Everything posted by Zed Head

-

Rebuilt engine won't "first" start

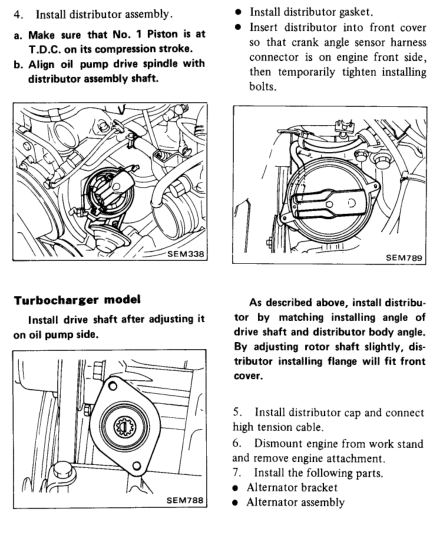

site, his fat side matches the fat side you showed except it's off by about a tooth. Here's the 280ZX pictures. They show a rotor for NA and the half moon for turbo. site, it's not clear if this picture is a good setup or bad.

-

Rebuilt engine won't "first" start

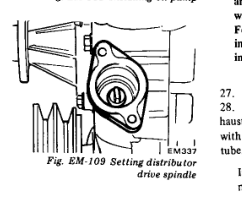

Actually site might be right. The small half is on the other side. Nissan drew bad pictures for the distributor setup. Here's the setup picture from the FSM. Are you sure that you're on the compression stroke? The timing mark matches twice, once on exhaust and once on compression.

-

Emissions saga and a home test for idle setting/tuning tip

Any chance you could check the label on your other AFM? I'm curious. I notified the MSA guys, thinking that we had two rich MSA AFM's. @rcb280z

-

HG stop leak recommendations?

Here's the permanent stuff that hardens, and one of the the silver powders (aluminum dust). There's a bunch. Don't forget the raw egg fix. https://barsleaks.com/product/head-gasket-fix/ https://www.amazon.com/Silver-Seal-Radiator-Sealer-Powder/dp/B000AME522/ref=cm_cr_arp_d_product_top?ie=UTF8 https://www.goldeagle.com/product/alumaseal-radiator-stop-leak-powder/

-

Rebuilt engine won't "first" start

Notch matches groove, timing mark at zero to ten on the compression stroke, front edge of rotor pointing at #1 plug wire. Those are the things you can set up from the beginning and the engine should start. Those are all of the "timing " things. The links help get things right the first time around, but after that the various marks are used to confirm. You only need to rotate the engine to the compression stroke. Remove the valve cover and the distributor cap and check all of those things.

-

HG stop leak recommendations?

Have you tried retorquing the head bolts? Won't hurt unless you break one. Is it the original engine? Might be that the original gasket material just shrinks, degrades, and leaks after so many heat cycles. It's some kind of organic material. Mine looked fine after took the head off, except for the leaky spot. The metal cylinder seals were fine.

-

Emissions saga and a home test for idle setting/tuning tip

That would be good to know. Should have the blue Fuel Injection Corp. sticker on it. No Nissan stickers.

-

Emissions saga and a home test for idle setting/tuning tip

I sent you one a couple of years ago. I was wishing I hadn't yesterday. But the one I had left did the job. I'm going to leave it on and the MSA will be my emergency AFM, on the shelf. I wonder how they set those reman AFM's. Maybe they have the wrong calibration settings at Fuel Injection Corp. I was told that the FIC remans had a thicker and more durable carbon trace. But it doesn't help much if they won't pass emissions. Not clear if they actually run air through them or just set mechanical settings and assume that they will work right. https://fuelinjectioncorp.com/products/air-flow-meters/ @Joseph@TheZStore @James@TheZStore

