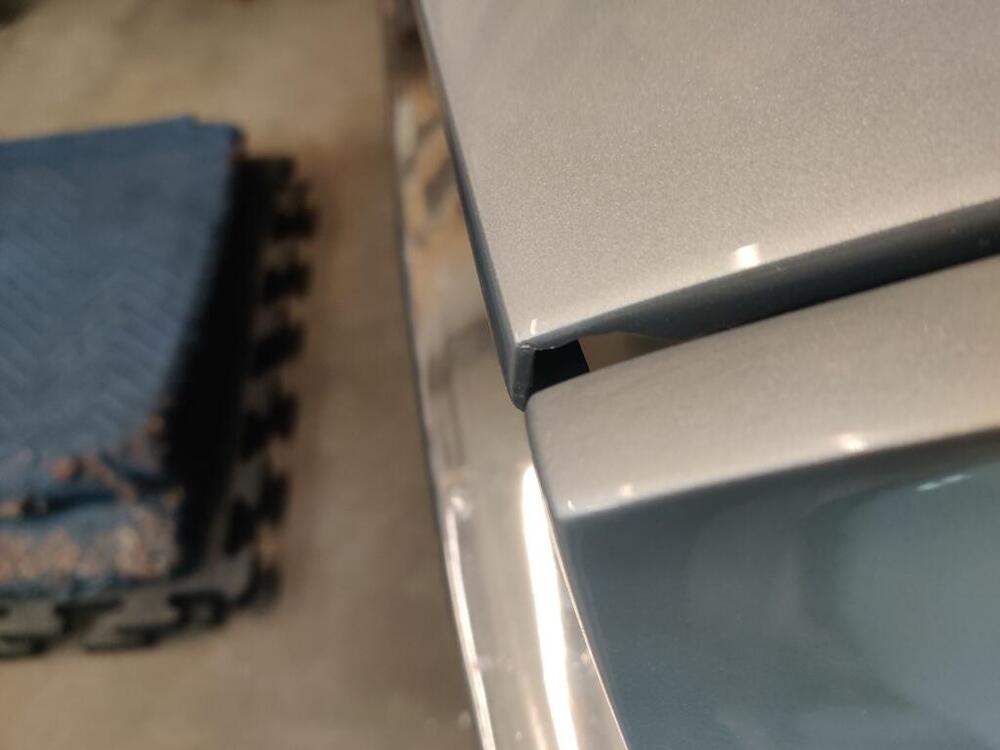

It was with some dread that I installed the hood onto the car. Flashback to when I was scrambling to get the car finished for transport to the body shop in February of last year, and when I installed the hood, I saw that I had some panel alignment issues. I won't rehash all of it here, but I provided details in the document I wrote up for the body shop. This should have been a checklist for them. But clearly, they did not do several of the things I pointed out for them. Quoting from my write up:

"The hood:

The front lip, at the very left corner edge of the hood, is bent outward a touch. I didn’t notice it until I started fitting the hood for the last time. I tapped the front lip at this corner with a body hammer to move it back a touch to align with the left headlight housing and the resulting movement caused some small chips of the primer to flake off. The left front corner of the hood will need some attention - possibly some more tapping with a hammer and possibly some primer application.

The hood has some scratches in the surface that will need attention."

Well, while the scratches in the surface of the hood were addressed, the corner of the hood got ignored. The front left corner still sticks out a bit, and at the top corner, I can see where the primer chipped.

So, this is just another reminder that "next time", I will not be leaving anything to anyone else - I will do it all, and I will do it right.

With this type of thing, my frustration level is high. I still need to massage the fit of the hood a bit, but I decided to move to other things for now.

