Everything posted by 240260280z

-

HLS30 00048 Gets A Cover Page

http://www.atlanticz.ca/zclub/members/gabringuette/index.html

-

VIN #22 for sale

The VIN number on the firewall looks like the "HLS30-000" part is a very different font from the "22" font. The size of the rivets on the dash seem bigger than on vin 48 http://www.atlanticz.ca/zclub/members/gabringuette/index.html Take a good look if you plan to buy it.

-

delrin/aluminum tension rod kit

Sir I dub thee an honorary Canadian.

-

1980 C-Prod Runoffs

Thanks, that was great... felt sorry for the tr8 in second.

-

UK, NZ, AUS, Other "DATSUN" or "DOTSUN"

Most Canadians I know pronounce DAT as "DAT" which is like "RAT" .Most Americans I know seem so pronounce DAT as "DOT". How do the rest of the English speaking regions pronounce it? FYI I also say Mazda with Ma like Macaroni but my friends in Upper Canada say Ma like "Maw" as in Mom.

-

anyone from Saskatoon Saskatchwan?

I saw an orange 240z when in Regina and left a note but no response. I know a guy at SaskTel who has a Lotus Europa... that's as much as I can help. Welcome!

-

popping through the exhaust at 4500 rpm or so.. HELP!

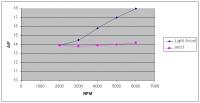

I now think it is a vacuum leak because at WOT the manifold and engine bay vacuum/pressure difference approaches 0. However, with the partial throttle opening under light acceleration, the manifold vacuum will increase with rpm and more air will flow into the manifold down stream from the throttle valve due to the increased vacuum with RPM . This plot of the data shows it:

-

another identify these carbs for me please thread

Attached is a pdf detailing the strange beastie: flat top with side fuel bowl HJL38W.pdf

-

another identify these carbs for me please thread

Hitachi Flat tops from ~ 1973-1974 http://www.cardomain.com/ride/2388737/1974-datsun-260z#23887370010

-

popping through the exhaust at 4500 rpm or so.. HELP!

A quick and dirty to make sure you get more than enough fuel: Do another WOT run and measure A/F Drop the jets two full turns then repeat the WOT run.... hopefully the A/F will go below 14. You can also idle and measure the A/F then pull the choke and see if the a/f drops

-

popping through the exhaust at 4500 rpm or so.. HELP!

Perfect. That means you either have a manifold leak or carb issue. Did you try spraying a solvent at all margins and hoses/caps of the manifold to see if idle rpm's increase? This is a quick way to check for a leak.

-

popping through the exhaust at 4500 rpm or so.. HELP!

Actually the WOT plot is very flat. Does the car have a smog pump or cat upstream from the O2 sensor?

-

popping through the exhaust at 4500 rpm or so.. HELP!

The data shows that you are lean when applying light pedal and normal with heavy pedal (WOT). I assume there was no popping with the heavy pedal? If so then that rules out ignition. The carbs should roughly perform the same for light pedal and heavy pedal. Since there is more manifold vacuum with your light pedal the first thing that comes to mind is that the leanness may be due to a vacuum leak in the manifold which is neutralized at WOT. But if there is no vacuum leak then the problem is that your carbs are not metering fuel properly. I would recommend that you set the jets lower so that your light pedal A/F is lower. With both light pedal and heavy you go leaner A/F at higher RPMS. This can be the SU piston rising too quickly or the needle taper not metering properly . You can experiment by doubling the springs in the domes to slow the piston rise (for more venturi pullon the fuel) (or add weight inside the dome). Or conversly you can remove the springs forlesspressure so that the piston risesquicker and exposes more fuel. You can also try pushing the SM needles deeper into the SU piston to increase the fuel exposure with piston lift to try and get more fuel in the upper rpms (raising needleis similar to dropping the jets but the exit point of the fuel is higher) . Reference:

-

DIY Injector Cleaning Info

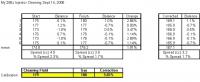

During that summer I did the same tests on my Toyota Echo. Cylinder 1's plug colour showed leaner than the rest and an initial flow test confirmed this lower flow. After cleaning, all the injectors flowed the same. After 800km of driving, I re-checked the plugs and all looked the same.

