Everything posted by Patcon

-

Deja Vu: 1971 Restoration

Steve does nice work!

- 1976 280Z Restoration Project

-

73 240z turn signal light issue

Check all your grounds...

-

Project Boondoggle (or, so I went and bought a Z!)

Yeah, for short term use they don't look bad. It takes as long to figure out how to adjust the welder properly as it does to physically weld. Just remember when you add heat to a panel it expands. If you don't let it cool enough between welds it will warp or oil can. Disepyon had some good advise and pictures in his build thread. Hew went back and dollied his weld seams to make it right. You just have to learn to look at the panel and know whether the metal needs to shrink or grow. Shrinking is discing or torch and cooling. Growing means dolly work...

- 1976 280Z Restoration Project

-

New Air Cleaner

Thanks for the reply They are proud of that aren't they!!! I was thinking I could use that on my son's 510 but the back plate is already drilled so it won't work. Might look on the ITG website for some options

- 1976 280Z Restoration Project

-

Project Boondoggle (or, so I went and bought a Z!)

I thought there was some adjustment at the door but it may only be at the body. The door really needs to go in provided the gaps at the hood and cowl are good. Does the bottom of the door line up well? If I had to move the door in and there wasn't any adjustment I would take metal off the mating surface of the hinge. The face where it bolts to the body. There is plenty of meat on the hinge to allow for small adjustments like this. You could also do some dolly work on the mount surface of the frame to try to get some room. If you over drive it then you can use body shims to perfect it. When you work on the lunar surface you need to guide coat. Some cheap black lacquer spray paint or some good dry powder guide coat. Work on the panel, then guide coat. Sand with some 180. The high spots show up first. Work them down some. The low spots (where the guide coat remains) need to come up. Then repeat, repeat, repeat... If you have an area of stretched metal (if it took a pretty hard hit) you may need to shrink it. Shrinking discs work well but a propane torch also works and sometimes it is easier to use. Heat the spot some, cool with a wet rag or you can let it air cool. I always use a wet rag. It is amazing how it will tighten up a panel.

-

New Air Cleaner

Where did you source that air cleaner? Is the foam oiled?

-

SU Carb Rebuilder in FL

I agree with Mark unless you want them totally restored. Then your best options are the two you already mentioned...

-

Cody's Goon

Thanks I watched several of those videos, but the trim they are working with looks multiple times thicker than what these Datsuns used. You just don't have much thickness to work with. It has to be very close to perfect before you start removing metal or you will cut through.

-

Cody's Goon

I thought that might be the case too on whether it will rust or not. I don't know why that is but I have heard of that. I guess some of that depends on what alloy is used I sort of had the same thought. No where but up from here...

-

Deja Vu: 1971 Restoration

That car is perfect!!!!!

-

Bought # 4858

That's unfortunate, but repairable...

- Bought # 4858

-

Bought # 4858

That's great. Glad it worked out so well. If only all PO repairs were this easy to set right!

-

Cody's Goon

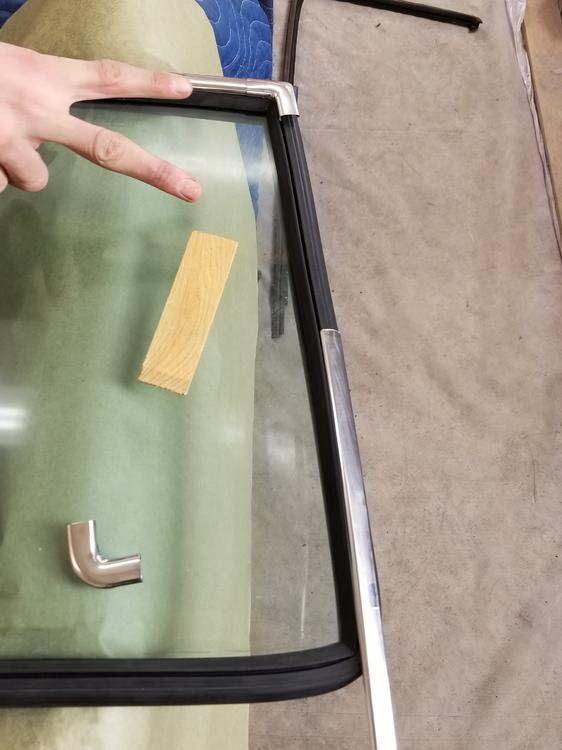

Tomorrow we will probably try to get the glass into the hatch. Hope that gets 2018 off to a good start...

-

Cody's Goon

Those are nothing but a big razor blade spinning around!!! I bought a new dual speed Eastwood buffer 1800/3600 rpm. The low speed allows you to buff plastic lenses. It also allows you to buff stuff like this at a lower speed. I should have turned it down sooner. You do have to be careful! I read on another forum that a member let a piece of trim get away from him and it basically took his nose off! I tend to avoid the 510 forums. They tend to be really course! and sometimes stupid cheap! The realm isn't too bad but Ratsun seems to be more so. Anyway I stewed over this for a while and read a bunch of threads on other forums. One of the problems is that the trim is really thin! Unlike the trim on other classic cars which tends to have some thickness which makes repair easier. So at this point I have a 10 -15 degree bend in the trim about 6" from the end. It's bent in the flat direction not the easily corrected thin direction. So I figure it's trash any way so how can I mess it up??? So we broke out the MAP gas. I had already tried shrinking the bulging area to straighten the piece to no avail. So I clamped the short end in the vise and heated it cherry red and stretched it down to straighten it Took 4 or 5 tries and I ended up with this Now these pieces are stainless so they can be buffed out. The profile of the piece is sort of like a "J" with the hook of the J going in a groove in the weatherstrip. The leg of the J lays flat over the face of the rubber seal with a metal hem on the outside edge to finish it. It is easiest to slide it in and the corner pieces act like sockets to connect all the corners This is what the repaired piece looks like now. Serviceable but not pretty. Ok at 10 feet. I will keep my eyes open for some better trim. If I had the rights tools I probably could make it perfect. You just need a trim anvil, a lot of jewelers hammer and a lot of time Much happier now. Happy New Years!!!!

-

Car worth? How much would you pay?

That's cheap as long as it's not loaded in rust!

-

Cody's Goon

Well now I'm mad!!!!! I was buffing a piece of rear glass trim for Cody's hatch. Buffer took it and bent it. I don't have the skills to straighten it... Haven't been able to even find one for sale yet...

-

Caswell Plating

Thanks Steve I will look into another one

-

Caswell Plating

Yes, I am using a submerged aquarium pump. Although it could be possible I need more agitation, but the surface of the liquid does move That is all good info. Would more current reduce the edge highlighting effect? My tank is a 5 gallon bucket with two 6" wide plates extended all the way to the bottom on opposite sides. I may eventually make a plating barrel, but it will have to wait for the next car. There were a couple of threads on the Caswell forum that mentioned getting almost a chrome look from a plating barrel but being unable to get it when hanging parts. The centers of those parts basically look unplated. That is why they didn't chromate....

- Cody's Goon

-

Lost the Parking Lights (with diagnostics)

Yes, absolutely!

-

HLS30-07848

Car was a salvage flood car out of Miami. Water probably came in through the vent tube. The sad thing is if the car got dewatered faster it would be easier. It sat at the auction for awhile before it came up for sale.

Subscriber

Subscriber