-

Emissions saga and a home test for idle setting/tuning tip

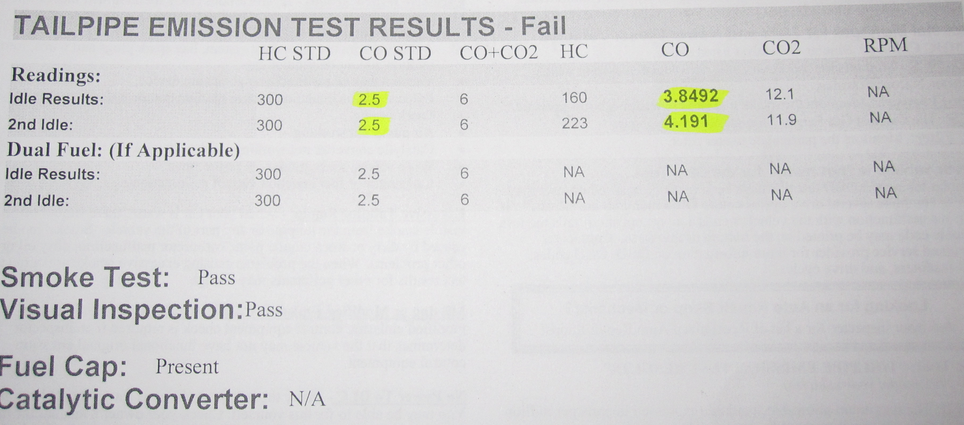

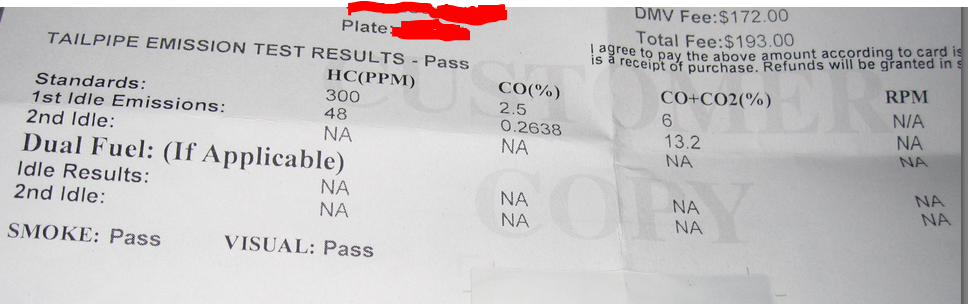

I just got my car checked for emissions again so that I can renew my tags. We're on a two year cycle here so that gives plenty of time to mess around and get it screwed up . I had my car running greatly and went straight to the emissions check station without doing anything to help it pass. It failed, of course, so I spent the next few hours dinking around with the idle air bypass and my fuel pressure and failed three more times. So I went home and realized that I was using my MSA AFM that I had bought new nine+ years ago and that it had always run rich. I don't know why, it just does. No matter how far I back out the idle air bypass I couldn't get it to lean out. I pondered drilling out the bypass passage to let more air past the blade but it's not an easy operation. So I pulled my last old AFM down from the shelf, an original 75/76 AFM, and installed it. Then I leaned out the idle air bypass until removing the oil filler cap caused it to stumble to barely running. I went back to the test center the next day and passed on the first shot through. I realized as I was tuning that I could remove my oil filler cap and the engine would not stumble, when I had bad results. I had forgotten about that basic "running rich" test. Even though it was not noticeably rich, it wouldn't pass, and I could leave the cap off with no problems. Anyway, the short story is that if you can remove your oil filler cap and your 280Z doesn't notice, you're probably going to fail the idle emissions test. So that's the tuning tip. If you're in CA with the 2500 RPM requirement the same test might still help. And even though I could leave the filler cap off, it still only failed CO. Not HC. It was very close.

-

HG stop leak recommendations?

Pretty sure it just jams up small holes. Flows right through the big ones. Doesn't harden that's why it kept squeezing out the relatively big leak at the back of the head.

-

HG stop leak recommendations?

Is that the top of the block, near the heater hose in the first picture? I had that same leak n my 76 engine. Barr's Stop Leak worked for a while. It eventually extruded through the gap, leaving a small pile of powder back there. You could also buy an OEM stop leak. Ford has one. I've seen the part number but don't have it handy. Looks like GM has one too. You could probably go to a Ford Dealer and ask for stop leak pellets and they'd know. Here's an example, but I've seen it in my Ford service manual also. https://forums.tccoa.com/7-engine-4-6l-5-4l/121432-ford-suggests-stop-leak-their-new-modulars.html And, of course, you'll take heat from the "do it right" crowd. Even though Ford adds it at the factory in new engines, apparently.

