Everything posted by inline6

-

Dave W 1971/240Z rebuild

My hardware was nearly perfect and yes, the plastic parts came out like white chalk. Thanks for info. If I have more parts to have plated, I will pass along the recommendation to shorten the time in the hot acid.

-

Dave W 1971/240Z rebuild

How is it that the parts with plastic on them you have re-plated like the fuel rail and the throttle rod don't have plastic damage?

-

1971 HLS30-14938 "Lily" build

Did they do anything special to get the windshield to go into the car so easily?

-

My two swiss S30Z Fairlady Restoration build thread

Yep. Also, I measure the outer diameter of them at .175" inches. They are similar to the clips used for the inside trim panels in that they utilize a small plastic shaft which is pushed into a hole in the center of the rivet. Pushing it flush with the top of the rivet expands 4 "fingers" behind the hole which is what grips the part into place.

-

My two swiss S30Z Fairlady Restoration build thread

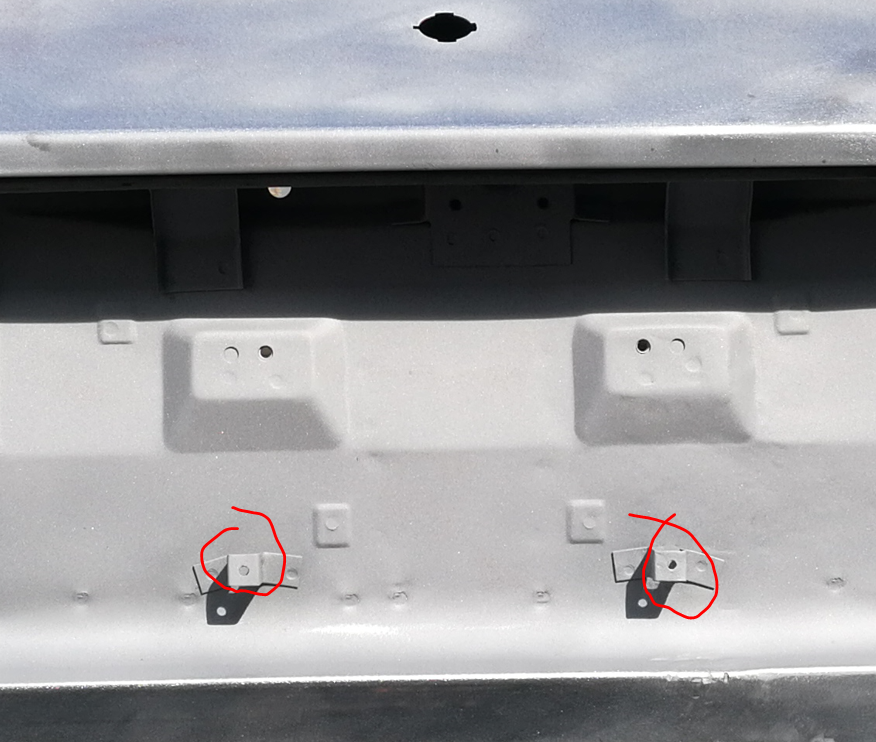

I have some of the correct plastic rivets. They are quite small in comparison to the plastic rivets used on the interior trim panels. I will get some dimensions on them. I was able to source them new from Nissan within the last couple of years. These holes use the same plastic rivets, but you may not have those brackets anymore as they may only be on US cars for the US license plates.

-

Seat slider knob - The Unobtanium

Yes, thanks for the exposure to another source!

-

Seat slider knob - The Unobtanium

Steve Nixon makes a replacement also: https://www.240zrubberparts.com/product-page/240z-seat-adjuster-knob If you want the one you got there to be shiny like the original, you could probably wet sand and then polish it. Maybe fitting it temporarily to a shaft and spin that in a drill to sand and polish.

