Everything posted by Zed Head

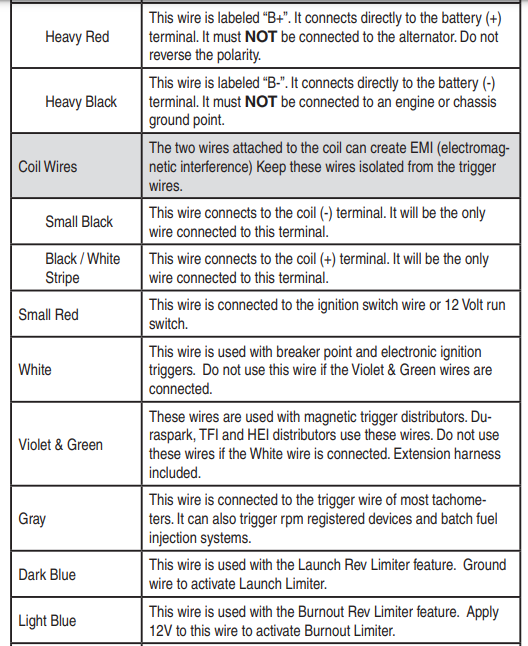

-

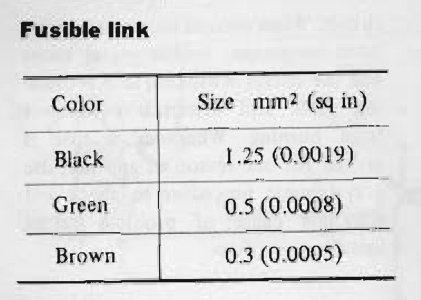

EFI Fusible Link Amperage

-

Strange intake noise?

You posted in the 1975 "strange intake noise" thread. I used the 1975 FSM. Still - wrong test method. There is no method for measuring resistance across the vane sweep.

-

Strange intake noise?

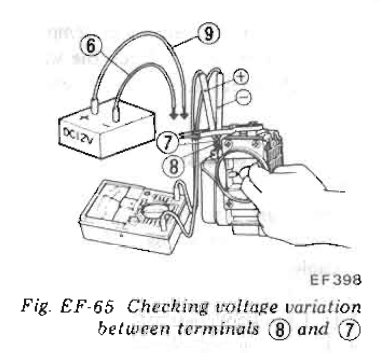

You have the wrong picture with the test method. The picture is for a single resistance measurement, not vane movement. Here is the correct picture. Terminals 7 and 8. And you're looking for smoothness of the voltage reading, not resistance. Page EF-51 and 52. p.s. you should not sand the carbon trace. It's not very thick, you could ruin it.

-

Master cylinder bench bleed

Looks used. Are you trying to find out if it's good? The larger bore will actually create less pressure. It's bigger because the ZX's had rear discs.

-

77 280z Restoration

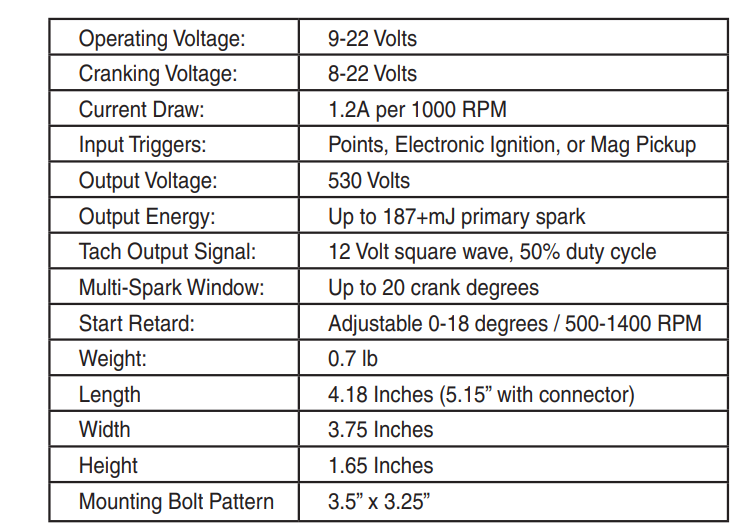

My comment about capping the blue wire in the engine bay wasn't right. You need it on the coil. So you'd just cut the tach branch off of it and use the branch for the trigger wire. Seems like all of the needed wires are almost ready to go. It will all make sense once it's in hand. Looks like SteveJ is trying to get to plug and play, with connectors and all. I'd probably just set up a terminal strip. Anyway, don't forget to position it so you can see the adjustments. Good luck.

