To the original poster (OP), I offer my opinion. I only have experience with Mikuni 44's... so stating that up front. David Weber of Malvern Racing (long dead, but was a friend of mine when I was a young kid) told me that Mikuni 44's are the best carb for Datsuns. He didn't care for any Webber variant and the 40's were no good either in his opinion. I was 18, and running a 2.3L stroker motor in my 510. Know that there are many variables in engine building and you can get lost in them. That said, don't.

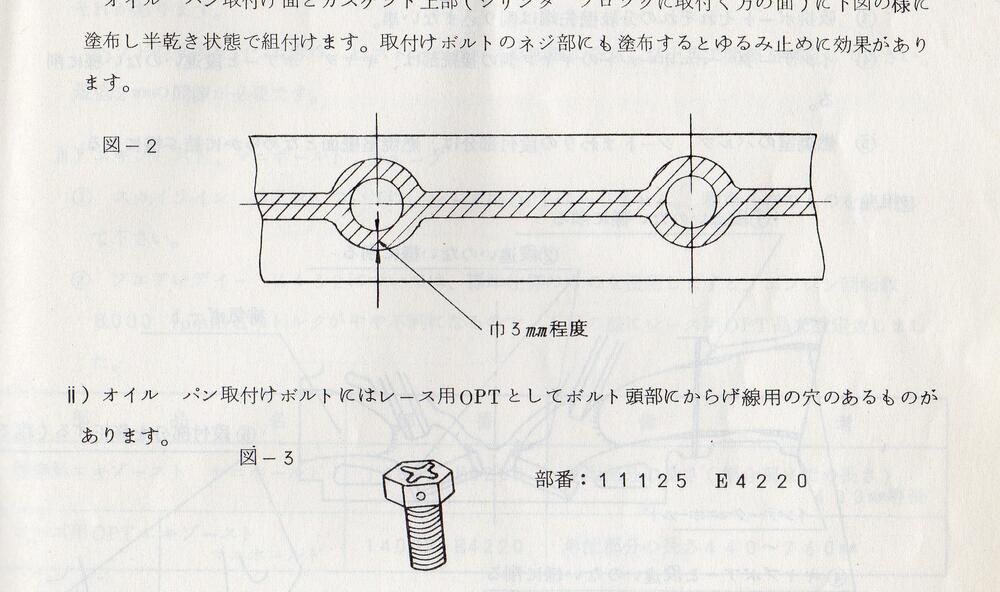

Rebuild the 44's you have. Match the intake side ports of the manifold to the carbs outlet if you wish, or don't. Not an issue for a street car. Taper from intake inlet to head side should be gradual, but for a street car, again, it doesn't really matter. Do source RUBBER carb isolators. Dave said the others are trash, and Mikuni's won't operate properly if the fuel is bouncing around inside the carbs.

Mikuni's can be tuned for street without issue. I was running 40mm chokes on the 510, and it was totally streetable with a 490/290 cam. It was my car in college. Lotsa fun.

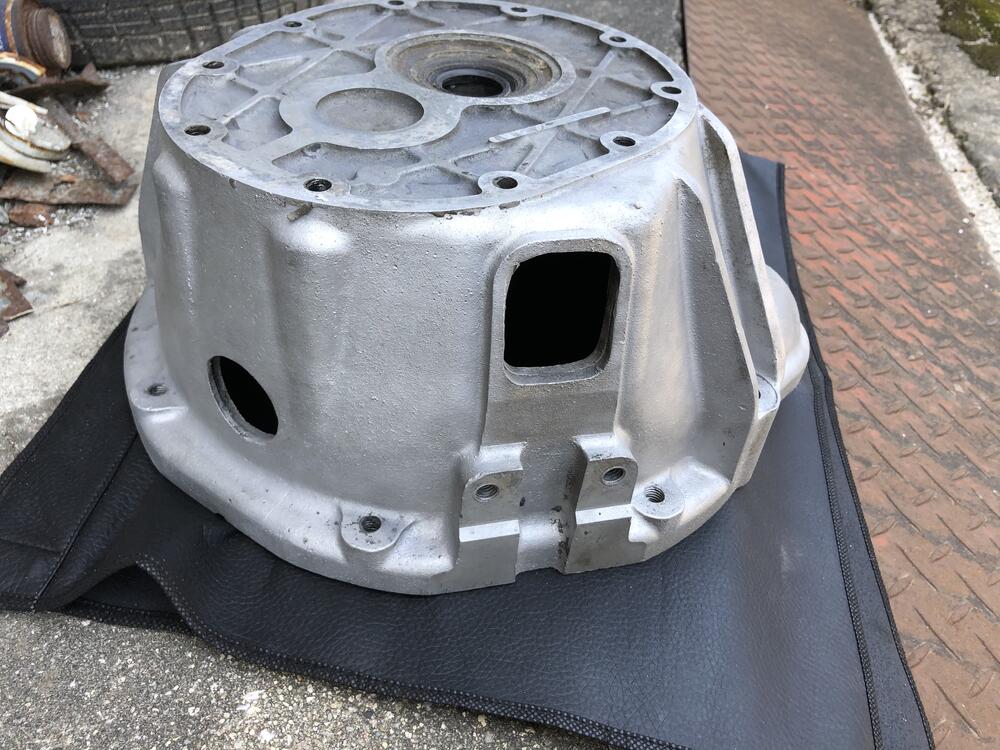

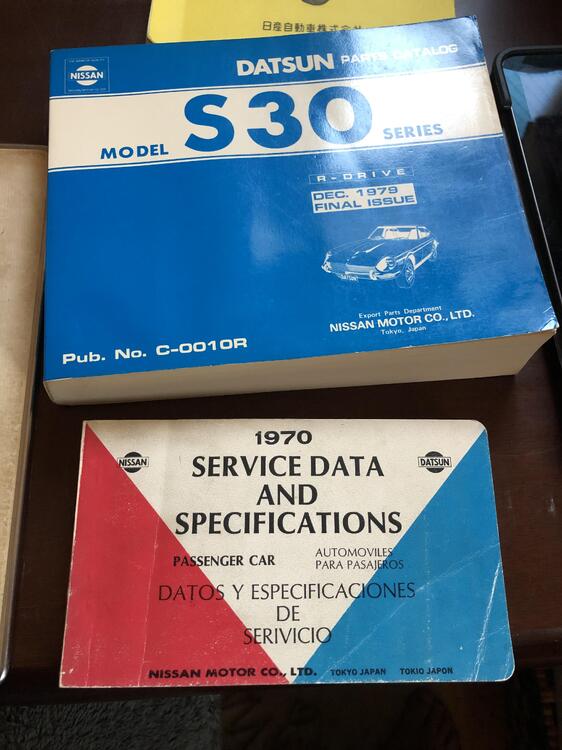

Separately, I have run 44's on my 240z as well. 2.933L technically because sonic bore testing wouldn't allow me to go past 88.5 on the bore. Narly cam, still totally streetable. Lots of fun. The crazy loud wine is a Kameari chain tensioner which I may have had a bit tight.

Subscriber

Subscriber 3Points11,142Posts

3Points11,142Posts