All Activity

- Past hour

-

Sealing an oil pan

Yarb, it is the gasket I found at Rockauto. I think it is a cork type. Steve from AZC recommended to use the RightStuff gasket maker. I used it in the past, it seals well, and is a major pain in the neck to deal with if you want to remove stuff. Steve mentions it in his note with his oil pan that the best way to install the oil pan is with the engine out of the car :-) I wish it was my case. With an oil pan installation, the clearance on the 280z is tight already. The oil pickup on the AZC pan creates an issue trying to install the pan without jacking up the engine to give more room. If I use an RTV like RightStuff, I would swear that stuff all over while trying to install it. It would be a mess. What I did is to put a thin layer of black permatex onto the AZC pan and glue the cork gasket to it. Give it a few hours before the final installation. Now I can move the oil pan around the oil pickup with all my bolt holes nicely lined up etc. The gasket wouldn't move it I bump it against something. Apply some black permatex in 4 areas the FSM talks about, and you are all set. I don't think it would matter if it was a cork type gasket or a rubber one. I just need some material to seal the oil pan against the engine. I am sure some other guys have a different way to deal with it. If my engine was out of the car, flipped over, I would be happy to lay a nice bead of the RightStuff and carefully place the AZC oil pan on top of it. I am sure there would be no leaks since this stuff truly seals.

-

Sealing an oil pan

I do have a question out of curiosity, Why do you choose to use a cork gasket. I am definitely not a resource on gasket types used but I personally have not seen an old cork gasket that they used in the 70’s era on a Datsun. I realize I’m opening myself up to criticism.

- Yesterday

-

Fast2go joined the community

-

Sealing an oil pan

I installed the AZC pan, very nice piece. No leaks yet - I used a cork gasket with a few small blobs of black RTV in the areas suggested by the FSM. It might be in my head, but the engine noise had quietened down since the pan installation.

-

Replace or Not to, that is the question

Thanks, Yarb. I am on hybridz too, I joined it when I started exploring the Megasquirt/turbo upgrade (I was getting fed up with the AFM/running lean etc lol). There is less traffic now as it used to be.

-

Replace or Not to, that is the question

@Zed Head I was merely stating that most folks here haven’t gone that route and trying to be helpful of pointing him in that direction if needed.

-

Replace or Not to, that is the question

@cgsheen1 has turbo experience. darom is already on Hybridz anyway.

-

Replace or Not to, that is the question

Going with the turbo will probably result in getting most of your answers from Hybrid Z’s site. Not a lot of folks here have gone that route.

-

Replace or Not to, that is the question

Hi Zed, unfortunately I didn't take a picture of the back side of the PP. I did inspect it, it looked like a brand new brake rotor, no scratches, smooth surface. No discoloration. Appreciate you checking it out for me. I took the car for a test drive - the shifts were fine, no slipping. Re: the turbo - I am looking at the Protunerz turbo kit. A larger flywheel (240mm) is probably what I am going to end up with. I am sure I will have questions for you guys here on this forum later on :-)

-

-

4/75 Datsun 280Z; Leaf Green, CA market, 250K miles, Long Term Project 03/2023-

Glad to see you back.

