Everything posted by Captain Obvious

-

Perplexing "FUEL" light malfunction

Dr. Dave using stone knives and bearskins.

-

Perplexing "FUEL" light malfunction

So Dr. Dave, Can we drop back one last time... Is there any possible way your thermistor is NOT dunked in gasoline at half tank when the light comes on? I know you verified that the holes allow liquid to enter the sensor. Is there any possibility that the location of the holes is important? Stagnation perhaps? Does your old thermistor on your original fuel sender unit still work? If so, any thoughts on swapping the two and getting on with life? Want to send me some parts and I'll see what I can do with them?

-

Perplexing "FUEL" light malfunction

Well that one is easy but you're sure pulling out the stops with the Andromeda Strain reference!! That was a fantastic movie. I saw that movie many moons ago (waves arm), and it scared the craps out of me. And to be honest, I remembered the basic plot and story, but I didn't remember the details of the bell clapper on the teletype. I had to go look that one up!

-

Rear bearing end play

In agreement with everyone else. I don't see any reason you couldn't retorque. I will, however, say that I would not a retorque to change anything. In theory, your inner races have been (and still are) clamped tightly against the distance piece between them. In order to change the end play, you would need to either move one of the outer races closer together (which you should not be able to do) or shorten the distance piece. In theory, of course. Who knows what will happen in real life when you put the black iron pipe and the breaker bar on it!

-

Perplexing "FUEL" light malfunction

Yup. I measured mine at approx. 5.4 cold. Maybe yours is a couple hundred milli-Ohms higher because you're in hot sunny FLA.

-

Perplexing "FUEL" light malfunction

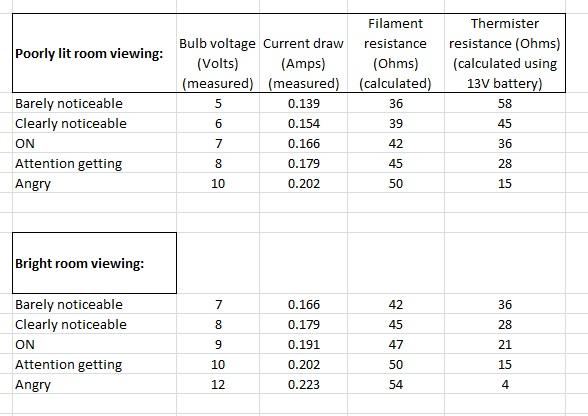

I got data. I applied voltage to a FUEL warning lamp indicator (red lens and all) and "analyzed" the brightness. I came up with the highly subjective brightness levels of: Barely noticeable Clearly noticeable ON Attention getting Angry I measured these values in both a "poorly lit room" and a "well lit room", and here's what I got. It's neat (geekwise) that you can clearly see the filament resistance increasing as the current (and temperature) goes up: It appears that what you really want is for the thermistor to work the way it's supposed to. Failing that, I would try maybe a 50 Ohm pot in series and see what happens? I'll leave it to Dave to calculate the power dissipation in the pot and determine if it's feasible.