-

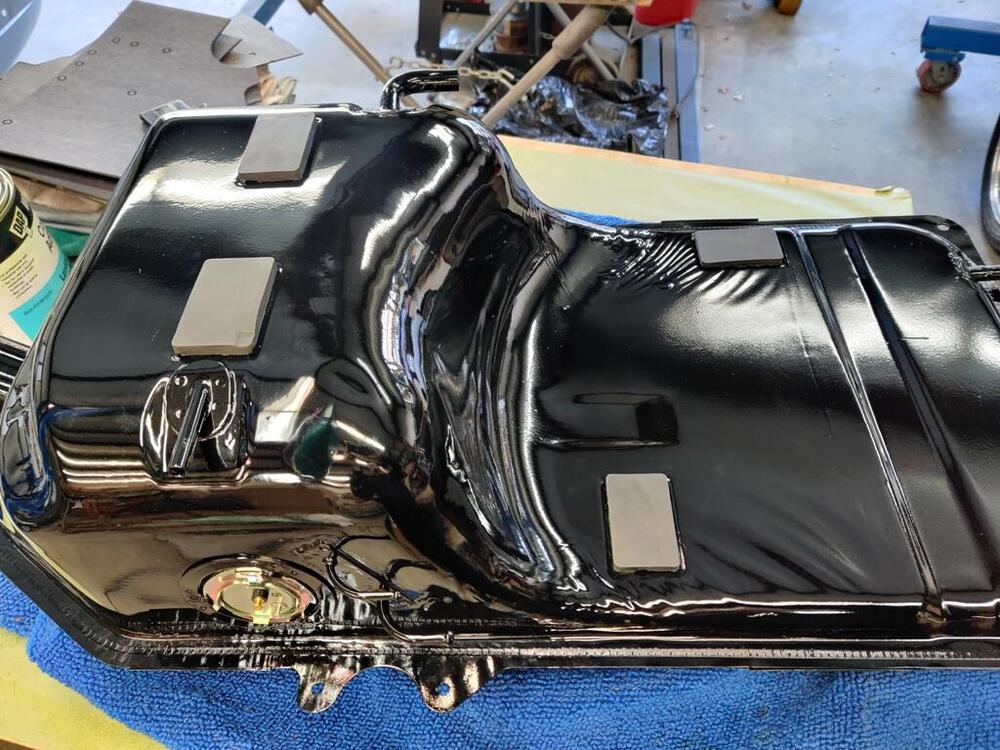

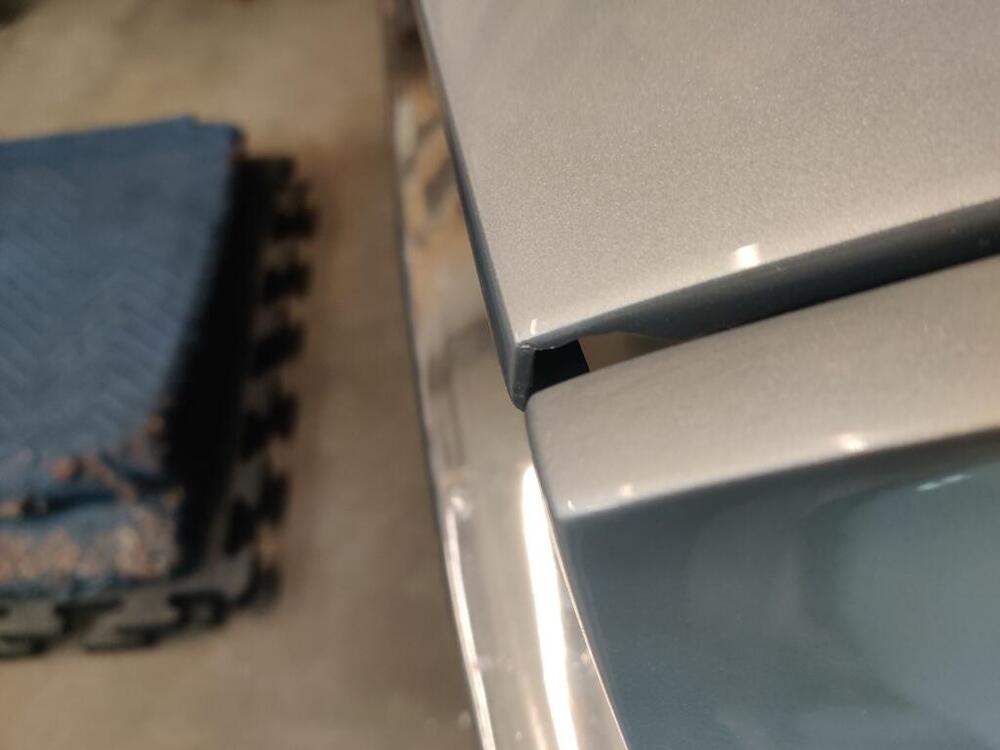

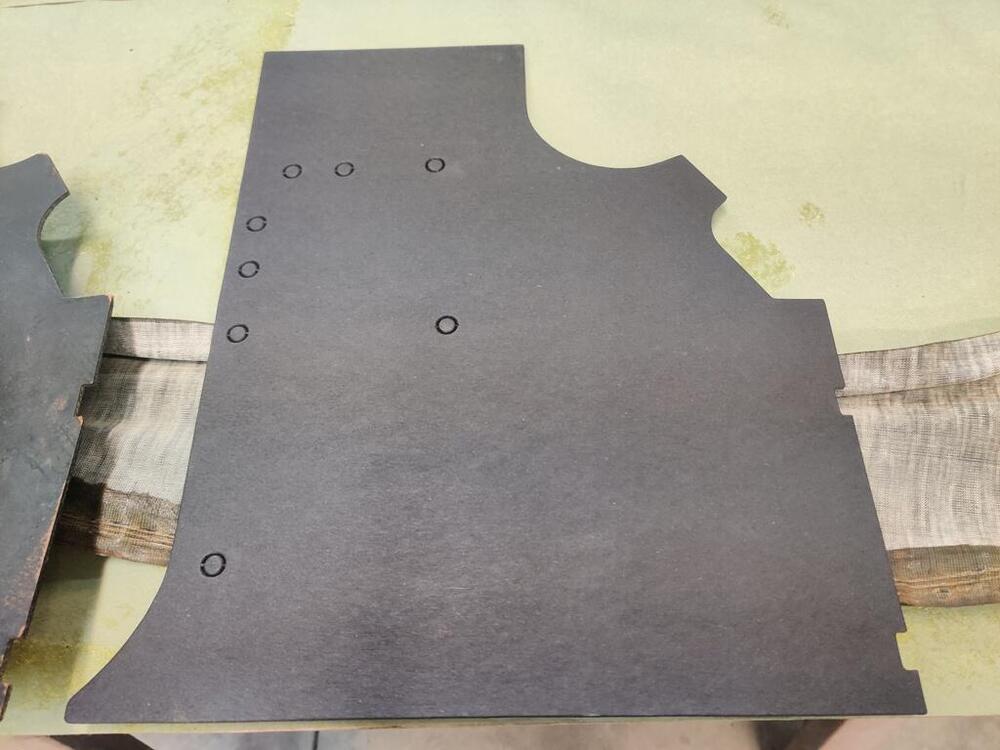

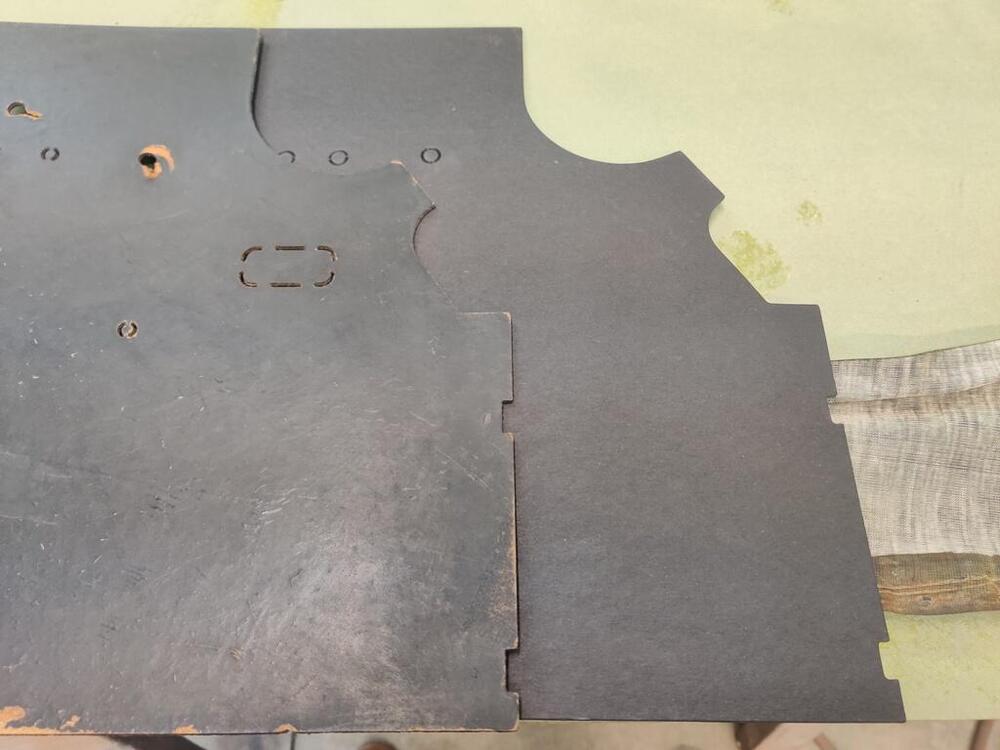

Restoration of BringaTrailer 240z - HLS30-35883

Yesterday, I completed the very difficult task of installing the vinyl A-pillar/side trims. I took my time. I found it helpful to examine the old ones very carefully while trying to get the new ones installed properly. I discovered that the quarter windows have to be out to install these properly. So, I had to take those back out temporarily. Like many things, it is a whole lot easier when you have done one. The second one was much easier and took much less time to install. The only part that didn't turn out perfect is where the side welting butts up against the header. I left a bit more vinyl material there than I should have. If I could do them again, I could get them perfect. But, it isn't worth spending all the time and effort to rip out these, cut new ones and do another install. I found the clips to be more useful with these because I wanted the vinyl to stick to the inside of the weld flange too. It sticks perfectly to the outside of the weld flange without the assistance of the clips. But on the inside, the vinyl is at an angle pulling away from the flange. The clips help it seat there. I had today off from work, so in addition to the usual weekend hours, I was able to spend another 6.5 hours on the car. 🙂 The rear hatch glass has been sitting in a corner waiting... for the scratch remover kit I ordered to show up, and for me to devote time to removing the scratches. The kit has arrived: I found out about it on Youtube. I was intrigued when I saw a video that showed removal of a deep scratch. I had used Eastwood's kit, and found that it was barely adequate to remove some light wiper marks from my BWM M3 windshield. That is not a fault of the product, but I did not realize until I saw this video that there was a product that could remove deep scratches. But, I did not choose to work on that today. Like the rear hatch glass, I cleaned my windshield and installed the NOS rubber weather strip on it. I bought the windshield a few years ago when I was finding it hard to source a windshield without the blue "stripe" of tint across the top. It was made in China, but appears to be a decent quality one. I am going