Everything posted by Zed Head

-

Remove my l28

Step #1 - get off of the LGLS770 and communicate normally. Tapatalk won't cut it.

-

To machine or not to machine (flywheel resurface). That is the question

It's been noted before that the 225 mm stock flywheels aren't available. I know a local shop that had a few in inventory a while back. Somebody on eBay might have one. But apparently nobody is casting them anymore. One more NLA part. I have a small collection of used ones that I think will last me. You might try the wrecking yards for used.

-

HEI Upgrade not working on '78 280Z

12.2 volts is ~ 50% charge. 11.8 is essentially dead. Get a good charge, start over and see where things are. 12.6 or higher is about full charge.

-

HEI Upgrade not working on '78 280Z

It sounds like you're saying that after it started and ran, then died, that after that it never started again, and that now when you turn the key to Start, you hear a noise from the starter that sounds like it's spinning. When you turn the key to Start and hold it do you hear a spinning noise, constantly? Or does it make a nasty noise, you let go of the key, and it makes a spinning noise? I'm thinking that your battery might need a charge. Check voltage on the battery and make sure it has a full charge. You can get misdirected when the odd things happen. Voltage should be 12.6 or higher.

-

HEI Upgrade not working on '78 280Z

No, that's bad. Sounds like the coil is grounded all of the time. Either through a bad module or incorrect wiring. If you turn the key off you'll find that the coil negative terminal has continuity to ground. Something is shorting power to ground all of the time. It does explain the "no-spark" though.

-

To machine or not to machine (flywheel resurface). That is the question

Monroe describes looking for heat-checking, and sanding and cleaning if there is none and the surface is flat. It worked for me. If you use a hard block when you sand, the sanding pattern will give you a good idea of the quality of the surface. A good consistent pattern can only be achieved on a flat, non-heat-checked surface. I like to use a flashlight behind my straight edge to see how flat a surface is. Just a trick that works. My first flywheel had a visible wear pattern shown by a straight edge. I sanded it and used it anyway and it gave me chattering problems when it got hot. I don't know if the it was the flywheel or the clutch. It was a Zoom Perfection clutch kit. My second one was perfectly flat by straightedge and worked fine after sanding and cleaning, with a new, different brand, clutch kit. Rhinopac brand. I like to experiment though so take that in to account.

-

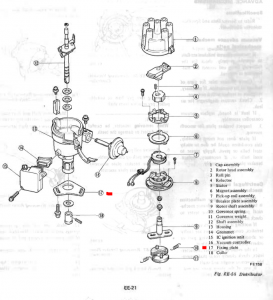

1979 280zx distributor Fixing plate needed!

I think that he needs a different piece. He actually went and found the exact Nissan name for the part. Unusual. Apparently the remans don't come with it. Pretty sure that you posted a picture of the varieties of this part in the past.

-

Redwing's Car - An Update

I wonder if raising the idle speed slightly would help. The rich oily fuel air blend might be too much for a cold engine. As I understand things, on the dual pickup ignition systems there are two things that keep the idle speed up when the engine is cold - the AAR and the second pickup. The AAR stays open for just a few minutes, but the second ignition system keeps the timing advanced until the engine warms up. Which could take about 20 minutes. Advanced timing increases engine RPM. Anyway, it might be worthwhile to increase idle RPM a couple hundred RPM. Turn the screw circled counterclockwise. You can actually do it by hand some times. Stole a picture from this link, post #4 - http://www.classiczcars.com/topic/37021-no-idle-screw/

-

Redwing's Car - An Update

Sorry to hear about your dog site. If I remember right she's the one that leaned forward in anticipation of your shifts when riding along in one of your Z's. That's a special skill, hard to replace.

-

Cleaning valve cover question?

You're cleaning the inside of the valve cover? Not the top of the head? Mineral spirits should work. But a can of carb and choke cleaner would probably blast the crud out and dissolve the varnishy stuff. That's what I'd use, just for ease of application. Seems better to me. Don't get the carb cleaner on any painted surfaces though. It's a potent solvent.