-

77 280z Restoration

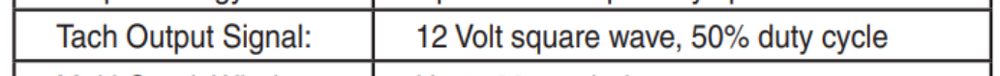

That seems right. You'd have to guess that they were aware of the tach problems with the MSD boxes and engineered a "tach adapter" right in to the system. Looks like the same signal that the old ignition module would deliver. On-off-on-off...12 volts. The blue wire is branched at the ignition module. You might be able to just attach the old ignition module blue wire at the Pertronix box, since it's there, (Edited >and cap the blue wire end in the engine bay.) Not clear if the 2200 ohm resistor is needed. Probably won't hurt, it's good insurance against shorts. Stuff to think about.

-

FPR project - cheaper, more available (for a while anyway)

Here's the Walmart version. Herko. Never heard of them. Actually doesn't look bad. https://www.walmart.com/ip/Herko-Fuel-Pressure-Regulator-PR4082-For-Renault-Fiat-Alfa-Romeo-78-89-2-5-Bar/855274203 https://herko.com/

-

FPR project - cheaper, more available (for a while anyway)

Here's another option that only requires some hose adapters. No luck on Rockauto though. Spendy. https://www.blackvlvparts.com/product/bosch-fuel-pressure-regulator-2-5-bar-7564131/

-

FPR project - cheaper, more available (for a while anyway)

I got reinterested in a thought I've had before about finding a way to use a more available FPR on the 280Z fuel rails, since the stock PFR's are becoming scarce. I just looked on Rockauto and they don't even list FPR's as an option, not even an out-of-stock listing. https://www.rockauto.com/en/catalog/nissan,1978,280z,2.8l+l6,1209260,fuel+&+air I browsed around Rockauto and realized that the 2.5 bar (36.3 psi) pressure spec. was only around for a few years. Then they went to 3.0 bar, or some odd spec like Ford used of 2.7 bar (why Ford, why?). But I found a Bosch listing and cross-ref'ed it to Rockauto. I don't have my tools available or I might try to build something but it looks pretty easy. A small block of aluminum with a few holes in it should work, I think. Just posting in case somebody wants to try it. It might even be worth producing for sale. Here is the trail I followed. https://electromotive.com/our-products/2-5-bar-rail-mount-fuel-pressure-regulator/ The Bosch number - https://www.ebay.com/itm/275118121382 Rockauto using the Bosch number - https://www.rockauto.com/en/partsearch/?partnum=0280160225

-

Dropping Overnight Fuel Pressure

I don't know how it could be cleaned. I think you'd need a new one. Or a good used one. Here's a picture I took of one that I tore apart. The fuel comes in from the side port and forces the valve open to exit down the hole in the middle of the center tube on the right. You can see the wear marks on the seat where the exit port tube seals.

-

Dropping Overnight Fuel Pressure

Probably the fuel pressure regulator (FPR). The valve seats are just flat pieces of steel. Any rust or small particles can hang them open a bit. I tested quite a few used ones when I had quite a few and most of them leaked down. Took some trying to find one that didn't. If the return line is still pliable you can clamp it and see if it holds.

-

77 280z Restoration

It looks a lot like the MSD box. The wire colors are even similar. Makes a person wonder. Who knows. Should be fun. It does multi-spark which should help idle smoothness. Good luck. https://cdn.shopify.com/s/files/1/0247/6913/4628/files/512.pdf