to wait for a warm day and put the windshield out in the sun. I want the weather strip to heat up and relax in the sun before I attempt the install. I will do the same for the hatch glass. I had not yet shared pictures of the new firewall insulation installed. When I applied the vinyl to the foam for the new headliner, and while the contact adhesive was in the spray gun, I installed them. I think they turned out to be very nice. I was held up on finishing the installation of the windshield wiper motor and mechanism because I was searching for a suitable replacement for the plastic "push clips" that hold the wiper bag end together. I found these at McMaster-Carr and they turned out to work nicely. After snapping them together, I just use small clippers to clip the extra portion of the post off. Additionally, I came across a forum thread in which @Captain Obvious described the proper function of the wiper arms. I had no idea that the round spring that always breaks was responsible for changing the off/resting position. I saw where some had bent the end of the existing, broken spring, so that it has a new "tang" to fit into the slot. I modified my spring today (third pic). It works perfectly - I can rotate it with ease in one direction and when I rotate in the reverse direction, I can feel the spring acting like a "one-way clutch". It grabs the eccentric piece you see and rotates it, which because of the offset, changes the length of the wiper arm assembly just a touch. This is what alters the "parked" position of the wipers to something just a bit lower than that of in operation mode. Cool! I believe this is the correct way to assemble the linkage to the motor, but I will leave the wiper off when I turn on the wipers to test them. Thanks for the tip @emccallum! Next, I moved over to gluing some more parts. Wiping the tool door cushions with lacquer thinner cleaned them up nicely. Then, I used a small brush and the same contact adhesive to install them. In this case, I didn't put adhesive inside the groove of the rubber cushions, as that would have been difficult and would have made a mess. Because I only put adhesive on the metal, I used the file clips to hold the cushions in place until the glue could set. While I had the adhesive out, I also glued the rubber blocks to the gas tank and installed the new gas tank sender unit:

