Everything posted by zKars

-

4 Speed Bell Housing swap to 5 Speed Case : FS5W71B : Reverse Switch Modification

Here is the visual on the switch locations Four Speed, Five Speed, further forward. 7/8 further forward. Inside, here is the 4 speed reverse shift rod with it's indent and here is the 5 speed reverse shift rod with it's indent. Switch tip sits where the blue line is in neutral, then as the fork is pushed forward as you go into reverse, the switch plunger tip climbs that ramp and depresses the switch turning on the reverse lights. Note the longer flat part to the right of the tip. This allows the reverse switch to remain OFF when the trans in 5th as the rod is pulled back. Handy.

-

4 Speed Bell Housing swap to 5 Speed Case : FS5W71B : Reverse Switch Modification

Let's review pro's and con's: 1. Do without reverse lights. Well if you left the switch in and hooked up you'd have reverse lights all the time. No. 2. Drill a new hole in the 4 speed case 7/8" further forward, plug the old hole. Sounds simple enough, you have to have the right size tap and drill bit, and if you look closely, that dang thing is not 90deg to the case, it's kinda angled. The nose of the switch has to be in the JUST the right spot. And you'd have to experiment with spacers since there is no raised area on the case like the stock one, and it might leak, and ..... No. 3. Modify the shift rod to move the indent where it needs to be to activate the reverse switch in it's current 4 speed location. This is my choice. The rest of the thread is about how to do this easily. 4. Go choose a 5 speed with the right bell housing to begin with, dipstick.... No fun just doing the simple thing is there?

-

4 Speed Bell Housing swap to 5 Speed Case : FS5W71B : Reverse Switch Modification

Today's little task is to choose a 5 speed to add to my latest 510 project. Decided on one that is a bit of an un-known. It "looks" like the 82-83 ZX close ratio trans case, long ears, one exhaust hanger, reverse lock out blah blah blah EXCEPT it has a front case that has the rotated clocking for an L motor that would be mounted vertically rather than at our 12 degrees CW slant. Big deal, I've been hoarding 4 speed bell housings for various swaps, so I'll just go get one of those. Quickly it reminded me that while it bolts right on, the 4 speed housing reverse switch is in different spot than on the 5 speed housing. Well the only difference is that it is pretty much 7/8" farther to the rear. What to do. There are only these options: 1. Do without reverse lights. 2. Drill a new hole in the 4 speed case 7/8" further forward, plug the old hole. 3. Modify the shift rod to move the indent where it needs to be to activate the reverse switch in it's current location. 4. Go choose a 5 speed with the right bell housing to begin with, dipstick.... Enny meany miney moh...

