All Activity

- Past hour

- It only works if I spray gas into the air intake.

- It only works if I spray gas into the air intake.

- Today

-

4/75 Datsun 280Z; Leaf Green, CA market, 250K miles, Long Term Project 03/2023-

Very cool! Looks like the new shop is a nice upgrade. Looks like you might have more acreage too...

-

Replace or Not to, that is the question

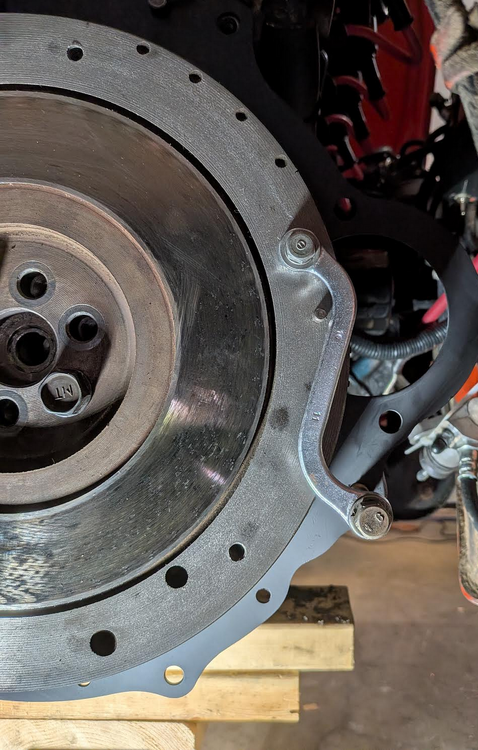

I think Yarb's thought might be it needs surfacing.. There are some chatter marks and possibly some blue hot spots too. Yarb, be me to it by seconds...

-

Replace or Not to, that is the question

IMO that needs to be machined and cleaned up. From what I can see you have hot spots.

-

4/75 Datsun 280Z; Leaf Green, CA market, 250K miles, Long Term Project 03/2023-

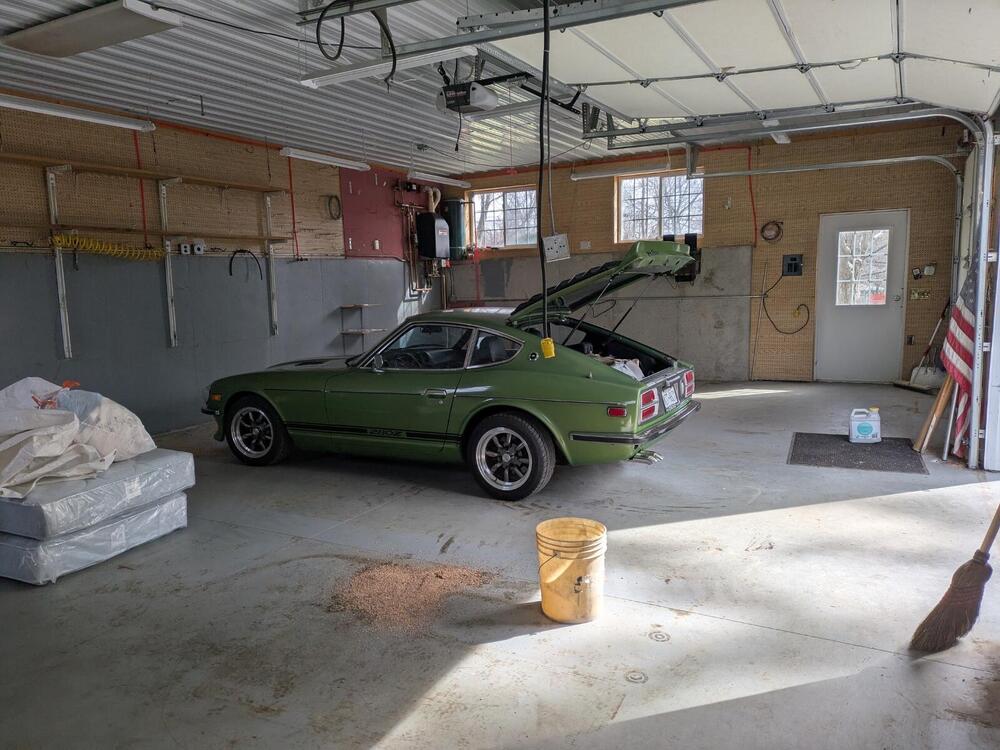

Moved upstate to Ithaca NY back in April. Had the 350Z shipped up ahead of us, then took the 280Z on. a clear day. Still no work on the cars yet, still setting up the grounds, garage & house Garage was used as. workshop, so it has a couple of 240 circuits, air compressor lines & ports, and radiant heat. Little more cluttered now, still working on setting it up Added glass panels to each door for more light Outside garage back in April: Better weather Adding slabs outside the barn & garage for me to work on - there are no flat/level/safe areas on the property outside of the garage

-

Replace or Not to, that is the question

Yes, it is quite heavy (over 20 lbs?).