-

HEI Upgrade not working on '78 280Z

You can get a new module for ~$20 at OReilly Auto. They do go bad (I've had one), maybe that's why the Regal was in the yard . If it doesn't fix the problem, at least you'll have a spare. But do #6 first. It will test everything before the module. And you don't need a spare spark plug (in case you don't have one handy), you can just place the metal end of the HT lead ( the center coil wire) close to a ground and look for spark. Each time you tap the jumper from the coil (-) to ground you're doing exactly what the module would do. Each tap to ground should cause a spark from the coil's center wire. If you get spark that way, the module should be able to do the same.

-

Redwing's Car - An Update

She has a 76 with the lower energy ignition system. You might be thinking of 78 and on. Spec. for 76 is actually .031 - .035" so it was on the high end. I looked back through the original thread but can't find anything about miles on the engine. My 76 had high miles and worn valve seals and burned some oil at high RPM. Those plugs seem pretty black and the fact the engine ran very well but you still ended up with black, wet plugs, after just a few miles with the new plugs seems to indicate some oil leakage in tot he cylinders. I can't recall much at all either, about the general state of the car when received. Maybe it's a high mile car that sat, or a low mile car that sat, or a high mile car that was a daily driver. The first two could cause a little rust in the cylinders that might wear in to shape, the last would mean it just is the way it is. Someone mentioned Italian tune-up a while ago, I think. Maybe it just needs some good road runs to settle down. The daily warm-ups and mail box trips though, might not be enough to keep it in good shape. They like to run.

-

HEI Upgrade not working on '78 280Z

And, since I'm here, before I sign off, might as well mention the distributor. If you have power to the coil and the module is right, then you should get spark. The distributor is connected directly to the module and will make it trigger if it's right. There are several things to look at there, easy to do. There are just so many small things that you could confirm are right, if you use the meter and work through the tests. There's a flow chart in the FSM. Super easy, and it's the only good "process of elimination" to use.

-

HEI Upgrade not working on '78 280Z

Just to draw out another detail. Clarity on what exactly is happening will help a lot. You've lost the buzzer and, apparently, some other things - "like the ignition isn't even being turned on". But 12 volts at the coil only happens when the ignition is on, so that statement is a little unclear. Also, you should measure both sides of the coil. It will tell you if there's continuity through the coil circuit. You should see battery voltage on both + and -. Anyway, the answer's there somewhere. Diagnose first, fix second.

-

HEI Upgrade not working on '78 280Z

I think that you might be wrong. Some basic troubleshooting with a meter should find the answer. Although, a sketch of the wiring would tell if the module should work. Some of us have pondered the 280Z ignition systems far too deeply.

-

HEI Upgrade not working on '78 280Z

First, you need to show us how you wired it. Did you follow Eurodat's guide? He installed his the way that you did. It is possible. But no guesses can be made without knowing exactly what you did. At least make a list of the wire colors and where you attached them to the module. Second, have you confirmed that you have the basics, like power to the coil with the key On? Third, did the seat belt buzzer work before? If it did, you might have blown a fuse or a fusible link. The seat belt buzzer shouldn't have anything at all to do with the ignition module. So that might be a clue that you bumped or shorted something.

-

Somebody go get this- 1974 260 for $200

Marysville, WA. Where's Rossiz?

- Disc Brake Options for 280Z: best street package value

-

Disc Brake Options for 280Z: best street package value

Here's something from a guy who seems to know what he's doing. He did a nice writeup on the "bellhousing' swap for the 71C - 71B 5 speeds. He put a lot of thought into it. Nigel. http://forums.hybridz.org/topic/113199-yet-another-rear-drum-to-disk-conversion-option/?hl=%2Brear+%2Bdisc#entry1060325

-

New 240Z owner!

The race guys say that the best way to stiffen up a Z body is with a roll cage. You might consider that if you're just looking for resurrection and not restoration. Use the cage as the central structure, like a tube frame. Or just build a hybrid tube frame/monocoque chassis.

