For the 1971 Monte Carlo, the Works team appeared to employ (from what information I can gather) what is basically a 2-channel power amp with gain control to facilitate communication between driver and navigator. The essentially muffler-less cars were already loud to begin with (by all accounts), and subtracting any sound deadening, plus the incessant constant rattling of two in-cabin fuel pumps, one could imagine the occupants would be losing their voices around day 2. Interestingly, I have a fair number of period photos where the team did not appear to be wearing headsets while underway, so perhaps the system didn't provide the expected benefit, apart from when the occupants donned helmets.

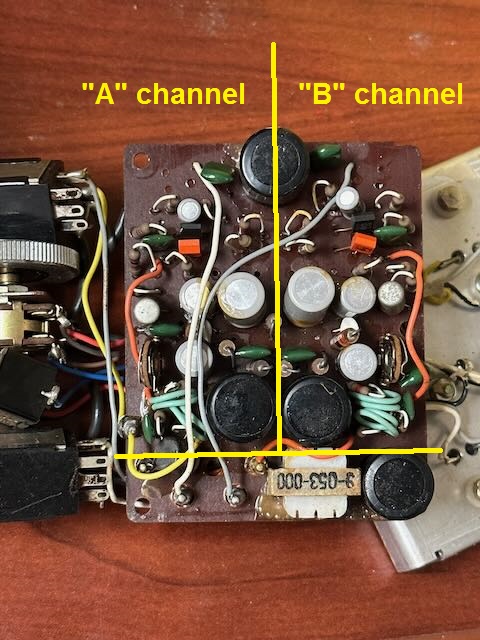

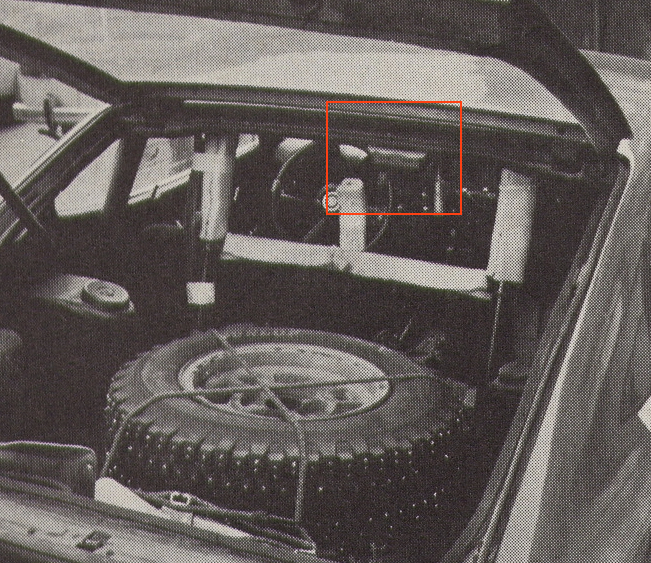

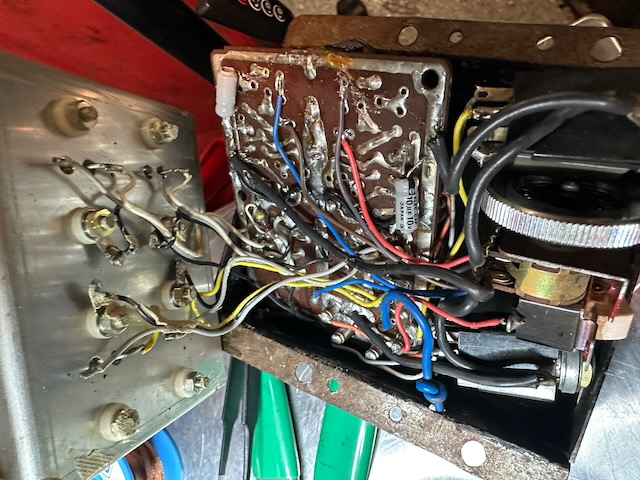

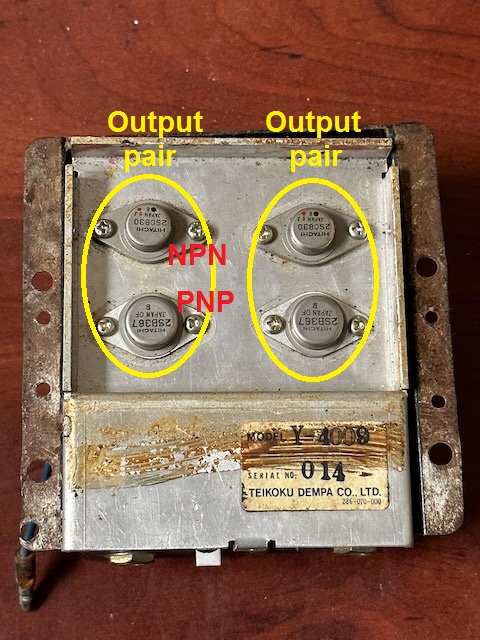

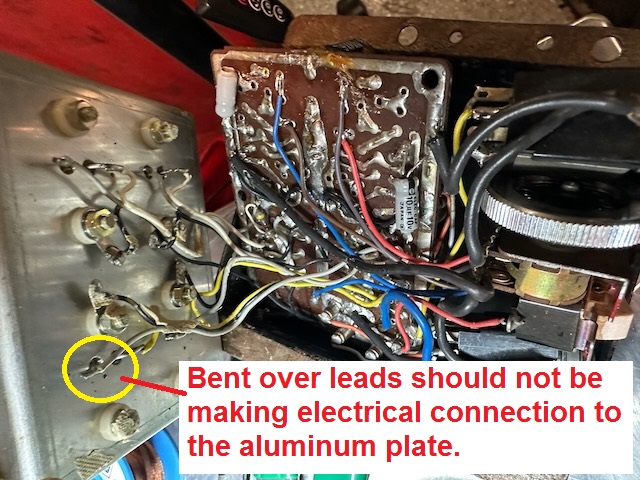

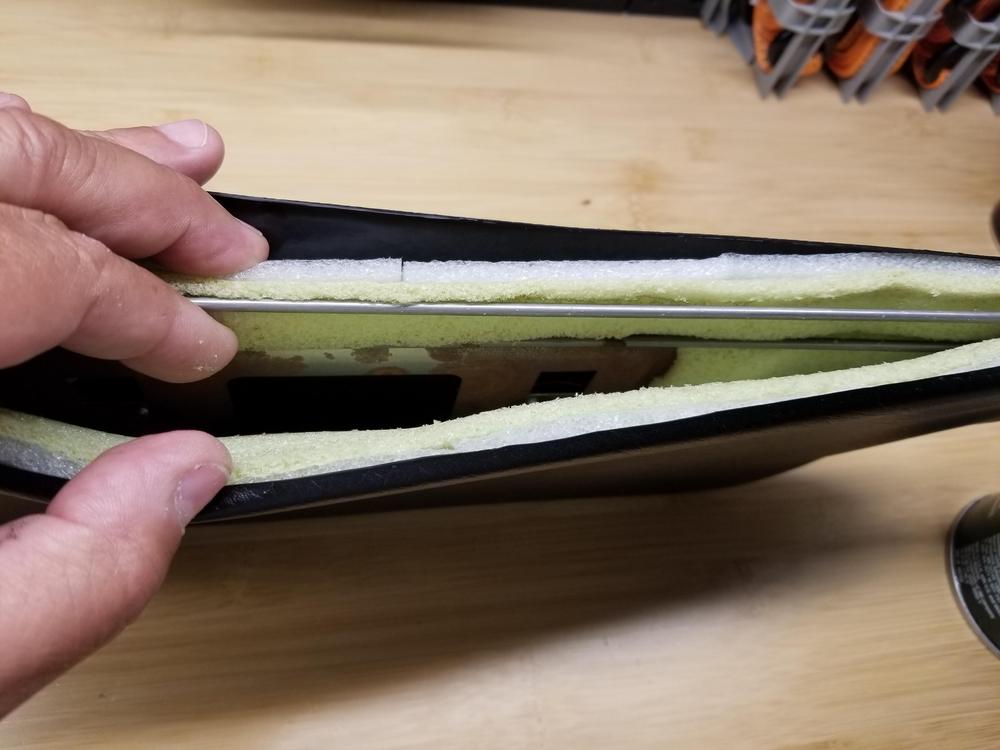

I believe mine to be original hardware, as I have a detailed picture of it installed in the car from the 71 Monte Carlo (last picture below), and another from October 1971. It is a very compact 12V device, made by Teikoku Dempa Co. LTD, using 1/4" headphone jacks to a pair of mono headsets with microphones. Teikoku Dempa has been in business since the 