Everything posted by Zed Head

-

starter issue, wiring?

The starter draws huge current. It should draw through the main positive cable. But it also needs a good ground. Are you sure that the "fusible link" is on the positive side? Or do you have it connected to the wrong terminal at the starter? I'll see if I can see it in your video. Anyway, it sounds like your starter circuit is the problem.

-

starter issue, wiring?

When, exactly, does it "burn up"? I remember your past threads. Does it get hot when you connect the battery, or when you turn the key on, or when you turn the key to Start, or when the engine is running? I would narrow it down to one of those four, it will tell you a lot.

-

starter issue, wiring?

Isn't that what the condenser (capacitor) in the distributor is for? The ballast is to keep the coil from burning up. It's the thermomechanical version of "current-limiting" ignition modules. Kettering.

-

Z's on BAT and other places collection

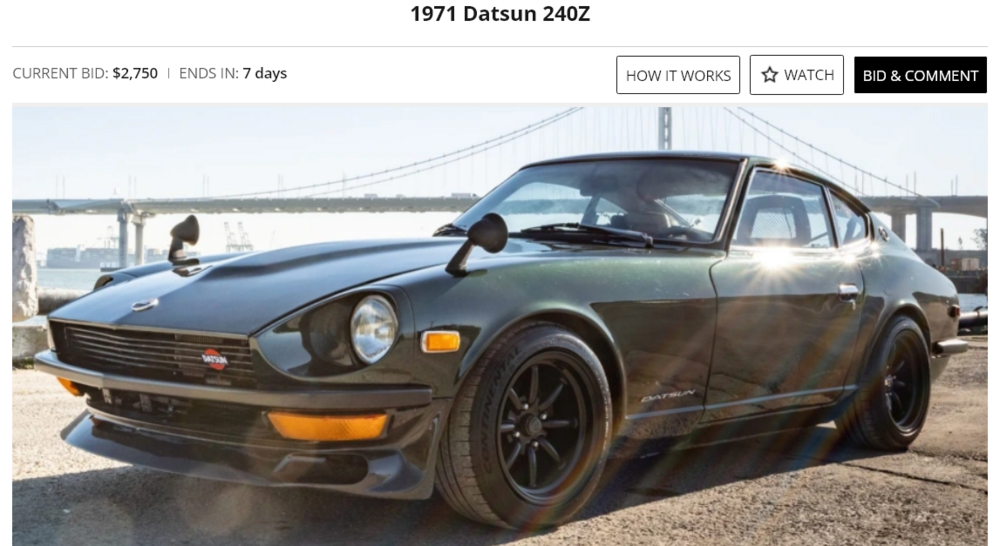

This Beverly Hills car actually looks kind of interesting. Beat up, but hard to tell how bad. https://www.beverlyhillscarclub.com/1971-datsun-240z-c-13399.htm

-

Z's on BAT and other places collection

I think is where BaT RNM's end up. https://www.hemmings.com/classifieds/cars-for-sale/datsun

-

Z's on BAT and other places collection

This was on BaT a short while ago. Made it to $27,250. Looks like the reserve was $45,000. Red... The Hemmings article uses the BaT verbiage as the seller's description. I wonder if BaT allows that. Seems like free work. It's not fantastic but still has that tone to it. https://www.hemmings.com/stories/2022/01/14/after-some-minor-updates-and-refurbishing-this-1971-datsun-240z-is-primed-for-long-countryside-jaunts https://bringatrailer.com/listing/1971-datsun-240z-201/

-

Clutch slave cylinder

I've had a brand new slave cylinder leak. Sometimes you'll find machining grit inside if you take them apart, even brand new. Quality control on aftermarket parts is just poor. Take it back and see if you can exchange for a different brand, then take it apart at home and clean it up inside before installing. I think that EuroDat has seen similar if you want to search for past posts about it. @EuroDat

-

R200 long nose gear supplier

I'm saying just buy a complete used R200 with 3.9 gears. Typically found in the 1980 -1983 280ZX 5 speed cars. They're out there. You could probably buy a complete junked 280ZX for less than the cost of new gears if you find them. Actually, I doubt that you'll be able to find gears for sale. A used R200 is probably your only option.

-

R200 long nose gear supplier

It would be easier and more effective probably to just buy a 3.9 R200 with good gears. I don't think I have ever seen anyone talk about worn gears on their R200. But here are the part numbers if you want to try to track new gears down. http://www.carpartsmanual.com/datsun/Z-1969-1978/power-train/differential-gear/r200/13

-

Z's on BAT and other places collection

-

Z's on BAT and other places collection

Too bad the 280Z's don't generate the same excitement. Seems like the 240Z's are becoming collector things, like Pokemon cards. The value is in the scarcity. The value could disappear overnight once a new thing comes along. No offense intended, just a thought. https://cardcollector.co.uk/collecting-pokemon-cards/

-

Z's on BAT and other places collection

I'm not trying to cause trouble. Just talking about an interesting car. Your build thread is too long to search through to find the explanation. It really stands out in the pictures.