-

Engine mis

Are the wheels hanging or are the stands under the control arms? If the wheels are hanging the u-joint angles can cause binding and clunking as the wheels spin. You started with a miss and now you have a transmission problem. Doesn't really follow. Move the stands to under the control arms to get the wheels back to normal ride height. Only need to do it on the back of course.

-

76 280Z 2+2 Sale

Pretty nice paint and a good color. Couldn't the painter find some newspaper to cover the battery and other goodies? Looks like one of those bank robber quick color change jobs. Not terrible, adds character. Are those eBay fusible links? Good luck.

- Duffy's 1/71 Series 1 240z build

-

1976 280z rough idle then dies.

He started another thread -

- Duffy's 1/71 Series 1 240z build

-

Rear Freeze/Core Plug

I pulled a freeze plug once by poking a hole in it with a sharpened nail, driving a long wood screw in to the hole, grabbing the end of the screw with a pair of vise-grips, and levering it out by using a big screwdriver under the vise-grips and a wood block as a fulcrum. If there's enough meat left around the edge that might give you something to work with. Just an idea, to build on.

-

Rear Freeze/Core Plug

Your "we" is the small we. Most of "us" appreciate that there are many ways to get a job done. And, "we", meaning "us" (maybe just "me") only diss people who are judgmental. Let the guy do what he wants to do. It's his car. Plus it probably has a high VIN.

-

Rear Freeze/Core Plug

Good ol' JBWeld...

-

Rear Freeze/Core Plug

Written like somebody with lots of time and money. Edited - don't want to get in trouble. Beside that - wouldn't you just pay somebody else to do the work? Be honest.

-

240z Transmission Input Shaft Play

And if you get a new clutch kit, make sure it matches the sleeve.

-

240z Transmission Input Shaft Play

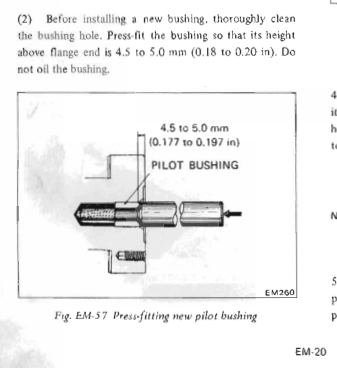

Nissan has the stuff for that project all spread out in the FSM. The pilot bushing is in Engine Mechanical, but it should be in Clutch or Transmission. I've had one get stuck when installing, had to break it out and buy a new one. Wide tolerances on aftermarket parts. To Mark's point, you might have to wire brush the splines on the input shaft, so the disc slides easily. They get rusty and gummed up.

-

1976 280z engine runs rough then dies, will not idle.

While you're there you should probably replace all of the hoses. Even the injector hoses if they have that braided hose on them, which seems to be on the rail. Probably original. Mine were and they eventually sprung a leak. I smelled fuel, stopped, popped the hood with the engine still running, and a thin stream of raw gasoline shot by my head to the sidewalk. Luckily there were no people walking by, and i had a screwdriver in the car to crank the clamps down. The hoses had tiny lengthwise cracks. You can probably see them with a bright light on the end of the hose. Plus you'll probably bend things if you try to replace the FPR without removing the injectors. I've seen many bent rails.

-

Rear Freeze/Core Plug

How about driving it inward, then bending the piece that's left while it's inside the head, so that it will come out of the hole? Probably work best if the rim that's left is even thinner. Or youmight find that driving it inward breaks the bond to the head and once you break that bond it will pull out. Or, if you have a steady hand, saw or grind several notches in to the piece that's left so that it is more likely to bend as you try to pry it out. Your biggest risk, probably, is damaging the seat for the new plug.

-

thoughts on broken door handle

Kind of doesn't make sense, what you're trying to do. I did like AV8 in my 76 and figured out what needs to go in first and getting the little nuts off the back of the handle, etc. The rod just presses in to the bushings. No need to break anything. Can't tell what stage you're at, if you have the new handle in already or if you're trying to figure out how it works first.