All Activity

- Past hour

- L20b Cody's Goon

- Today

- L20b Cody's Goon

-

Replace or Not to, that is the question

Hope everything is dry now and your leak is all fixed up!

-

1971 HLS30-14938 "Lily" build

That sounds like a great way to spend the weekend! For a bonus the weather was nice too.

-

L20b Cody's Goon

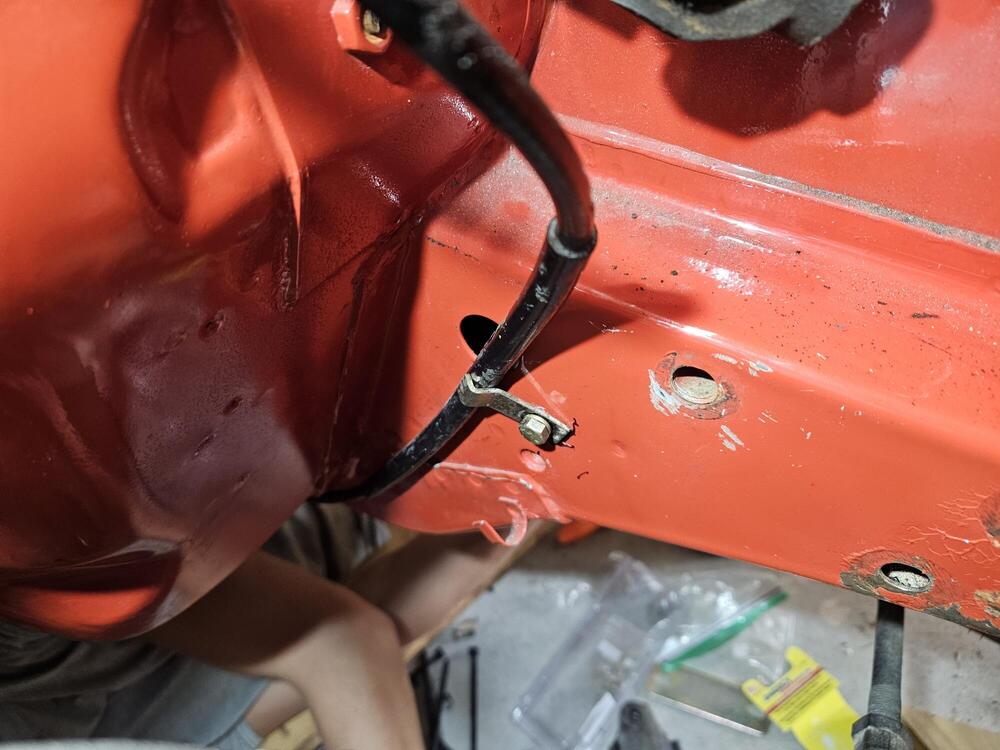

We talked Cody into working on his car today instead of Lily. So we went over to the other garage and put as much together as we could. Pinned the parking brake cable back from the exhaust replaced the clutch master line and the clutch master The we hung all the exhaust, made up fuel lines to the carbs, primed the fuel pump, Rigged up an ignition system and some temporary power. I need to get the engine bay harness sorted but I can't get it done yet. We got fuel to the carbs but have no spark. Coil ohm's out good. We replaced the matchbox on the dizzy but still have no spark, so I ordered another cheap one off Ebay. It will be here later this week...

- Yesterday

-

1971 HLS30-14938 "Lily" build

We checked the timing. It was about 14 with 32 or so all in Here are my mechanics Morgan is home from school for a few weekends and her boyfriend Mark was here too. They're all good with tools and willing to help

-

1971 HLS30-14938 "Lily" build

Cody has been back from Fla for about a week. He finally got a break. We had a short family vacation and then spent all weekend working on cars! He spent 3-4 hours tracing the turn signal circuit. In the end we switched back to the original hazard switch and that made everything light up the way it should. The flasher was bad but I have a new electronic one to use. We also made short jumper harnesses to go between the US harness and the JDM tail lights. The green and yellow will come from the brake switch at the pedal and then it should all work appropriately. We also got the car fired up yesterday. I bought a cheap L6 electronic dizzy off ebay. I swapped it in for the old match box dizzy and it fired right up. I guess the matchbox went bad the last time I tried to fire it up because it sort of bumped over for a sec and then no spark. We'll see how long this dizzy lasts Ordered a reverse switch for the transmission and that may be sorted. Need to sort power for the blower fan and some odds and ends electrical and it will be close to ready to test

-

240Z Hood Front Lip Corners - Need stock reference photos for my repair.

Yup, I now recall the hood was pranged and repaired many years ago.

- Racing Mirror Gaskets

- Racing Mirror Gaskets

-

240Z Hood Front Lip Corners - Need stock reference photos for my repair.

