Everything posted by Patcon

-

Oil Sump OEM Gasket

I wonder if there is a good course to play in Branson?

-

Home Built Z 'Full video build'

That is super cool! I didn't know they did that. Yes, I imagine that would make it much faster and less error prone.

-

New boxes

Nope don't own a pallet jack. I have a skidsteer with a set of forks, so I doubt I will ever feel a need for one. Yes because I am so tall!!! Helps keep from bending so much and aggravating the back. the lower table would be nice for larger items or really heavy items, but I think the higher level will work better. Plus the bottom drawer is now about 9" off the floor. The finished top is about 36" AFF so, counter height

-

1971 HLS30-14938 "Lily" build

I need to get Cody a new hat. He get's some flash. My hat does pretty good at responding. What hat are you looking at?

-

Home Built Z 'Full video build'

Seems like that is about mid point for Highland machines. I saw one that was $14k USD. You need to add some of the machine details in the next sewing video. I don't really understand what the computer would do on a machine like that. Is it single needle of double needle, etc. Half of retail isn't really that crazy when you look at how good it works. I spent more than that on my welder. It's downright cheap looking if you're shopping for real estate in Sydney!

-

New boxes

I really wanted them to be semi permanent so I could pull on the vise all I want and not have them slide around. There is so little room in my shop now that there is nowhere else to move them.

-

240z Front Control Arm Bolt

same here

-

Rust Advice 78 280z

That is correct, Dave Patton

-

Home Built Z 'Full video build'

Cool. Do you care to share the brand if it's an internationally available machine? I am interested in doing some shopping for a heavier machine.

-

Free for shipping

That sounds right. I parted one a few years ago.

-

1971 HLS30-14938 "Lily" build

The wire speed might be a little bit high, but it prevents burn back like that. The gas was on but when the primer burns it makes it look like that. That was a half dozen quick welds. One time I burned through it. I had to keep moving the voltage around depending on where on the edge I was welding. I really just wanted to add enough to then knock it down. So I stacked it in different ways until there was enough there.

-

Home Built Z 'Full video build'

What did you buy for a sewing machine? What are you using as a pencil on the fabric?

-

1971 HLS30-14938 "Lily" build

Wow! Those don't look too good. Is that just a rusty glob or something else? It looks like the lense is cracked and all gobbed up

-

New boxes

It already is. It's amazing how fast flat surfaces in my shop accumulate stuff!

-

1971 HLS30-14938 "Lily" build

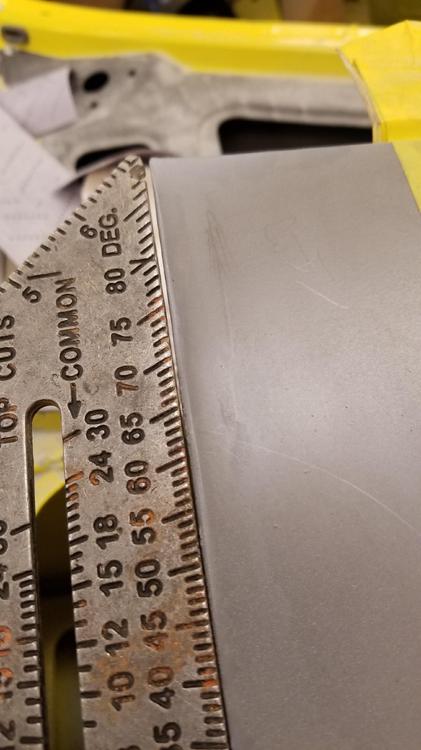

I am in the midst of blocking the whole car and doing the fine filler work. There is always another spot you missed. I am still waiting on my Australian help to arrive! I also had a problem spot on one side of my hood. My hood is a 25 year old after market hood so it has some issues. One was at the upper left corner, it turned in significantly and showed badly against the inspection door. So I added to the edge with the welder. It wouldn't looked so bad if I had stripped the primer back further Shaped it down A little short strand fiberglass to seal it up. It might need a touch of filler, but it is much straighter

-

1971 HLS30-14938 "Lily" build

I ordered these screws for the turn signal lenses Here is the finished repair on the one signal body The screws had a small plastic washer on them. I thought I would use a small rubber O ring unless there is a better idea

-

New boxes

-

Free for shipping

-

We're bringin' back the Flat Tops!

Perfect, thanks. They look really nice like that.

-

We're bringin' back the Flat Tops!

Thanks What high temp clear did you use?

-

We're bringin' back the Flat Tops!

What was the refinishing process for the front calipers?

-

Classic Motorsports Mag

I don't agree with your assertion, and I was going to write a rebuttal to your post. After having thought about it, I am not going to provide a rebuttal. As I doubt, I will change your mind and you haven't changed mine. It seems like a poor use of time to try. As well as the obvious thread jack it would be. My apologies to @7tooZ for the distraction.

-

Recoating single stage outside the recoat window - sealer or no?

Adhesion should be fine. Skip the epoxy

-

Hello

What is the air dam? It's interesting looking.

-

Recoating single stage outside the recoat window - sealer or no?

I don't know why you couldn't go right over it with color, now that it's knocked down to 400. I think the recoat window refers to running color over color with no sanding in between.

Subscriber

Subscriber