Everything posted by Zed Head

-

HLS30-09579 selling for pretty cheap on eBay

They have a pretty cool barn though. Snohomish is in the wet part of Washington. It was probably back in a corner...

-

Transmission Swap

Depends on what you mean by "sort it out right". There is no 7/71 Type B console. There are other ways to get the Type B to work with all of the original Type A parts. The most effective seems to be bending the shift lever.

-

HLS30-09579 selling for pretty cheap on eBay

It has an automatic transmission. Booooooo.....

-

How to tell which head I have?

A hard freeze could probably do that. "Freeze" plugs aren't really there for freeze protection.

-

Brake Problems (still)!

Can't tell where you checked for vacuum. Is it possible that the check valve is in backwards, or that something is blacking vacuum from the booster body? Or maybe something is bound up in the booster itself, not letting the vacuum do its thing.

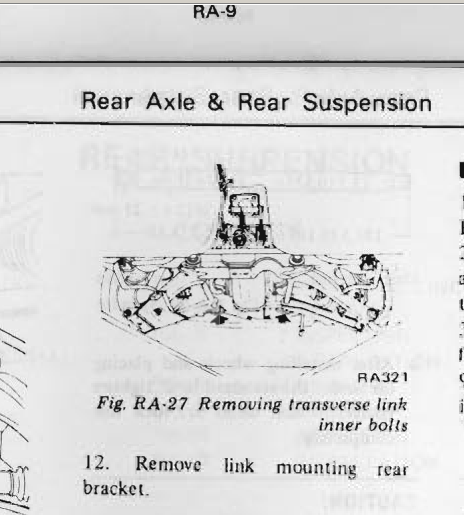

- Problem With Differential Installation

-

Relay Testing and Fuel pump help

If you disconnect the hose there, there will be no fuel flowing through the FPR. Take the FPR out of the flow path to see if it is clogged. You'll have fuel flowing only through the rail.

-

Relay Testing and Fuel pump help

You must have a 78 rail and FPR. So that takes out the connections between the rail pieces as the problem source, it's a one piece rail. There's only one connection left. If you still get 50 psi from that spot there's something clogging the rail. If pressure drops the problem is in the FPR. That's one crusty looking FPR.

-

Home Built Z 'Full video build'

Couldn't tell if it was smoking because the key was on or because the battery was connected. A better way to test the wiring before connecting the battery is to measure resistance between the positive cable terminal and the negative cable terminal. A short circuit will show up as low resistance. Then you can go wiggle and disconnect various circuits until the short circuit is found. You can do the same when turning on the key. All circuits should have some resistance.

-

Spindle Pin Installation

A lug nut on the threads will give you something to hold on to for spinning. Same pitch and size.

-

Spindle Pin Installation

The thoughts above were developed while I was working on my own spindle pins. I found that the area in the bore of the casting around the lock-pin was deformed, as well as the spindle pin in itself. A rat tail file will clean up the bore.

-

Spindle Pin Installation

You don't need a precision fit, as Dave WM says. Making it looser is probably actually bad for it in the long-term because it gives it more room to flex in the bore, concentrating load on the lock-pin area. The purpose of the very tight fit and the lock-pin is to make the pin become "one" with the casting. Ideally, once assembled, the pin does not move at all in the bore of the casting. An alternative view. If you can get it jammed in to where the lock-pin lines up correctly, you're done, essentially. Lock it down and call it good.

-

Relay Testing and Fuel pump help

If you run a hose from the exit of the FPR in to a can and still get high pressure then the FPR itself is a likely cause. The FPR is just a pressure relief valve. When pressure rises to its setpoint it lets fuel exit and go back to the tank.

-

Relay Testing and Fuel pump help

If you want to narrow things down further, disconnect the FPR at its exit. That is a likely spot for misalignment. Since the FPR has two entry points it seems most likely that the single exit is clogged than both entrances.

-

78 280z poor braking

There are two chambers in the master cylinder, on the same piston. Sounds like you might have blown one seal. Since the pedal moves far it should be pushing a lot of fluid. Somebody helped me solve a bleeder screw problem once when they noticed how much fluid was leaving and reentering the reservoirs. Have somebody watch the reservoirs while you press the pedal. If a lot of fluid moves there's air in the system. If very little fluid moves you probably need a new MC. You can have a bad seal inside but no fluid will leak out.

-

78 280z poor braking

Make sure that bleeder screws are at the top where the air bubbles are. You can see the little channel for the screw. The end of the channel has to be where the bubble lives.

- Problem With Differential Installation

- Problem With Differential Installation

-

Relay Testing and Fuel pump help

Since you replaced some hoses you should move the gauge back to right in front of the rail and measure there. You're narrowing things down. Zero pressure on the return line might be good. seems like you would have seen a pound or two. If you still get high pressure from right in front of the rail, then the blockage is in the rail, or the FPR, or the line to the FPR, or the return line between the FPR and where you have the gauge now.

- Problem With Differential Installation

-

How to tell which head I have?

-

How to tell which head I have?

Should be letters and numbers cast in to the head up by the 1 and 2 plug holes.

-

correct torque, clutch bolts

We can all only guess, but one possibility is that since the requirements are exactly known and cannot be exceeded, it's safer to set a mid-range torque value to reduce the possibility of damage. The springs of the pressure plate are the limiting factor for force on the bolt heads. Plus, the bolts have leverage since they're out on the perimeter of the plate so don't see as much force as they might in a different application. Just a guess. I've never heard of anyone having a pressure plate come loose. I wouldn't exceed the spec. Imagine your aggravation if you strip a thread or break a bolt trying to be safer.

-

Seriously? I'm not watching porn...

-

1978 280z what is this Filter Looking in fuel line?

Then sell it all on Craigslist ten years later...