Everything posted by Zed Head

-

strange issue with 78 280z running - I'm at the end of my rope!

If I had a stock system and was looking to buy new injectors, I would get Standard brand, either the FJ3 or FJ707T. (Rockauto has good deals. Data is sparse but they might be better for heat soak than others. Before you buy though, since you're going to take things apart, you might leave the injectors connected to the rail when you remove them (they'll come out as an assembly), reconnect or leave connected the fuel hose and electrical and squirt in to some containers for a short time ( use small coke bottles). You'll get an idea of how unbalanced the injectors are. Do it outside though, with a breeze and no open flames. You should notice if #5 is totally dead. The engine will run a little rough and the spark plug would be dry or oily, but different from the others.

-

strange issue with 78 280z running - I'm at the end of my rope!

It's not how long the engine has run, but how much current is running through the module that heats it up. High RPM passes more current through the sensitive parts as it generates more sparks. High RPM, heat, weird behavior, turn off engine, cool down, back to normal.

-

280zxt timing

You never said which turbo engine management system that you're using, but I assumed 1983 280ZX turbo since you said 24 degrees timing spec. Your sig says 1972 240Z, so you're probably working with a turbo swap in to an older car. Now you have a different TPS. What exactly are you working with? Did you test the TPS circuit at the ECCS plug, or at the TPS itself. It's always best to test at the plug first so that you know what the information the ECCS or ECU is getting.

-

strange issue with 78 280z running - I'm at the end of my rope!

Good luck. There are so many components that work together, that "close enough" just doesn't work very well. You'll end up adjusting something else instead of the actual problem. The best method is to make sure that everything is exactly as it should be. If you report numbers in your posts, instead of looks good and checks out, you'll probably realize that the numbers aren't quite right. An ohm here, a psi there, a small vacuum leak...the tiny things add up. If you find yourself deciding to adjust the AFM spring, make sure you mark your starting point. So you can go back. On the ignition module - often they don't fail completely. They show signs of failure, then come back to life when they cool down a little bit. So, spark testing won't tell the whole story. Watch the tachometer needle next time it cuts out and starts bucking. The tach sees what the module is doing.

-

strange issue with 78 280z running - I'm at the end of my rope!

You said everything checked out but you're reporting fuel pressure that's 10% too high. The proper number is in the Fuel Injection Handbook and the FSM. High fuel pressure will cause things to be rich. With the potentiometer, you have rich on rich. The cutting out sounds like a problem with the TPS. Did you wash the engine recently? They get wet and do what you're describing.

-

over night battery dies

short in alternator

-

280zxt timing

The distributors are not the same, at all, between NA and turbo. My point was that the ECCS controls timing. And that it only advances timing, which is what you want, when the TPS indicates that the throttle is at idle or the engine is cold. I would get in to the FSM and check that the TPS works right.

-

280zxt timing

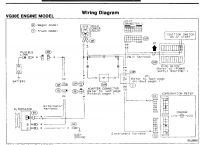

Nissan really did assume the system was perfect and would never need adjustment, apparently. Maybe it has something to do with a switch the ECCS uses. Picture attached. Throttle valve switch not showing idle?

-

Distributor Breaker Plate Parts Picture - In order

I stopped by Harbor Freight to see if they had any clamps that would fit the breaker plate and came away with one that worked out great, a 2 1/2" nylon spring clamp. Three required, $1.29 each. Just enough force to push the spring down and expose the slot for the circlip. Still takes a little adjustment since the bearing holder wants to get stuck in the slot too, but it's cake compared to trying without it. There may be other ways but this worked for me.

-

Making Fusible Links

If you prowl the salvage yards you'll see many fusible links on pretty high-end luxury cars, like BMW's, up in to years in the (edit - not sure of year)s. And if you're familiar with home fuses, you'll know of "slow-blow" fuses, used to take a surge so that fuses don't blow unnecessarily. If they didn't look like scabbed-on backyard fixes even when brand-new, people would probably be fine with fusible links. And it they rated them by current flow, like a typical fuse, that would help too. But, instead, they're ugly looking, confusing scraps of wire. Unfortunately, even if you want to swap to fuses, yous still have to calculate the desired upper limit for current on the circuit. Just one of those primitive things that has stuck around, like the AAR valve.

-

Swell!!....

My original tach would "hang high" when it got hot in the car. 1976 280Z. Mid-summer, after a long drive, it just wouldn't come back down, it hung at around 2500 RPM, I think. After everything cooled, it went back to to normal. I got tired of it and swapped a 1978 tach in. I don't really understand how these tachs work, so couldn't even guess on a cause.

-

Distributor Breaker Plate Parts Picture - In order

No, the plastic bearing holder was intact. That's the only reason I took the time to take it apart and clean it up. I had to pick through some old ball bearings to get three that weren't rusted. I know what you mean though, I've had a broken plate. I guess I haven't seen a newer rebuilt distributor, I haven't seen that new piece. I haven't seen that many distributors though, just a few I've picked up here and there.

-

Modern injectors, new fuel rail - no heat soak problem

We just finished a mini-heatwave here, broke some records, temps in the 90's and high 80's, and I've been driving all over the place, parking, shopping, doing stuff, and no sign of heat soak. Still unclear if it's the injector change (Bosch 280 150 901 or Standard FJ707T), the aluminum straight-shot rail, or a combination of both, but there is hope. Just a follow-up as summer arrives, for those heat-soak sufferers.

-

Distributor Breaker Plate Parts Picture - In order

I just refurbished an old breaker plate and took a picture of all of the pieces laid out in the order I took them off, in proper orientation, except for the bottom spring plate bearing holder, which is upside down and opposite the way it would go back on. But it's obvious how it fits when re-assembling unlike some of the other parts. I spent more time trying to get the circlip back in place than anything else. I'll devise some sort of jig before I try to put another one back together. Just posting for the record for those who get disoriented while taking it apart. I always do.