-

Restoration of BringaTrailer 240z - HLS30-35883

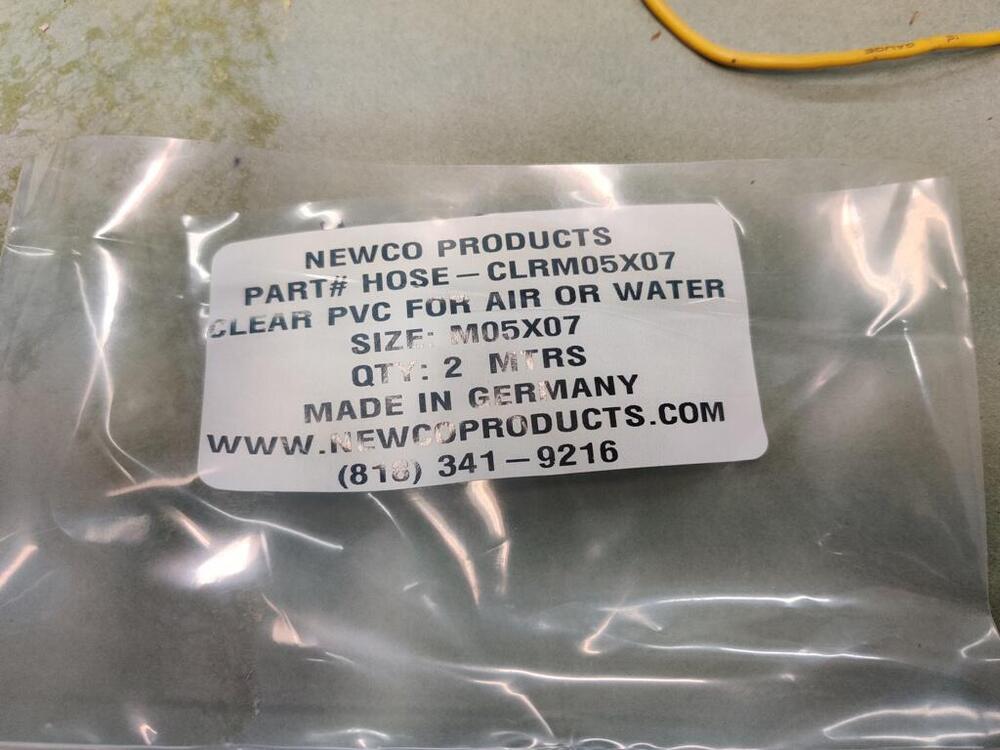

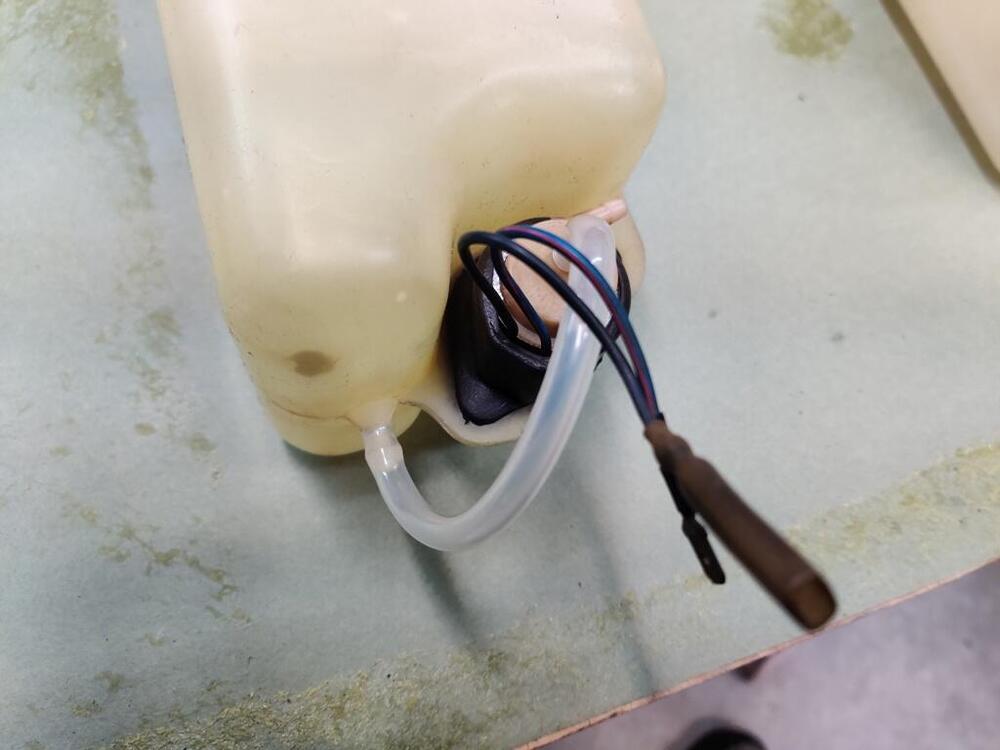

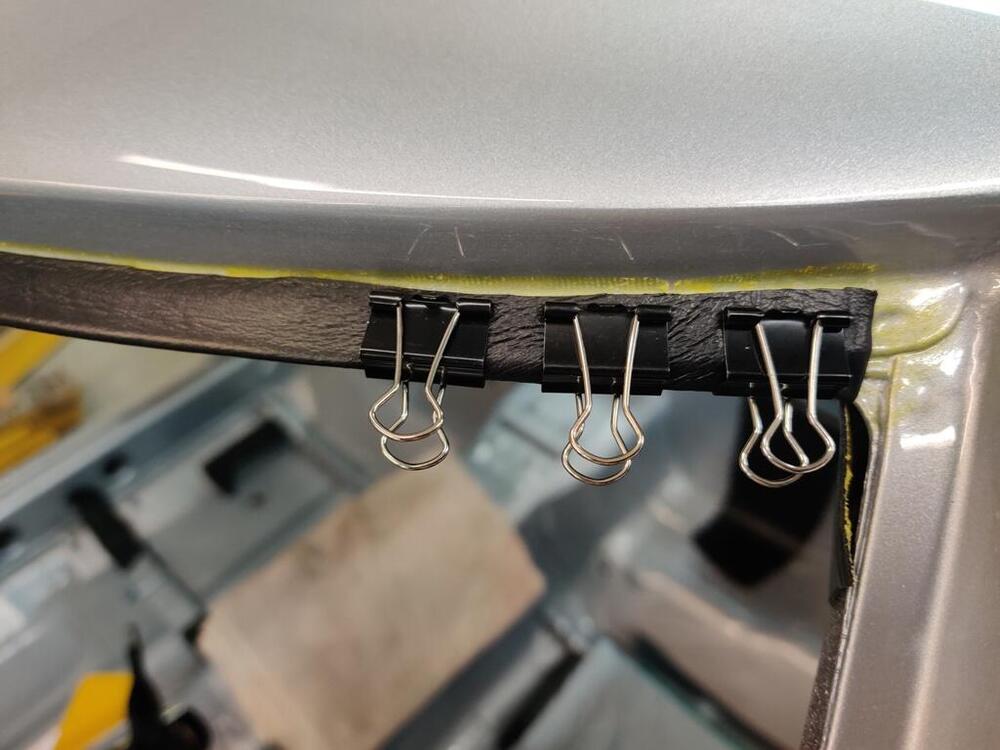

It was with some dread that I installed the hood onto the car. Flashback to when I was scrambling to get the car finished for transport to the body shop in February of last year, and when I installed the hood, I saw that I had some panel alignment issues. I won't rehash all of it here, but I provided details in the document I wrote up for the body shop. This should have been a checklist for them. But clearly, they did not do several of the things I pointed out for them. Quoting from my write up: "The hood: The front lip, at the very left corner edge of the hood, is bent outward a touch. I didn’t notice it until I started fitting the hood for the last time. I tapped the front lip at this corner with a body hammer to move it back a touch to align with the left headlight housing and the resulting movement caused some small chips of the primer to flake off. The left front corner of the hood will need some attention - possibly some more tapping with a hammer and possibly some primer application. The hood has some scratches in the surface that will need attention." Well, while the scratches in the surface of the hood were addressed, the corner of the hood got ignored. The front left corner still sticks out a bit, and at the top corner, I can see where the primer chipped. So, this is just another reminder that "next time", I will not be leaving anything to anyone else - I will do it all, and I will do it right. With this type of thing, my frustration level is high. I still need to massage the fit of the hood a bit, but I decided to move to other things for now. I unpacked the new kick panel covers. I bought these from Motorsport Auto. They are "ok". They are not quite as thick as the originals... even when measuring thickness at the top edge of the old ones where no water has gotten to fiber board and caused it to swell. There are slight differences which you can see here: Second pic shows thickness of the top edge - old one is on the bottom. Next, I pulled out my collection of windshield washer reservoirs and pump motors. I sourced new windshield fluid hose from a company called Newco (see the tag for sizing info). I used a clean rag and lacquer thinner and some #0000 steel wool dipped in lacquer thinner to clean the outside of the reservoir. My pump motors were seized. I dis-assembled the first one, but there was no saving it - there was too much corrosion. The second one was in much better condition. Dis-assembly and reassembly was enough to get it running nicely. It may not last long in service, but we'll see. The last thing I did today was glue the front edge of the header vinyl. This contact adhesive is magical: Though I bought a bunch of the folder clips you see in one of the pictures here, I was amazed at how quickly this adhesive worked to secure the vinyl to the weld flange. I brushed it onto the backside of the vinyl and on the top side