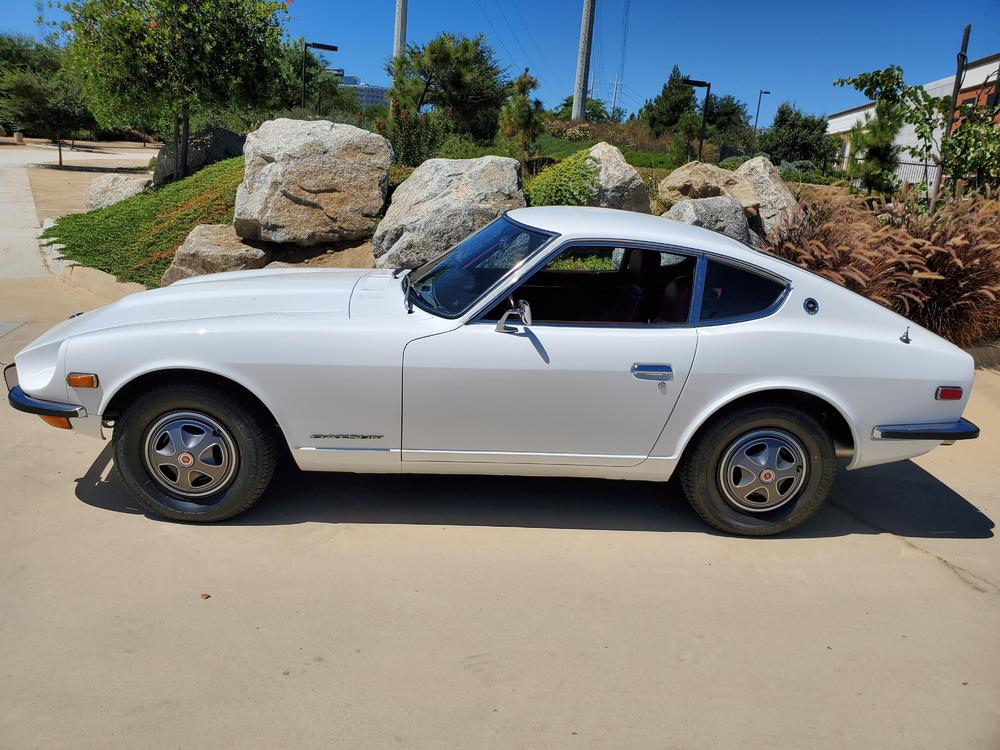

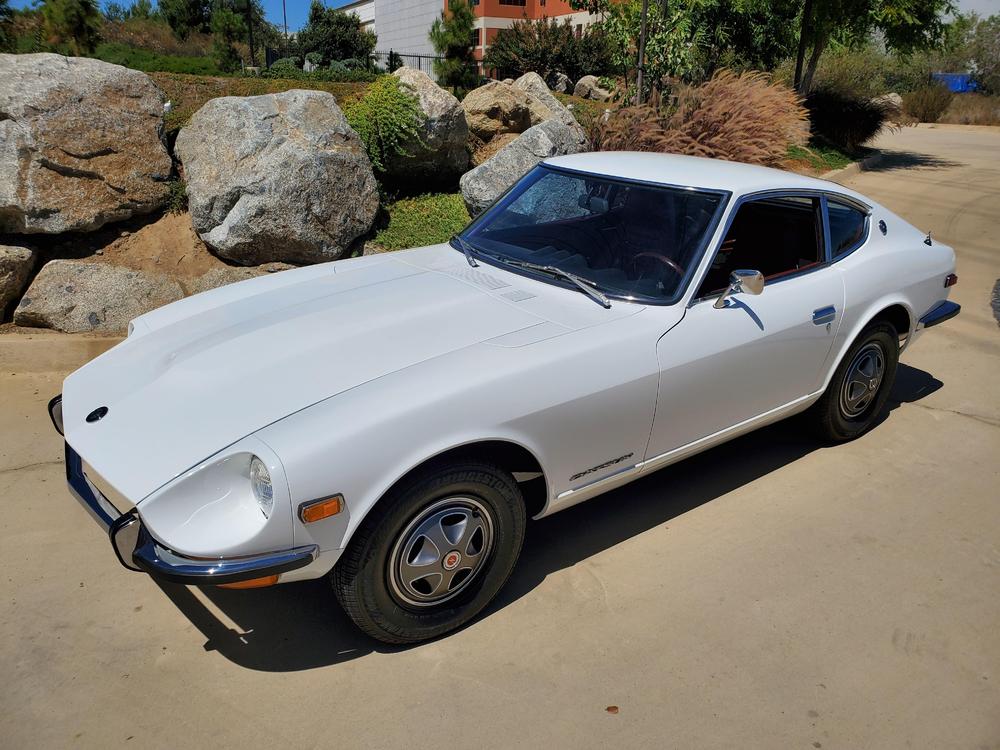

Ever since purchasing my 1970 240Z last April I found the refurbished seats lacking support. I searched for the recommended seats for swapping, but was unable to find any in both nice shape and reasonably priced. Purchasing locally appeared to be the only option due to shipping costs.

