Everything posted by Captain Obvious

-

1978 280z will not start without ether

Glad to help. Since it runs fine once you get it started, it's got to be something relatively simple. Just need to find it. On the 78, all the fuel pump control relays are on the bracket in the engine compartment forward of the battery. The same bracket that the fusible links attach to. Let us know what happens when you pull the black/yellow pulled off the starter.

-

Wiper arm linkage assembly parts

The trick is that the spring and the eccentric cam that the spring winds around... Ready for this...effectively changes the length of the wiper linkage so that the park position IS lower than their lowest point of travel during regular operation. The spring only positively locks into one end. The end that is bent to fit into the Millenium Falcon is the only positive engagement. The other end of the spring does not lock into anything. It's a one-way clutch. Like a Chinese finger torture grabber toy. You can slide your fingers easily into the toy, but can't pull them out because the toy contracts on your fingers and prevents removal. Easy in, friction out because of the clutch. The spring does the same thing, but in rotation. In the direction of "normal operation" the spring unwinds a little getting larger and slipping. Other direction, it contracts a little and when it gets smaller, the center hole grips the eccentric cam. That friction rotates the cam a little and makes the linkage a small amount longer which in turn makes the park position lower than normal operation. I'm hoping I got that right... I'm at a little disadvantage here since I don't have the parts lying loose anymore. I've got access to my buddies linkage which is not yet back in his car, so if there are still questions, I can take his apart again. As for fixing it, my buddy GGR (you met him in Toronto) was able to make a new bend in the end of his spring. Unlike yours, thankfully his did not snap off again. But prior to that success, I had identified what looked like a suitable replacement spring on the HELP rack at the parts stores. I didn't have a caliper with me, but there was a blister pack with a couple springs in it and one of them looked very close. I was thinking it could be used to replace the original. If you're interested, I'll take another look next time I'm at the store.

-

1978 280z will not start without ether

Crash, But before you start testing complicated things... Try this. Pull the small Black/Yellow wire off the starter and then turn the key to START. The starter should not spin (because of the wire you disconnected), but the fuel pump should run. Can you hear the fuel pump running in START?

-

1978 280z will not start without ether

It's not the blue wire off pin1. Once it starts, it runs fine. The ECU is getting the spark signal once the engine is running. It's something else. One of the fuel pump interlock relays or something inhibiting the ignition only while cranking.

-

1978 280z will not start without ether

Well if it does the same thing when you just shut if off for a couple seconds, then there's something that is inhibiting either spark or fuel pump operation when the key is in the START position. Everything works fine when the key is in the ON position, but it doesn't work right in START. So if you can get it started, it's fine in ON, but getting it started is the issue. With that in mind, I bet you could roll start it just fine. Without ether. So I don't know the 78's like I know the 77's but it's either the fuel pump isn't running in START, or you aren't getting a spark in START. Just as a quick way to narrow the field, when you are cranking and cranking it and it won't start... Do you get a good spark while you are cranking it?

-

New connectors

Joe, If you decide you're going to place an order with Eastern Beaver, would you send me a PM first? I'd be happy to piggyback onto an order and share the shipping costs.

-

1978 280z will not start without ether

Crash, Does it do the same thing even when the engine is warm and has only been off for a few seconds? In other words, give it a shot of ether and get it running. Take it for a ten minute drive. Shut if off for ten seconds, and what happens? Does it start then, or does it need another shot of ether? If it needs another shot, it's not the thermotime or cold start system and more along the lines of the oil pressure stuff that siteunseen mentioned. Some kind of interlock problem or ignition switch issue.

-

pilot bushing fit

That's funny stuff right there!!!! HAHAHA!!!

-

240z Auto trans and torque converter-free in Detroit

So nobody else has ever heard the wild tale that the auto bell housing can be used for a manual box conversion of some kind? Ringing any bells anywhere?

-

Deja Vu: 1971 Restoration

Ooops. Looks like you're right. For some reason I thought this was an original style rubber bushing job. With the poly, it doesn't matter. So nevermind me. Carry on. Thanks Dave!

-

Deja Vu: 1971 Restoration

Looks fantastic! Make sure you do your tightening of all the suspension bushings with the suspension loaded. I did my rear bushing tightening with the rear tires up on moving dollies. That allowed the rear wheels to squirm around into correct position while still allowing enough room underneath for me to get under there and work wrenches.

-

Wow -- '74 260Z sells for $46,000.00

That's a little harsh. I don't have pockets that deep either, but still...