of the weld flange. I let it dry for about 4 minutes. And when I pulled the vinyl toward the windshield opening, I tugged on it pretty good. Just touching the vinyl to the forward edge of the weld flange... was enough to hold the vinyl at the tension I had put on it. It was wild. I then folded the vinyl over around that front edge and pushed it onto the adhesive on the top surface of the weld flange. It stuck and didn't move. I didn't need to use the file folder clips. It just stuck. I used my Exact-o knife to cut the excess vinyl off at the point where the weld flange ends: I put some clips on in the corner, "just in case", but I am sure they were not needed. This adhesive is wonderful and a joy to work with.

-

1971 HLS30-14938 "Lily" build

Just Dashes has been in business a long time and has many happy customers. I see that the before state of your dash was not that bad - the cracks are not very large. When the original pad has huge, deep cracks and has "expanded" in size, I think repairing it by grinding down the old foam and layering new on top is not a great idea. Here is a video from their website.

-

1971 HLS30-14938 "Lily" build

Sorry this happened - I can imagine how you felt when it happened, and how you feel now. Regarding the best option for dashes, I believe Vintage Dashes is the best option. When I bought mine, in came in a box via UPS/Fedex. You have to re-use your metal frame, but removing the old and mounting the new on the frame is not difficult. I don't recommend Just Dashes. They repair the existing dashboard. They retain a lot of the original foam which is old and brittle. And, if the dash has large cracks, the "pieces" have moved somewhat from the their original locations when the pad was all one piece. I had one done by them years ago and it ended up having fit issues around the glove box door and being a tad oversize... with the gauges fitting extremely tight. I feel like the result would be questionable at best for a pad that is cracked severely. And, I think they are even more expensive than Vintage Dashes. Garrett

-

Need R200 Differential Advice

Did they swap to the 3.545 and tell you after the fact when the payment was due? I would be upset if that happened. I would have liked to attempt to source a gear set before having them assemble it.

-

Best Starter Motors replacement

Nice - had no idea these existed. @Av8ferg I know you said you are looking to replace it, but the clicking... and banging on it with a starter... could just be the solenoid. Finding one at a suitable price and the work to replace it may be more than you want to take on - I understand. Having rebuilt my own starter not long ago, I realize that there is a certain amount of work that goes into rebuilding them, and assuming that was done... it might be a waste to chuck it without cracking it open to have a look. Or... it might be wise to just move on. It is nice to know that these new options exist.

-

Z's on BAT and other places collection

Facebook. In their infinite wisdom, they make it hard to copy a link.

