Everything posted by Captain Obvious

-

L24 Rebuild -Again!

And it looks to me like one of the holes is marked, but not drilled? Is that your sync pulse?

-

What maintains the fuel line pressure when the care is off?

I bet you say that to all the Z's.

-

Internally Regulated Alternator Trivia - Bootstrap Current?

Zed Head, Water mark on the outside of the relay body? Nice! That's an interesting story if it could tell it, huh? So if you measured 0.3A to the relay, then you're dissipating between 3 and 4 Watts inside that tiny little box. It's gonna get hot in there. For both you guys, next chance I get, I'll take some pics of my 77 relay with the cover off. Mine went intermittent after being on and baking for however many hours it took to accumulate just under 100K miles on my car. IIRC, it's crispy...

-

Internally Regulated Alternator Trivia - Bootstrap Current?

According to the wiring diagrams, both 76 and 77 used the same "always powered" relay coil, but the internals of the 76 brake warning relay was different than the internals of the 77. Implication being, they used a different relay between the two years and maybe the relays they used in 76 are more robust than the ones used in 77? I don't know for sure, but you might not suffer the same hot coil crispy fate with your 76 relay style. Does remind me about another point about the relay and the alternator upgrade though... The brake warning relays used in 76 and 77 are designed to actuate (pull in) at a coil voltage less than the full alternator output. If you've done the internally regulated alternator and rewired your brake warning relay as a result of that upgrade, you're probably applying more voltage to the relay than it was designed to handle and might have inadvertently accelerated the hot crispy coil burnout. The relays are originally driven by the "N" output of the alternator which is actually the "Neutral" output from a three phase generator system. The voltage at this neutral connection is full output divided by the square root of three. Because of this, the brake relays are designed to pull in at about 60% of the alternator output voltage, or about 7 Volts. If you've reconnected that relay coil to full alternator output voltage as part of the alternator upgrade, you're overdriving the relay. Zed Head, How did you reconfigure your relay when you did the upgrade to make the light go out?

-

Z scam ?

That car ad showed up in my area as well. I bet the guy at the other end of that phone number isn't very happy right about now...

-

Internally Regulated Alternator Trivia - Bootstrap Current?

Glad to help. I'm sure you've mentioned it in the past, but out of curiousity, what year Z are you working with? Because if it's not a 78, I think it's just a matter of time before your brake warning relay goes belly up. In the original configuration, they are energized any time the engine is running and the heat eventually takes it's toll.

-

Hella H4 Conversion headlamps don't fit

I doubt the dielectric grease will melt. I was going to suggest RTV instead of the grease though. I mean, how many times do you think you'll be in there changing bulbs? Hopefully never. I don't think you need a hi-temp RTV grade either. I'm sure it doesn't get hot enough to warrant that. I just worry about the duct tape adhesive though. I've seen it get gummy slidey when used on a hot car surface in the sun. Then after a couple months, it dries out and doesn't stick anymore. Adhesive turns to powder. My first thought would be to use some of the non-permanent peelable RTV that they sell for temporary winterizing of your windows.

-

Hella H4 Conversion headlamps don't fit

Hmmm... How hot do you think the bulbs get?

-

Hella H4 Conversion headlamps don't fit

Maybe the two of you used different Hella versions? (Are there different Hella versions?)

-

Internally Regulated Alternator Trivia - Bootstrap Current?

Speaking of closing the loop... I'm sitting here right now wearing my new favorite shirt from The Back Forty Beer Company!! Thanks bud!

-

Hella H4 Conversion headlamps don't fit

I know this might not work for you, but since I don't drive my car in the wet, I'd leave the boots off and take my chances. Are the bulb housings you purchased different than the ones they sell in the H4 packages for our cars? I haven't looked into it, but I'd be surprised if the upgrade packages have problems like this. Do they use shallower housings or something? I'm sure you won't like this idea, but you could always cut the back of the bucket out like I did:

-

Internally Regulated Alternator Trivia - Bootstrap Current?

And then we'll take it higher?

-

Internally Regulated Alternator Trivia - Bootstrap Current?

Haha! Glad you did that. I was internally questioning the way you took your measurements, but I considered the chances that they included a resistor in the gauge assy so remote that I wasn't going to even bring it up. I figured that the chances that maybe I misunderstood what you did combined with the very remote possibility that they included one there didn't make it worth it to continue to chase it. So thanks for closing the loop!

-

Car pulls Left Under Braking

Yeah, I hear you that you exercised the pistons in and out. In theory that should have verified that they are OK, but if you're getting uneven wear up front, something's not right. Are the pads on each side the same as eachother? By that, I mean... I understand that driver's side is different than passenger side, but are both the pads on the drivers side the same or is one of them worn more than the other? What about pass side? What are the chances that the pads are getting hung up on the caliper body? I've seen rusty chunks get in the way and pads that are a tiny bit too wide that don't move freely in the slot.

