Everything posted by Zed Head

-

Transmission Noise in 3rd Gear - F4W71A

Have you checked the action of the shift fork on the coupling sleeve, and the sleeve on the hub? I wonder if the sleeve could get cokced on the hub as the fork pushes it over. Like if one tine of the fork was ahead of the other. The sleeve should lock in, or center over its final position, but maybe you're getting incomplete travel and final engagement. You have it all torn donw now but you might find some sign on the parts. Maybe a loose fork on the rod. The roll pins do fail. Ideally, you would check the action by moving the shift rods with it mostly assembled. There are also the detent pieces in the adapter plate. The balls, springs, and pins that set the final position of the shift rods after a gear selection. Your description sounds like something relatively large wobbling around the shaft. If all of the bearings and other parts seem undamaged and correct then it seems like the parts must not be correctly positioned.

-

How do I test power to wiper motor??

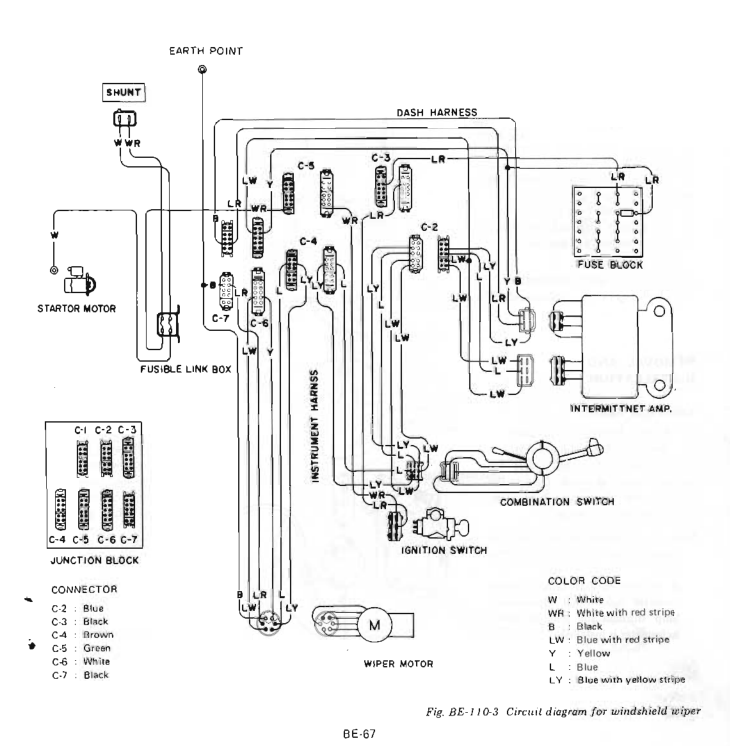

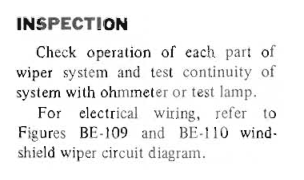

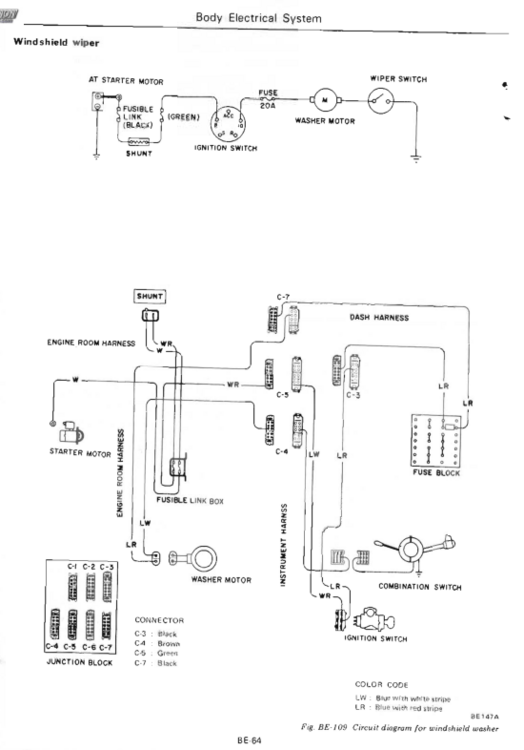

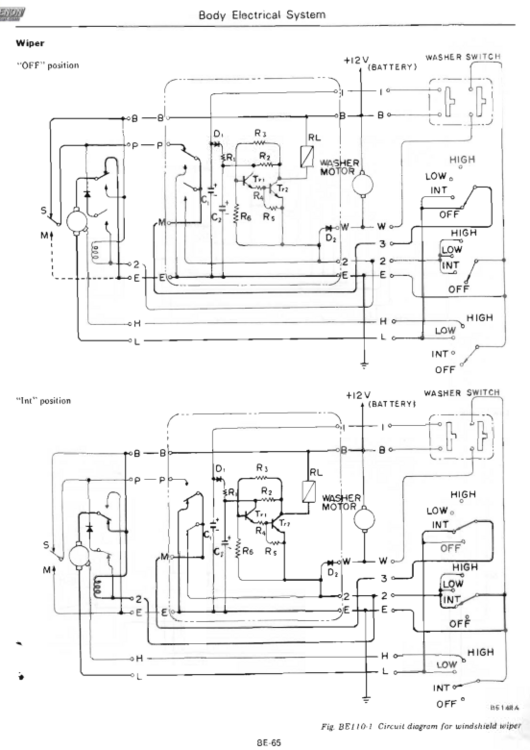

Not sure which side of the harness you're looking at. Remember that the switch harness colors probably don't match the main harness colors. Here's a better diagram.

-

How do I test power to wiper motor??

You might read some of the Honda upgrade threads. People have dug in to the operation of the factory motor so that they can replace it with a Honda motor. There's probably a schematic in one of them.

-

How do I test power to wiper motor??

-

How Do You Properly Run An Oil Catch Can?

p.s. we used to build vent filters for our vacuum pumps that were about 8 inch lengths of two inch pipe packed with stainless steel wool. The steel wool collected the suspended oil and let it drain back in to the vacuum pump case, while the "cleaned" evacuated gases could exit. The same basic concept as the steel wool in the block side port in the Datsun blocks, I think. If I was going to run a vented valve cover I'd build something like that, concept-wise, to keep the area cleaner. It would probably be ugly, but might be effective.

-

How Do You Properly Run An Oil Catch Can?

