Today, I was excited to do some brake and clutch bleeding and then drive the car around in my neighborhood a bit. It was a beautiful, sunny day, and I was looking forward to it. However, it was not to be!

I spent 8 hours trying to bleed the brakes instead. The rear circuit would not move any fluid. I experienced this once before with a "nearly new" Honda S2000 brake cylinder. Each circuit has a little valve that operates. I am not exactly sure how it works, but basically, there are conditions where the fluid will move one way but not back. That valve got "stuck" with the S2000 master cylinder. And I recall it taking me forever to figure it out.

That experience was fresh in my mind as I attempted to bleed the brakes and the fluid was not moving either direction for the rear circuit. Though I knew I had a problem, I could not figure out what was going on.

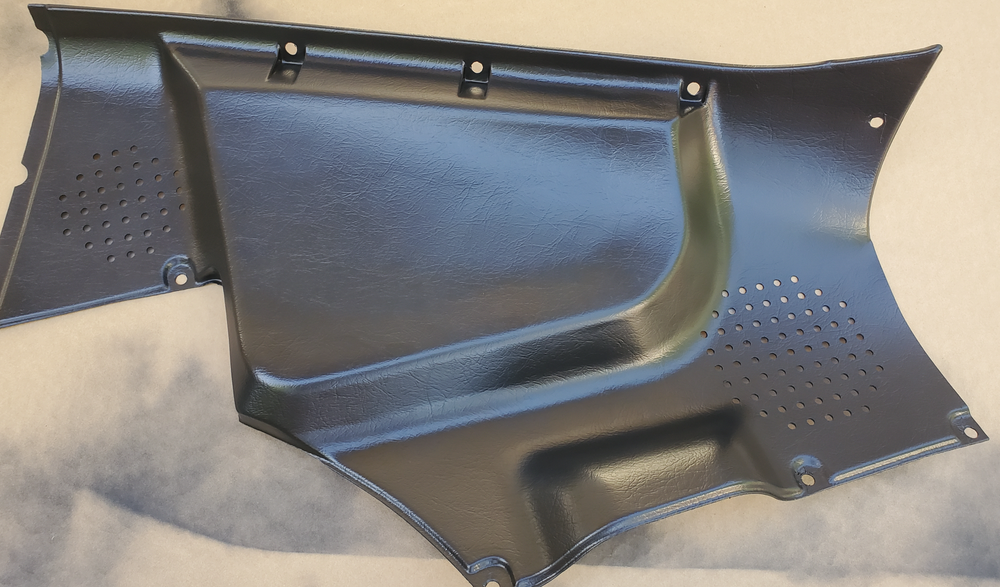

For my 8 hours of frustration, at least I can share what I finally found out to be the problem. This is the piston assembly for the rear circuit.

Unless you are lucky enough to find a new old stock Tokico master cylinder (and pay big bucks for it), then you will likely want to do what I have done hear to ensure that you will not have the same problem.

Here is my rear piston assembly. As you can see, I have removed the "cap" to the far right in the picture. For quite a while today, I tried spraying lubricants and blowing compressed air in the holes of this cap. But that did nothing. Eventually, I became frustrated enough that I put it in my vise (with flat metal plates instead of the serrated teeth) and clamped down on the sides of this cap (with the piston assembly sticking up vertically). I grabbed the piston assembly and wiggled it one way and then the other, unsure what would happen. Luckily, the cap is a light press fit to the end of the piston assembly. And yanking one way and then the other, I was able to pull the piston assembly from the cap. As soon as it came off, I knew I would be able to solve my issue. As you can see, there is a spring... and a little rod with a rubber seal on it (the piece with rust on it, second from the left).

Some #0000 steel wool cleaned off the rust from that piece. And a brass "pipe cleaner" type brush cleaned the rust from the hole in the piston assembly:

From there, I dabbed a bit of brake grease on these parts and reassembled them. I fitted the spring and tapped the cap back on with a small hammer. Now, this little valve works at it should.

Determined to not have wasted some much time today, I am going to go out to the garage and bleed the brakes now like I originally intended to do today.

Subscriber

Subscriber 2Points1,282Posts

2Points1,282Posts