-

Replace or Not to, that is the question

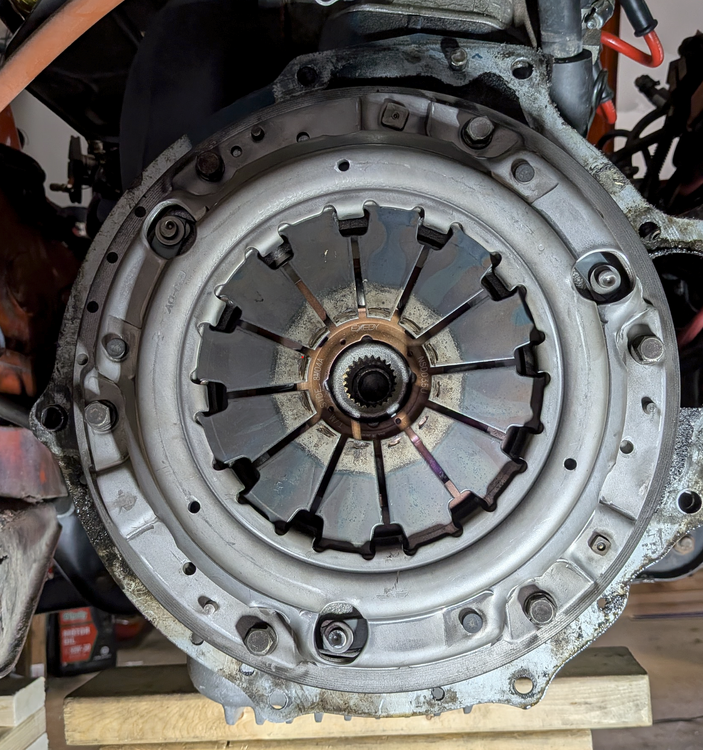

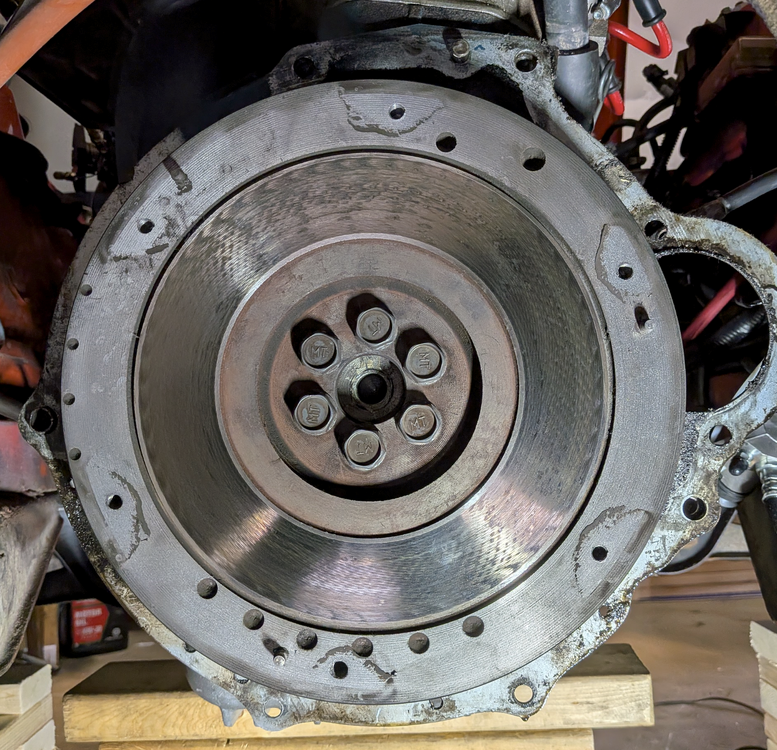

I meant the contact surface. The other side, the friction surface. It can get hot spots also. Hot spots are not necessarily bad though. If it worked fine, no chatter or slippage, and it only has 1000 miles I'd just reuse it. But that's just me. Do you know the brand and type? It might give a clue on how appropriate it is for a turbo engine. Nissan used the larger flywheel and pressure plate for the turbo and 2+2 cars. 240 mm instead of 225.

-

Replace or Not to, that is the question

-

Replace or Not to, that is the question

Or it might be that it's not even worn in yet. I don't see hot spots. Might help to post a picture of the pressure plate.

-

Replace or Not to, that is the question

Shoot, I wish I would have posted my flywheel's picture for you guys to review too. Here is what it looked like when I removed the clutch disc: Previously I didn't have any clutch slipping/disc chattering issues. My plan is to install the turbo next year and replace the clutch with a beefier version if it is needed. Either I will re-surface the stock flywheel then or go a with new lighter version, I will have to do a research about it/ask the forum for an opinion. Appreciate your input.