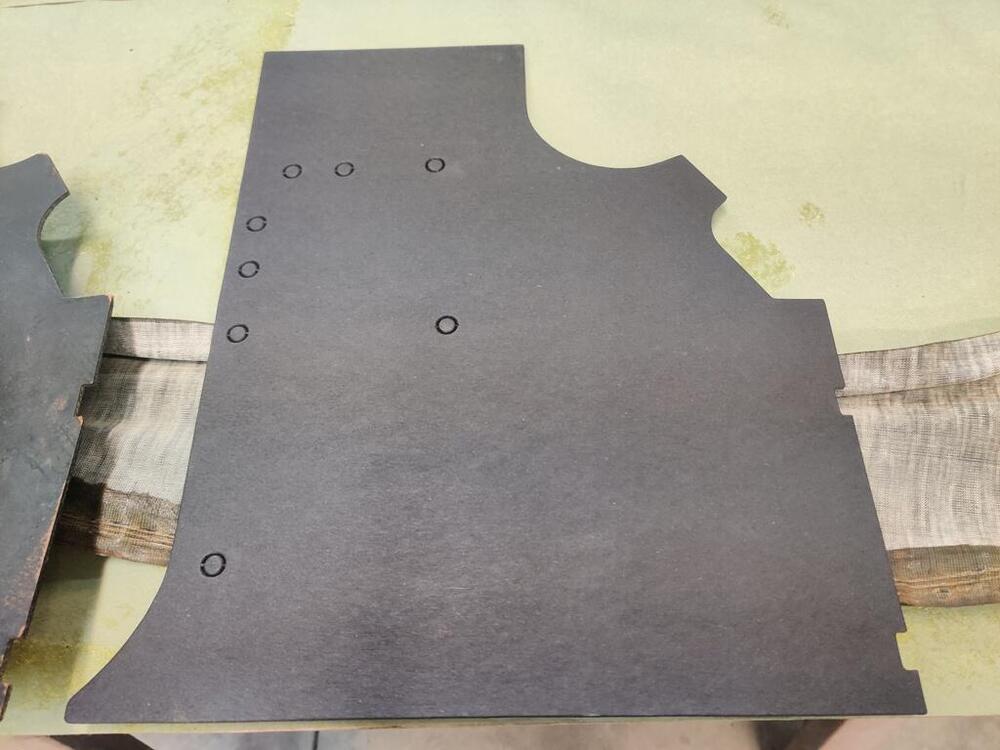

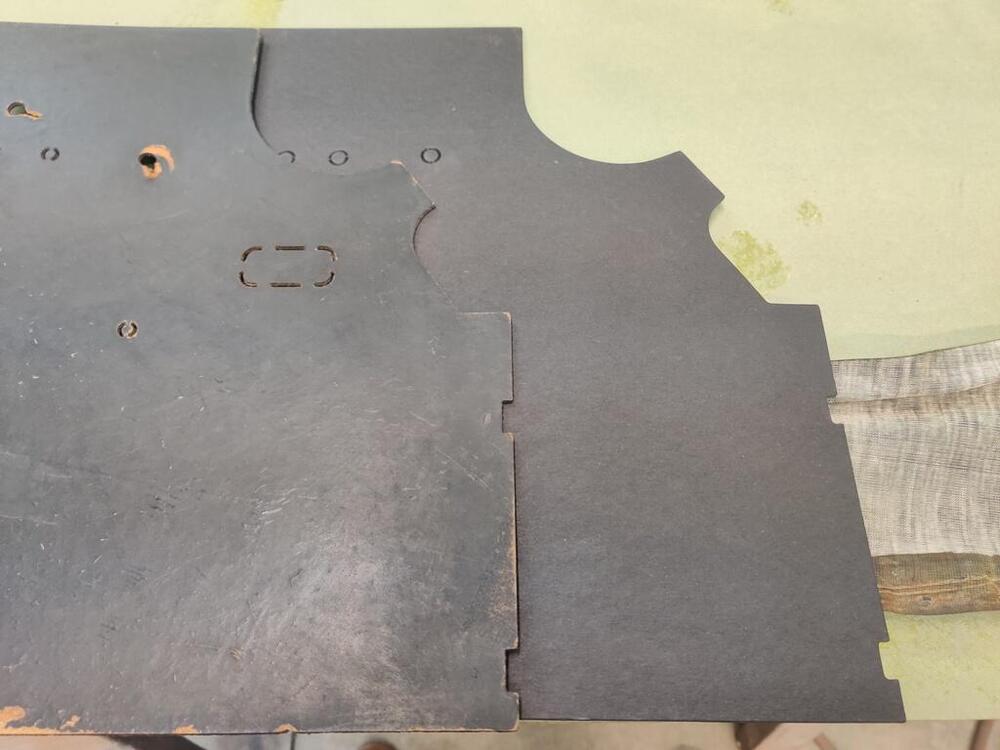

I unpacked the new kick panel covers. I bought these from Motorsport Auto. They are "ok". They are not quite as thick as the originals... even when measuring thickness at the top edge of the old ones where no water has gotten to fiber board and caused it to swell. There are slight differences which you can see here:

