Everything posted by EuroDat

-

Looking for Throttle opener control valve and servo diaphragm for a 240z

Try googling "idle stop solenoid". Toyota and many others used them in the early 80's to close the carburetor throttle to stop the engine. You can use it to step up the idle when the compressor in activated. http://www.auto-parts-online.com/uploads1/prod61/img3_00/000/8949076_1282214161.jpg

-

What maintains the fuel line pressure when the care is off?

Hi Gary, Its not simply one thing that holds pressure. Pressure "leak down" can be caused by several things and you can test the system to narrow it down by using a pressure gauge. Things that can cause pressure loss are. 1. FPR is leaking back to tank. Common with aftermarket FPR's 2. Leaking fuel injector or CSV (cold start valve). 3. Check valve in pump discharge. 4. Leaking hoses. The quickest way to test it is by fitting a Tee piece with a pressure gauge after the fuel filter. I would also replace the hoses from the filter and the return line. Use enough hose both sides of the tee piece so you can clamp the hose to block sections in. 1. Start and run the engine and then stop engine. Check for pressure drop. 2. Do this test again, but then clamp the hose between the gauge and the Injectors/FPR. If it still drops at the same rate your pump is leaking back to the tank or a hose is leaking fuel. If not them you problem is further down the system. 3. Repeat test, but now clamp the return line from the FPR. If it now holds pressure, then you have a leaking FPR. 4. If it still loosing pressure then its an injector or CSV. You can remove the two screws a d lift the cold start valve to check it. 5. If all those items check out, then its most likly one or more leaking injectors. Hope that all makes sense... Edit: Out of curiosity, why did you change the fuel pump and regulator? I think you injectors will be ok from your description of how it starts. They generally start really rough on one or more cylinders until the fuel air mixture settles down on the cylinder with the leaking injector. Yours seems to start up ok. Most likely causes are the FPR or check valve in pump. Chas

-

To Dream the Impossible Dream (Redwing's Z cars)

Steve, Fuel starvation could be as simple as a blocked inlet screen on the fuel pump. These pumps really drop in performance when they pull the slightest vacuum. A pressure gauge will tell you a lot more. I would also do a simple flow test to determine the condition of the pump. Remove the return line after the FPR, best to remove it over the other side of the motor. Run the pump through the FPR by activating the AFM or remove the spade terminal from the starter. You should get at least 2 liters a minute. If I was changing the pump, I would look for a bosch. They can be found for a little more than the Airtex, but from what I have see and heard, they last and perform much better.

-

To Dream the Impossible Dream (Redwing's Z cars)

That manifold is from a 78 280Z or a 79/80 280ZX. The throttle body has a nozzle for the pcv. The later ZX doesn't have it. It has the two connections in the rubber hose betweeen the throttle body and the AFM.

-

To Dream the Impossible Dream (Redwing's Z cars)

Steve, If its still fitted with the JECS relay you can open them easily and clean the contacts. Mine was playing up and I did that and its been working the last 10 months and no issues.I also have the bosch unit, but you can't open it without breaking the case apart. I have posts in a thread here somewhere with the two next to each other and the JECS open. The bosch unit is readily available if it comes to that. It ws used on Mercedes 280, 300, 350 and 450, Porche, Alfa, Opel and Peugeot in the seventies. Ill post the part numbers later. Chas

-

Xenon S30 and S130 site - kind of messed up right now, here's a path

Mike, I could upload what I have. Will that be a problem? Don't want to offend anyone. The documents have the Xenon certificate. Chas

-

Selling 1978 280z

John, set you a pm, please read. chas

- 1976 280Z Restoration Project

-

Restoring the 280Z EFI Fuel pump (if possible)

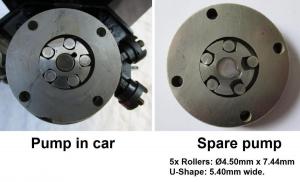

Pulled the pump out of the car today to compare the internals. It also has a small leak around the terminals. More notacable in cold weather because the fuel doesn't evapourate so quick and you can see a dip hanging from the terminals. I will start calling them 280ZX (Spare) and 280Z (in car) pumps because they seem to have increased the capacity in the later model. The impeller, rollers and outer ring are 7.5mm in the 280ZX pump and 7.00mm in the 280Z pump. The inlet screens are not interchangable. The 280ZX screen is 1mm bigger than the inside diameter of the 280Z inlet. I am now thinking of swapping the impeller, rollers and outer ring to make one good pump. That would be the 280ZX motor and inlet coupled to the pump middle section from the 280Z pump. After the holiday break Ill try to get a ring and rollers fabricated the spare unit. That will depend on price. Here are some photo's of the parts. 1st row: Rollers showing worn 280ZX roller 2nd row: The outer ring thickness differences. The 280ZX is 7.5mm (0.5mm thicker) 3rd row: Roller length and the inlet filter screen. Won't fit the 280Z without force.