-

Chassis Dimensions and the BF-3 PDF

The reference points used to generate that 913mm measurement are tricky to replicate in practice. If you look closely at the small sectional drawing of the front shock tower, you'll see that the 'A' point actually lies on the plane defined by the underside of the shock tower cap. You can't measure at this plane unless you remove both front struts and then use either a trammel bar or a plumb laser. So, instead, you have to measure across the tops of the shock tower caps. But... Not so apparent from the sectional drawing, but very clear to the naked eye, is that the shock tower cap has a lip on the top (this is a little more evident in the sectional drawing of the rear shock tower that appears on the right side of FSM Dwg. BF-3). The top of this lip sits (by my measurement) 13mm above the bottom (reference) surface of the cap. So when you take the 13.5-degree cant of the front strut into account, it means that if you measure the A-A distance at the top of the lip, the result it will be somewhat less than if you were measuring at the (intended) bottom surface of the cap. My calculator says that 'somewhat less' = 7mm, so a measurement of A-A taken across the top of the lips should be 906mm. Now, if you left the press-in black plastic trim buttons in place (did you?) and took your measurement across the top of the buttons, you'll be measuring at a plane that's even higher above bottom (reference) surface of the shock tower cap. 906mm will shrink to ~ 902mm (est). Also: It's difficult to make this measurement accurately with a steel rule or (worse still) a tape measure. The correct way is to use a trammel bar*. If you used a steel rule or tape measure, your measurement accuracy will be no better than plus/minus 1mm (and more likely only plus/minus 2mm). * You can make your own single-purpose trammel bar. Start with a 4-ft (1219mm) length of 1" x 2" lumber and two 6-inch lengths of straightened 0.032" wire. Drill a slightly undersized hole into the flat side of each end of the wood strip (drill all the way through) and then press the wire lengths into the holes. The holes should be about 900mm apart. Now, using 1-qt paint cans sitting on each front fender, support the wood strip (your 'trammel bar') above and across the shock towers. Adjust the projecting length of the wires as required. Then line up the tip of the LHS wire with the centre of the LHS shock tower trim button. Then -- taking care not to disturb the trammel bar -- bend the RHS wire until its tip aligns with the centre of the RHS shock tower trim button (you may need to go back and forth a bit, until you're satisfied that both wire tips are correctly aligned with the centres of the trim buttons). To get your final measurement, transfer the paint cans and the trammel bar to your shop bench (don't disturb the wires!). Then position a steel rule on the bench top so that it sits under the wire pointers and take your measurement.

-

-

14 inch aluminium for stock 240z

Bit late to the party but I believe my 280z came with the same or allmost the same wheels. Don’t know if they are modified as I haven’t taken the wheels off yet but I must say they look pretty good under my silver Z. Attached is one of the pictures from the auction I bought the car from. The seller also included the original set of wheels but I prefer these. Tire size is 225/60R14 in the rear and 195/70R14 in the front.

-

Z Restoration Progam

@Patcon Having said that, I just looked through the excellently-researched 'Vintage Z Restoration Program Historical Compendium' put together by Chris Wenzel @26th-Z and he too specifically quotes powder coating as having been used. From the Compendium: "Nissan literature talks briefly about updating some aspects of the 240Z. A 3-row radiator was used and the tire specification was updated. In an effort to provide more durability to suspension components they were powder coated "to factory colors" so as to "ensure that you will enjoy your 240Z's performance for years to come"." Obviously it's a quote from NMC USA's VZ Program sales literature, so I don't know if that was the reality or not, but the fact that the independent Japanese journalist who visited Pierre'Z in person reported the same thing might suggest something. Of course he could simply have been quoting the literature, I don't know. I've always found powder coating to be much too thick on such parts, and there's always an issue where the powder coating transitions to a wear/bearing/mounting surface. I've seen it peel away in those places, so I much prefer paint (as per original manufacturing). Inspection of a few VZ Program cars would probably settle the question as to what was actually applied on them.