My hood looks more like that ^^^^ on the inside

-

Replace or Not to, that is the question

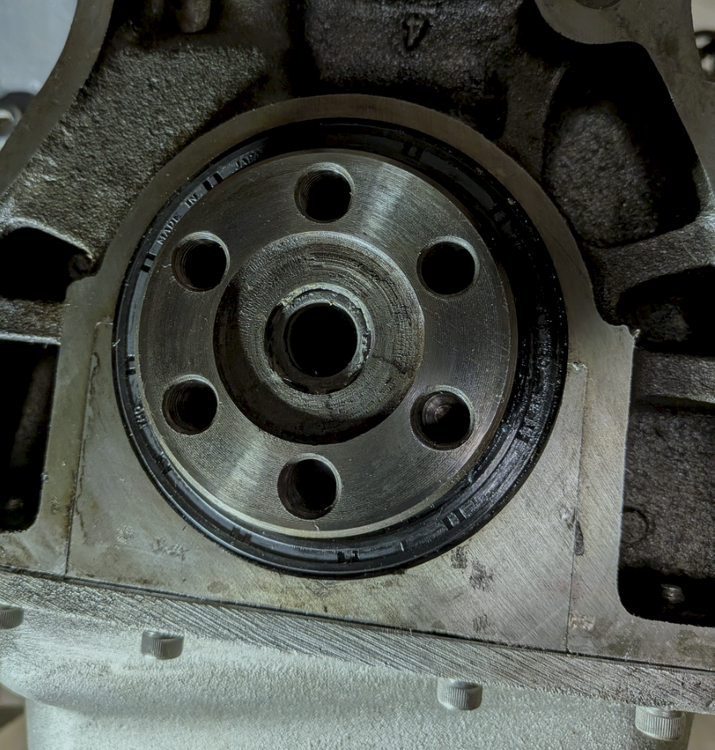

I tried using the sharp punch tool/screw extraction method while removing the seal. It immediately moved sideways inside. I was able to use a hook tool to extract the seal out. If anyone is interested, I found a plumbing part at Menard's that can be used for the installation. It is called '4x3 Red Bushing Con, SXH SDR35 SW' in the Plumbing section. Its inside diameter fits nicely over the crank. Once the seal is positioned, it was easy to tap it in. I had to dremel inside a little to make sure the 'tool' sits flush: Thanks to everyone for your input. I lost my clutch alignment tool from the Exedy kit, had to order a new one at O'Reilly's.

-

240Z Hood Front Lip Corners - Need stock reference photos for my repair.

This one is close to real.

-

240Z Hood Front Lip Corners - Need stock reference photos for my repair.

Uncrunched hood: Good point on the tip, correctly wrinkled steel, spot welds visable. (factory paint on this one)

-

240Z Hood Front Lip Corners - Need stock reference photos for my repair.

Sorry. This is a NOPE. Point of hood is wrong, no spot welds noticeable, way too smooth - it's been filled...

- Car runs but rough. Afm ?

-

Replace or Not to, that is the question

The seal needs to be flush with the back of the block. It will go deeper, ask me how I know. Had to order another one from nissan🤦♂️

-

Z's on BAT and other places collection

@zspert , do you know if the heads for the program cars had hardend valve seats installed as part of the rebuild? What I'm really wondering is, should I be running lead-free additive in my car?

-

Replace or Not to, that is the question

Thanks! You are right, aviation permatex is a sticky substance.

-

Replace or Not to, that is the question

Sometimes new seals come with some little dabs of lube already on the inside lip. If yours did not, you can just use motor oil, or my favorite... silicone grease. As for the outside surface, I would do the same there. Motor oil or silicone grease. I wouldn't use anything that sticks like the aviation permatex. In my experience, the outside of the seal has significant interference with the hole you press it into. In fact, I've had to hit them harder than I was comfortable with just to get them seated into place. If your experience is like mine, you'll be thankful for the slippy on the OD, not the sticky. Use your old seal as a protection ring to tap your new one into place. And make sure the new one is square when you are done.

- Racing Mirror Gaskets

-

dutchzcarguy started following Racing Mirror Gaskets

- Racing Mirror Gaskets

-

To replace or not replace ball joint.

I never knew these baljoints can be taken apart.. as they are not that expensive i always installed a new set.. less than 100 euro's a set, orig. nissan parts. (No idea what they cost these days..) With new ones your not indanger to drive other people off the road, you sleep better.. ;-) Thanks Zed for that vid and the warning..

-

Stepdadmaterialz joined the community

-

Replace or Not to, that is the question

Great, thanks guys - I feel better now since I know that the auto shop actually replaced the front gasket. I bought a rear main seal from Rockauto, Mahle, JV637, made in Japan. Looks very solid. The last question - the inside lip of the rear main seal per Tom's book will be coated with moly/petroleum jelly. What about the outside seal surface and inside the engine where the seal goes? Wipe it clean with a solvent? Should I smear some aviation permatex on the outside of the seal before its installation? Thank you.

-

Gas Tank Order From J30 in Netherlands

A brief update: I picked up the transmission jack at HF . Other stuff filled most of the day but I managed to get the jack in place and raise the tank with it. Actually got the filler hose and clamp in place. Yeah. then I went to the other end to raise and hook it up. That's when the filler hose came apart and fell back down. Turns out that I failed to raise the jack enough so that it would hold the filler tub hose clamp assembly together. My bad. Anyway, I now know that I can get the filler tube aligned and joined which was my original issue. By now my neck was telling me to take a break so I'll get back to it tomorrow smarter than I was today. Thanks for the advice all. Rodger