If you want to avoid the fumes you'll have to run a closed system, like a PCV. So any vents under the hood won't work. Or you could run the vents to an area that is clear of the cabin, maybe all the way back the rear of the car. If you run a closed system it needs to be properly balanced so that you don't have high air flow through the crankcase pulling suspended oil out before it can settle. I've been hanging out on a Ford truck site and people get on there all the time talking about how they're pulling like a pint of oil a week in to their catch cans. Maintaining their catch cans turns in to a full time job. I think that the catch can system designers might be designing their system to pull a lot of oil. The people that have them want to see stuff in the can. If it's empty they'll think the can is not working. Even Ford has jumped in to the "upgrade" game but their system has to meet the PCV needs. It's more complex than the typical shiny metal can aftermarket systems. Interesting to study. Read the hype in the a copy. https://www.cjponyparts.com/ford-performance-oil-air-separator-kit-passenger-side-mustang-5-0l-2018-2021/p/M6766A50A/ https://www.cjponyparts.com/ford-performance-oil-air-separator-kit-gt350-gt350r-2015-2020/p/M6766A50K/ https://www.cjponyparts.com/catalogsearch/result/?q=+Ford+Performance+Oil-Air+Separator

-

Transmission Noise in 3rd Gear - F4W71A

There is bad information out there on the various web sites about the Z car transmissions. And the kits are incomplete. Here is where EuroDat got that drawing. Compare the part numbers and you might be able to confirm that it's the same bearing used in the later four and five speeds. Then use EuroDats's writeup to cross-reference. Click through the four speed page and you'll find the early 4 speed. You can probably find a cross-reference to the Nissan part number also. http://www.carpartsmanual.com/datsun/Z-1969-1978/power-train/transmission-gears

-

Getting the 73 Back on the Road

What is it? I can only see bubbles in your picture. Is that a welded seam or a pipe fitting? Seems like Quickjack is overly confident in their manufacturing process. A leak in a pneumatic system is a pretty significant miss.

-

Intermitent start and no turn signals when it does not.

I had a switch from a parts car that had a problem and I was able to fix it by restaking the pins on the back. I tested it with a meter, after I had already taken the car apart, then started wiggling the pins and found that one was physically loose. In the parts car, which I had running for a while, the starter would catch then let loose as I tried to start the engine. Very annoying. I thought it was the starter but it seemed to actually be the switch.