-

Voltage/ Resistance for Coil and Ballast Resistor 1971 240z

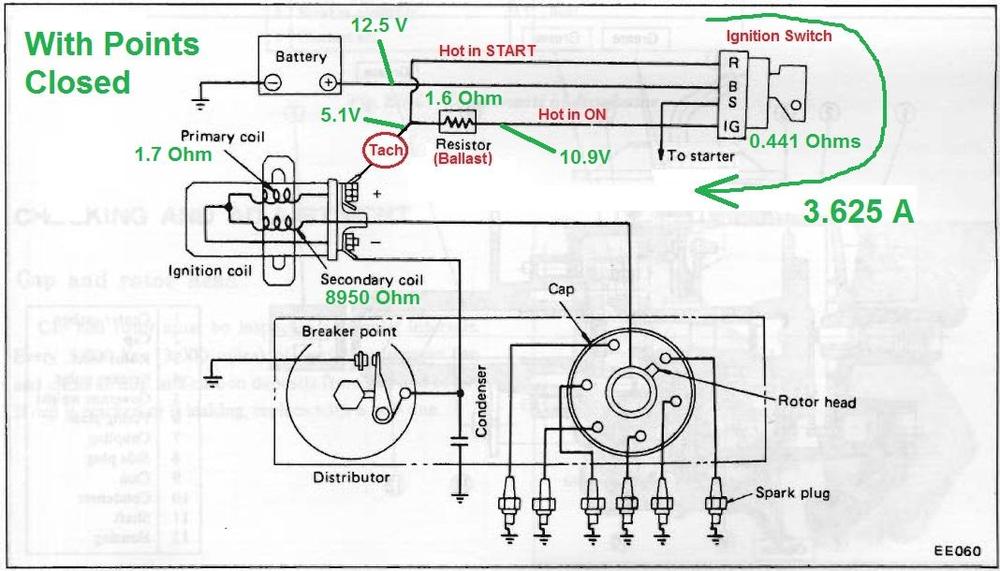

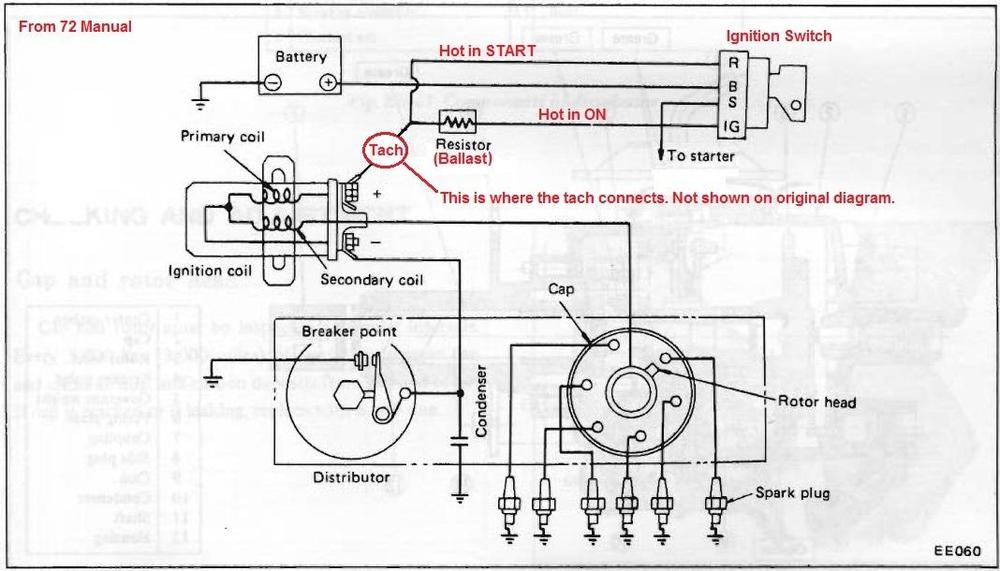

Well with the numbers you supplied*, everything looks fine to me. First off, you need to understand that the numbers you supplied were with the points closed. I don't know if you did that on purpose or not, but that's where you engine ended up the last time you shut it off. If the points were open, pretty much everything you measured would be full battery voltage instead of the readings you got. But with the points closed, here's some stuff you can infer from the readings you took: 1) You're pulling 3.625 Amps through your ballast resistor and into the coil primary. Seems completely reasonable to me. 2) (Assuming a loaded battery voltage of 12.5 Volts) You're losing about 1.6V worth of battery voltage in your ignition switch and the associated wiring. That means the total resistance of everything involved is just under a half an Ohm. That seems a little high to me, but for fifty year old wiring and maybe an original switch, it's probably expected. It won't prevent the car from running, but might be time to clean some connectors and replace the ignition switch. 3) You're dropping about half your ignition voltage across the ballast and about half across the coil. Based on the resistances you measured, that makes perfect sense. A little off, but perfect for a reality check. Putting all that info on the circuit diagram, it looks like this: As for the numbers on the coil with the engine running? You're trying to take a DC measurement on something that is not DC and you need to be careful about how you interpret those numbers. Assuming you're using some new fancy fangled meter, it's probably providing some sort of "averaging of the signal" it's trying to read. If that's the case, then those number look OK too. You're using a DC scale to average a pulse width modulated waveform, and the "averages" look reasonable. * Except the coil secondary. I'm assuming you're reading the scale incorrectly and (as SteveJ mentioned earlier) it's actually 8.95K Ohms, not 8.95 Ohms. I think your meter is auto-ranging and you're not seeing the tiny "K" somewhere on the scale.