-

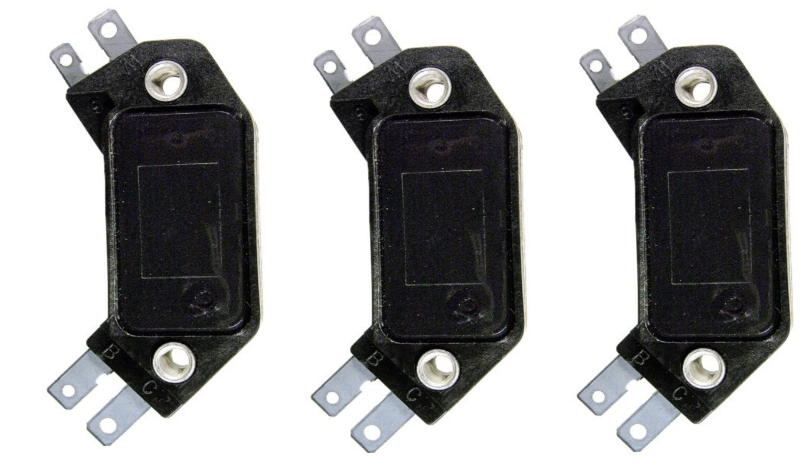

77 280z Restoration

I I was starting over I'd probably mount three AC Delco modules in the old ignition box and wire them up with a switch that allowed me to change from one to another. AC Delco is OEM for the time I believe. More expensive too, $36 versus $21, although that could just be name recognition. The Pertronix box looks interesting though. https://www.rockauto.com/en/catalog/chevrolet,1977,camaro,5.0l+305cid+v8,1035111,ignition,ignition+control+module+(icm),7172 https://www.acdelco.com/

-

77 280z Restoration

The problem is the American owners ripping off their American customers. Not the people who make the product. The owners love it when people bash "China". It's their cover. They just keep raking in the easy money while everyone complains. The owners are the ones that set the low standards and accept the low quality product to pass on to the disappointed consumer. Anyway, you'd hope that a company introducing a new product would put the effort in to using the best design elements. But I wouldn't be surprised if there was just a tiny ignition module inside that big shiny Pertronix box. Probably assembled in America but the parts made elsewhere. Sorry, it's just today's reality. If I was looking for reliability I'd try to adapt a system from a modern car. Today's cars are designed for low maintenance and low emissions. They can't have ignition systems failing. Most cars have computer controlled ignition but I wonder if some don't have the older style still. I tried to find an OEM GM HEI module but it looks like they're all aftermarket now.

-

saturday night music thread

-

77 280z Restoration

I think that there might be a Pathfinder thermostat that fits, it's just not official. But it is Nissan. On the GM HEI module the supposed 4500 RPM limit is really just a red herring that David Vizard created, based on his interpretation of the design. He never verifies what he thinks happens. He just didn't like it and voiced an opinion. It's in one of his books. And, 4500 V8 RPM = 6000 six cylinder RPM, spark-wise. There are many options out there. You have to be careful on the old brand names. The companies are long gone, most of them consolidated under one corporation and parts made in Asia. MSD is part of Holley and Holley just got "owned" by private equity money. https://www.empowermidocean.com/ https://en.wikipedia.org/wiki/Holley_Performance_Products "On September 22, 2015, Holley acquired MSD Group, which includes brands MSD, Mr. Gasket, Lakewood, Accel, Mallory, Hays, and SuperChips. On March 12, 2021, Holley announced they had entered into a definitive merger agreement with special purpose acquisition company Empower Ltd (Tkr: EMPW) that will result in Holley becoming a publicly listed company on the NYSE under the new ticker symbol “HLLY”."

-

Duffy's 1/71 Series 1 240z build

Do you really need a scope? A slow turn of the switch and a meter should tell the story. It would have to be controlled by the width of the moving contact. If it bridges On and Start it's "bumpless", if it doesn't there's a bump. p.s. the bridging would be only at the "between" point. Not when it was fully to the Start position. It might be in one of CO's links but I remember people having problems with their Haltechs or other EFI systems losing communication from Start to On or vice-versa. The computer resets and it causes problems. Can't remember what the cause or solution was though.