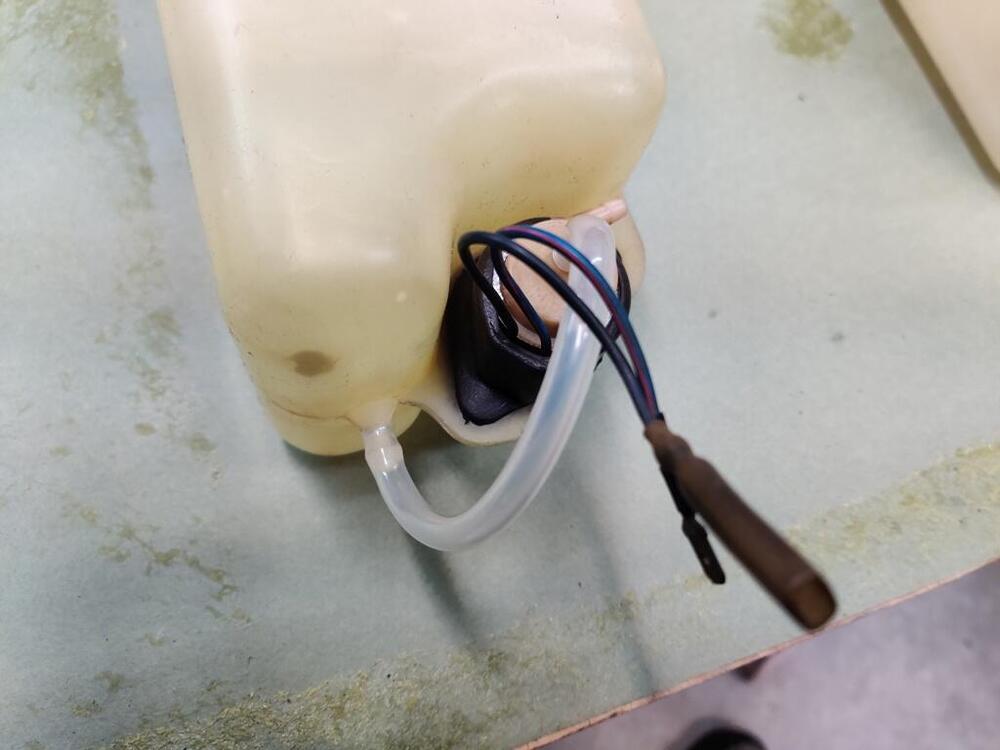

Second pic shows thickness of the top edge - old one is on the bottom. Next, I pulled out my collection of windshield washer reservoirs and pump motors.