-

1973 Rebuild

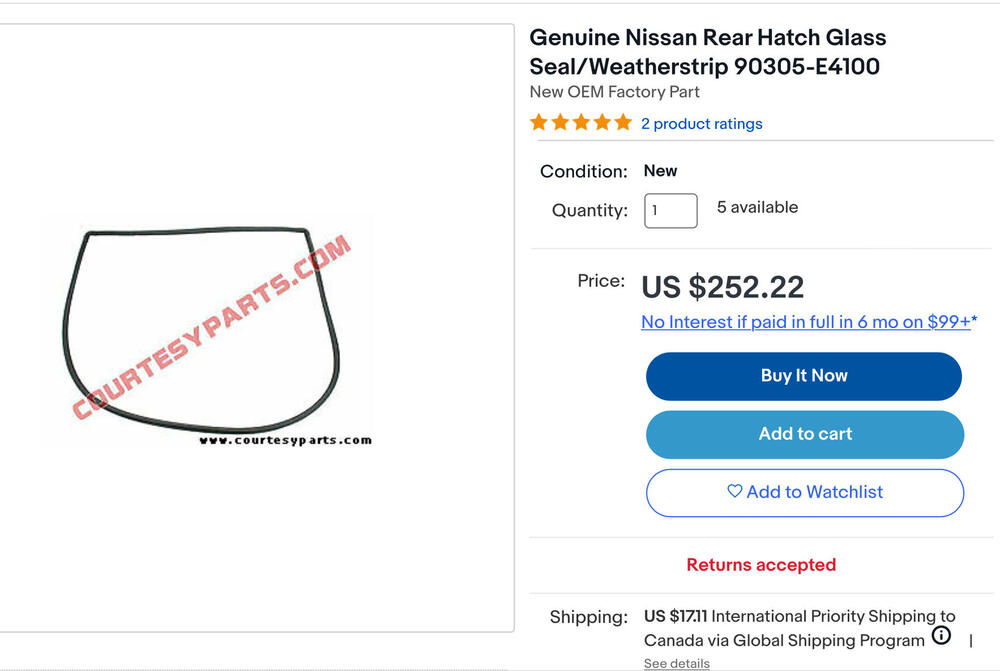

Check with vintage rubber and see if their seal is any different. I’ve only installed one of those and don’t recall if the seal was molded more in those lower corners or not. I get your frustration. Just looking for an OEM gasket. Courtesy Nissan on ebay? https://www.ebay.com/itm/275142887420

-

1973 Rebuild

I know you can’t have anything in backwards, the seal has molded corners at the top and you just make it fit around the lower corners, which is why it doesn’t worth a good gal darn….. That is one nasty seal for sure. Does that seal have four molded corners? I just pulled three precision rear window gaskets, all are top corner molded only. The OEM gasket has 4 moulded corners, which I feel you absolutely need to get those bottom corners to fit right. You might have to glue those corners into the curve of the hatch somehow. I’ve had this issue too but never this bad. BTW. Corn starch is now my absolute favorite rubber lube for window seal installs. And it works on putting the trim in the groove afterward too. So slick, so dry, so easy to clean up, so cheap.

-

Making replacing your windshield yourself easier.

Tool #4 More of a technique. Pulling the rope around the corners. That top corner on an S30 is real pointy. But all you have to do is make circles with the rope as you pull it. Move in as big a circle as you can with about 2-3 inches of rope between your finger and the rubber. Rotate in the direction that moves the rope along the easiest. Watch the rope where it goes into the rubber to see which direction I mean, generally CW if your moving right to left at the bottom left corner for example. Keep making circles while you pull. And tool #4a, wear a leather glove while pulling rope, takes the pain away from the rope ripping into your delicate little patties with the rope wrapped around the digits and palm. You can concentrate better and whine less.

-

Making replacing your windshield yourself easier.

Tool #3: Lubricant When I first starting doing my glass, I followed almost all the on-line advice and used soapy water and / or window cleaner spray (windex or Invisible glass) to lube the rubber to help get it on the glass to start, and to get the gasket and rope to slide and slip easier during installation. I quickly found this was a messy and relatively in-effective thing to do. Both evaporate quickly and are never where and when you need them when you need it. I went dry from that point on. For one thing, keeping the gasket on the glass and having it stay there while you work on getting it all on the glass is someplace I want MORE friction to keep it in place, not less. And I have to problem pulling rope out of dry groove and if I spend time getting the whole thing settled into the window opening BEFORE I start pulling (see above about pinch weld distance) then being dry is just fine. BUT, that said, if I found a “better” lubricant, I’d use it. I think I have my holy grail on this as well. Baby powder. Well, actually Corn Starch. Dry, cheap, stays in place, wipes, blows or washed away when you’re done, and most importantly, takes away all rubber tackyness. A little goes a long way. Dip a finger in the powder, rub it on the rubber to leave a very very thin white dusting of powder where you want it. If you want to use Baby powder go for it, but you better be able to explain that pretty smell to your significant other… I’m looking forward to using it on the SS trim groove as well, to help get that nasty stuff in place a little easier.

-

Making replacing your windshield yourself easier.