-

Voltage/ Resistance for Coil and Ballast Resistor 1971 240z

-

Perplexing "FUEL" light malfunction

I can help with that tomorrow. I will push current through one of those little bulbs until it starts to "noticeably" glow. The current measured at that point will enable me to extrapolate how low the sender resistance needs to go in order to light the bulb. I had previously measured the bulb current (directly connected to a power supply) at about 230 mA. So that's "full bright". In order to reach that level, the sender unit would have to drop to 0.0 Ohms. Clearly the current at which the bulb is "noticeable" will be less than that.

-

Perplexing "FUEL" light malfunction

Well I'm no help on the sensor resistance front. I pulled my HVAC bezel off and measured the resistance. Open circuit. Thinking that maybe I had a bad wire or connector somewhere, I pulled my little access hatch off in the rear and measured it right at the tank. Open circuit. I know the rest of the system works because if I ground the bulb wire back at the tank, the lamp comes on, but without a working sender, it'll never come on. I don't usually run the tank down so far as to really care, but my warning sender is fubar.

-

Rust Advice 78 280z

Hahahaha!!!!!

-

Restoration of BringaTrailer 240z - HLS30-35883

I'm still confused, but no big deal. I assume I'm just confused by the terminology. Thanks though!

-

Perplexing "FUEL" light malfunction

Well OK. I stand corrected, 50mW IS enough power to heat that thing up! Dave, I'll check my cold resistance too when I get a chance just for another data point.

-

Wipers running backwards !?!

Haha!! Yep, I remember! Good times!!

-

Perplexing "FUEL" light malfunction

Oh, and about this. Great pics and write-up. I went through all of this a bunch years ago and only took a couple pics. I replaced my loose turn signal pivot with a threaded in version I made on the lathe and I cleaned out all the switches and put in headlight relays. Hopefully both of us are done with issues on any of that stuff!!

-

Perplexing "FUEL" light malfunction

But that's the problem with DC non-inductive loads. I'm saying that I don't think suppression diodes are the answer. I started typing a whole bunch of stuff about inrush currents, arcs, plasma, and ionization, but worry that we're getting too far off topic and stopped. Let me know if you really want a bunch of details. Transient suppression and mitigation is not an area that I ever specialized in (it's one of the mysterious black arts of engineering), but I just can't picture diodes being an answer for DC loads unless you are trying to deal with the flyback from an inductive load. Sorry OP for the diversion as well. I'll try to keep my mouth shut now!

-

8/71 SU Carb Help, Float Bowl Adjustment

It sounds like empty bowls to me. Check the float bowl level with a clear tube. Don't just measure something mechanical on the float itself and assume that will result in a correct level. You actually have to measure the level directly. Do you have the little screen filters in the carbs? Maybe they're clogged?