-

Interior door sill scuff plate for '78 280Z

Jim, I have a set of the long ones, I think so anyway. They don't fit my 77 so I thought they are for a 2+2. The guy I got them from said they were for a S30 coupe, but I doubt it. I asked this question a while back and sought of forgot about it. BTW if anyone wants them, they can have them for shipping costs. No damage, but they need polishing. http://www.classiczcars.com/topic/49525-differences-between-the-aluminium-sil-kick-plates-coupe-22/

-

Hs30-00019

George, The mans got talent. Awsome work you are doing on the project. Bodywork is not my thing, but I repect you guys for having the dedication and skill to tackle these low vin restorations. Looking forward to seeing more. Chas

- 1976 280Z Restoration Project

-

Restoring the 280Z EFI Fuel pump (if possible)

I suspected they would be 5mm. Thanks for taking the measurements. Looks like Ill be up for a new set of them too.

-

280zx pedals

If you are stripping it don't forget the engine and its components like: alternator - should be a 60 amp internal regulator version. Its bigger than the 77 280Z. distributor with internal ignition unit. webbed inlet manifold in rumorred to be better againsg hot start issue. fuel pump back ag the tank. The fuel pump configuration is a little different but all the essential parts are the same.

-

Restoring the 280Z EFI Fuel pump (if possible)

Thats true. I forgot about that really wide tolerance for the pressure relief valve. The pressure wasn't worrying me because it was above the 36psi FPR maximum. Its the noise it making when its running at that pressure. I think the vertical lines in the ring and causing the noise when the rollors move over then. Its a lot noisier than the one in the car. I found an old photo of my good pump to compare with these rollers. There is a lot of wear on them judging by the photo. These measure in at Ø4.5mm and Im wondering if they were more like Ø5.0mm when new. I can't confirm that just assuming. The groove is 5.4mm wide which give 0.9mm clearance.

-

Restoring the 280Z EFI Fuel pump (if possible)

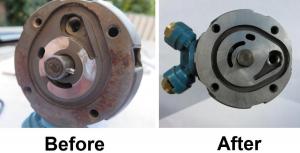

This all started because I was curious why it was making so much noise and performing so badly, but now I think I may have a real chance of improving it. I cleaned up the pump motor end and inlet part today. The first problem was I couldn't think of a way to work the motor end without getting a lot of fine material in the motor. Then I thought of trying grease to fill the holes and later flush it out by pouring fuel in from the outlet end through the motor. It seemed to work ok. Next I sent the drawing of the center ring and the rollers to a machine shop that does work for us. It will be interesting to hear what it will cost to make. In the mean time I will assemble the pump and do a free flow and pressure test to see what the rework has done to its performance. This pump barely making 3.3 (48psi) compared to the other pump making 3.7Barg (54psi). Here are some before and after photo's

-

Restoring the 280Z EFI Fuel pump (if possible)

Well at least Im not the only one that does that kind of thing. A couple of weeks back I was cleaning my ballast resistor and it looked like new for about 20seconds until I dropped it and it shattered.What are the rollers and impeller like? This one seems worn when I compare it to the phots on Alanticz and from memory of my in car unit. I would like to keep the original style. Thats why Im tinkering with this one. It works, but it sounds awfull and it doesn't pump as much as the one on the car now. Site, Thanks, I have read just about every page on Blues Atlanicz site. Its an ecellent source of info. The tech tip on these pumps is more external and replaceable things like o-rings. My problems with this pump is its worn out. Really no other word for it. Thats why I thought Id play with it a little, if I stuff it up no loss and I can always go aftermarket with the Bosch pump.They use them here a lot on the old BMW, VW, Alfa and porches etc with the bosch J jetronic systems. Bosch still make them in the Cheq republic I think. The maximum pressure is a little higher than the original, but that is controlled by the FPR. Google this part number 0580254984 and you will find them easy enough. http://www.ebay.com/itm/Bosch-0580254984-POMPA-CARBURANTE-ORIGINALE-Volvo-240-turbo-Porche-911-/371382769888?pt=LH_DefaultDomain_101&hash=item56782358e0&vxp=mtr http://www.amazon.com/dp/B001CO2LI2/ref=as_sl_pd_tf_lc?tag=boschfuelpumps-20&camp=213381&creative=390973&linkCode=as4&creativeASIN=B001CO2LI2&adid=18GFZW2S9TJX21X6FHXH&&ref-refURL=http%3A%2F%2Fwww.boschfuelpumps.com%2F