Tool #2. Using a rope to get the rubber lip over the pinch weld as you pull the rope out, is the secret to the rope trick of course. As long as you have the glass and gasket pushed as far down into the window opening as you can, the rubber lip will be as close as it can be to the pinch weld. Then when you start pulling the lip over the pinch weld, there will be enough lip to get over the pinch weld and stay there as you move around. But still, the initial “get the lip over” is rarely ALL the way over the pinch weld and down as far as it CAN go, and MUST go to get the whole thing properly seated. If the glass and gasket are not down in the opening as far they can go then the lip is too far away from the pinch weld and very little if any of the lip is going over the pinch weld when you pull the rope out. If you find this to be case, don’t bother going ahead, take the glass back out and re-set from the start. If you have replaced the vinyl trim on the top or sides, and have it lovingly glued to the pinch weld, and have used modern replacement vinyl, chances are that stuff is thicker than the original stock vinyl making the pinch weld even thicker and tougher to get the rubber over and seated. Get a buddy to push in the gasket/window from the outside at the place you pulling rope, to KEEP the thing in down and in place as you push the rope out to keep the gasket and pinch weld as close as possible. You can lube the gasket so slides closer easier. More on this later. Assuming you get the lip over the pinch weld enough so that it stays, I immediately starting pushing it down over the pinch weld further using my flat plastic stick. THrough experimenting, I don’t just push on the rubber to force it down over the pinch weld, I stuff it between the glass and lip pointing nearly down and flat, pushing it along flat tip first, right behind my rope pulling, which forces the rubber lip downward further over the pinch weld as I go. I’ve never felt like I’m pushing hard on the glass or in any danger of breaking it. Almost all the force is parallel the glass surface and downward onto the rubber lip. This tool and others are part of a generic set of plastic clip and panel removal tools you can get from many auto stores and Amazon and such. Anything long and flat and tapered will do. And Plastic of course.

-

Making replacing your windshield yourself easier.

Just to add a couple of details that make this job easier for me. Tools. 1. Getting the rope in the groove. If getting one rope in the groove is tough for you, and my suggestion of using two ropes gives you the willies, then use this trick Go buy a 6 inch piece of 1/4 OD brass or aluminum thin wall tubing from a hobby supplier. Stuff your 3/16 rope through it (I flared one end to make it easier) and use this stiff piece of tubing to poke the rope into the groove (use the un-flared end), then just draw the tubing along the groove feeding rope into it as you pull it along. Keep it poked deep in the groove as you go. Should take you under 60 sec to get the rope all the way around and tucked in real pretty.

-

ZCON 2022 Roll Call

Oh wow, that's neat! Sorry, no can do. That Z passed on a few years ago, don't even have one at the moment. Dang picture makes me a bit misty, sniff..... You-all have fun this year! Drool over the new Z for me. I'll show up again next time the show is bit closer to home.

-

Making replacing your windshield yourself easier.

Ok, this will seem real obvious when i say it, you’re going to kick yourself for not thinking of it, but here goes. Use two ropes. Start center top AND center bottom. Pull the bottom left and right a little, pull the top left and right a little, keep working out to the edges. Stop about an inch short of the sides. Keep prying the gasket all the way over the pinch weld with a flat plastic tool all the way across the top and bottom. Just put the tool between glass and gasket, and push the gasket down and toward you, away from the glass, and push it down hard over the pinch weld to seat it fully. Do not pry against the glass, no need to, you are pushing the rubber lip all the way (down at the bottom, up at the top) over the pinch weld. Once both top AND bottom lips are pulled over the pinch weld and seated, that sucker is trapped in place. Now go around the bottom two corners and up the two sides with the two separate ropes and finish by going around the top corners. Bang you’re done. I did the rear glass by myself. Did not require any outside pressure. Yes I went out a couple of times and taped the glass/gasket to help it lay as deep and flat as it can. Did not struggle in any way shape or form. Took under 10 minutes from start of pulling. Z windshields “should” work just as well. They have more curvature, maybe a friend to help keep the gasket/glass flat and seated deeply as you pull both top and bottom over the lip. Should have some to do this summer, will keep you posted.

-

Making replacing your windshield yourself easier.

