Everything posted by Zed Head

-

1970 240Z in SD. Surprised if this lasts one day.

I was going to post the CL ad Reply thing for a snarky response but it didn't get through. $100,000 between privates? For a 240Z? Holey Moley.

-

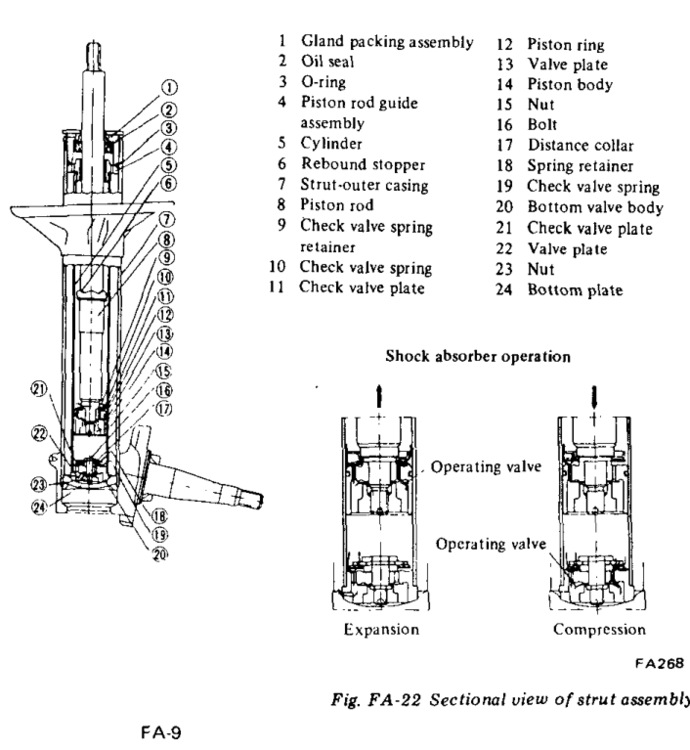

Strut Tubes & Struts

You should post the deal link. That's pretty good. The aftermarket KYB's and others get around normal maintenance. They are basically a shock inside a shock tube.

-

1970 240Z in SD. Surprised if this lasts one day.

What was the original price? Never mind, I'm guessing $22,000 was original and you thought that was too low. You think that that car is almost to Excellent level. Pump, pump, pump it up... (90's flashback).

-

1970 240Z in SD. Surprised if this lasts one day.

But what's happened, with the price bloat, fits the model. Kidding, but not kidding. Wouldn't be a surprise if URGELIS was behind it.

-

1970 240Z in SD. Surprised if this lasts one day.

This might be a clue - "California Datsun Series one 240z justice." Beware... "I will send more photos to interested parties, but pictures do not do this original California Datsun Series one 240z justice."

-

1970 240Z in SD. Surprised if this lasts one day.

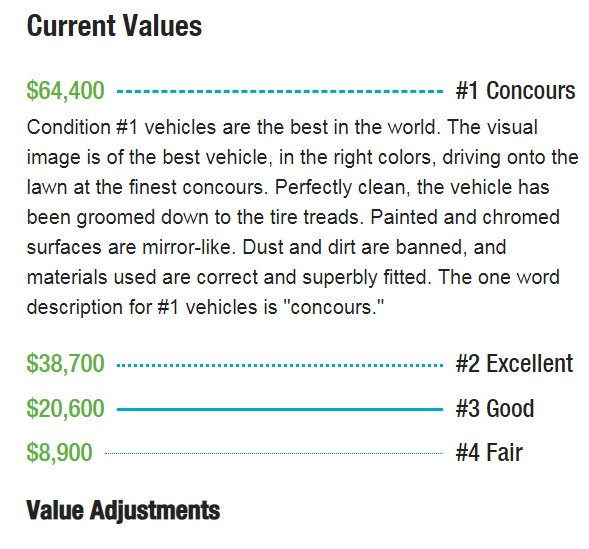

Congrats, you made sure that it will last much more than a day. Probably months or years now. Greedy. Looks like it's between a 4 and a 3. https://www.hagerty.com/apps/valuationtools/1970-datsun-240z https://www.hagerty.com/valuationtools/Classifications-and-Conditions I thought SD was South Dakota.

-

280ZX FPR Wows

Closeout! $15. Will require some fitting. https://www.rockauto.com/en/catalog/toyota,1982,celica,2.8l+l6,1278402,fuel+&+air,fuel+injection+pressure+regulator,6124

-

280ZX FPR Wows

Most EFI systems from the 70's and early 80's run at 36 psi. 2.5 bar, in European terms. BMW, Volvo, Saab, Mercedes, etc. Might find a cheap one you can retrofit that way.

