Everything posted by siteunseen

-

Stroker 3.1

He'd destroy a bowling ball with a rubber hammer. He was left for a half a minute without me and tried to ride on my poor dogs back like a horse. Little turd isn't coming back to my house until he's married.

- Camshaft advice

-

Tranny Fill Plug Removal

Or...

-

Stroker 3.1

That's funny! My nephew had something similar with plastic tires and all it did was spin on the hardwood floors in my sister's house. I wrapped the one that turns with Gorilla Tape and he crashed into her dining room table, put a big ole knot on his forehead. No more inside driving for him, luckily it's only too cold for a month or two down here.

-

Vapour Lock Definition

-

A touch of art

The best collection I've ever seen! Your own car show.

-

A touch of art

Is this the guy that did @Diseazd?

-

A touch of art

I know what I'd do!

-

Tranny Fill Plug Removal

Great idea! I'm about to do my differential and will try that if it's as tight as my 280s was. Seems like those are female type plugs and I used a half inch pull handle or ratchet. That's one helluva oil pan you got on there!

-

Vapour Lock Definition

Anyone heard from the other New Zealander whose avatar was his wife holding a white poodle? Super nice guy that was a lot of help to the members here. Can't think of his name and hadn't seen any comments from him in a year or so. Seems like he had a 2.4 in an Austin Healey?

-

sweatys rebuild

Do you read "Anniston, Alabama" anywhere on there? ACC?

-

how high will they go?

Oh what I'd pay for small penis bragging rights! Do I pay by the inch or the girth? I guess I'd need to ask the boobies thread women? They don't care too much I bet, just measure against stacks. Shower or grower.

-

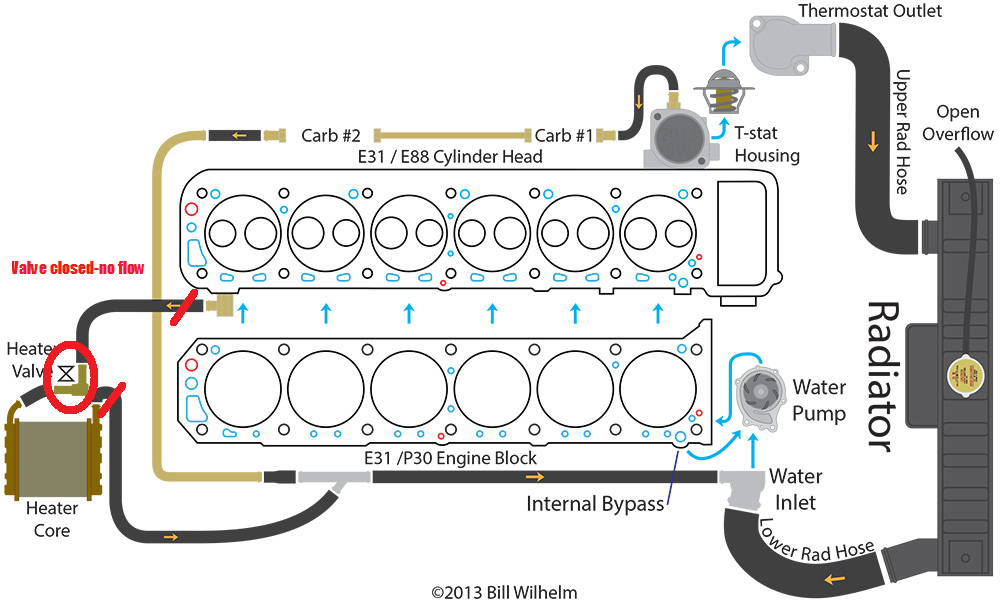

Coolant flow question; advice needed please

Thank you SwettyBetty, I'm gonna try the OE setup first then go for other ways like your's and Captain Fantastic's as options. I think my core is good and okay but I do like the idea of the valve in the bay. So if all else farts out that's what I'll do. Thanks again for your help. Cliff

-

Fatal Error, Forbidden?

I worked in construction until the bottom fell out in '07, 20 years I paid into "welfare". Then I wised up and started using my money to make money. My best move, or worst in some peoples opinion, was never getting married and not having kids that I know of. I'll die alone in a nursing home but as long as my parents don't see it I'm okay with that. Hard work is what makes the world go around and I respect everybody that works day to day, it's just not for me. I'd rather work on these Zs & be a dirty old man until I'm a dead old man.

-

how high will they go?

Wow! I see now why folks are attempting to reproduce those. I think you need them Mr Betty. Your Z will be so much faster, aerodynamics and all.

-

Coolant flow question; advice needed please

I've deleted the coolant line that runs through the intake manifolds on my 240. Now I'm UN- bypassing my heater core for defrost function to work properly. The "T" that connects the hoses under the spark plugs that feeds those two components, heater core and intakes outflow to the radiator will now only flow coolant from the heater core's outlet. Would this cause any problems? Should I run a straight hose from the outlet of the heater core to the radiator's outlet to the water pump? Confusing to me so any opinion right or wrong could help me to figure this out. Thanks for any help!

-

Motorsport conversion calipers

Zcardepot uses Maxima calipers for their rear disc conversions. Try google, there's some info out there. Good luck.

-

Heater core hose configuration help

Holy crap! Give me a motor rebuild any day over interior work. Putting the OE radio in last month used up my months supply of heroin now the new heater valve and hoses finds my bag empty again. Flushed it out with a hose pipe then stuck my finger in the out flow hose to check for leaks. It leaked around my finger only, thank goodness. I can't take anymore today but tomorrow the inlet hose and valve go on then I'm checking myself into rehab.

-

This Old Cam

I can't see any oiling holes in lobes so maybe it's not for an EFI turbo head? It's a mystery!

-

Heater core hose configuration help

The 240's valve shuts off the flow through the core. I was worried that coolant would be coming inside the cabin all the time but it won't be until the valve is opened. So plugging the elbow on the head is the same as closing the valve. Don't know about the 280's, they are different

-

Fatal Error, Forbidden?

Too funny! That's where "working is for suckers" comes from I guess. As Fred G. Sanford does, I coordinate.

-

This Old Cam

I've always read EFI cars don't run good with high lift or smaller base circle cams? That one says "turbo" so it's made for EFI. Chickenman has the best advice. Get the number off the end and google it.

- Water ****

-

Trouble tuning SU carbs

My rebuild kit came with SMs from Ztherapy. Runs good on my slightly modified free flowing 2.4. msa 6 to 1 header and 2.5 premium exhaust. Their dvd has old info on setting the floats though. You can't measure .5" with the lids upside down. Needle valves are too sensitive.

-

Fatal Error, Forbidden?

Works fine, thanks Mike. Working is for suckers.