Here is the statement of the problem I “usually” have. I start by pulling the bottom lip, from the center in each direction, and eventually work around to the top center to finish. The bottom and sides usually go just fine, but that top, that dang top, it almost always wants to sit out too far, no matter what experienced helper I have pushing gallantly from the outside to keep its a$$ in place, it just wants to stick out just far enough to make pulling the lip over the pinch weld a real tough deal. Yes I make sure the gasket in fully seated deep in the opening to start, keep pushing it down as you work around, it all looks great until you get to those top corners and around to the top. I always get it, but its more work. Don’t get me started about that dang hatch glass, that gasket has a smaller and stiff lip that is really hard to get over the pinch weld than the front and the top is usually a real nasty deal to finish. I have tried starting at the top, but gravity works against you the bottom now wants to stick out more than ever.

-

Making replacing your windshield yourself easier.

Many of us have learned to replace windshields ourselves. This thread is not so much a tutorial on the whole process, there are great threads for that else where. I just to add a method that will make the generally accepted technique of using a rope in the pinch weld groove to pull the inner lip over the pinch weld, into an actual pleasant experience rather than a test of will and strength. Here we go. Just tried this today on a 510 rear windshield after a common struggle with the front. The experience on the back was heavenly.

-

Installing Windshield - Tell me if I'm crazy

All day and not one of you had the guts to just reply “You’re Crazy” Fine. I’m not sharing what I found out. Ok, fine, I will. Don’t do it. The corner pulling is too tight, too much risk of tearing it. The wonderful soft rubber in the Datsport gaskets might survive it, but “No chancey Mr Dancey” for Precision brand. Besides, I devised a method to do it the conventional way that surpasses any previous method I had used up to now. Will share in a better thread.

-

Installing Windshield - Tell me if I'm crazy

And a hint about doing glass installs. Many say they use soapy water or even spray can glass cleaner to help lube things as they get the glass in the WS and to get the rubber to seat well in the car, but I never use it. I find it dries out too fast and doesn't really make it any easier. I have no trouble doing it dry. But, couple areas are a bit sticky, like roping around the top corners and getting the SS trim in place. I'm going to use Corn starch this time around for lube. Tried on the door weather stripping miter corners of the 510 (if you know you know) and man, it totally removed the tackiness and its dry and blows away. No mess. Baby powder is the same stuff just smellier and 100x the price. I'll let you know

-

Installing Windshield - Tell me if I'm crazy

I've installed a dozen or so windshields between 510's and Z's in the last few years, I find it pretty easy now. But today I'm about to do it again (510), and something popped into my head. There is, after all a fairly big vacuum in there that allows things to slip in pretty easily.. Why not put the gasket in the car over the pinch weld FIRST, THEN put the glass in the gasket. Put the rope in the glass channel rather than the pinch weld channel and pull it over the glass? Any one else try this before? What madness makes me think this might be a tad easier since your pulling rope on the outside rather than cramped in the car, and I can push down with one hand while pulling rope up against that force with the other? Maybe once I actually try this it will be mind numbingly obvious why you would never do it that way. Maybe the pointy corners mean you have to pull out a lot of rubber at once and risk tearing it. Maybe you still need two people at the very least to get started since you have that free hunk of glass sliding around until it get it started. Yeah, I'm crazy for sure. But I'm not sure I can rest until I try. Anyone want to convince me one way or the other?

-

Accelerator J rod part number 18300-E4601 and subsequent

I have not seen anything about a specific VIN when the change was made, but as noted above, the one with the welded J hood is “Early” (up to jan 71 ish) the smooth simple bent “J” is later.. Notice the bell crank ball arm on the other end is at a different angle as well. This likely corresponds to when the firewall belcrank mount change occured as well. Early geometry sometime resulted in a oscillating pedal motion and engine surging. Haven’t talked about this is quite a while