In my research I found Miata owners using Subaru BRZ/Toyota 86/Scion FR-S seats and since Miata seats are popular swaps for 240Z’s, I decided to focus on the Subaru/Toyota seats.

BRZ seat measurements:

Seat: 19.5” wide x 19.5” long

Hinge Width: 22”

Seat Back Height: 33”

During the research process I found a great post by Sean240Z from Feb 2013 that provided great how-to information.

Before getting into the how-to details, here is my evaluation:

Pro:

Recaro-like; very comfortable; great side bolstering; seats recline; sturdy; drivers seat height adjustment; strap to keep shoulder harness in position; seat back release lever provides easier access to jack, tool boxes and rear deck.

Con:

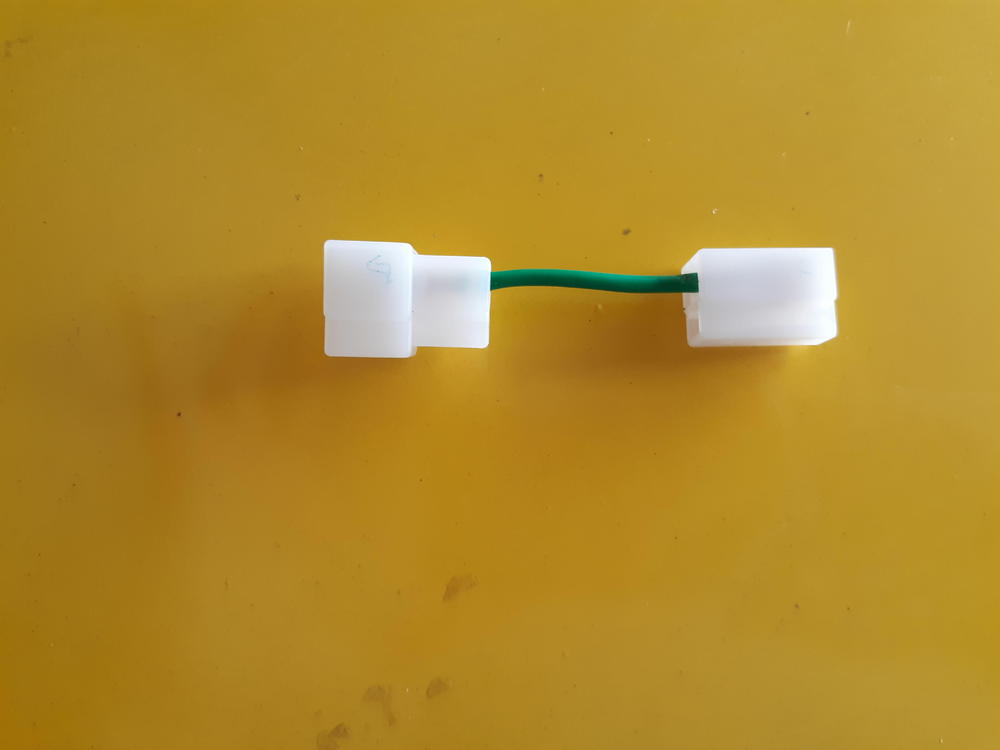

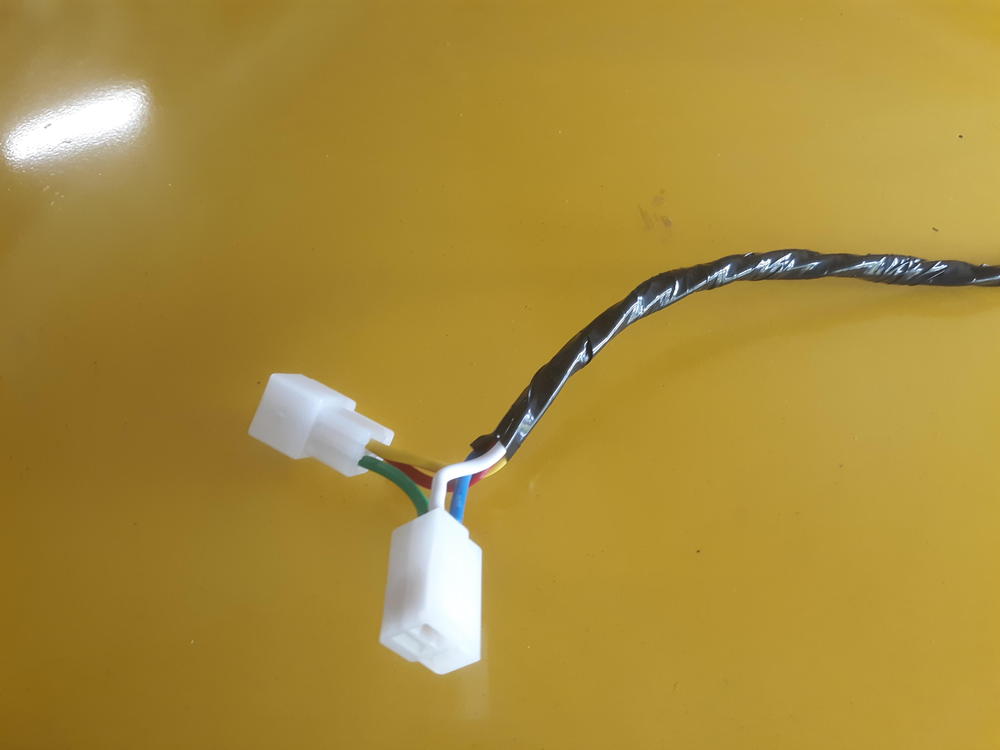

Seats barely fit in Z car; loss of headroom; entry/exit; heavier than original seats; airbag.

I’m 6’2”, 185 with 34” inseam and I fit comfortably. I must now lower my head more to get into the car. I think the max driver height is about 6’3” with the seat reclined.

Installed Measurements:

Driver Seat:

Steering Wheel to Seat: 6” (vertical)

Firewall to Seat Back: 48”

Gas Pedal to Seat Back: 41”

Steering Wheel to Seat Back: 18”

Seat Bottom to Ceiling: 35.5”

Reclined Seat Bottom to Ceiling: 37”

Passenger Seat:

Firewall to Seat Back: 45”

Bottom of Glove Compartment to Seat Back: 31”

The BRZ seats I found are black Alcantara with red stitching and leather trim from a low mileage wreck. They were priced at $200 each at an auto recycler, but they discounted them to $100 each. After a good cleaning, they are great looking seats.

For installation I made four steel adaptor plates (1/8”x3”x18”). Steel purchased on eBay.

Instructions:

