Everything posted by Zed Head

-

Distributor Help/Identification

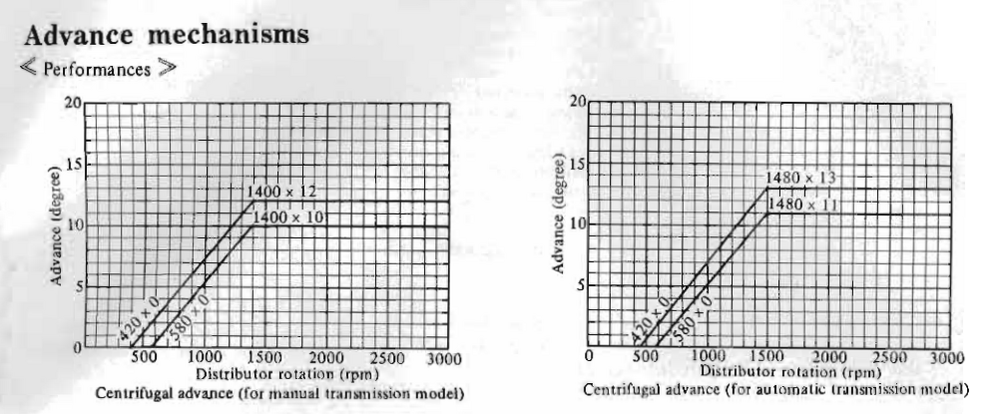

I'd check your mechanical advance weights and see what maximum advance will be at high RPM, full throttle. Then do the math to get about 32 - 34 degrees total. That's the magic number for best performance for most engines. Don't forget to double the number stamped on the weights since they are distributor degrees not crankshaft. e.g. weights stamped 9 will give 18 degrees mechanical. I've seen 11's. 34 - 22 = 12. You might even have 12's. Always a good idea to check the centrifugal mechanism anyway, sometimes things get gummed up or fall apart. Here's the plots from the 73 FSM.

-

Impossible Oil Leak?

You can even get a whole cap. Not Nissan though. https://www.carpartsmanual.com/datsun/Z-1969-1978/engine-280z/cylinder-head/39 https://www.sixityauto.com/gates-31109-engine-oil-filler-cap-for-15255-21b00-16920-60b02-e8dz-6766-a-15610-p2a-000-e7tz-6766-a-3022017404.html

-

Impossible Oil Leak?

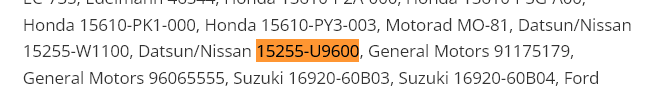

Don't know why I didn't go here last time, it's usually my go-to place to go to. https://www.carpartsmanual.com/datsun/Z-1969-1978/engine-280z/cylinder-head https://www.carpartsmanual.com/datsun/Z-1969-1978/engine-280z/cylinder-head/39 https://www.carpartsmanual.com/datsun/Z-1969-1978/engine-280z/cylinder-head/40 Not really sure what these guys mean by "reproduction TPU". Probably better than rock hard though. https://www.ebay.com/itm/275346381999

-

P90 images.

Here's Dover. Still in business. https://www.doverheads.com/ https://www.doverheads.com/wp-content/uploads/2021/07/Dover-Cylinder-Head-Catalog-2021_07.pdf

-

P90 images.

Skimming is to increase compression ratio? Still not grasping the overall plan. It's basically a square exhaust port P79 head. Like building a flat-top piston 280ZX engine. If you put a cam in it all of those nice perfectly centered wear patterns go away. I guess I'm saying it has high value as-is. You could probably sell it or trade it for three or four heads that could really use some reworking.

-

P90 images.

Looks in very good shape. Sure you want to mess with it? What are your plans, there was advice in the other thread.

-

Engine rebuild smoking

I wonder if a bore scope would show anything? Down the plug hole and maybe down the intake runners. Leaking valve seals should cause oily intake valves. Of course, if it's that you'll end up removing the head anyway. Still interested in what the block and head guys did or said that they were going to do. No details. Have you checked the spark plugs? Maybe it's just one or two cylinders.

-

Valve Cover Ventilation Hose Flame Arrester

Another. https://www.roversnorth.com/parts/603330_flame_trap_new_old_stock_3_5_3_9l_v_8_special_price_while_supply_lasts

-

Valve Cover Ventilation Hose Flame Arrester

I searched "flame trap" on the Google and some interesting things came up. https://mossmotors.com/379-580-flame-trap

-

Rough running engine with no explanation

I read more of your details and see that you have 180 marked. How did you get the water temperature set? Must have taken some time. Could be some error there. You might jump the pins at the sensor connector in the harness at the thermostat housing then measure continuity at the ECU connector between 13 and 16 like suggested. It should be very low, like under 5 ohms. If it's good you won't have to mess around with the wires.

