Everything posted by Zed Head

-

Cannot get injector pulse - passes EFI bible tests!

Found a picture on zcar, from Echutton. I think he's a member here. http://www.zcar.com/forum/10-70-83-tech-discussion-forum/398985-78-datsun-power-line-circuit.html @echutton

-

Cannot get injector pulse - passes EFI bible tests!

I don't see the other ground wire for the EFI system. It could be attached somewhere else but it came from the factory with a plastic connector, to a pigtail at the battery negative post. Somebody has monkeyed with yours, that battery cable to the firewall is way overkill.

-

77 280z with N47 head, stock engine, should I remove exhaust port inserts? Does it help?

If you measure the area of the port without the liners you'll probably find that you'd have to do a lot of extra work to get the header opening to match the head. If the header opening is smaller than the head opening you'll get turbulence that will ruin flow. Beside that, without a lot of other head work, enlarging the exhaust port is probably pointless. Somebody over on Hybridz showed that there's very little gain in flow from removing the liners. They're cast in. Some grinding on certain areas will get them to fall out, sometimes they fall out on their own. Once they're out you'll have a rough casting that needs smoothing.

-

Cannot get injector pulse - passes EFI bible tests!

Here's another. I think I mentioned this in your other thread, but when you're working on these old EFI systems it pays to try to absorb what the tests are for and how the various parts work. It really is simple enough that at least parts of it should make sense. Modern cars have so many inter-related parts and are so complex that sometimes all you can do is keep running tests. But these cars can be understood well enough that you don't need the tests after a few run-throughs. You've been working on yours since August, you really shouldn't be too lost. No offense. I have faith. The multimeter is your best tool.

-

Cannot get injector pulse - passes EFI bible tests!

You need to start over, measuring the basics of voltage to the the things that need power. You said that you measured voltage in your first post, so you must have more than just a noid light. If you don't have spark and you've lost power to the injectors, check your fusible links.

-

Cannot get injector pulse - passes EFI bible tests!

1978 doesn't use the ballast.

-

Cannot get injector pulse - passes EFI bible tests!

Basically, I'm just offering things to do because you're completely out of ideas. Better to try them than to overthink, I think.

-

Cannot get injector pulse - passes EFI bible tests!

Not sure you understood what I was saying. It relates to "quality" of the Pin 1 signal. The ECU is designed to trigger when it "sees" certain voltage activity on the wire from th coil's negative post. I don't know if it uses "flyback" which would be a big pulse, or if it uses just the up and down from battery voltage to the voltage after the drop when the coil is charging. As far as before your teardown, that was before you tore it down. Who knows what you bumped, removed and reassembled, or did "while you were there"? You're after the teardown now. And, most of us that use a meter a lot, don't use "continuity" for anything. We measure an actual resistance number. It has more information, and is almost as easy to measure.

-

Cannot get injector pulse - passes EFI bible tests!

I don't know. All I know is that I've had ECU problems, and tachometer problems, both due to changing one of the components on that branched circuit. You might double check the blue wire connection at the ignition coil, clean it well. The Pin 1 circuit. Maybe you have continuity, but the resistance is too high. Do you have the factory stock ignition system or something else? I think that people have reported the MSD system, and/or Crane, doesn't work with the 280Z EFI. Here's an example from MSA's site - http://www.thezstore.com/page/TZS/PROD/12-4005

-

Cannot get injector pulse - passes EFI bible tests!