-

Getting the 73 Back on the Road

The Quickjacks were dropped in to your thread with no introduction. They look interesting. Is this them - https://www.quickjack.com/

-

Transmission Noise in 3rd Gear - F4W71A

I think that one of your adapter plate bearings is bad. I don't think that the shaft should move back and forth like that. @EuroDat @zKars @Dave WM

-

Intermitent start and no turn signals when it does not.

I thought he meant jump at the battery. It's sounding like he meant he jumped the solenoid, bypassing the ignition switch. More words would have helped.

-

Transmission Noise in 3rd Gear - F4W71A

On further thought I'm not sure about my post above. The sleeve and hub mate around the full circumference, the gear teeth mesh at a single point around the circumference. So a noise that changes with RPM would have to be related to the mesh point of the gears. I think. Anyway. Another quick way to get a look is to drain the fluid. The stuff that comes out will tell a story. Looks like you must have drained it, was there anything there?

-

Transmission Noise in 3rd Gear - F4W71A

Sounds like something on/in the coupling sleeve and hub gears. Could be a chunk stuck in the teeth or a broken tooth. The shafts and main bearings are all shared between and the gears themselves are constantly meshed so a gear problem should be heard all the time. Only the coupling sleeve and hub meshes when you select a new gear. Although, there is a needle bearing under each gear that might deflect under load. Others have more transmission experience. Seems like you'll need to take it out and apart though to know for sure.

-

Transmission Noise in 3rd Gear - F4W71A

Can you add some detail? Are you saying that the clunking rate is constant despite RPM? How can that be? Does it continue to clunk if you're in 3rd with the clutch pedal down, car not moving? Or does it only happen when the car is rolling? Clunk is not very descriptive, even with the awful added.

-

Intermitent start and no turn signals when it does not.

Should have put this in your first post. You did the classic "selective information disclosure" in your first post and sent everyone off on a path they would not have followed if they had known.

-

Intermitent start and no turn signals when it does not.

When you jump it you're putting outside power directly to the cable ends. Kind of sounds like dirty cable end to battery post connections. When the current from the starter motor (lots of amps) hits them the corrosion heats up and expansion opens the connection. Then it cools down and closes and will pass enough current to run lights and things. Very common, many starters have been replaced because of it.

-

Need a little help

You didn't even tell people what year car you're working on. Had to go dig to find it. Is it the 1972 shown on your profile? I only see 5 wire ends, of unknown colors (stripes matter), except for the black one. Can't be too hard. Good luck.

-

Z's on BAT and other places collection

Orange classic 72. But he has urethane on the front. Somebody tell him. https://bringatrailer.com/listing/1972-datsun-240z-183/

-

Putting in a replacement L-28

I have a memory of there being two short bolts and two long ones, of the four across the top. Maybe you got a short one in a long hole. And, if it is the right bolt but it is stripped, maybe there are usable threads left at the bottom of the hole, that a longer bolt will grab.

-

Parts Wanted: Need a bell housing from an FS5W71B 5 speed

http://zhome.com/ZCMnL/tech/240SX5spd/Transmission2.htm

-

240z gas tank fuel feed line question

I've used JB Weld on a pinhole leak on a Pathfinder. It was still seeping as I pressed the glob on to the hole. Worked for a few years then I removed it and reapplied. If it had been completely dry probably would have worked forever. They even wrote up a procedure for it. https://www.jbweld.com/projects/gas-tank-repair

-

Parts Wanted: Need a bell housing from an FS5W71B 5 speed

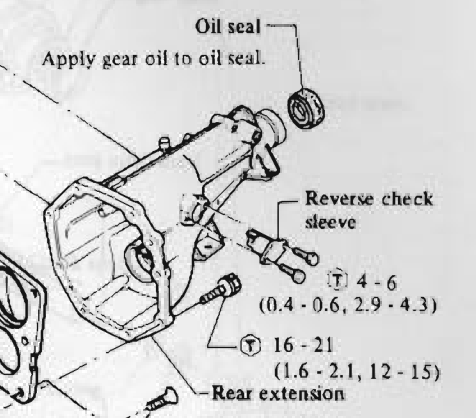

That picture you show is from the tail housing, not the front case. It's the "reverse check sleeve". Four speed front cases/bells will work also. You might have to drill a new hole for the reverse switch. Easier to find a four speed case.

-

COVID-19

A strange story. The damage is already done. https://www.keprtv.com/news/local/kennewick-family-changes-stance-on-vaccine-after-getting-covid-19

-

Water Pump Install (HELP!)

Might be the wrong bolts for the holes. I think there might three different lengths. Found a thread - Post 80 on...