-

Rough running engine with no explanation

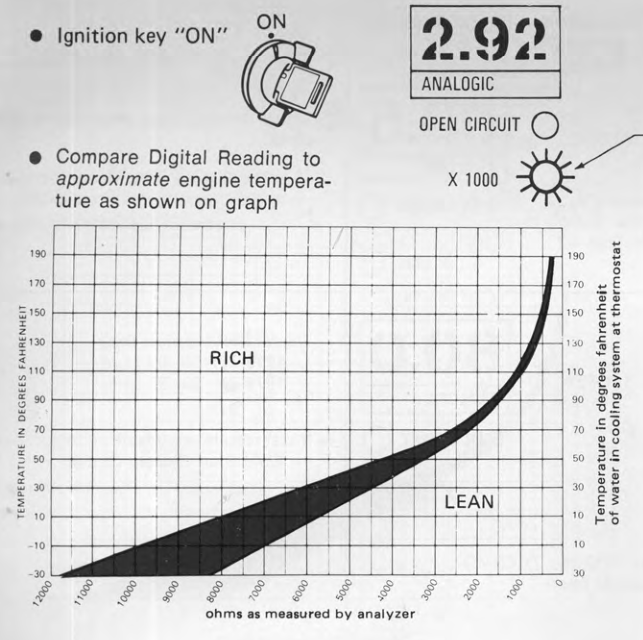

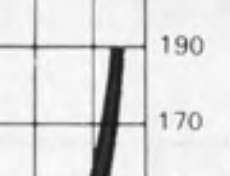

Here is Nissan's documentation from the 1980 EFI book. Since you're mostly looking at a warm engine, the resistance at 180 is probably the most relevant. I'd guess that their spec is 250 to 275 ohms, by eye (edit - probably more like 300 to 350 on the high end since the line is 500. Of course, they are just lines on a piece of paper [pixels on a video screen]). Seems to match what CO's plot shows. Yours all seem rich. Did you measure at the sensor pins or at the ECU? Might have resistance at your bullet connectors in the sub-harness oe at the EV1 connector itself.

-

Impossible Oil Leak?

I'm trying to get past the assumptions. The means to know are at hand...

-

Impossible Oil Leak?

Just curious but I had an exchange about this in the past and proposed that maybe the cap would still seat well without the gasket. Could you try yours and see? I think I was just being obstinate and that I probably actually had a gasket on my old cap. My memory was of looking at it and being surprised that Nissan used two hard flat surfaces to seal the oil filler area. But the car was gone so I couldn't check it.

-

Impossible Oil Leak?

It's actually a shaped gasket, by CO's picture, not an o-ring. The question is, does it still exist in the cap. The fact that oil is leaking from two places kind of suggests blowby pressure. Maybe a clogged PCV valve or hose.

-

Engine rebuild smoking

Oil smoke has a distinctive smell, and so does gasoline vapor. Might be worthwhile to run through the cloud and see what it smells like, if your nose works. And water vapor dissipates pretty quickly. You could put a smooth cold surface at the exhaust pipe, a mirror or a piece of chromed metal, and see what condenses. If it's as bad as you describe you should get something.

-

Engine rebuild smoking

Details might show something. "Did" is not enough. Valve seals can get damaged during installation. You might even see something just by removing the valve cover and taking a look. Is there blowby? Smoke from the oil filler cap? Wrong/poor rings and ring sealing should show up there also.

-

P90 barn find

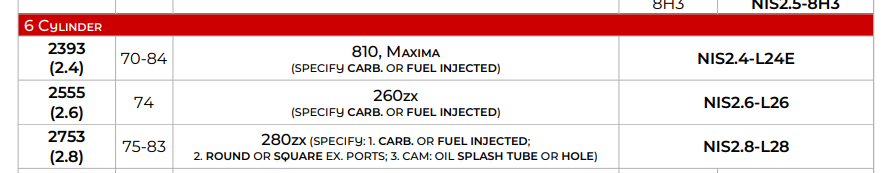

It has the same chamber volume as a P79 head. With flat top pistons it will have the same CR as a 280Zx engine, 8.8. One benefit is the lack of exhaust port liners.

-

P90 images.

Are those the solid rocker arm pivots? They look adjustable. Should be fun. What will you do with it when it's done? And, have to ask - what is all of that stuff?

-

My 1978 280z is Running Poorly Looking for Repair Shop In Florida to Fix It

Was the ECU replacement new or just a different old one? The symptoms do fit a bad ECU. But a bad ignition module is also a possibility. If the tachometer needle is showing high RPM when you know it's low that is a sign of a bad ignition module. The ECU opens the injectors for every third ignition pulse. So it's dumping too much fuel because the ignition module is creating too many sparks. SteveJ can do a module swap if appropriate. And, banging on the ECU is the old ECU testing method.

-

Rough running engine with no explanation

This seems most likely. I remember way back in my early car days spending a lot of time and effort trying to figure out a similar problem, only to find that it just needed a tuneup. Really, just new clean plugs. The carbon will absorb moisture while sitting and get more conductive. Then you get no spark. 40 psi is high on the fuel pressure. Many new aftermarket regulators seem to run high. 4/36.3 = 11%. That's a lot of extra fuel. Plus, if you have a new aftermarket AFM it might be running rich also. My MSA reman did, bought back in 2009/2010. And, I've also read that there is a lot of variability in the coolant temperature sensors. An adjustable FPR like Hussein Holland and I were talking about might help solve the running rich problem simply. Watch out for the shiny aluminum adjustable FPR's, they almost all leak pressure rapidly when the pump shuts off.

-

Rough running engine with no explanation

I'd pull injector plugs. Electronic ignition systems don't like it when their spark can't get to its intended destination. It will go somewhere though. I damaged an HEI module when I left two plug wires off.

-

Rough running engine with no explanation

Is it running bad rich or running bad lean? Bad lean would give you some intake popping and bucking. You might check the FPR vacuum reference hose for fuel. That is something that could go bad suddenly. Also, if you still have EGR might be worth checking that. Maybe a channel opened up in the EGR passage. And, of course, the old thrown rocker arm. Fairly common after an engine has been sitting. You can eyeball that under the valve cover.

-

Help identifying Nissan turbo parts

Could you add some poorer pictures from farther away? Throw some more dirt and grime on also. Ha ha ha...

-

FPR project - cheaper, more available (for a while anyway)

-

Referral link

Mike replied to a Support request that I made. In case anyone else has concerns. Thanks Mike. Sorry to be a pain, but it's a big deal these days. There really are hackers out there, and many of them are pretty good at what they do. https://www.classiczcars.com/support/1485/