-

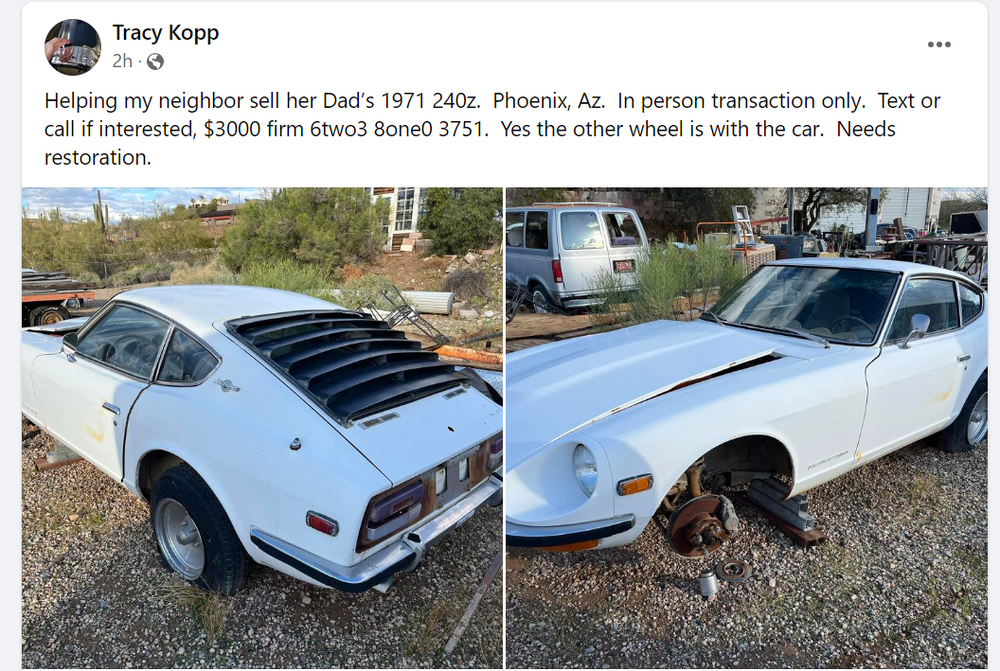

Z's on BAT and other places collection

May already have a buyer in line - but this is a killer deal: 4XXX VIN, white on black. Appears to have original radio, early brake rotors, valve cover, steering wheel. Appears to have little rust. Appears to not have accident damage. Key parts of original interior are there but possibly in rough condition (center console, seats, ash tray, etc). $3000 - looking for in person transaction in Phoenix AZ.

-

Restoration of BringaTrailer 240z - HLS30-35883

I have found many things in your build thread to be helpful! I will look through again for that. Thanks.

