Zed Head

Free Member

-

Joined

-

Last visited

-

Currently

Viewing Topic: [2025] What Did You Do To/with Your Z Today?

Everything posted by Zed Head

-

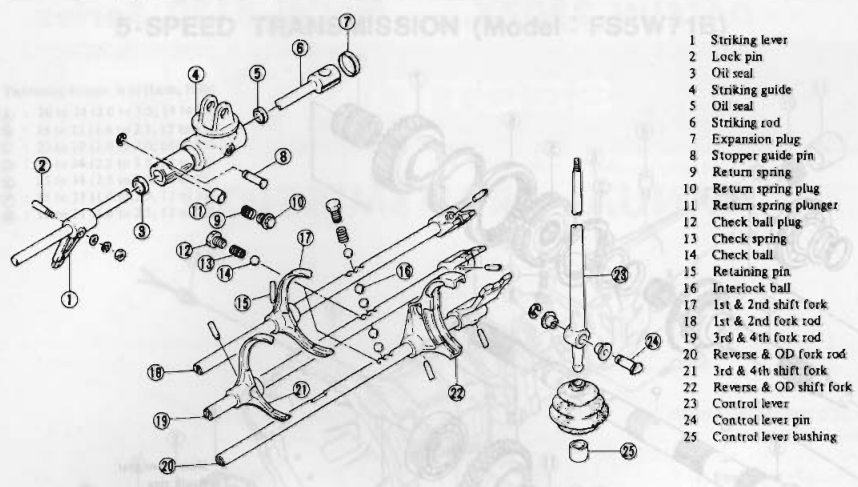

Reverse Gear Question

If it's doing the opposite then you must be seeing the other end of the indentation. Not sure how that could be unless the rod moved. But the striker shouldn't work correctly then. @zKars knows more. I'm just eyeballing the drawings and parts and moving things in my brain. You said earlier that sometimes it's difficult to get in to gear. Maybe that's a clue.

-

Reverse Gear Question

I get an error message when I try to watch the video. You might upload to Youtube and post the link.

-

Reverse Gear Question

-

Reverse Gear Question

There are detent balls/plugs/springs in the adapter plate that hold the rod in the proper position. Things would have to be way off to get the ramp in the wrong place.

-

Reverse Gear Question

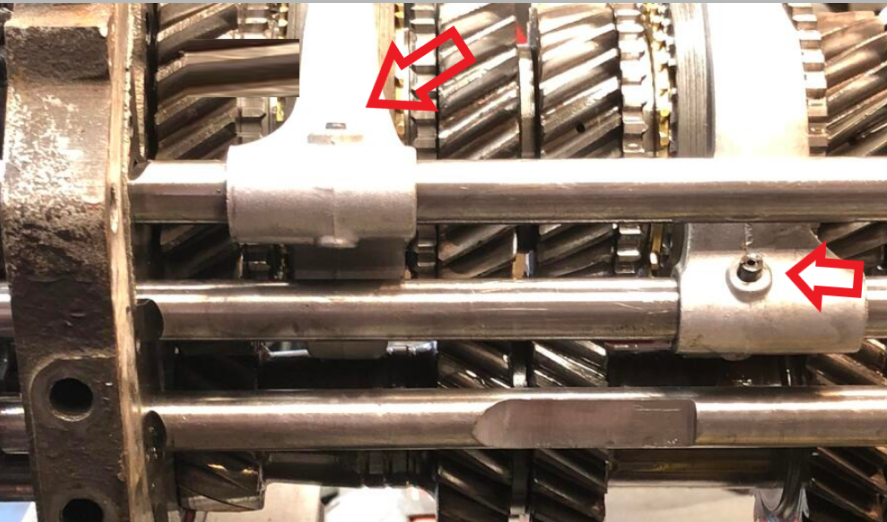

Looks like the correct hole. The switch button would sit right next to the ramp edge. Just a tiny movement moves the button. Before you start filing away at the button you could just thread the switch in to the hole partially. You could use a meter to see when the contacts close then back it off a thread. Then put the transmission in reverse and see if it works correctly. If it does then a washer or some filing should get you there. This is what you should see in the hole when it's in reverse and not.