- Duffy's 1/71 Series 1 240z build

- Duffy's 1/71 Series 1 240z build

-

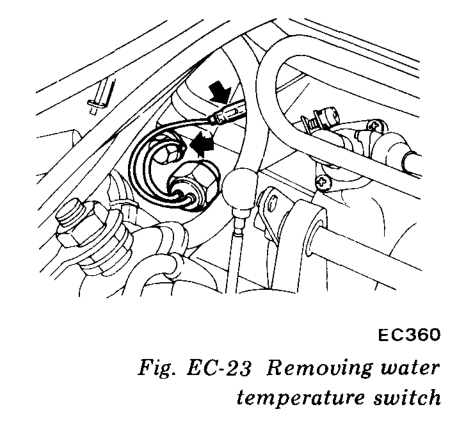

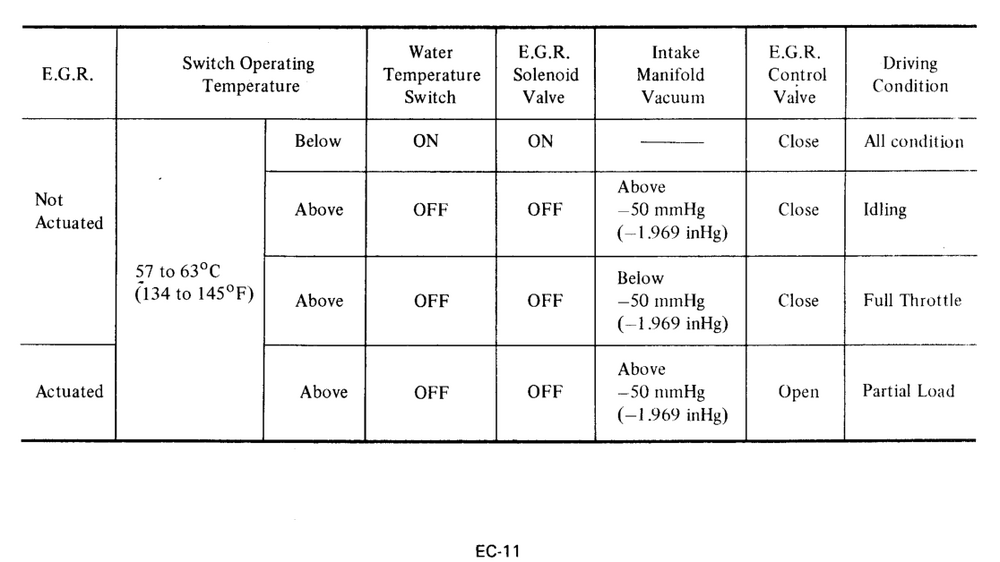

Strange intake noise?

Looks like the switch locks out the EGR system at low engine temperatures. Can't tell if the switch is normally open or normally closed though. You didn't say what temperature the engine was at. Emission Control (EC) chapter.

-

Timing issue 75 280z

These engines seem to throw rocker arms occasionally, especially if they've sat for a long time. Maybe the valve guides are tight since they're new, or they're drying out as it sits. Apparently today's detergent oils drain more fully than non-detergent. (Obscure factoid I picked up somewhere). But since it's open you migth as well check the wipe patterns. Maybe they're off and a rocker arm pad caught an edge. There have been some posts on the forum about bad wipe patterns causing a racket. The notch is on the gear which is bolted to the camshaft. I think that the only way the cam could be off is if the locating dowel was missing.

-

123 Ignition

Also, something I've noticed in these types of conversations - the focus tends to be on "maximum power" which you'll only see at wide open throttle, high RPM. Most of us never use that area. I think that getting the vacuum advance dialed in will have more affect on driveablity. And, probably, the RPM at which maximum mechanical advance is "all-in" as they say, whether it's 28 or 36. Like if you compare the 72 and 73 curves above you'll see that 72 is "all-in" about 800 crankshaft RPM sooner than 73. 2000 versus 2800. They used to make machines specifically for setting distributor curves. You can spend a lot of time on it. https://www.ctci.org/sun-distributor-machine-the-ultimate-tool/

-

123 Ignition

We had a thread conversation a while ago about how 34 degrees seems to be the optimum mechanical advance limit across a wide range of engines. I posted some dyno run videos and maybe some other links. Not sure why, I think it has something to do with just the nature of the piston movement (you can cover a lot of degrees near the top with very little piston motion) and the basic design of most older engines. Anyway, if you browse around the internet you'll see 34 degrees a lot. There's also a thread out there, either on this forum or Hybridz where a guy was setting timing by ear, expecting to hear some knocking when he was "maximized" but he never did and ended up leaving power behind because he was over-advanced. He discovered it later when he did some dyno tuning.

-

Mating engine to transmission

People have just eyeballed the disc over the spigot/pilot bushing to get it centered with good luck.. I'm pretty sure that you can get it centered also by eyeballing the edges of the disc on the flywheel. Just make the edges even all the way around. Sometimes, you can just wiggle the transmission around and/or lift it up and down a bit to get the shaft started. The input shaft actually has some play in it so even though the transmission body might be aligned the shaft itself can be a bit low. Your input shaft has a pretty big chamfer cut in to it so should actually be easy to start. Put a small amount of grease on the tip it, it might help. But, I've had a pilot bushing that was just wrong-sized. It wouldn't fit in the crankshaft. I had to break it in to pieces to get it back out after getting it halfway in. So sizing errors are possible. Might be worthwhile to spend a few bucks and get another of the same brand just to be sure it fits the input shaft. Then maybe replace what's in there with the known quantity.

-

Mating engine to transmission

How far does it go? How big is the gap?