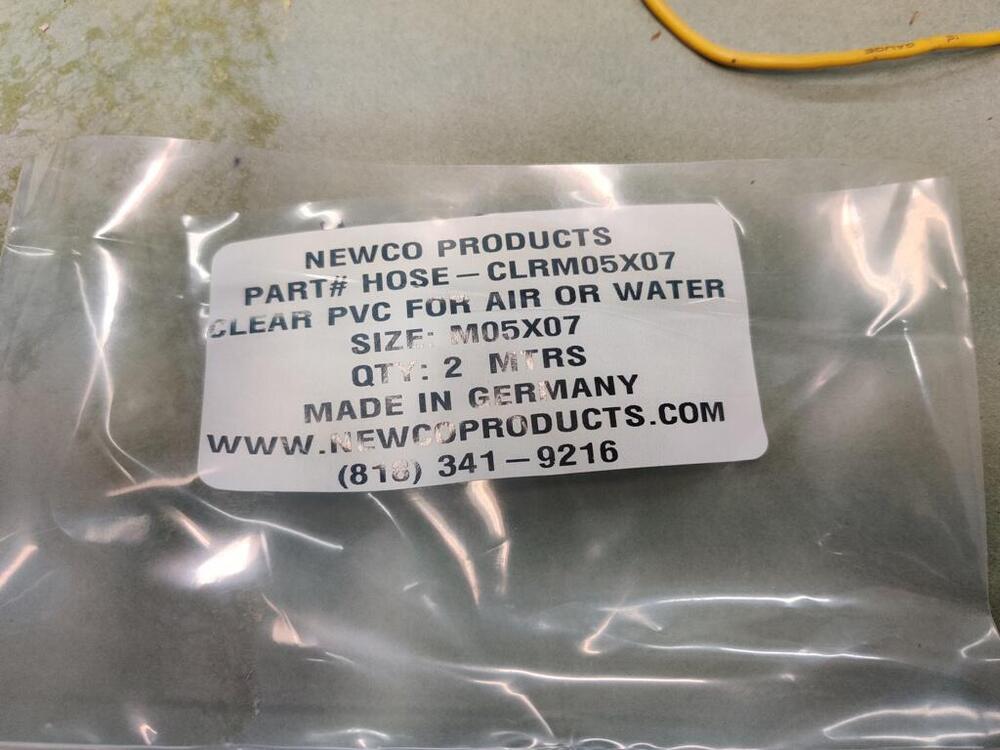

I sourced new windshield fluid hose from a company called Newco (see the tag for sizing info). I used a clean rag and lacquer thinner and some #0000 steel wool dipped in lacquer thinner to clean the outside of the reservoir. My pump motors were seized. I dis-assembled the first one, but there was no saving it - there was too much corrosion. The second one was in much better condition. Dis-assembly and reassembly was enough to get it running nicely. It may not last long in service, but we'll see.

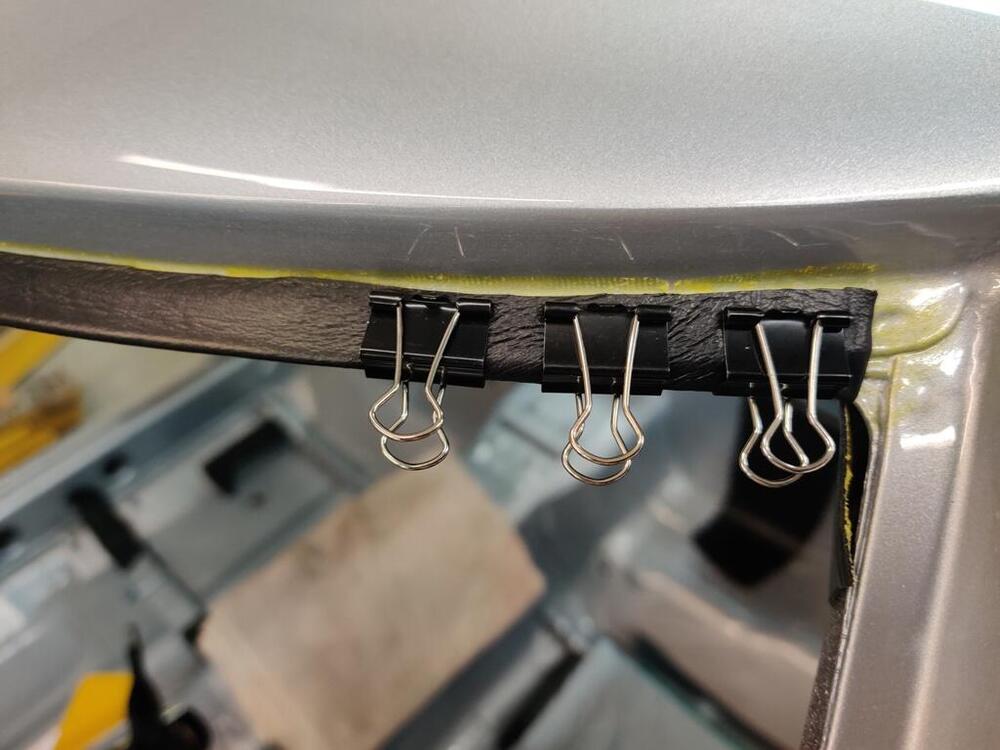

The last thing I did today was glue the front edge of the header vinyl. This contact adhesive is magical:

Though I bought a bunch of the folder clips you see in one of the pictures here, I was amazed at how quickly this adhesive worked to secure the vinyl to the weld flange. I brushed it onto the backside of the vinyl and on the top side of the weld flange. I let it dry for about 4 minutes. And when I pulled the vinyl toward the windshield opening, I tugged on it pretty good. Just touching the vinyl to the forward edge of the weld flange... was enough to hold the vinyl at the tension I had put on it. It was wild.

I then folded the vinyl over around that front edge and pushed it onto the adhesive on the top surface of the weld flange. It stuck and didn't move. I didn't need to use the file folder clips. It just stuck. I used my Exact-o knife to cut the excess vinyl off at the point where the weld flange ends:

I put some clips on in the corner, "just in case", but I am sure they were not needed. This adhesive is wonderful and a joy to work with.