-

Z Restoration Progam

You mean...rocket science?

- Yesterday

-

Z Restoration Progam

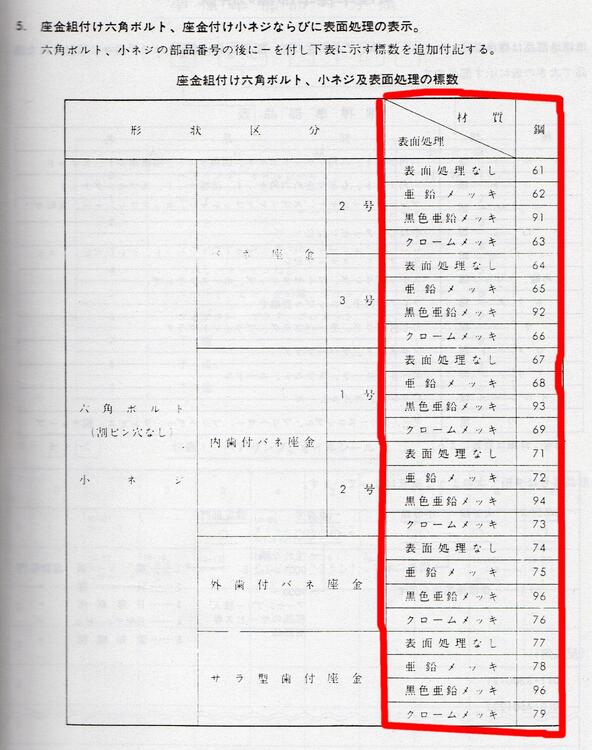

In Japan the use of Cadmium electroplating in auto manufacturing was officially banned in 1969. Before that it wasn't widely used on higher-tensile fasteners due to the phenomenon of Hydrogen embrittlement. Nissan (Japan's) own documentation for the S30-series Z's componentry - according to and conforming with N.E.S. (Nissan Engineering Standard) - states that most of the non-Chrome electroplated parts were Zinc ( 亜鉛 ) 'Aen' galvanized, with various passivated finishes. Here's just one example page of the quoted N.E.S. finishes for fasteners from the C-236 Nissan parts catalogue for the S30, HS30 and PS30 models: Heading translates as: 'Indication of washer-assembled hex bolts, washer-mounted machine screws and their surface treatments. The part numbers of hexagon bolts and machine screws are followed by a ' - ' and the characteristic in the table below. Washer-assembled hex bolts, small screws and their surface treatments'. I have roughly outlined the relevant example surface treatments in red. They read, from the top: NO SURFACE TREATMENT GALVANIZED BLACK GALVANIZED CHROME PLATED ...and this pattern is repeated for each sub-classification of fastener down the page. The Japanese for 'Zinc plated'/'Galvanized' is 亜鉛メッキ ('Aen Mekki').

-

Replace or Not to, that is the question

Is that your flywheel?

-

Z Restoration Progam

About 35 years ago, I was in the process of restoring a 240Z, as well as parting out another for spares. I took an assorted group of 10 or 15 nuts, bolts, washers and couple small parts off the Z's to our Materials Lab. "Our" being Honeywell Space and Strategic Systems Lab. A Materials Lab with men and equipment that supported putting men on the moon and probes on other planets. I ask the guys to tell me what was used for plating and corrosion protection, as I intended to have them re-plated. After testing them, they told me they were Cad. plated and given a yellow chromate conversion bath- and to be sure to wear a mask if I used a wire wheel ((bench grinder) to clean them up. Cadmium is very toxic and you don't want to breath any in. Given that the OEM fasteners on a now 50+ year old 240Z, treated with a little penetrating oil will break free and unscrew, without twisting off, is witness to me of Cadmiums use. That doesn’t happen with zinc plated fasteners in automotive use. In addition to Cad. plating having three to four times the durability of Zinc, Cadmium offers increased lubricity, so threaded fasteners release and unscrew. If you are not absolutely certain - best advice is to treat them as having Cadmium Platting..and be careful how you handle and clean them up.

-

73 Dash Replacement Project

Well done Ken. Perseverance par excellence! Dashboards are not fund to work on.

-

Replace or Not to, that is the question

Update: put the transmission back with the Dorman $6 clutch alignment tool for 24 splines. Installed 2 guide bolts (don't forget to put slots into them, otherwise you won't be able to remove them). The transmission was in 1st gear, I moved the rear shaft a little to help it ease into the clutch splines. It took 10 minutes. Here is my improvised flywheel hold tool (saw some guys on youtube doing this): Next is the driveshaft, refill the tranny and exhaust mounting.

