Everything posted by Zed Head

-

Differential breather leak

The minutiae is the most interesting stuff... I think that there might be two different breather types. The text below is from the web link shown. The breather on my car was pointing sideways. I think it may have "walked" its way around after a few million heat cycles. http://www.carpartsmanual.com/datsunS30/PartNumberDetails/tabid/1848/Default.aspx?PartNo=38352-78600&SectionNo=088B&KeyNo=10 Section 88B Key# 10 Datsun 240Z/260Z/280Z Differential Gear, Pinion & Cover (R200) 38352-78600 BREATHER Model code: C30-SUT Newer part numbers: Older part numbers: 38352-78500 Part No. Model Applied Date Qty Ica Superceded From To N F BREATHER 38352-78500 - 7510 1 38352-78600 7511 - 1 38352-78500

-

Is this rear suspension part bent?

Show a picture of your differential housing, from the back. Maybe someone hacked an R200 in there. I don't have a 240 but that looks abnormal to me.

-

Need 82 280zx Gas Tank Any ideas where to find one?

I was browsing through this place two days ago - http://www.picknpull.com/locations.aspx?View=Detail&ID=119&ClusterID=5 - and saw three 280ZXs that weren't listed on their web page. One was an 82 or 83 (late 82 build date), I think there was an 81 and I don't know the other, someone was taking the five-speed out so I left it alone. I asked the guy at the counter why they weren't in the inventory and he said that some cars just don't get listed right. You might have to go there, since they won't be able to see it on their computer. It might be worth a drive.

-

Exploded Schematics for Zs Online

I just found this interesting site that I have not seen before. Worth a look, the menu is on the left side. - http://www.carpartsmanual.com/datsuns30/DatsunFairladyZIndex/Engine280Z/tabid/1545/Default.aspx Of course, 2 seconds later I stumbled over the atlanticz site - http://www.atlanticz.ca/zclub/techtips/explodedviews/280z/index.html Good views of things you can't really see like the door lock mechanism and window regulators.

-

Differential breather leak

Mine too is slowly covering the back of the differential housing with oil. Luckily, the dirt stops it from dripping on the garage floor. I wonder if a piece of sponge or cloth or maybe a plug of Scotchbrite might stop the splashing, but still let it breathe. I've never had one off so don't know what's inside but have to assume that the leak is oil getting splashed up, probably in a fine mist form, in to the vent where it can then dribble out and down the differential housing.

-

Weird noise ?

Bees can't fly faster than 50 mph. Have you been underneath to look around? If it's RPM independent then everything from the tail end of the transmission back should be looked at.

-

E12 vs Pertronix

Wow, I guess you get what you pay. I've not used either so can't speak to reliability. That's good information. Side note re money - the E12-80 uses the VR trigger so you could retrofit to the very inexpensive GM HEI module in the future, if you had to, with some wire splicing and a little fabrication.

-

E12 vs Pertronix

You might compare the costs of the two modules. I think that you can get the new Pertronix kit for about 70% of the cost of even a cheap O'Reilly's E12-80 module. The junkyard would save some money on the E12-80 if you can find one, or you could spend a lot more for higher quality. Up in the 2's. Besides that, the big plastic E12-80 "matchbox" won't polish up very well.

-

'76 280Z Question on dist/manifold vacuum, dist timing, fuel pressure, brake booster

That thing I tried to draw an arrow to is a rubber plug. Underneath it is the idle air adjustment screw. You'll probably need a small screwdriver or an awl to pry the plug out. It is about 1/2" tall. I'm just pointing it out. I don't know if you'll want to mess with it or not. If you're trying to get things back to stock performance, you probably want to leave it alone for now.

-

Need 260Z Distributer Info

Here is a way to test that I have seen in various places, including on this forum. It's from a writeup on converting to the GM 4 pin HEI module. I cut out the install portions,but you can read the whole thing here - http://www.sonic.net/~kyle/hei.html - if you want. Date: Sun, 12 Mar 1995 19:49:02 -0800 (PST) From: Andrew Levy <allevy@violin.aix.calpoly.edu> To: Z-car <z-car@CS.Princeton.EDU> Subject: ignition - HEI Mime-Version: 1.0 Sender: snd@CS.Princeton.EDU Precedence: bulk ..................... First you need to determin the polarity of the wires going to the distributors pickup. Some have a red and a green wire, the red is the positive. If you have one with two green wires or you can't tell what color they are you will need to test them. This can be done by rotating the dist. shaft the same direction as it would be turned by the engine and use a volt meter to establish the polarity. This system generaters AC current so look for a positive reading when the raised portion is approaching the pick up and negative when it departs. You could try to establish the polarity by starting the engine and use a timinglight to check each combination, the one that gives you the most retarded timing should be correct. ................

-

Need 260Z Distributer Info

The red wire coming off the distributor should be the positive one. I've read that you can hook them up backward but your timing will be off and will jump around a lot, because the triggering point will be incorrect. If so, just switch the wires and the timing should steady and go back to the proper range, where it was before you started the swap, assuming that you have not moved the distributor body. Hopefully for you, you will have a red wire. I have seen some pickup coils that have been spliced to have two blue wires, so you might have to trace the red one down from the pickup coil in the distributor.