-

Reverse Gear Question

It's not common but occasionally the roll pins that hold the fork to the shaft break or fall out. You can see them in zKars's pictures. I'm not saying that's what is happening in your case but the transmission is a very mechanical device. Gears and rods and other parts made of steel and aluminum. If it worked before and it's not working now, that implies that something moved. It might be that the switch contacts are so close that a fraction of a millimeter has caused it be on all of the time. Who knows. You could get your eye or a camera up by the hole in the transmission and see what's in there. If it still looks like zKars's pictures then it's probably the switch. Funny, but one of zKars's roll pins looks like it's working its way out... @zKars

-

Reverse Gear Question

Here are some pictures of the area of the rod that moves the switch.

-

Reverse Gear Question

Have you tried connecting the electricals with the sensor removed? It's not clear that the switch itself isn't stuck. There's not much to it. The rod has a section cut out with a ramp. The ramp pushes the switch contact point closed when the rod moves. If the switch is good the only other reasonable possibility is that the rod is moving inside the fork. That would not be good.

-

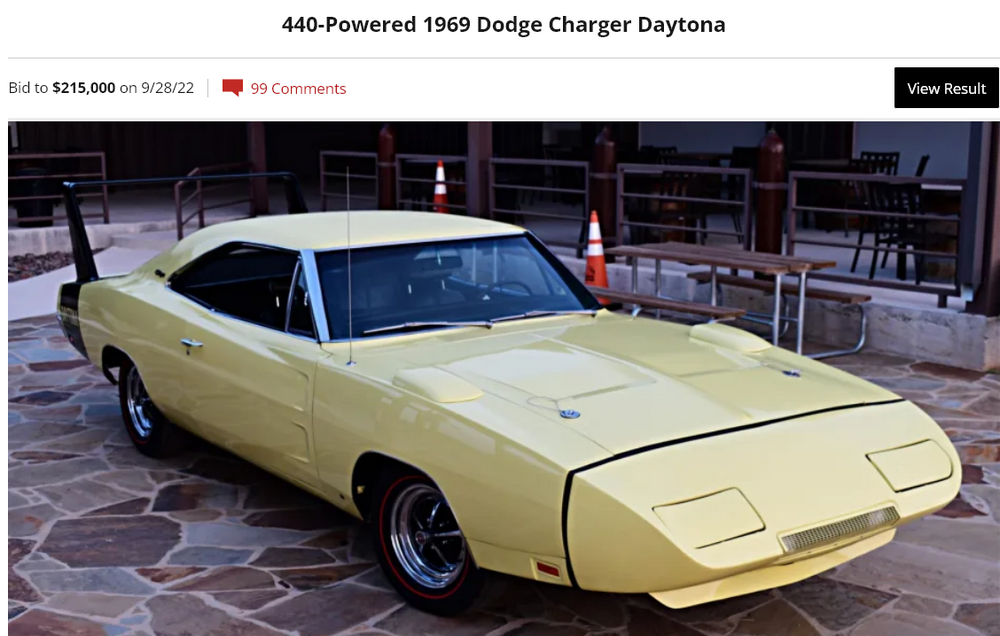

Z's on BAT and other places collection

Check out this 66,000 mile beater. Doesn't even have the original drivetrain. There is a lot of free cash floating around out there looking for a new home. https://bringatrailer.com/listing/1969-dodge-daytona-2/

-

Parts is Parts, Until They're Not

The pickup coil contains the magnet in the 280Z distributors. I think he has a 77 280Z. I'm not really sure what's inside the 280ZX "pickup coil". The magnetic material is under the stator ring. I'd guess it's just an iron ring wrapped with copper wire. https://zcardepot.com/products/distributor-pickup-coil-280zx?_pos=1&_sid=35eb01fb4&_ss=r

-

Z's on BAT and other places collection

6,000 mile, one owner probably helped. And +373 pictures over the front page images. That is a lot of money though.