-

Car pulls Left Under Braking

I'd be hard pressed to believe the problem is low pressure on the right. It's certainly possible, but I'd be more suspect of: Sticky pistons or pads on the left that don't retract like they should? Sticky pistons or pads on the right that don't extend like they should? Air in the line to the right side caliper?

-

Internally Regulated Alternator Trivia - Bootstrap Current?

Zed Head, Yeah, I know I'm often long winded with my posts. I really try not to, but I have a hard time complete ideas out concisely. I like to think that if you can stand to make it to the end of my long explanations, it would be worth it? It's always the tradeoff being clear and being "that guy". So even if you don't check your charge lamp during the lamp test mode, a quick glance at the voltmeter will tell you if your alternator has bootstrapped correctly and snapped into regulation. And barring a spontaneous alternator failure, you only need the bulb at startup to get you over the hump. Once the alternator is generating it's own rotor winding current, you should be golden until you shut off the engine. The only other thing the charge lamp would do is light up while you're driving if your alternator or something else close to it went belly up and get your attention immediately. I think adding another path for some excitation current would be a good idea, and I agree that a simple failure mode carbon comp resistor (as opposed to a bulb filament or relay coil winding) would be a reliable way to do it. I would use a value that's on the same order as the bulb filament and/or brake warning relay coil resistance. That brings me to Geezer's post... Geezer, I'm not sure if that resistor on the diagram is a "representation" of other resistances in the system or if it's an actual component they put in there to increase system reliability. But I can tell you that putting a fusible link where that resistor is shown would not work in this situation. The resistance of the link would be too low and the charge lamp would never light because all the current would flow through the link instead of the bulb. You need something with more resistance than a piece of wire. Theory says that if the charge lamp consumes 3.4 W at 12V, it should have a filament resistance of about 42 Ohms, and that's about what I would use in parallel with the bulb. Something like 40 to 50 Ohms. Maybe since my car seems like it wants a tiny bit more excitation current, I might push it a little lower than that. Another question for discussion would be... Where to physically locate that resistance? It would work anywhere, but what are other's thoughts on the location? I've got my idea, but want to hear other suggestions first.

-

Internally Regulated Alternator Trivia - Bootstrap Current?

OK, nothing special about the 78 gauge. I would have been surprised if there was. So if that resistor DOES exist, it's not in the gauge. Thanks for checking. If it exists, it's probably a plug-in like the tach resistor, but I don't have any 78 harness stuff to to poke around with either. About the brake warning lamp stuff... In 78, the brake warning lamp check relay is wired in parallel with the charge lamp and hence, it will supply additional current into the alternator rotor windings at bootstrap. So in 78 at least, it might not be that a blown bulb would render the charging system incapacitated. Depends on the resistance of the relay coil. I don't know the resistances of either the charge lamp filament or the brake check relay coil, but it would be interesting data. In my case, I've got a 77 with a charging system rewired like a 78, including the brake check relay. However, prior to my alternator upgrade changes, my brake check relay had already been disconnected because it wasn't working properly. So in my case, there's a chance that if I were to wire in a 78 style brake check relay the additional current draw through the relay's coil would be enough to get me up over the bootstrap hump. So yes, your charging system (and mine and probably everyone else who has done the internally regulated alternator mod) is relying on that single corroded bulb. But in theory at least, you would know that you had a problem because the charge lamp would not light up when you turned the key to ON before you cranked it. You're SUPPOSED to scan the entire dash for anomalies before your start the engine. I know nobody does this, but you're supposed to verify that the brake and charge warning lamps light up properly. It's a bulb check safety procedure. Just like the bulb check mode on a new vehicle. Every time you get into the vehicle. Make sure the bulbs work - Check Engine, SRS, BRAKE, TEMP. Yeah, I don't do it either. In 76, the brake check relay was driven by the alternator as well, but it was done a little differently. In 76 and 77, they used a set of normally closed contacts and energize the coil when the alternator is working properly. So if the alternator stops working and the N connection goes dead, the brake relay coil de-energizes and lights the BRAKE warning bulb. In contrast... In 78 they use a set of normally open contacts and de-energize the coil when the alternator is working properly. So if the alternator stops working and the L connection goes dead, the brake relay coil energizes and lights the BRAKE bulb. That's why you needed to find a different place to connect your 76 brake relay coil. The sense of determining proper operation changed between 77 and 78. They both need a "high" to shut off, but the 78 won't "supply current", only "not draw current".

-

Internally Regulated Alternator Trivia - Bootstrap Current?

Haha!! Thanks Jim! I'll be OK. No need for us both to be struggling!

-

Internally Regulated Alternator Trivia - Bootstrap Current?

I thought about this as well and I agree. If it exists...

-

Internally Regulated Alternator Trivia - Bootstrap Current?