-

'78 Black Pearl Restoration

You should only adjust the AFM (air flow meter is more correct for the year and the car, not mass air flow [MAF] sensor) if somebody has adjusted it before you. Otherwise, never mess with the factory setting. There are blobs of glue that should be intact, holding the spring adjustment in place. Any small leak in to the intake system or crankcase will cause a high idle speed. Large leaks will cause the engine to die. AFM or BCDD problems are possible but last resort. Good luck, have fun.

-

'78 Black Pearl Restoration

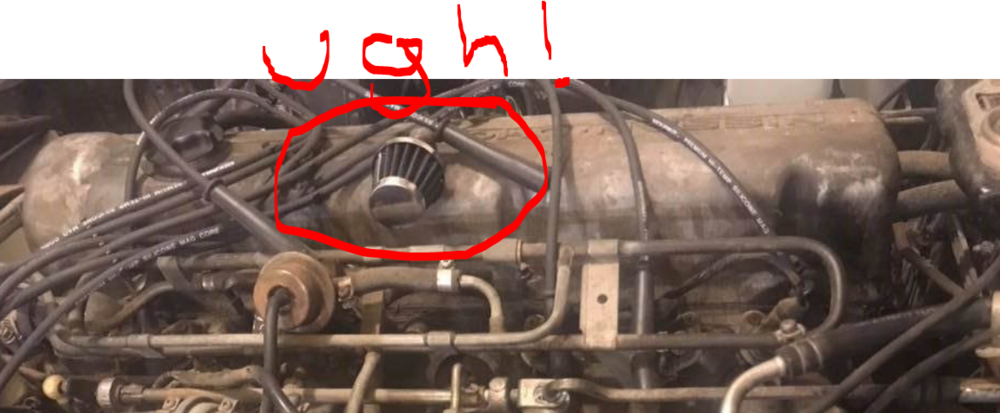

It runs and is drivable. You're ahead of many. A few things I saw that I didn't see mentioned by others: You should never see 16 volts on the voltmeter. That's not a fusible link problem, that's a bad alternator (actually the regulator in the internally regulated alternator). Assuming that the wires to the T plug on the alt are intact. I think that 4 speeds were an option in 1978. 5 speeds were standard issue. But they are direct swaps so it's possible somebody just blew up the original 5 speed and swapped in an old 4 speed. The engine does not have a functional PCV system. The little filter on the valve cover is a sign. If it was tuned to stock settings it wouldn't even run with the opening to the crankcase, through the valve cover. Unfortunately that means you probably have a tuning adventure ahead of you as you get things back to stock condition. Overall, with the fusible link silicone and the valve cover filter, it looks like somebody has been hacking in the engine bay. good luck. Check out the downloads section for an official 1978 FSM.

-

the rear end clunk

I did not see much of the typical diff movement that causes a clunk. The worst clunks were at about 40 seconds and seemed to be more from inside the diff, like gear lash, or pinion pin play. The half shaft didn't even move much on some of the clunks. They do wear out. Looks like an R180, which is weaker than the R200. Take the cover off and you might find something. Easiest just to drop the diff with the mustache bar attached, then remove the mustache bar, and the cover. p.s. that's a lot of fuel hose dangling back there. Reminds me of when the UPS driver flagged me down and said "there is a LOT of liquid dripping from the back of your car". My fuel hose had split. Luckily I was running distance from home and had some spare hose.

-

'75 280Z Headlight Relay Upgrade

My suggestion is that the relay at the fusebox is the only relay. Not an additional relay. Full power still passes through the dimmer switch/ground. But only enough to power the relay passes through the weak switch on top of the column. Simple, easy to apply, gets rid of the main problem.

-

brake warning light - relay bad

Thanks for the pictures. Looks like it's rated for 12 volts even if it's never supposed to see it. And it just sends it to ground so nothing on the back side to drop current. Heat, moisture, vibration, age...lot's of reasons for these old parts to fail. You'll need the wiring diagram and the colors from the harness, I think, to figure out the circuits. The wire colors on the components are often different than the harness. Atlanticz has a 75 diagram but I just looked at it and it doesn't show the relay. 76 is probably your best shot. Or just use a meter. Two grounds, two powers, but only one power wire with the engine not running and the key on. https://www.classiczcars.com/files/category/1-wiring-diagrams/