-

Electrical Engineering Geek out. Coolest Switch Ever

Sometimes you find something so cool you just have to share it. Only electrical geeks will truly appreciate the engineering behind this amazing device. Behold the StewMac “FREE WAY ULTRA SWITCH” Read deeply into the specifications for this thing. It’s mind blowing. Today you’d do that level of switching sophistication with software and transistors. Though not if you’re a musician apparently. There just has to be a way to use in a Datsun. Use your imaginations. Enjoy! https://www.stewmac.com/electronics/components-and-parts/switches/free-way-ultra-switch/?utm_source=facebook&utm_medium=cpc&utm_campaign=pla&fbclid=IwAR0YLOqtfkuf7P3pU5U1-8y-GUQq0DAT3ijot58HA4WGxjiRK0EHCliiVAI_aem_ASTU1W3q0D2S5H0v8nqQHse-oXHOV9923BOfddgOcjqRR397O4C8gYfb9AgOl4wdqVDthbtRnwpiwta59eYrGLhanTqJkwoXQRjQht4sGniybm0TOJp6Lu2KmXapqbfOnMA&fs=e&s=cl

-

belt molding

Just because there is no sense in starting another thread on this, I’ll share my experience on this. It’s four door 510 door weatherstrip day (week actually) around here, and I purchased the replacement strips from Datsport in Australia. http://www.datsport.com/rubbers-510-sedan.html Part number SBO51F-14 They are perfect fit replacements for the stock items. I must note that the 510 rubbers are quite a bit different than the Z pieces. Much smaller, and too short. so stop drooling, the Datsport parts don’t fit. As to the Lowes.com garage door weatherstrip mentioned above, Lowes Canada does not carry it but Homedepot.ca does! https://www.homedepot.ca/product/m-d-building-products-2-inch-x-9-ft-premium-rubber-weather-seal-replacement-garage-door-bottom-black/1001120751 I’m working on modify one of those heavy staplers to punch right through and make installation easy. None of the staples I’ve found yet match the 10mm spacing of the stock staple legs. I’m going to try some modern 3m adhesives and see if I can make a sandwich that stays together without staples at all. There sure are lots of aftermarket rubber companies that make various “Belt moldings”, steelrubber products being only one. And lastly, if you think even new perfect fitting seals keep water out of your doors you’re a dreamer. Slow it down, sure. Much better time spent water proofing the inside bottom of your doors with yearly maintenance and added application of spray in creep and lube rust proofers and making sure the drain holes are open.

-

1973 Rebuild

But of course. Long since lost, not even sure I took any.

-

1973 Rebuild

Yes I did put a small roller bearing into the clutch pedal arm where the old pin hole was to both remove slop and make it a never-wear-out-the-hole situation. The added benefit was a smoother pedal fell, although it was likely as much a simple improvement over the old pin the worn out hole feel. I used a small 1/4” ID router guide bearing with maybe a 1/2 or 5/8“ OD and just tack welded the outer race to the pedal arm to keep it in place after drilling a matching hole for it to sit in. I used a grade 8 1/4” shoulder bolt that fit the bearing nice and snug too with a nylok nut to keep it in place.

-

72 Z Bumper rubber refresh recommendations

Mother’s “Back to Black” works well for me. Another somewhat more industrial product called “Rubber Renue” is also quite good. Here is a picture of a couple of cowl drain hoses from a 510 that I “restored” yesterday. Guess which one got the Back to Black treatment after a good scrubbing to remove oxidation and dirt. Also amazed at the condition of these soft rubber hoses after 53 years.

-

Correct fasteners for Intake and Exhaust Manifolds

Remember to be extra careful when selecting the longer of the two thermostat housing to head bolts! It penetrates the head and can come in contact with the timing chain guide. More than one unfortunate soul has broken the guide in the process. (Cough cough) The right length is under 70 mm IIRC, something like 63mm? The fiche part number is not a 08xxx that gives you the bolt spec as least not in the fiche I have : 11063-21001 #41 in this fiche, #38 in the fiche shown above.

- Has Anyone Ever Created a Nut & Bolt List of the Interior of a 240Z

-

slight exhaust popping and low power ......

We discussed the “missing dizzy spring” on a thread here some time ago. Long story short, it is by design, the spring is not missing. Concentrate on the sticking advance issue. I’m willing to bet one of your choke nozzles is stuck down even if the cable is trying to push it up. Give both a good finger shove upward under each carb. Secondly check fuel deliverability. Pressure and volume.

Subscriber

Subscriber

.thumb.jpg.9b58746cdd059b3c846a862cab047a98.jpg)