So, my latest learning from doing the bodywork on this car... This is a pretty important lesson to learn with regard to filler work. Here is how my passenger door looked in bare metal:

The door wasn't sand blasted. Don't do that, by the way, of course. The paint was stripped off with a 36 grit disc on an air sander. Followed by 80 grit on a DA. Next pic shows body filler which was applied on top of epoxy primer. An obvious issue is that I have over sanded the filler and broken through the epoxy primer to bare metal. The instant you break through to bare metal, unless it is a high spot which will be pretty obvious, stop sanding. But, what I really want to point out is with a large panel, such as this passenger door, you can't assume it is flat enough to just skim coat with filler, sand, and spray a couple of high build primer coats on it and call it done. Note the bottom half of the door and that oval spot of body filler:

After more filler applied and more sanding... note the oval spot is still there:

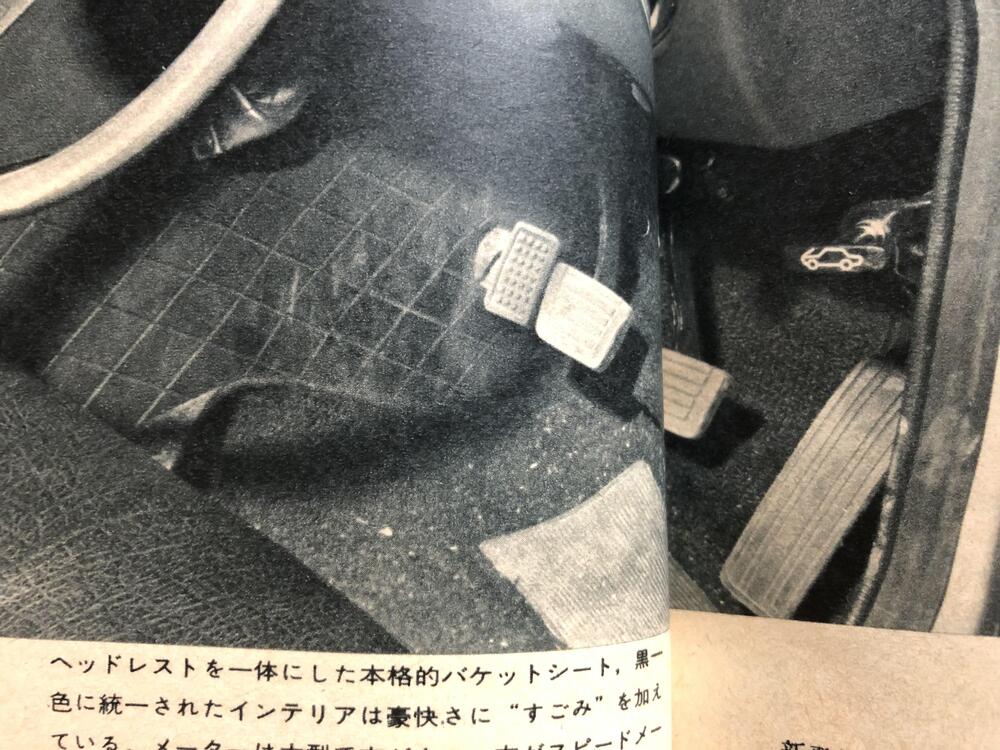

In this pic, I have applied high build primer filler... and note the oval spot on the lower half of the door... this time with white body filler added. Are you starting to get a sense of the repetition here?

right

Almost a year ago, the bodywork on this door still wasn't right.

So, here is what I have learned. Don't over sand. Other than possibly being a good workout, it wastes time and materials. Critically, for large panels, use a straight edge, or look at the reflection with a coat of wax and silicone remover on the panel, and check for any concaveness across the span of the door. It is exceedingly difficult to address the panel being ever so slightly concave after you have sprayed primer filler. You need to check it while it is bare metal, and again while it is in body filler stage. Get the panel flat while in the body filler stage. Do not move on to primer filler until the panel is flat. Use guide coat, and wax and silicone remover and check progress. Primer filler is not going to fill a concave panel. That is another thing I was doing that was wrong. A picture from today - note the white filler in the same location as the oval low spot in the pics above, and which can be seen in the video above also:

I have learned a lot, but have done it the hard way. And it has cost hundreds of hours and hundreds of dollars in materials. The reflection looked really good prior to application of primer filler today, so I think this door is super close to done, at long last.

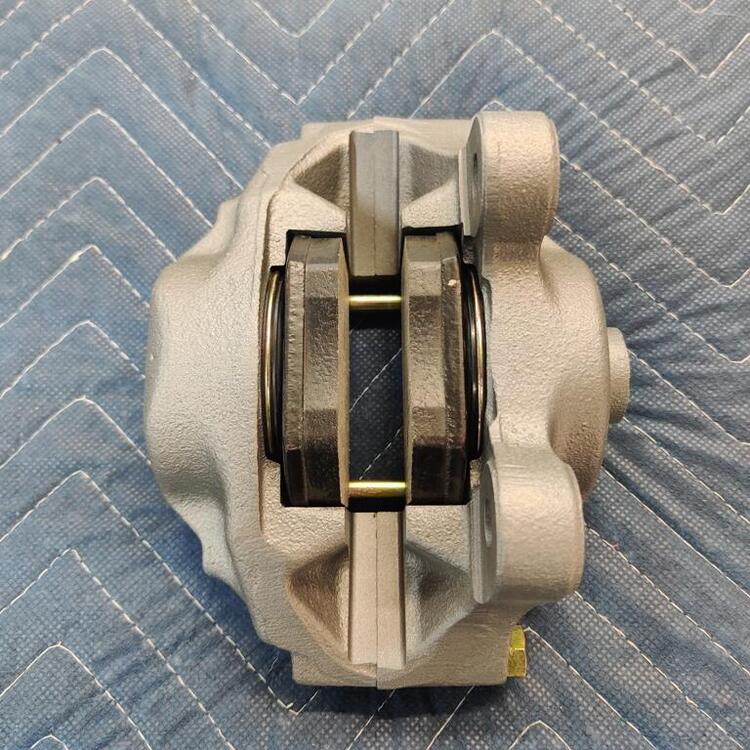

While waiting for filler to dry, I also assembled my brake calipers today. The original hardware was re-plated, insides of pistons sand blasted zinc primed and painted, caliper halves sand blasted, zinc primed and painted with Eastwood cast iron look paint:

Subscriber

Subscriber 4Points1,282Posts

4Points1,282Posts Subscriber

Subscriber 3Points428Posts

3Points428Posts