-

240z Auto trans and torque converter-free in Detroit

I don't want it, but I have a question. I heard an unsubstantiated rumor that the front bell housing from the auto trans can be used to as a bolt on solution to adapt a different gearbox to a Z. I heard there was value there. Anyone heard of anything like that?

-

Need Help Burning A Flash ROM

Good call. Not Bosch, but Siemens. It's not a German car, but it's got a German ECU. I'm not a big player in this realm and I've never heard of Nefmoto. I'll do a little digging there. I'm really hoping that one of the tuner guys that hangs out here on ClassicZ has a programmer that can do a 29F400. I tried it on an old Needhams programmer that claimed to be able to do this part, but I couldn't get it to work. Not sure what the problem was, but I didn't have a lot of faith in the system. The control lines didn't seem to be doing what they were supposed to be doing and it seemed like a programmer problem. Thanks for the input!

-

Clutch help in 71 with 5 speed please.

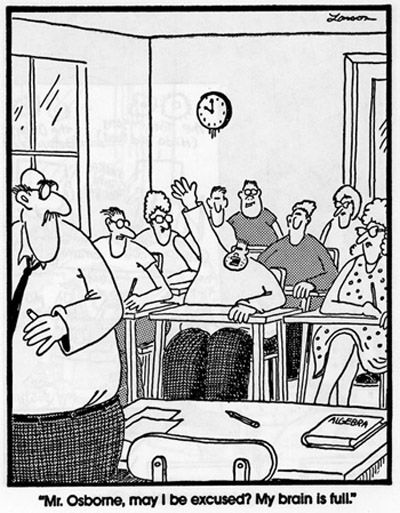

Haha!! You get 99% of my obscure references. I cannot possibly realistically expect you to get all of them. I was referencing an old Far Side cartoon:

-

Clutch help in 71 with 5 speed please.

Sorry. Once per day or my little brain overflows. Mr. Osborne, may I be excused?

-

Need Help Burning A Flash ROM

I'm looking to read, modify, and then reburn a flash ROM for a non-Z application. It's car related, but just not a Z. I apologize for asking this here, but you guys are the best. Anyone have a programmer compatible with an AMD part number AM29F400BB? It's a 32 Meg part and has 44 pins. It's a surface mount part, but I've got a 44 pin SMT to through hole adapter socket that would fit into a programmer that accepts 44 pin parts. Anyone got any ideas?

-

Clutch help in 71 with 5 speed please.

Thanks for the pics guys! One more tiny piece of knowledge that I didn't have yesterday!

-

Clutch help in 71 with 5 speed please.

Does anyone have a pic of the adjustable style clutch slave rod? I've never seen one of those beasties.

-

1971 HLS30-14938 "Lily" build

Yeah, that would be great if you have an AFM as well. Keep me posted, and take care of your back!

-

Heater valve copper thermostat wire-do I have to remove the dash?

Haha!! Well clearly the answer is we need you around to answer the really tough questions! We can handle the easy ones.

-

Duffy's 1/71 Series 1 240z build

Yes, they are yellow zinc. At least when I bought them a couple years ago. This is what they look like: And just in case there is any question about the orientation of everything, here's how it should go together. Small washers on the ends. Concave side of the large washers toward the bushings. Poly in front, rubber in back: And here's how it should look when installed:

-

Duffy's 1/71 Series 1 240z build

Go to rockauto and buy two boxes of AC Delco part number 45G25036. The picture on rockauto is wrong. The picture shows just the bushings, but in fact, each box has one complete T/C rod worth of parts! All the washers, bushings, sleeve and nut for one side. Buy two kits and put the bushings in a box for the future and just use the rest of the kit. Best eighteen bucks you'll spend on suspension parts! On edit... You're going poly and are going to be needing two rubber bushings anyway!! With two kits, you'll have four. Just put two in a box for future use and use the other two on the back side now!

-

Heater valve copper thermostat wire-do I have to remove the dash?

Pffffft. Who needs that 260 guy @SteveJ. I got this one. Those metal pieces are the spring loaded fingers that go between the HVAC control head and the metal bracket below it. Remember those two weird looking shoulder screws that go in from the underside? About a half inch long? Those fingers slip onto the bracket before those screws go in. The weird screws go through the holes in those weird brackets. The HVAC controls aren't hard mounted, but sorta "float" on those springs instead. No idea why they did that. Manufacturing tolerance stackup maybe?

-

1971 HLS30-14938 "Lily" build

Haha! And I thank you immensely! No hurry on sending a care package my way. I'm not taking my car down right now. With so few remaining Z days in my part of the country, I'm going to stall on any hard core work until the weather turns! And as for your back, I completely understand. You know I'm there with you bud!!