-

Restoring the 280Z EFI Fuel pump (if possible)

A while back I cleaned my 280Z fuel pump and replaced the o-rings. Its running ok and I compared it to an old reserve pump. The reserve pump delivered about 75% of the flow compared to the one in the car. Since these pumps are getting harder to find in good condition I decided to take a closer look at the spare pump. The outside looked shocking, corroded and rusty so I cleaned and painted it to make it look respectable. After opening it up Im wondering it was worth the trouble cleaning and keep it as an emergency unit. The inside is showing a lot more signs of wear compared to the one in the car. There are possabilities to improve it. I was thinking of making a new center section (intermediate part) and maybe new rollers. The inner ring of this part has vertical lines which reduce performance some and make it noisy in operation. These parts are made from hardened steel, maybe steel type S890 (890MPa tear strength) would be suitable. Not sure what it would cost to make. The inlet end plate could be surfaced 0,1mm to remove most of the wear. That would increase the crush on the o-ring, but it should be ok. That should improve the output and reduce the noise a little. Opinions welcome. Here are some photos of the worn parts and a drawing of the part for possible replacement. PumpRing1_Rev0.pdf This post has been promoted to an article

-

Project Crush

If he has done a valve job and didn't protect the seals when installing them the valve could cut the seal with the groove in the valve stem. Its hard to believe that would use so much oil. No mention of a big cam. If it had a high lift came with the standards oil seals. The spring collar can crush the seals and destroy them when the valve is at its lowest.

-

Project Crush

Im wondering what the compression is. A F54 flat top with a N47 head will be running high compression somewhere around 10.5:1. Valve seals typically smoke when you coast down a hill then use the throttle. The high vacuum when coasting sucks in a lot of oil and the engine burns it all when it back under load. If he did this N47 mod on an old tired bottom end it could be ready to give up. Thats often the trouble with unknown history. Its generally not very good otherwise he would tell you all about it.......

-

ABARTH Exhaust Any comments

That seems to stick in my memory as well. Its going back 3 years this September. Like I said in the ealier post, It sounds awsome. Not what you would expect from a 240Z. I like the over under style of the rear muffler I remember Abarth back when I had a Fiat 127. It had a sports air cleaner from Abarth. I think Abarth worked very closly with Fiat or Fiat may have been part owner. It was farely popular with the Fiat guys. Back in the early eighties they had a Fiat Ritmo 125TC that was designed by Abarth. It was christened the Golf GTI killer. Abarth was a bit like what BRE was for Datsun.

-

ABARTH Exhaust Any comments

I should have taken a better look at the website. That is the guy. He doesn't have mush for datsuns, its mostly fiat.

-

ABARTH Exhaust Any comments

There is a guy called Ling or something that used to sell the stuff here in Nederland. I think its old stock he was selling. Looked like it had been in storage for a while. I have seen a couple of his systems at an Oldtimer day at Zandvoort raceway here in the Netherlands. Abarth systems some awsome, but the systems I saw were no bigger than 2". I think it was intended to give the "standard" 240Z a sportier sound.

-

Slipping Clutch.

If you measure the distance from the front of the bellhousing to the clutch fork you should read about 110mm for a standard clutch give or take a couple of mm for wear and tolerances. This is on a standarx clutch and aftermarketunit could vary a little. This will give the slave cylinder about 10mm IIRC. The slave cylinder has a small spring behind the piston to remove slack in the mechanicals. If the collar is too long this piston will be pushed right back hard and the clutch will not release completly. If you can't push the clutch fork into the slave cylinder, then you have a problem. This could be your problem and shortening the push rod could be enough to solve the problem. Edit: I see you have an old style slave with push rod. Mist that with all the 280zx stuff. If you are using the older style it needs an external spring to pull the fork back to the slave cylinder. To adjust it remove the spring. The piston should bottom out by adjusting the fork and them turn the nut 1-1/2 turns back. Replace spring. That will give you the correct free play in this type. If there is not enough adjustment to do this then you have a problem with mismatched parts.

-

Hardway's 1971 240z #8011 - Build and Repair Thread

It was probably over adjusted when someone maybe tried to raise pedal height. The self adjuster shouldn't do that if working correctly. The FSM mention several methods to adjust the brakes. In the later 280Z its by activating and releasing the handbrake. Dave did a very nice job restoring it