1940s, making radios under the Clarion brand name. It's not clear to me whether this device was stock, a special order by the Works team, or potentially even a modified over-the-counter item. The unit wasn't working, so I decided to take it apart for a little exploration and diagnosis. It didn't take long to discover a fair number of leaky capacitors, which are in need of replacement. Probably best to replace all that I can find components for.

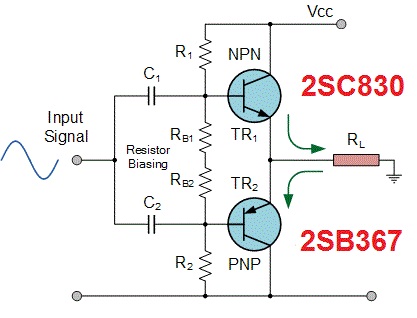

Although Ive taken a circuits class in my youth, I'm not an electronics repairman, so I'm on the hunt for an enterprising repair shop, likely a tinkerer with an oscilloscope who would want to spend a few hours reverse engineering the board, replacing the caps, and matching the system to my headsets. I'm taking a first-pass stab at creating a circuit diagram using some simple circuit design tools, so whomever takes on the job isn't starting from scratch.

Worst case scenario is that I'm forced to put the original electronics aside for storage, and retrofit the box with a modern 2-channel amp, so it at least looks the same. In the mean time, it would be fun to find out where the Clarion on/off switch and volume knob came from. Perhaps there is an old Clarion transistor radio which uses the same equipment?