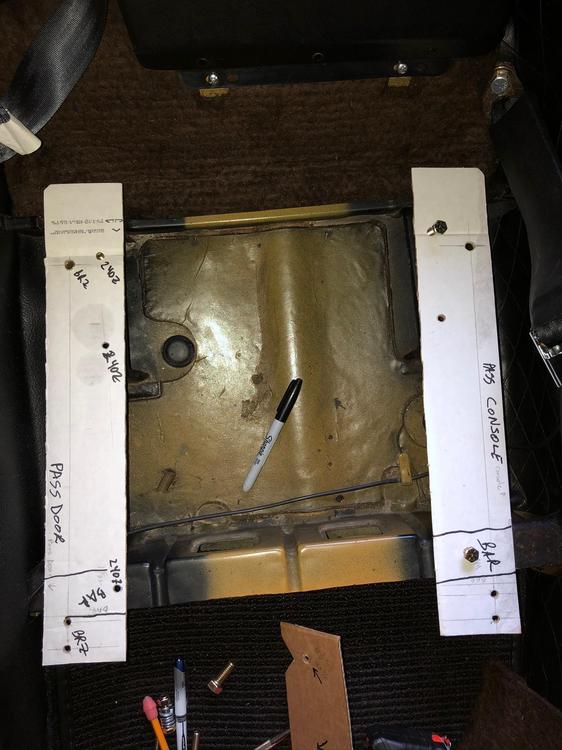

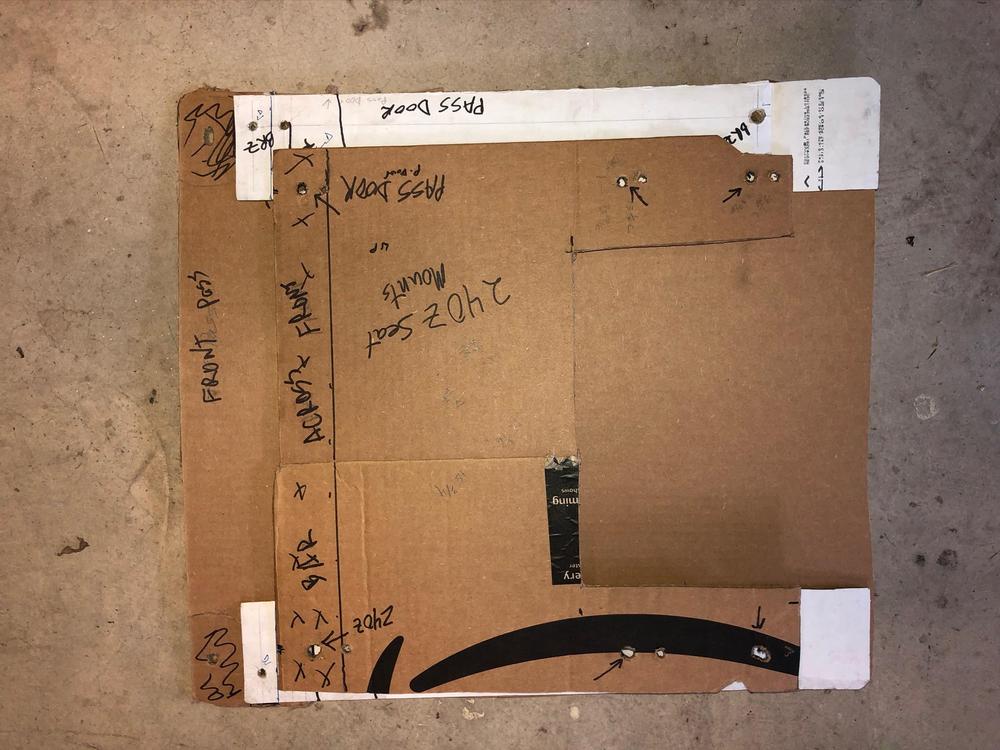

Remove original Z seat from passenger side; make U-shaped cardboard pattern of Z car mounting area and cut two 3”x18” pieces of cardboard to represent the steel adaptor plates. Mark orientation of cardboard to Z, such as passenger door side or console side.

Cut off the two front “cat paw-like” portions of the BRZ seat mount. They extend too far forward and are not needed.

Insert new seat into car to test fit; locate rear seat mount area to be trimmed on the Z car. Trim mount area until BRZ seat does not wobble and the adaptor plates lay flat. Paint the area trimmed so it does not rust.

Determine slider position in relation to Z’s front mounting bracket and Z seat mounting holes; depending on the slider, there should be a slight exposure of the slider track rearward on the passenger door side only. Once installed, there is plenty of adjustment to slide the seat forward.

Create cardboard pattern of entire BRZ seat, including slider mounting holes. Test fit in Z car and draw a line representing the front mounting bracket. Remove BRZ pattern; cut slider mounting holes and test by mounting the cardboard to the bottom of the seat using nuts and bolts.

Place the Z cardboard pattern in original position; mark mounting holes and draw a line representing the front mounting bracket. Cut mounting holes and test by mounting on bottom of Z seat.

Layout cardboard seat patterns, line up front mounting bracket line and determine best position for mounting holes on adaptor plates. Cut holes in adaptor plates and test fit in car; install Z mount bolt pattern, then adaptor plate patterns and finally BRZ seat pattern. Always better to test fit with cardboard than after drilling holes in the steel.

Drill holes a little larger than needed, file off rough areas and test fit. If fit is good, clean up and paint adaptor plates to deter rust.

Insert bolts through the front bolt holes to attach the adaptor plates to BRZ sliders. Note that sliders must move forward to access the mounting holes. Push sliders forward to mount rear slider bolts. Note the bolt closest to the door must be tightened when the seat is in the car.

Place seat with plates attached into Z car. When the plates are attached to the Z car mounting brackets the bolt heads may interfere with sliding the seat. If so, then loosen BRZ mounting bolts and insert washers between slider and adaptor plate to raise the slider and clear the bolts going into the Z’s seat mounting holes. Another option is to use carriage bolts with flat heads. The BRZ seat hinge area fits very tight, so ensure that the seat belt buckle is visible. If not, it is almost impossible to access it later.

After completing the passenger side, repeat on the driver’s side. Cardboard patterns can be flipped over and reused, but make sure the holes are marked to avoid confusion.

Good luck with your install!

Subscriber

Subscriber 3Points2,228Posts

3Points2,228Posts