-

Interesting 280ZX on Portland CL - Might have extra benefits

Saw this yesterday - http://portland.craigslist.org/clk/cto/2132183103.html Text from the listing - 280z 1980 - $600 Date: 2010-12-27, 10:18PM PST Reply to: sale-zwtre-2132183103@craigslist.org [Errors when replying to ads?] CLEAN TITLE BROKE UP WITH MY BOY FREIND NOW I HATE THE CAR. 360-772-0926 * it's NOT ok to contact this poster with services or other commercial interests PostingID: 2132183103

-

My Car Won't Turn Off

I don't think that your problem is related to the original 2002 post, unless you also removed some jumper wires so that you could plug the old regulator back in. Was the old regulator plugged in before you replaced it? If it was, then your mechanic might be right. The key can be removed from the ignition on these old cars, in any position. Why did you feel the need to replace the regulator? All of the ZX alternator upgrade write-ups described leaving the old regulator unplugged, most suggest removing it. You can't follow the instructions AND end up with the old regulator plugged in to the harness. It would be odd if the car would run with an internally regulated alternator running through an external regulator. I can't say it's not possible though.

- Creaking and Groaning in passenger rear quarter

-

Adjusting Valve Lash (Clearance)

One advantage to doing them cold first is that many, maybe even all of them, will be in spec. when you check them hot. If they are in spec. you don't need to loosen the locknut, just move on to the next one. You will end up only actually adjusting a few of them hot.

-

Car won't start!

Make sure that your voltage regulator is working. Your 260 should have an external regulator unless someone has switched it to an internally regulated alternator. You can probably have it checked at an auto parts store (take the new alternator in with it to confirm it's not damaged) or measure voltage at the battery while the engine is running.

-

wich engine should i keep ?

Good work. An L24. Is that the engine in the car or the extra? That's one, what does the other engine show? Back to your original question - it depends. I would use the one that is in the best condition, if i was trying to save some money. Or the L26 if I was looking for more power. What are you trying to do? Good luck with the project.

-

wich engine should i keep ?

mike260z, it says on the page that you linked, that the P30 was used for both the 240Z and 260Z. Arne's suggestion gets right to the best way to find out. It is stamped on the block. Right above the starter, a flat spot. You might have to scrape some grime off to read it.

-

wich engine should i keep ?

I am not an expert in this. But these two web pages suggest that the motor in your car might already be an L26. Apparently the E88 head was used for the 260Z also. http://datsunzgarage.com/heads/ http://forums.hybridz.org/index.php?showtopic=62691 Here's one more, with block data - http://datsunzgarage.com/engine/index.htm

-

amp gauge to volt gauge questions

This thread jumps around but has some good info about deleting the amp gauge and 240Z wiring in general, late in the thread. http://forums.hybridz.org/index.php/topic/96568-alternator-question/page__pid__910910__st__20#entry910910 The wiring diagram for a 78 should help you get the voltmeter in, since it used the internally regulated alternator and a voltmeter. The diagram should show you connections all the way to the alternator.

-

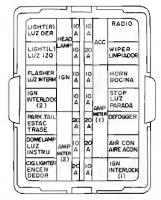

Fuse Box

-

Losing Faith

It's looking more and more like timing, either the distributor is off time or the plug wires are off. Sledge, I have found that, in general, if you can line up the two lines on your distributor housing, that your timing will be close. The marks are right next to the adjustment screw/bolt. You'll know what I mean if you look down there. It is also possible to put your distributor in 180 degrees off, although it does not seat very well. If you could get the engine to Top Dead Center and the timing mark at zero, and pull the distributor cap, the rotor should be pointing almost straight ahead. If not, you have timing issues.

-

Losing Faith

Sounds like either fuel or timing, or both. Did you mess with anything else while you were trying to get spark? FastWoman offers a simple, effective test to see if timing and spark are correct. Buy or borrow a can of Starting Fluid, spray some in the manifold and crank it over. You could spray it through a vacuum line if you don't want to pull the big hoses in front of the AFM. Or pour a little raw gasoline in there. If timing and spark are close, it will rev up for a second or two, before dying again.

-

Losing Faith

What was the problem? Details please...

-

Losing Faith

If that is the case, then they probably just deleted one of the BW wires along the way, getting closer to the 1978 version. But back to the reason for failure - did you determine why the first one failed? If your alternator is spiking out high voltage occasionally, it will toast a module immediately. If you had a cause for the first failure and did not find it/fix it, you might have just wasted another. A bad ground at the module can waste one also. You weren't really clear on when the 20 minutes, then no start happened. Was that with the first one that failed, now you have a new one that has not worked at all? Or did one fail, then the new one ran for 20 minutes, now no spark. It sounds like you were diligent with getting the right part and connecting it the same way. You should probably go back to the original problem when the first one died and see if you missed something. Time for Christmas lights...