-

Restoration of BringaTrailer 240z - HLS30-35883

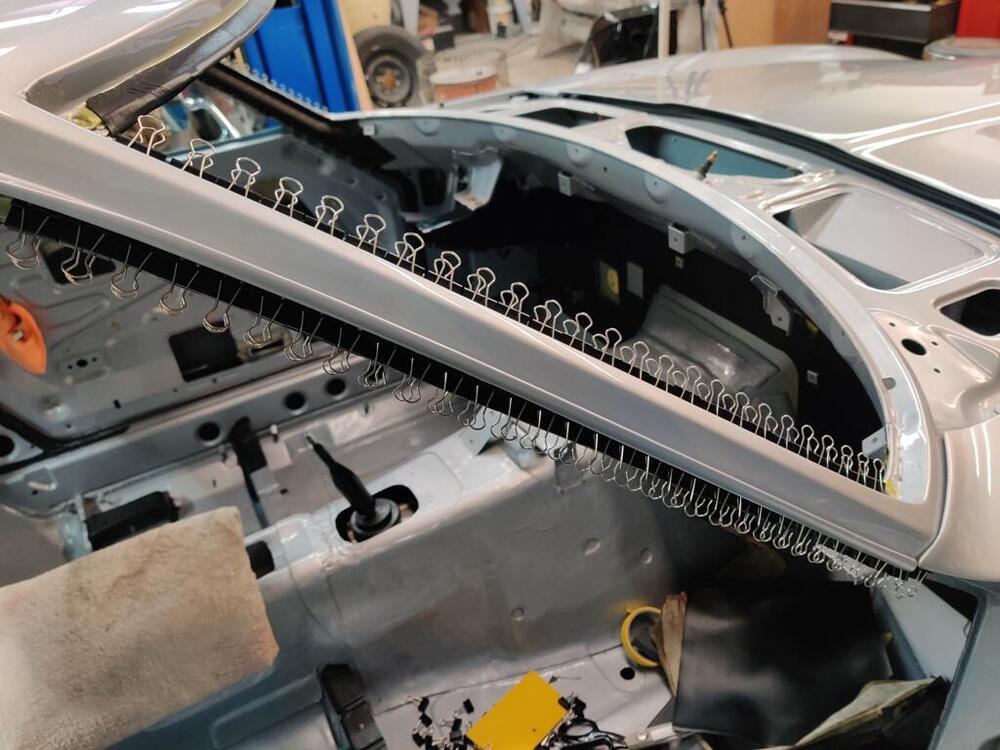

Thank you - very kind of you to say! Today, I picked back up with gluing interior pieces. Spraying glue is not something I have much experience with. So, I was nervous about installing the new headliner in the car. For example, I don't really know the right amount of glue to apply. Too little, and it might stick for a while, but fail later. Also, there is an amount of drying time that is important. Depending on the size of the piece being installed, you may have to wait a length of time, as the adhesive doesn't stick well when it is too wet. Or, if the piece is very large, you don't have to wait long at all, as it took some of that waiting time to apply the glue to the large surface area. There is a window of time where the glue transitions from wet... and a "tackiness" develops. After more time, the adhesive feels dry to the touch. And yet, if you put two pieces with seeming dry adhesive together, they can stick immediately... and not allow for pulling apart for "re-alignment". Over the past two days, I have found that waiting is necessary, but the pieces should be assembled when the glue is still at the "tacky" stage. At this stage, you can pull it apart and reposition a bit. If you wait until it is dry to the touch, then when you put the pieces together, they stick pretty strongly, and it is not going to go well if you try to reposition things. With all that weighing on my mind, I worked on cutting foam and vinyl pieces for the windshield header and side panels. I carefully examined the old foam and made new pieces that matched the thickness, width and length. Because some of the original pieces were only about 1/8th" thick, I bought that thickness of replacement foam. To match the thickness of the other original pieces, I stacked new strips of 1/8" thick foam, using just small amount of glue brushed down the center of the strips so they would stick together. From the old pieces, you can learn things, so you should keep them until your new pieces have been installed. For example, by looking at these indentations in the end of the old foam, I was able to eliminate any question about the correct location of the foam on the inside frame. I was also able to determine where there was overlap of original foam pieces. And that helped me locate the a-pillar piece of foam on the car in the same place as it was done by the factory. This foam compresses with very little pressure. While stacking 3 pieces high was a bit thicker than the original, it compresses easily, and will compress to the proper thickness when the vinyl is pulled and stretched over the foam. After getting the grey foam in place on all three sides, I masked off the frame area as described in the how to Restore you Datsun Z car book. Then, I took a moment to organize things so I could spray the inside of the roof of the car, and the back of the new headliner, and install the headliner in the car. When masking the rails, I made sure not any part of the rail surface was exposed to catching any adhesive. Even a tiny portion of the edge of the frame, if exposed, will subsequently collect some of the spray on adhesive. And it will become a problem when you go to position the adhesive covered back surface of the headliner in place. A touch of cement on the frame, if present, will touch the cement on the back of the headliner and "bite", causing difficulty with getting the headliner, up and over... and subsequently tucked behind the frame edge. Speaking of tucking behind the frame, I used a large plastic body filler spreader, which turned out to be a great tool for the job. There was a fair amount of force necessary to get the headliner to go from outside the frame to squished... and then, using the edge of the spreader... pushed inside the gap between the outer panel and the roof structure. The "extra" headliner material has to flatten out (behind the frame, hidden from view). Again, I was very happy when, like the gluing operation to adhere the vinyl to the foam to make the headliner, the installation of the headliner also went well. There were a couple of nerve racking moments, and 3/4 of the way through getting the edges tucked behind the frame, I was feeling some fatigue in my arms and soreness in my back from getting poked by various "not soft" parts of the transmission tunnel. From there, I started the next project: to install new vinyl onto the windshield header (front portion of the roof frame) and the side panels (side portions of the roof frame). I found it best to do things here different than Wick Humble's guidance. I was able to use a small brush and only apply adhesive to the underside of the back weld flange of the header. I let that dry a bit, and then positioned the header vinyl directly on that adhesive. I didn't use the welting at all, initially. The vinyl was simply hanging down from the back edge of the header, across the header's full width. Then, I aligned the white dot on the welting with the center of the header. I pushed the unglued portion of the header vinyl upwards and pushed the welting onto the back edge of the header, forcing the vinyl to tuck between the new headliner and the frame. The glued part of the header vinyl did not move as I did this. Only the non-glued part squeezed between the new head and the frame. At this point, the header vinyl is held captive by the welting, and it is ready to be pulled forward, and out through the windshield opening. It will need to be pulled with a good amount of force so as to compress the foam that is on the header, and create a tight, wrinkle free finished appearance across the entire header panel. And that has got me thinking... I don't know how in the world they did that at the factory - keep a lot of tension on the vinyl covering the header panel. The way the windshield goes in, the windshield gasket tends to push the vinyl on the header backwards. If the glue holding the front of the header vinyl were to not hold firm, the vinyl would be pushed back somewhat, allowing the header vinyl to relax... and be loose. If that happens, the finish look is not going to be nice, and who wants to pull a windshield BACK OUT, just to fix a loosely fitting header vinyl? I am not sure how I will proceed. But, I am thinking about buying a whole bunch of these, which I have seen other people use on other car restorations. I think I will need to apply the glue, and wait for it to dry... more than I have been, so that it will have the most strength possible. And then, I will pull the vinyl a good bit to the get material tight, and wrap it around the windshield weld flange, and clamp it in place very tightly to keep it from slipping back and causing a loose fit. And the glue will need to dry for at least 24 hours before I attempt to install the windshield. So, that is what I am thinking. Anyone else have luck using a particular technique?

-

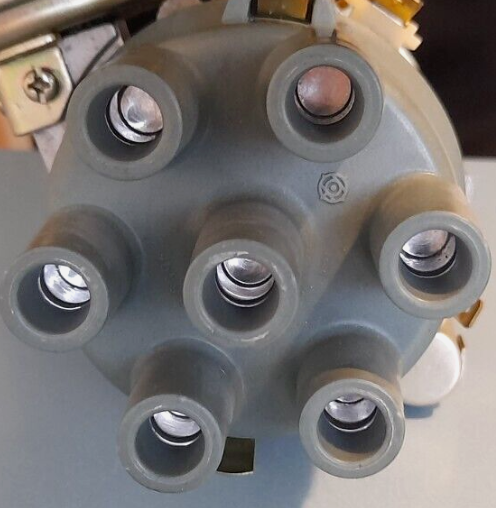

Original Distributer Cap Color

A while back, I heard that the original distributer cap was grey. Going off of that and a poor quality picture on BAT, I was able to find a grey YEC branded cap, but didn't know if it was close to the correct color. Today, I found a picture of an original Hitachi distributor cap: Putting that here for reference for others.