-

Z's on BAT and other places collection

-

Z's on BAT and other places collection

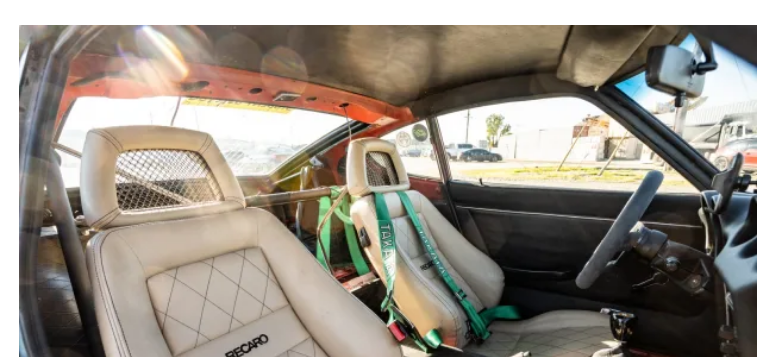

Isn't it really a resto mod? Resto perfecto maybe. Parts have been replaced with better parts, but they are not original, therefore not resto. Just pretending I'm a car show judge. Anybody know what this thing is...

-

Engine Swap or Rebuild?

Looks like the silver foil from the top of a gallon jug of oil. ? If it is a bearing failing you will hear it eventually. Measuring cylinder pressures, examining cam lobes, checking timing chain wear...those are the typical things you'd do to determine engine wear. 136,000 miles is not a huge number for these engines.

- Engine Swap or Rebuild?

-

Z's on BAT and other places collection

Is this yours Cliff/site @siteunseen ? I see orange. Condolences if it is. It's been Californicated. https://bringatrailer.com/listing/1971-datsun-240z-210/ "This 1971 Datsun 240Z was acquired by the seller four years ago while in Alabama, and was subsequently repainted in metallic green."

-

What is that and What is the purpose?

Might this be part of it? Sorry.... https://www.theguardian.com/sport/2022/jan/11/georgia-alabama-national-championship-game

-

Parts for Sale: FS5W71B M27x1.0 main shaft nut - right hand thread

All of the 5 speeds through 1983 are called FS5W71B. The label doesn't tell everything about what's inside.

-

resurrecting a 1977 280Z

You can buy this length in coated professionally prefitted tube at your local auto parts store. Run a piece of string or wire over the orginal to get the length. Bend the new one to match the shape. I might have mentioned this already.

-

Water pump aluminum/iron

Your antifreeze should contain corrosion-inhibiting chemicals. The block itself will rust if you don't use proper antifreeze, it's cast iron.

-

Water pump aluminum/iron

You might be thinking of stamped steel versus cast iron. I've never seen an aluminum impeller. Compare the AISIN and Airtex pictures to the others. I think that most people like the cast impellers. They were hard to find for a few years but it looks like they're back. https://www.rockauto.com/en/catalog/nissan,1978,280z,2.8l+l6,1209260,cooling+system,water+pump,2208

-

Parts for Sale: Datsun 280zx, A series, L series, 510, 1200 Matchbox distributor breaker plate repair kit.

Can you describe the material and the process used to make it? It looks interesting. I made a time stamp of the video that shows the broken bearing holder. for the impatient people. Good luck, think about doing the 280Z distributors. They have the same problem. Even the points distributors. 240Z repro parts might be a good market.

-

Z's on BAT and other places collection

-

Z's on BAT and other places collection

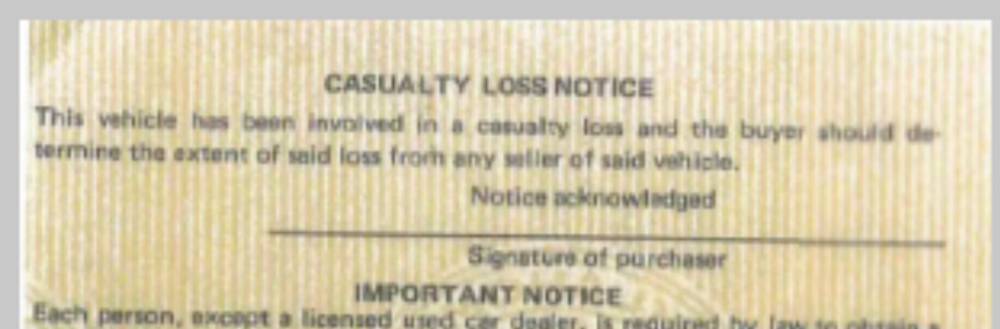

Seems obvious that it got crunched in the front, just by the pictures. The seller is not the owner, it's a sales shop. The guy has to know but he can claim he does not. His "techs" did the work, not him. Plausible deniability. It got to $20,550 but RNM. Does Nissan paint do this, even on a 71? The roof should look the same. It's been crunched and repaired.