-

Intake / Exhaust Gasket which I can cut to match ports

I'm almost positive that the Fel-Pro gasket is all organic. People call them paper gaskets. You could probably go to your local parts store and eyeball one, they are the common gasket. They do seem to require freshly machined flat surfaces to seal well though, whereas the MSA and Victor Reinz gaskets are thicker. I've used a Dremel tool on both the Reinz and MSA to fit to a stock manifold and head. They didn't fit the ports quite right on even the stock parts.

-

Making Fusible Links

Probably just the insulation.

-

Swell!!....

Get a piece of stiff mylar film and make a cone around the face of the tach. It will act as a ramp to get over the edge of the dash cap. It will probably take some real pushing from behind. I had trouble just getting mine started moving when I recently removed it, the original dash had molded itself around it. Even though I had it out a couple of years ago. This is without a dash cap.

-

Serial Number _vs_ Factory Service Manual Information

Whoever did us all a huge favor and copied all of the FSM's, for whatever reason, did not break 1977 in to chapters. I'm definitely not complaining,there would be many fewer Z's on the road without these documents available on the internet. So you have to download the complete 1977 FSM in one shot. The first link below will download and open the file on your computer if you have a PDF reader, like Adobe, in one shot. Very slow download. The second link will download a zipped file, that will need to be unzipped. A faster download but you need an unzipping program Index of /FSM/280z/1977 XenonS30

-

Internally Regulated Alternator Sense Wire

Considering the speed of electricity the only thing that should really matter is that there is no voltage drop (resistance) between the S wire and the feed to the loads. The main problem with the positive post connection, opinion, is that it is typically somewhat dirty and corroded, and has an extra interface between the wire end and the other loads. That's why I moved all of my stuff off of the battery, and just a ran smaller wire to the battery to charge it. I also ran my negative wire to a modified connection (a metal strap/plate from the starter bolt) though so that I could disconnect the battery without touching the posts. Battery posts are a pain in general. Edit - as of 1995, Nissan was running the S wire almost to the battery post, or at least one connection point away from the alternator. Notice which side of the fusible link the junction is on, it's not actually at the battery, but it's still almost connected directly to the charge wire at the alternator. Edit 2 - Forgot to say that one thing that I always consider when looking at how the manufacturers put their cars together is that the cars are designed for efficient assembly. So what you see may not be the best way to do things, just the best compromise.

-

L24 head swap question

]Word is that the valves might nick the edge of the cylinders, if the cylinder edges are not relieved where the valves pass by. Also, there are, apparently, several different versions of the E88 head. You would want similar combustion chamber sizes to get a similar CR. Why do you want to swap heads?

-

Internally Regulated Alternator Sense Wire

Weird that I saw that same exact S wire connection in a wring diagram the other day and wondered myself, again. There are discussions and recommendations around the internet about where to put it. The one I like, that seems to make "sense" is to attach it in some central location to all of the various loads. Consider the battery to be a load, not a supply, since it is a load on the alternator once the engine starts. I ended up attaching mine to the starter lug for while, which is where the charge wire ends up after feeding the fusible links, and recently moved all of my loads, from the starter lug and the positive battery post, to a central one post attachment point under the relay bracket, and attached the S wire there too. I did have the S wire attached to the battery post for a while but it seemed to make my voltmeter jumpy for some reason. This on a 76 with the alt swap so I had the dilemma you're describing.

- Serial Number _vs_ Factory Service Manual Information

-

280z electrical issue NEED HELP

Download the Service Manual for your car and check the Body Electrical chapter. Google the term "280z fusible link". Get a multimeter and start using it. It's the best way. Don't assume anything unless you've confirmed it with the meter, many parts get replaced for the wrong reason. Datsun Service Manuals - NICOclub

-

1978 Datsun 280Z Air Conditioner Question

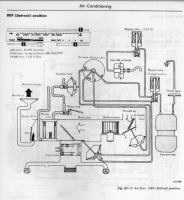

On the 76 those two heater doors are mechanical. The 78 diagram seems to show the same. You can see if they're open or closed by eye, and manipulate them with the engine off, just move the lever from Defrost (closed) to any other setting (open). Do you have the little knobs in the center of the vents pushed in to open them? And are your hoses still connected. Mine are old and inflexible, fit poorly, and get knocked off easily if I dink around under the dash. I've had my carpet get stuck in the doors and keep them open. It's cramped down there. Edit - used the Snip tool (a pretty cool gadget) to add a picture.

-

Modern injectors, new fuel rail - no heat soak problem

Thanks for the addition. The pressure leak-down could be a factor. Is your FPR lower than the rail or higher? Siteunseen's look higher in his pictures, which would just blow vapor past the FPR, leaving liquid behind. If the FPR is low, then the liquid gets pushed out, leaving the rail dry. Just working on the heat pipe/heat pump/"cooling coil" theory. The other difference might be the injectors. I did a little internet work and find that the four hole injectors that I have are called "multi-hole" type and the stock and the Bosch are "pintle". The Standard FJ series appear to be their own design, a variation on the Bosch design, according to their web site. Maybe the internals of the injector are a factor. Posted a couple of links below. The SDS description does not match the Bosch diagram for the multi-hole. Not positive what's inside my 280 150 901 injectors. I removed my cooling fan completely the other day. No more reaching under the dash to turn the timer on. My obsession with heat soak is diminishing... Nice metal work. I assume the new rail is of similar shine and detail. Tech Page Injector Spray Styles - Tech Corner Standard - Fuel Injectors