-

gort joined the community

-

rear clunking noise '76 280z

Understood Darom! If you decide you don’t need them and want to get rid of them, just shoot me a message. Thanks!

-

It only works if I spray gas into the air intake.

The OP implies that it ran when parked, but the pump and hoses indicate that somebody tried to get it running using a portable can on the fender or in the engine bay. Somebody either messed with it in the "year" (probably 3 or 4 in real years) it's been sitting, or the friend only had it running on a portable can.

-

Z Restoration Progam

Too bad the checklist notes weren't delivered with the cars. That would be cool to have today. I assume that people like zspert and Pierre are the Shop Reps? Who kept the Checklist documents? 1997 was well in to the copier and computer age. Any chance they're out there in copies or image form? I'm way over on the engine rebuilding end of the interest spectrum. It still seems unclear who managed the rebuilding of them. Did the Shop Reps just handle the shipping and receiving of engines to AER? Did they come back fully assembled, at least with heads, timing cover, fuel pump, etc., installed and torqued? Or did they come back in pieces and were reassembled at the Shop? Best to collect this information now, especailly in the States. Attempts are being made to create a new history, erasing the old. Somebody will realize what the Wayback Machine holds. It might not last.

-

rear clunking noise '76 280z

Hi @kw906! Thanks for the interest. I haven't taken my car on a long ride yet to see if the poly mustache bar bushings are transmitting too much road noise. If the noise is there, I would use these serrated washer insulators instead of flat washers that came with my poly kit.

-

kw906 started following rear clunking noise '76 280z

-

rear clunking noise '76 280z

Darom, I would be interested in buying the old mustache bar serrated washer insulators if you are going to get rid of them.

-

Z Restoration Progam

You totally missed the point being made. Randy Jaffe was talking about 'factory-correct authenticity', even to the point of hose clamp orientation. He clearly thinks Cad was the original finish. https://youtube.com/clip/UgkxAwPdmHPp1GDcsSL09MAx51Ak2gUs4hRh?si=S2GAydRujBcJszu_ Put your own reading glasses on and pay special attention to the word FACTORY: On the other hand, you deserve special points for ""...that may have been the case in Japan...". LOL. Do you write one-liners for Larry David, by any chance? Edit: Ha ha! You edited your post! Backpedalling.

-

77AkumaNoZetto joined the community

-

Z Restoration Progam

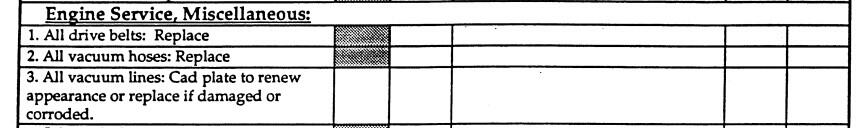

If Nissan says it's Cad plated then I believe them. Put on your reading glasses RAE and check what they wrote in an official document. All detailed in the Nissan Motor Corporation U.S.A. 240Z Restoration Program Quality Control Checklist. Now I know RAE will come back and say Nissan never used Cad but Gold Zinced the parts on the 240Z, but that may have been the case in Japan. This was a USA program and they sourced services locally in California. Cad plating was not banned from automobiles and parts in California until 2003.

-

Z Restoration Progam

In the Larry Chen YouTube video with Randy Jaffe, Jaffe was pointing at the engine bay component plating on his yellow VZ Program car and talking about "Cad plating" as though that was the original factory finish. Not the case. Most of it was Zinc, with a few different passivated finishes. No Cadmium.

-

Z Restoration Progam

Another interesting titbit from the program is that all the nuts and bolts etc were cad plated.

-

Let's show vintage racing pictures. I'll start.

-

Chassis Dimensions and the BF-3 PDF

Yes.... it's a mess. I did use the wrong numbers initially measuring directly from the C point. When I got under the car and meausred it, the only way I could square the circle was to use 465-15+6.5 to get the number between the two rear lower control arm mounts. That worked nicely. That means the front mount is 15mm from C and the rear mount is 456.5mm. Next problem is wether the front strut top distance is correct. My car is about 20mm closer than the 913mm measurement. Is the car bent? Or is the diagram wrong.....? I'd suspect bent car. As an aside, that photo you provided is not a 240z ....perhaps a 260 or 280.....IDK. but very representative of what im working with.

-

hsmontacargas changed their profile photo

-

Z Restoration Progam

A pair of cylinder heads and other engine parts - including an early type oil pan, painted Nissan engine blue, on a bench at Pierre's. Caption says that "...from now on, all engines and transmissions will be rebuilt at an NMC USA contracted factory in Texas. The proud staff at Pierre'Z were not happy with this decision. It seems they would prefer that everything was left with the car's 'foster parents' (ie in-house) if possible."