-

DIY Injector Cleaning Info

-

DIY Injector Cleaning Info

- DIY Injector Cleaning Info

Here is old data that I collected 5 years ago: "Lab" Notes Pintle Cap affects spray pattern when not fully seated 20 ohm vs 10 ohm vs 0 ohm current limiting shunt affects flow data - Example Experiment:10ohm gives 173cc/min and 0hm gives 178cc/min Filter presence changes pattern shape Back Flow with filter in makes biggest improvement when cleaning a poor flowing injector Cleaning fluid flow rate changes over time (use gas on final calibration test) - Example 177 cc/min with cleaning fluid = 188 cc/min with gas (6.2% increase) Electric Fuel Pump Pressure changes over time and the recirculating fluid temp. increases slightly. Best Cleaning Technique: Measure Flow Remove Pintle Cap and put it in Ultrasonic cleaner Backflow using 250cc of cleaning/test solution Remove mesh filter and put it in Ultrasonic cleaner Backflow using 250cc of cleaning/test solution Manually forward clean injector using direct spray from canned carb cleaner's straw then soak in cleaner while manually activating the injector open and closed for 1 min Manually forward clean injector using direct spray from canned carb cleaner for 30sec with the injector open to flush Pull mesh filter and pintle cap from ultrasonic bath and back spray filter mesh with carb cleaner Install filter and pintle cap Flow test- Should I replace injectors?

Yes I pulsed the injectors in the bath and also held them open. Yes they have removable screens.- Should I replace injectors?

I made a 6 injector bench with graduated cylinders, stock pump, fpr, valves, dropping resistors fuel filters and switches. For back flowing I just stuck the injector's snout up the rubber hose (where the barb usually goes) and clamped it. Here is a quick and dirty diy set up I thought of that does not even need a fuel pump: 1. Air Pig or plant sprayer pumping device or compressor 2. air coupling hose to a fluid reservoir 3. air valve before fuel reservoir 4. fuel hose from fuel reservoir to injector 5. wet valve between reservoir and injector 6. low voltage source to open the injector Basically the airpig/plant sprayer/compressor pushes the fluid though the injector. If you can adapt a piston or bladder you may even be able to use domestic water pressure.- Toyota calipers - 14" aftermarket wheel clearance

I did this upgrade with 14" western wheel turbines. No problem with clearance.- Should I replace injectors?

I built an injector flow bench and did lots of tests. The best results were obtained by holding the injector open and back-flowing. I also found that ultrasonic cleaning did not make a significant difference but it could have been my cheap $40 ultrasonic cleaner. You can clean your own injectors by using injector or carb cleaner and the straw while opening the injectors. A 9 volt battery and clip-on injector connector with a momentary switch will do the job nicely.- new member zdogg in calgary ab

There is a great Z Club in Calgary. I assume you know but if not: http://www.calgaryzclub.ca/ Welcome back!- How do I adjust my cam sprocket for chain stretch?

You will learn a lot from this job.- How do I adjust my cam sprocket for chain stretch?

- popping through the exhaust at 4500 rpm or so.. HELP!

Some tests: 1. Try dropping with damper valve in and also with the damper valve out to check for interference there. (compare front to back as this is a relative test). Swap damper valves and repeat. This should give you a good idea on how all damper valve and pistons interact. (PO could have easily swapped parts so make no assumptions... but for ZT resto's assume everything was matched up correctly). 2. Try piston drops (with damper valves installed) but this time just have the 4 (or 3) dome screws backed off to "less than snug" so that you can just slide the dome forward/backward/side-to-side by hand . Continue dropping and testing the optimal position of he dome by sliding it around. Next continue the drop test and slowly tighten screws in a cross pattern by 1/4 turns to ensure correct dropping of piston without binding. (you can do this with jets out if you want to eliminate any potential needle bind from this test). However I still think you have ignition/scatter problem. - DIY Injector Cleaning Info

Important Information

By using this site, you agree to our Privacy Policy and Guidelines. We have placed cookies on your device to help make this website better. You can adjust your cookie settings, otherwise we'll assume you're okay to continue.