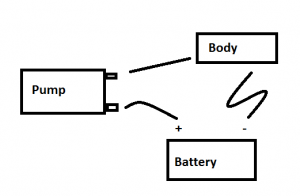

When you turn the key to "start," you can run the fuel pump for up to 5 sec. It sounds like when you let the key return to "ON" or "IGN," your pump might not continue to receive power. It may run just a few sec on the fuel pumped when you were cranking the engine. Ordinarily, the fuel pump is designed to shut down when the engine stops running (a safety feature). The strategy for detecting a non-running engine changed throughout the years. If your '77 is designed like my '78, this shut-down occurs when there is neither alternator output nor oil pressure. Either alternator output or oil pressure will enable the fuel pump relay. But check the FSM for your year to make sure. To get from point A to point B, you could "hot-wire" your pump. Run a wire from the + post of the pump to the battery, and it should whir away, enough to get you home to a location where you can take your time debugging the issue. But be warned: If you get into an accident, and if the integrity of your fuel system is compromised, your fuel pump could spray fuel all over the place, and you could die in a ball of flames, along with everyone around you. The safest route is just to have the car towed. Or perhaps you're on good enough terms with your ex that you can take your time debugging the problem where the car sits now.