-

Parts is Parts, Until They're Not

They aren't often bad. So, not really a high volume part. Probably not a large population of pickup coil buyers out there that could give an opinion. It would be interesting to know how they failed in operation. There's an air gap involved, and, of course, an ignition module, and some wires. It's not clear if a complete new distributor worked for you, or the pickup coil alone in the same distributor that other two failed in. The short answer though, I think, is no. Because it's not a common problem.

-

KONI Sports for Classic Z's

If you cut it with a hacksaw then a hand file should finish it off. We're all so surrounded by power tools now, especially those with the new high power batteries, that the old basic human-powered hand tools often get forgotten. The hacksaw was the right first choice. Minimal heat, not too much work.

-

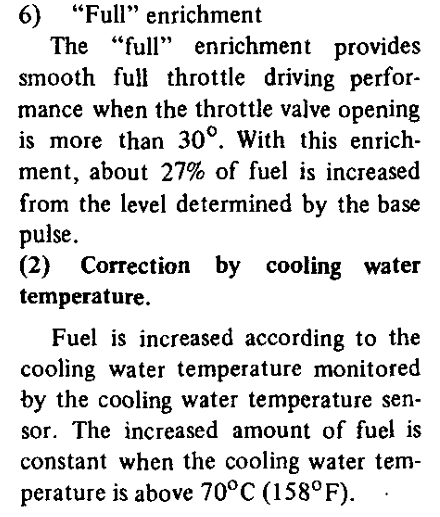

1977 280z possible EFI Problem?

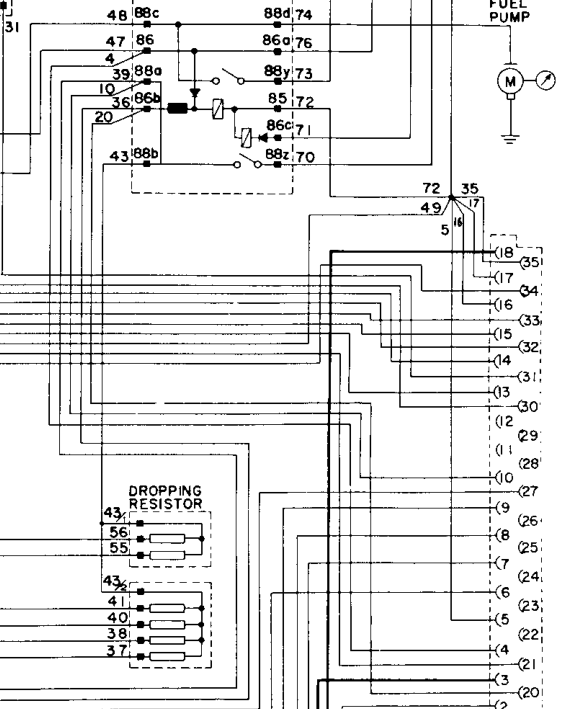

Could you describe the details of your ignition system? Do you have two pickups in the distributor? And the factory ignition module? Does the distributor vacuum advance work? Does your engine have the top gear vacuum control solenoid for the distributor? And do you have the factory EGR system intact and connected? And, have you checked the throttle valve sensor (aka TPS)? The two pickups might be switching, which would suggest a bad ignition module or a funky temperature switch. This could cause the rise and fall of idle speed. You could test this by disconnecting the temperature switch. The top gear solenoid and switch could be opening and closing the vacuum supply to the distributor. You could test this just by disconnecting and blocking the supply and driving with no vacuum advance. The EGR system has its own temperature valve but it also has a vacuum controlled valve. Might be harder to diagnose. Vacuum controlled valves can get weird if they cause engine speed to change. You can get a feedback loop going. The TVS might just be a sporadic problem. It's there then it's not there. If it gets stuck on open throttle it would add 27% more fuel than the rest of the system calls for. The distributor pickups are Engine Electrical I think, the TVS is in Engine Fuel, and the EGR is in Emissions. Read the first few pages of Engine Fuel is you want to get a better idea of how fuel is controlled, without having to read through the whole chapter. Something might fit your symptoms. Also, don't overlook just simple loose ground or wire that is causing either an open or shorted circuit. The temperature switch controlled things are susceptible to that. Here are a couple of examples from Engine Fuel.