-

Perplexing "FUEL" light malfunction

Yeah, that's very true. If I were solving this problem now, I would throw a couple hundred thousand transistors and a one time programmable chicklet at it and call it a day. In fact, that's what I did with my temperature/oil pressure warning lamp. Microcontroller reading a D/A and using digital filtering to weed out spurious false positives. As for the ballast resistor, it has a completely different purpose. They don't want the ballast resistor to change value, they just want it to limit the current to protect the coil and whatever is pulling it to ground. The reason it's necessary is because of the way inductors work. When you first apply voltage to an inductor, it acts like an open circuit. Infinite resistance. Won't allow any current to pass. Then as time goes by, the resistance of the inductor goes down, and it allows current to pass. More and more and more current as time goes on. And in fact, with a theoretical perfect inductor, after enough time, it appears as a dead short. Zero resistance. So the problem is, if there isn't something somewhere in the circuit that limits that current at the upper end, it can reach the point where it gets so high that it will damage something. The ballast resistor limits that upper end of the coil current. You see, when you have points, you really have no idea where the points were when you shut off the motor last time. Points may be open, or points may be closed. If you turn the key on and don't crank the engine, you will quickly cook your coil or your points if you don't limit the current. And the early electronic ignitions systems sit in a stable default state with their output transistors turned on. There is no current limit built into it at the upper end. So the same thing goes there... You could cook the coil if you don't have a ballast resistor. It wasn't until 78 that they started making the ignition modules good enough such that you didn't need the ballast resistor. I haven't played with one, but I assume they did that by building in an upper end current limit into the output stage.

-

Perplexing "FUEL" light malfunction

Dave, that's a good question about the cold resistance. That would be good to know. I guess I could check mine too without too much trouble. It's a little bit of a pain to take the stuff out of the hatch area to get to the connector, but if I get that curious, I'll do that. I bet there's a connector up under the dash I could use too if I dug into the wiring diagram. I'm assuming your 3K is not correct. At 13V supply, that will dissipate just over 50mW. I don't think there could possibly enough internal heating at that low power level to change it's resistance. It would have to be uber sensitive, and have an almost vertical knee in the curve. I'm with you... I think you've got connection issues elsewhere.

-

Wipers running backwards !?!

LOL. That's a great BTDT answer!

-

Restoration of BringaTrailer 240z - HLS30-35883

I'm not a body guy at all, but from what I thought to be correct, the statement confuses me. It is my understanding that all of the liquid and gelled and putty portions of all the body products are plastic (polyester or epoxy). You can smear plastic resin over fiberglass matt. Or you can smear plastic putty (available with or without fiberglass strands dispersed in it) on without the fiberglass matt. But in the end, you're always using some sort of plastic filler, aren't you?

-

Does EGR Delete reduce value?

I'm going to answer in a slightly different way: The only time it would really matter is for a stock correct specimen. And even then, the only cars that anyone really seems to care about stockness is with the 240s. Stock is "nice" for some people for the 260 and 280's, but it doesn't seem to affect the price nearly as much as with stock 240s. So..... Couple that with the fact that the EGR didn't start until the 73 240Z? My bottom line is the only time it would really matter much would be with a stock 73 sale. If you have a 260, or any 280, just do what Mark said and just put the parts in a box for the next owner.

-

Perplexing "FUEL" light malfunction

Oh, and BTW, the discussion of bulb filaments changing their resistance dramatically as they heat up reminds me... Sorry for the diversion, but since we're so close... The higher inrush current from a big-ish incandescent load (like headlights) isn't the most gentle thing that can occur to switch contacts. Between that, and the lack of arc extinguishing when you turn stuff off, you can eat up the contacts in the switch even though you aren't switching an inductive load. @ETI4K We were having a discussion some time ago and the million dollar question you didn't ask me is "OK, smart guy... Then if the headlights aren't an inductive load than why do the switches burn up like that? Huh? Why's that?"

-

Perplexing "FUEL" light malfunction

No! Own It! But I know exactly what you mean... Off quick, and slowly comes back. I'm sure you nailed it and it's just fuel sloshing onto the sensor.

-

Perplexing "FUEL" light malfunction

I bet that's just a slosh quickly dousing and cooling the sender. My DD does the same thing. I always pictured you as that kind of guy. Zed "Danger" Head