-

Mitchel0407 changed their profile photo

-

240z Door Hinge Rebuild

Maybe a bit late to the party but I’ll be using this thread to rebuild my 1977 280z door hinges as the passenger side in particular sages so much that the door won’t even close anymore. Any tips on removing and installing the doors on a 280z? The tricky bit is that they are bolted from the outside and I don’t want to remove the entire front end.

- It only works if I spray gas into the air intake.

- It only works if I spray gas into the air intake.

-

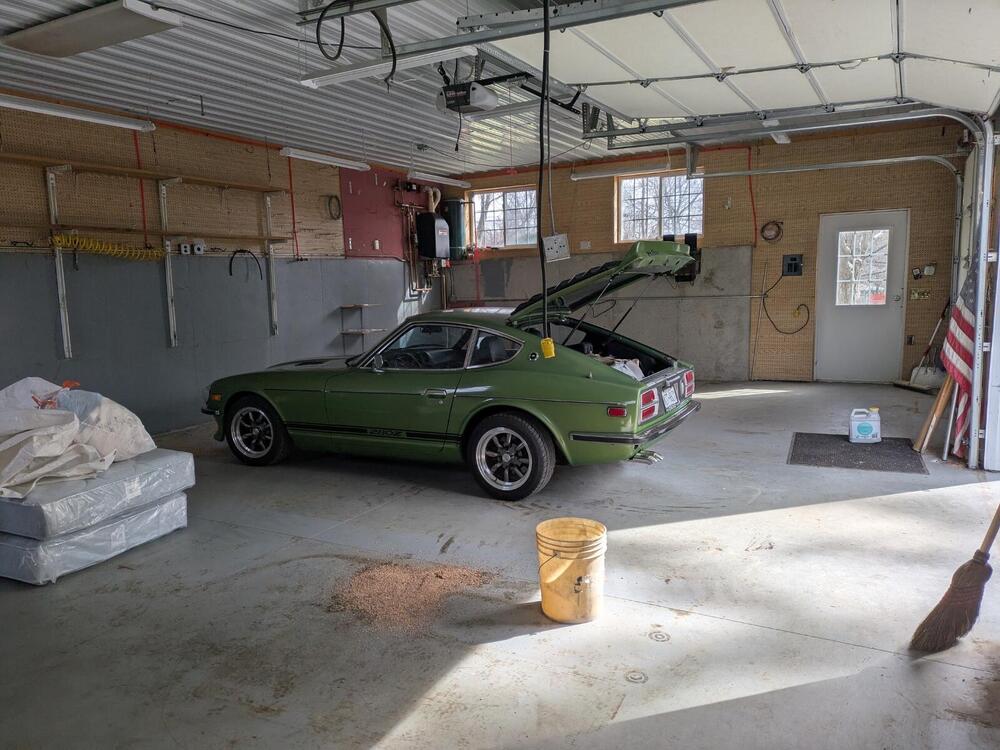

4/75 Datsun 280Z; Leaf Green, CA market, 250K miles, Long Term Project 03/2023-

Very cool! Looks like the new shop is a nice upgrade. Looks like you might have more acreage too...

-

Replace or Not to, that is the question

I think Yarb's thought might be it needs surfacing.. There are some chatter marks and possibly some blue hot spots too. Yarb, be me to it by seconds...

-

Replace or Not to, that is the question

IMO that needs to be machined and cleaned up. From what I can see you have hot spots.

-

4/75 Datsun 280Z; Leaf Green, CA market, 250K miles, Long Term Project 03/2023-

Moved upstate to Ithaca NY back in April. Had the 350Z shipped up ahead of us, then took the 280Z on. a clear day. Still no work on the cars yet, still setting up the grounds, garage & house Garage was used as. workshop, so it has a couple of 240 circuits, air compressor lines & ports, and radiant heat. Little more cluttered now, still working on setting it up Added glass panels to each door for more light Outside garage back in April: Better weather Adding slabs outside the barn & garage for me to work on - there are no flat/level/safe areas on the property outside of the garage

-

Replace or Not to, that is the question

Yes, it is quite heavy (over 20 lbs?).

-

Z Restoration Progam

You mean...rocket science?