I don't know if my alternator is a reman or not. There's a lot of things that could affect this, and I'm right at the borderline. Maybe your alternator is a tiny bit more efficient at lower RPM's. Maybe your charge lamp is slightly lower resistance than mine and passes a little more current. Or most likely, I suspect that your idle is simply higher than mine when you first start your car. I've got my AAR adjusted pretty low and because of that, I've got a slightly low cold idle. But in any event, you're right... It's more the mystery of the resistor on the 78 diagram than the way my alternator behaves. You don't need anyone else to take any readings to check your 78 voltmeter... Just measure the resistance across the CHARGE bulb wires (green and blue) and then pull the bulb out of the socket and check it again. If there's a resistor built into the gauge (which I really doubt), then you'll still see some resistance between green and blue even with the bulb removed. If the resistor exists at all, I suspect it's somewhere other than the gauge itself.

-

interior bulb replacements

Weird. I wonder why they discontinued the warm white. Glad I got mine when I did. Wish I had bought more than one. I don't have a 4-LED in warm white, so I can't directly answer the question. I have a 4-emitter in cool white and I don't like it. Both because it's cool white, and because it wasn't bright enough. I assume you dug around on the web to see if there were other places to buy the 6-emitter in warm white?

-

Internally Regulated Alternator Trivia - Bootstrap Current?

I did the internally regulated alternator upgrade a little while ago, and everything is fine with the exception of one ignorable low priority issue. Such a small issue that I wouldn't consider it a "problem", but more of a "curiosity" and it highlights some (what I think is) interesting alternator trivia. Goes like this... Sometimes when I first start my car and the RPMs are (cold) low right after I start it, the alternator doesn't spin fast enough to snap into regulation.This is evidenced by the charge lamp being lit and the voltage indicated by the voltmeter. I can give it a little gas to pull the car out of the garage and just that little bit of RPM increase is enough to get it to snap into regulation and from that point forward everything is fine... Charge lamp goes out and the voltmeter shows that the alternator is outputting a healthy 14ish voltage. The way the system is supposed to work is that the alternator pulls a small current (bootstrap) through the charge lamp and this current energizes the field coils until the alternator is spinning fast enough to produce field coil current by itself. Once the alternator is spinning fast enough to produce it's own internally generated field coil energy, it snaps into regulation and the bootstrap current flowing through the charge lamp stops and the lamp goes out. On my car, I sometimes need to increase the RPM's a tiny bit in order for this to happen. I'm not going to do anything about it, but I COULD also fix this by increasing the amount of bootstrap current. So... If I'm not planning to do anything about it, then why am I bringing it up in the first place? Because I noticed an oddity on the 78 wiring diagram that would support my theories and potentially fix the issue. In the Engine Electrical section of the 78 FSM, they describe how the system works (page EE-13). And on that page (and the following page) there is a circuit diagram of the system that includes a resistor in parallel with the charge lamp. This resistor could provide additional bootstrap current to add to what is pulled through the charge lamp: This mystery resistor is not shown on the complete car wiring diagram, nor on any of the circuit detailed descriptions in the Body Electrical section. Does anyone know if this resistor truly exists? If so, what's the value? Is it built INTO the voltmeter gauge, or is it buried in a wiring harness somewhere? Does it plug in like the tach resistor does? I simply can't sleep at night not knowing!!

-

Some Zcon Pics

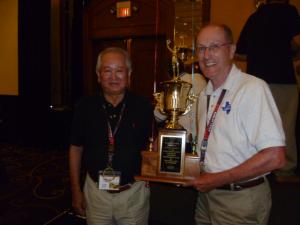

Jim3 A lot of our motley crew. Jim, Jim, Jim, Steve, Bryan, Bruce, Philip. The better halves So proud! Jim and Vicky Jim2 hiding behind so many trophies! jim2 Glowing trophies Mike W and Alex Gold winner and Mr. M

-

Some Zcon Pics

Here's my shots from the event. Flight to Memphis Dinner on Thursday Eve Bunch of us on Beale Street. Jim, Charles, Philip, Jim, Bruce, Jim Unicornicopia Taking a picture of Steve taking a picture from on top of the scaffold platform Me sporting my Fiero shirt at the Saturday show with a fellow Fiero enthusiast Philip presenting Mr. M a gift of a section of the first transatlantic communication cable laid between North America and Europe. The thing that looks like a cigar is actually a couple inches of the rusted original cable that's over 100 years old.

-

ZCON 2015 Hookup

Here's a couple pics from my Zcon adventures. Shot out the plane window while in the air on the way to Memphis. My Atlantic Z Car Club hat so graciously given to me by Blue: : And here's one that I took while I was out with Cliff at one of the brew pubs. This was at Wiseacre Brewing. They said they normally offer a rainbow topping for the Saison, but they had sold out earlier that day: Those are two general pics. I'll put up some more of the ZCon specific shots in the pics thread: http://www.classiczcars.com/topic/51932-some-zcon-pics/