-

Restoration of BringaTrailer 240z - HLS30-35883

The vinyl is "Ottertex", and it is sold in a few places. I got mine from fabricwholesaledirect.com. It is 54" wide and sold by the running yard. I bought three running yards because it was so inexpensive - it was only $9.99 a running yard. To ship it, they folded over and over into a square. When I got it, I immediately unpacked it. The folds and creases were visible even after I spread it out on a floor. Then, I rolled it up onto and existing roll of foam material that I bought previously. This was a few days ago. Yesterday, when I unrolled it from the foam, the fold lines were still visible. So, before gluing it to the foam, I used a steamer to relax the vinyl in those areas. It helped, but they were still visible. I was concerned that they would be visible after gluing. I was glad to see and very relieved that they disappeared when I glued it to the foam. Hi res photo: I think I am going to switch to this vinyl for the A-pillars and windshield header because it looks more like the original than the vinyl I bought previously.

-

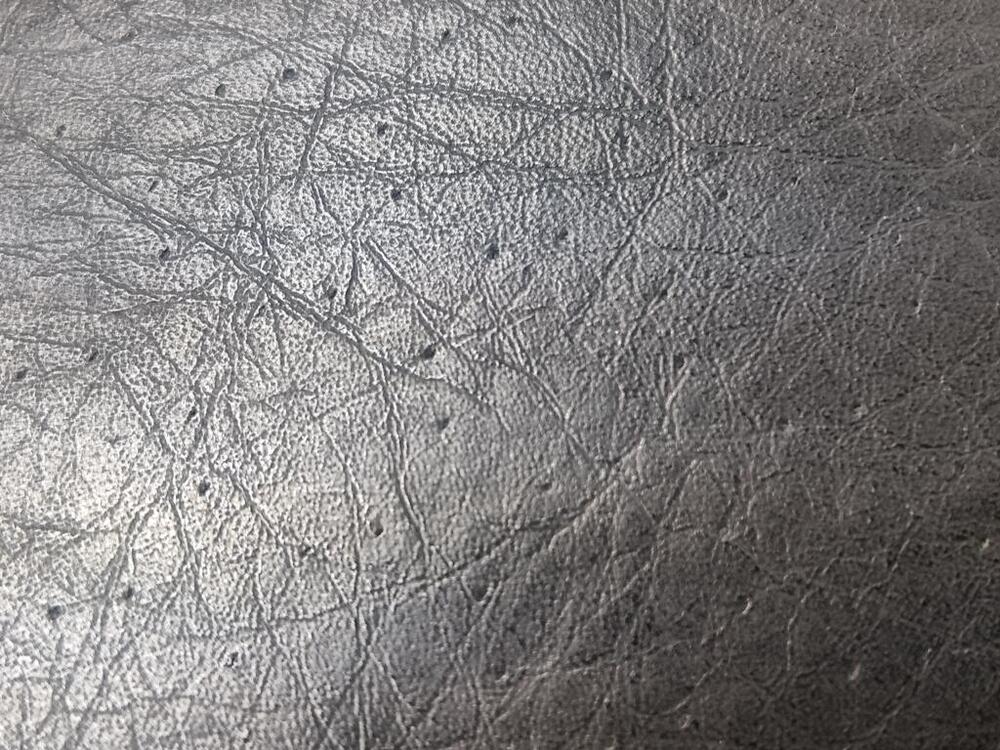

Restoration of BringaTrailer 240z - HLS30-35883

I spent many hours searching the internet and looking at vinyls, and I am pleased to have found a vinyl that looks similar to the original one for the headliner. I wasn't able to salvage my original vinyl, however, I think the headliner I made today looks quite similar. Original: As I said before, unfortunately, I wasn't able to glue the old vinyl to new foam without getting a lot of wrinkles: Unlike the old vinyl, the new vinyl has a cloth backing which makes it lay flatter and makes it stronger. I sprayed the contact adhesive out of a gun similar to a paint gun. The gun was purchased for doing this and it worked very well. The new vinyl: The finished product: While I had adhesive in the gun, I installed the new fire wall pads. I will put up some pictures of those being installed tomorrow.

-

[2024] What Did You Do To/with Your Z Today?

Good to know. I am concerned about the area where I welded on my gas tank. I chose to remove a "drain" that was added by the shop that cleaned and coated the inside of my tank. Though I believe I got it air tight again, I fear it may develop a leak in that corner of the tank. It is good to be aware of options.

-

Dave W 1971/240Z rebuild

Much of that looks similar to my process. My sanding utilizes those same grits. What is most different is the second pad, and DA. I use a rotary buffer for all three buffing stages. I use Meguiars Diamond cut M8532 with a lambswool pad. Then I switch to M8332 with a Meguiars yellow foam pad. At the end of this stage, the paint typically looks good enough to call it "finished" from just a few feet away, but there are typically some very light "swirl" marks if you look at it in the right light, or if you wait a week and look at it in direct sunlight. I don't see "light scratch" imperfections going in various directions at this stage. And for the final stage, I use Meguiars number 7 on a Meguiars black foam finishing pad. I have found this stuff to be excellent at removing the last evidence of any kind of buffing or swirl marks. I also use it for final polishing of plastic parts like light tail lights and the clear dashboard instrument lenses. I didn't wet sand and buff my current restoration project, but I have used the above process many times and the resulting finish is without flaws.

-

[2024] What Did You Do To/with Your Z Today?

Thanks. Looks like currently $625 + $165 shipping.

-

Dave W 1971/240Z rebuild

Hmmm. Are those in the clear coat only, or showing up from underneath the color coat and transferring to the top surface? What is your process starting with fresh clear coat that is ready to sand? Sanding with different grits? Wet sanding only? Buffing with different compounds? Changing pad type as you change compounds?

-

[2024] What Did You Do To/with Your Z Today?

Comes from overseas, right? How much including delivery?

Subscriber

Subscriber