-

78 280z Severe Driving Problems

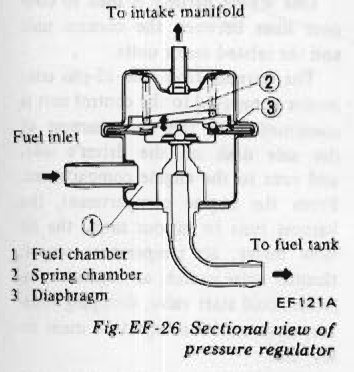

It does look like a bad FPR. My FPR bypass suggestion was just to make it more clear for Kinser since he commented on it. His early videos showed that pressure would drop below 42 psi. It's just hydraulic pressure on one side and spring force on the other. Tried to find a view of the offending part in the previous videos but couldn't. To Kinser - if you decide to get a new FPR beware the adjustable aluminum jobbies. They leak down rapidly on pump shutoff. Seems like they'd repressurize quickly but most people are annoyed when their FPR leaks down. It's a pain and causes starting problems.

-

Coil issues

It might be that you're just not "tapping" hard enough or your jumper connections are weak. The points and ignition modules have very solid grounds and contact points (think about how wide the contact areas of a set of points are) and make the connections and disconnections very rapidly. If you're just brushing your grounding wire on a piece of metal you might not be getting a full charge through the coil. Try a solid touch, make sure that current can flow, instead of a tap, and make sure your jumper connections are good enough to pass a lot of current.

- 78 280z Severe Driving Problems

-

Fuel Pump Plumbing Check

I forgot to say though, that I can't tell what's plumbed to what in your picture. All of the hoses head off the frame or behind something. Just can't tell. Can't see the pump inlet, only the outlet. I like the big "FLOW" arrow they put on the pump. Very helpful. Don't forget that all of the pressurized fuel hose should be EFI rated.

-

Fuel Pump Plumbing Check

The noise is often caused by the pump straining to pull the fuel through the inlet. Not really a hearing concern but a sign that the load is too high. Can cause overheating. Anyway, you might be fine with what you have. Power it up, see if it makes noise, see if it gets hot. See if the pressure is regulated correctly.

-

Spare tire option

Just a followup. Looks like SoCalJim has you covered. Your 260Z would have a full size wheel and tire. Tiny spares were introduced to the Z's in 1977.

-

Coil issues

Actually, when you do Step #6, copied below, you're performing the function of the ignition module, but not using it. So that step doesn't show anything about module wiring. Unless you leave the module connected to coil (-), which can screw up the test because the coil (-) never really gets disconnected. "a: Connect a jumper wire to the coil ( - ). Turn the key on and tap the junper wire rapidly on the car frame. You should see the spark plug sparking when you tap the wire. Be carefull for shocks from the coil." Any reason you can't just spin the motor with a spark plug on the valve cover? You could even just use the coil center wire on the valve cover and you'll get a spark for every cylinder. Take the other plugs out for more engine speed and more voltage.

-

Fuel Pump Plumbing Check

Looks like it flows over twice what an L6 needs. The stock pumps are about 30 gph, you're at 67. Not sure what car you're in but the 240Z's have problems with high flow EFI pumps, the retunr lines are too small. Some people have problems with their 280Z lines, when using the high flow pumps, apparently. And these types of pumps hate inlet restrictions. Not sure what type of pre-filter you're using but it should be a low restriction filter. The final filtering happens on the other side, the prefilter is just for the chunky stuff. Kind of looks like you'll have a noisy pump that gets hot and might fail soon. The system is not cohesive. What was the old pump that just failed? https://www.summitracing.com/parts/dwk-9-250?seid=srese1&cm_mmc=pla-google-_-shopping-_-srese1-_-deatschwerks&gclid=EAIaIQobChMIzMSewsP33QIVEKrsCh1IrQslEAQYAiABEgLCF_D_BwE

-

78 280z Severe Driving Problems

Pretty sure I've read about crude pressure adjustment via hammer taps on the spring side. Add some preload. Not sure how sensitive it is, maybe the vacuum port got pressed in somehow. It's just a pressure relief valve. The simple "FPR or blockage" test is to remove/bypass the FPR. A piece of hose will do it. Put a loop in it to make it easy to fit.

-

Coil issues

Show or describe how you wired the HEI in. It needs a good ground at the mounting grommets.

-

1977 dizzy internal part identification

I think that you're looking at the inner raise edge of the breaker plate. There's no wire. It just rubs. And sounds like a playing card in the spokes.

-

Rust Advice 78 280z

The threads are in the head. A stud or a bolt would be there, but they often break off. Your worst case would be that somebody broke the casting in the head. You'll know when you get it apart and get a better look. Good luck. Go slow and check those odd things that don't get disconnected, like the throttle linkage grannyknot mentioned, or the speedo cable. Brake booster vacuum hose, etc.