-

Ignition Systems Analysls

Another example of a writer/"racer" focusing on writing, not racing. The dyno results are what people really want to see.

-

Ignition Systems Analysls

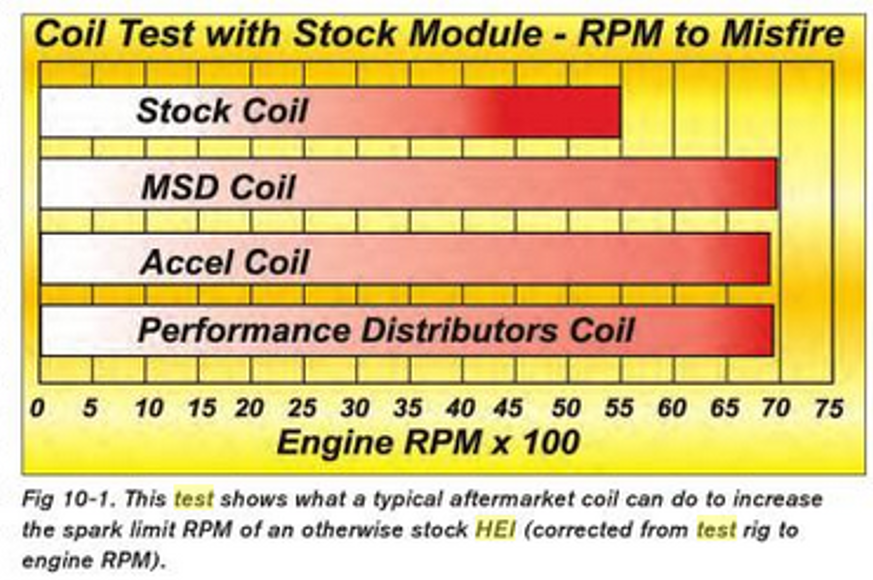

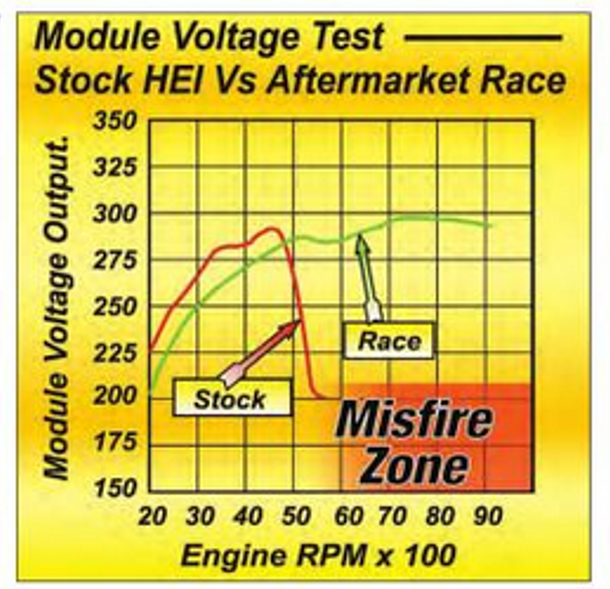

It's not a "rev limiter" it's a deficiency in the quality of the spark, according to Vizard. I remembered that I had found and copied some pages from an old article by Vizard and managed to find them again. His whole issue was that the stock HEI system's spark quality, aka voltage, dropped off too soon (for his desires). As I recall now, the reason it bothered me was that he was bashing the system based on race engine needs. Typical bench racer stuff. (p.s. actually, in looking at what he wrote, I realize that what's bothered me over the years is how this limitation shown by Vizard has been spread around the gear head world as gospel, even though it's basically nonsense for a typical car hobbyist.) In looking at the pages I even see that his "limit" was actually 5,500 RPM. His recommendations are for ways to get the RPM spark quality up to 7, 8, or 9,000 RPM. Here are a few excerpts from those pages.

