it will be situated alongside the module. I will need to sleeve the relay

Subscriber

Subscriber 2Points2,733Posts

2Points2,733Posts