-

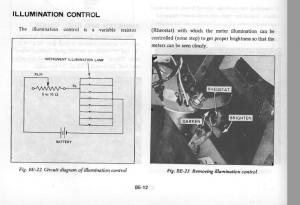

dimmer question

-

Not Z stuff - Internet sites sharing your email address - for the web gurus

Realized that Monster screwed up and that I was just being paranoid. I had clicked "send me similar jobs" on Monster for a single job description and instead of doing so Monster sent me a bunch of "finish job application" notices. The old "bait and switch", still alive, but with modern technology behind it. I'm running Google Chrome in Incognito mode so the Firefox stuff won't help. Thanks though. Pretty sure though that as fast a blockers are developed, ways-around follow. I still get videos that play automatically even though I have every possible blocking tool I can find loaded.

-

Redwing's Car - An Update

These engines will actually run really well with a rich mixture. So the new tune and clean that was done might still give a great running motor, but still give dirty plugs. (Edit - meant to say that a bad pump and rich running may not be related.) Plus, mailbox trips tend to not warm the engine up completely. Not a criticism, just a reality. Anyway, it turns out the plugs are still from when it was running poorly. I've kind of ignored the odd details and focused on the engine dying. That's the biggy. You can ramble around the country-side with a lean condition causing poor throttle response, or a rich condition causing watery eyes from the gassy smell, but engine dying tops them both. As many of us know, these engines will run very poorly for a long time, without dying. Engine dying and not restarting is unusual. Too bad about the tachometer. It's a good diagnostic tool, but they do go bad. I have a 78 tach in my 76. My 76 tachometer started hanging up when it got warm. I think that you're right about the EFI glitch causing the short-term stumbling while warming up. The AAR keeps RPM up for a short time when cold and if it closes a bit early there won't be enough air for the engine's temperature for it to run well. I wouldn't worry about it now, as part of the big problem. If it's consistent, you can just live with it while trying to figure out the dying issue.

-

Redwing's Car - An Update

This is from way back in the thread. It seems like the original problem is still there. I would venture that there three things that might cause the rough-running then dying. Bad ignition module - usually happens when the module gets warm, either after extended driving or after hitting high RPM. I had one that would always go bad after going above 3000 RPM. On mine, the tachometer needle would start jumping around and reading incorrectly, along with the rough running. Bad ECU - broken solder joints and/or bad transistors can happen. I've read several accounts of bad solder joints causing extra-rich (over-fueling) poor running. I also had an ECU that ran fine then just coughed once and died. Then it restarted a few times while tried to make it home. Bad fuel pump - the fuel pumps can overheat internally and lose power. Fast Woman has written about her pump in her 78 car that would start the engine and allow driving then slowly lose power and die. Let it cool down and it would do it again. I had a pump on my injector tester that would run fine for about 20 minutes then slowly lose power and pressure. 1. The fuel pump issue is easy to see IF you have a gauge mounted where it can be seen when the engine won't restart, or while driving. 2. The ignition modules can be tested with "freeze" spray. (actually this might be tough for Jai since it's up under the dash on the passenger side). Or by checking for spark when the engine won't start. Carry a spare plug, pull a wire, and check for spark. Difficult without a helper. Practice checking for spark when it's in good shape so you know what you're looking for. 3. The ECU is a tough one because it appears to be either too many injections or too long injections. Easiest is if you have a spare to swap in. Swap and hope. Just some thoughts, I didn't see any of these addressed WHILE the problem was happening. Sporadic problems are the worst, you have to be ready to jump out and start testing right away. At least you now have an engine that you know will run well. Considering the work that was done that improved everything, the filter changes and connection cleaning, I wouldn't be surprised if it was the fuel pump. The pump motor is exposed to the fuel, so old wet fuel can corrode motor parts also.

-

75 z, want to swap my 4 speed for a 5 speed, best option?

You can change cruising speed with a different differential. On that topic though, be aware that 1975 has an odd bolt pattern on the differential. So if you do swap differentials, you'll need to get a 76-78 propeller shaft (center driveshaft). Or swap pinion flanges. On the wheels - it's tire diameter that matters. A "normal" 14 wheel can have the same diameter as a 16" wheel with a low profile tire. http://www.discounttire.com/dtcs/infoTireMath.do On transmissions - many people focus on cruise but they should really focus on 1st gear.