-

KONI Sports for Classic Z's

Yours does not look the picture in post #1 or on MSA's web site. You said that you bought them from "Z Car"? Is that a typo? It's Motor Sport Auto or theztore.com. There's no projection on the bottom in their pictures. The part number seems different too, 29-2021. Not sure if that has meaning.

-

1977 280z possible EFI Problem?

The other thread seems to be gone but so is @siteunseen 's post that was in it. Oops. The test for the sporadically bad ECU problem is to bang on it. I don't think that it will show up from the Nissan test procedures. It might show up on a scope if you had one. That's the big thing at the small repair shops on the Youtube channels, they have scopes that they can take with them as they go for test drives. Pretty cool, but takes some money and know-how.

-

1977 280z possible EFI Problem?

The richness and erratic running kind of fit what's been reported for a failing ECU. I had one fail as I was testing it, but it just died completely as I was road-testing, then restarted after a few seconds. It did this about three times before it wouldn't restart as I tried to get home. I was about a mile from home. The exhaust smelled like fuel as I tried to restart it at the end. I ran home and got the original and the engine started right back up and was fine after that. Anyway, short answer, people have had luck diagnosing it by banging on the side of the ECU or wiggling the wires to it as the problem is happening. If the problem clears up then you know it's in the ECU. Apparently the problem is caused by broken solder joints. People have had luck reflowing them, I didn't try on mine. p.s. since the "problem" is fairly common it can be defined as an "issue". That's just how words work. "The issue under discussion is the common EFI ECU problem". https://dictionary.cambridge.org/us/dictionary/english/issue

-

tachmeter bulb replacement

Not sure how a light emitting DIODE can not be polarity sensitive. It's part of the definition isn't it?

-

tachmeter bulb replacement

Not really sure what you're saying here. There is no flasher on the tachometer bulb circuit that needs current to work properly. Id' guess that you have a contact problem.

-

Ignition Systems Analysls

That would be one question. Then there's the supposed 4500 (V8) RPM limit for the HEI module (which would be 6000 RPM for a 6 cylinder). Others might be "does the broken magnet in a ZX distributor cause it to stop working?", "what difference is seen between a 4.5 amp HEI module with a 0.6 ohm coil (factory setup) versus a 7 amp HEI module (Pertronix and others) and 3.0 ohm coil?", ... and on and on. Ideally, I think, you'd be driving a real distributor at a known high RPM. Then there are the other odd questions, like "why does a GM HEI module work as a replacement for a 280ZX turbo ECCS "ignitor" (power transistor) when there is no zero-crossing?". Is the 123 ignition module current-limiting? Is an old Ford ignition module similar in function to the GM HEI module even though it's designed for a Hall Effect signal? You could also get in to the heads of the engineers and explain why they changed the triggering mechanism from the single reluctor to the six point reluctor. You touched on it in a past post as giving a higher cranking voltage. I thought that it might also give more consistent timing cylinder to cylinder, because it averages all of the points in to one voltage pulse. People have found that the 280Z type reluctor wheels have enough variation between the points that the timing varies between cylinders. On the high performance engines it can cause problems. It's all interesting.

-

Improve cold start time?

-

70 240Z, metallic clang clang clang on acceleration, worse when cold.

The exhaust system is bolted to the transmission. Seems possible. "clang" is not much to work with. There is also the bushing in the tail shaft housing. You might grab the propeller shaft and see if it's loose.

-

Improve cold start time?

I see only one start. Have there been more? The conductive part of the relay is affected mostly by the contact points. Not really clear what you cleaned up. Did you take any pictures? And you reported zero after, but no number before. How much resistance? And, to be be picky, the relay would have to be actuated in order to measure the resistance to the components that get the power. Through the relay circuit. Just saying, it's hard to tell what you did. (p.s. it's "lo".)