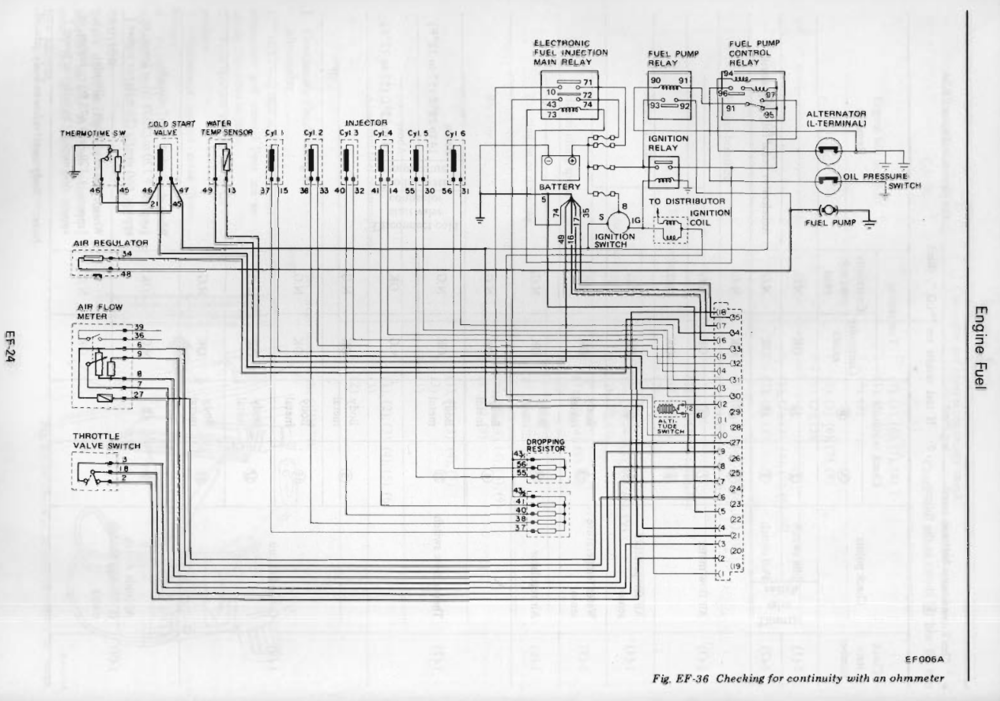

I missed the ground circuit test mention. The fact that your injectors don't seem to be opening seems to be the key. You've tested everything else. That means the ECU isn't triggering the transistors to ground the injector circuit. Maybe. I don't see any coolant temperature sensor resistance readings. If that circuit is shorted out, the ECU will supply less fuel because it thinks the engine is super-hot. Maybe the noid light pulses are so short that you can't see them. If that circuit is right then a problem with the voltage pulse on Pin 1 seems possible. I've mentioned several times over the years how I've had engines that wouldn't start when the tachometer was out. Not your case since your tachometer is in and seems to be working but it shows that the Pin 1 voltage quality is important.

-

Cannot get injector pulse - passes EFI bible tests!

I'm just going to start over without reading the other thread. Your tests so far have shown that you have spark, and timing is essentially correct, and the injectors are powered. Have you checked the ground circuit for the ECU? The EFI system has a dedicated ground circuit to the battery's negative post. Grounds are often overlooked. In all of your tests you have supplied the ground yourself, but the ECU might not have a good ground, for the injector-open circuit. No ground - no current - no injector opening. The Bible has a set of ground check tests.

-

Cannot get injector pulse - passes EFI bible tests!

Does it stay running after it starts? Not clear. Just trying to get a feel for the problem. The thing about the early Datsun EFI systems is that the Start functions are kind of separate from the Run functions. You didn't say year of car either. Forgot from your other thread.

-

struts

Seriously though, strut changes are pretty easy, with a few simple tricks, like unbolting the inner bolts of the control arms, for the 280Z. The 280Z struts are longer than 240Z so the descriptions of just dropping the back struts out form under the fender wells don't work. Unless you unbolt the inner attachment points.

-

struts

That is true. Why are you oiling fish?

-

struts

Didn't know it was a brand name too. There's no Monroe on yours though. He said Monroe quick struts. No offense zhead, but after 1,17X posts struts should be a piece of cake. You do need a spring compressor, for factory springs.

-

struts

"Quick" struts probably just means self-contained, like the KYB's and others. The factory strut tube damping parts are removed and everything is replaced with self-contained dampers. Oil, valves, shafts, everything. Not sure what your mechanic is talking about, with "special tools", unless he was planning to rebuild the factory internal dampers, which I'm not even sure can be done by today's mechanics. Maybe you have an old-timer who knows how to do it. There's no real benefit to doing all four versus at once versus just two, besides one shop visit versus two. That was your question and the answer is "personal preference".

-

1976 280Z Restoration Project

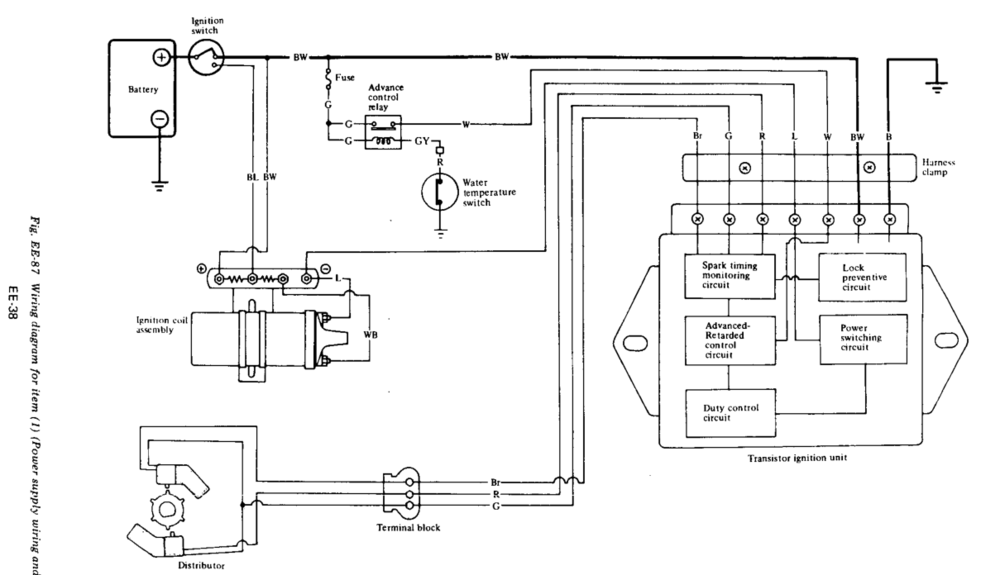

The "retarder" wire is the white one that goes through the coolant temperature switch. I was going to mention the possibility of blue wires. That's what the reman companies do. But they leave the colored ends as stubs at the pickup itself. Looks like you're figuring it out anyway. The last clue that might help you is if you get it all together and the engine starts but runs funny, and you can't get a solid timing light. If so, then the red and green, or brown and green, or blue and green, need to be swapped. The polarity through the pickup coil is backward. The voltage curve is reversed.

-

Nissan R200 Long Nose Diff 3.9/4.1 // 280z Mustache Bar

Maybe you saw this already but it's a very good deal. MFactory has a good reputation. Don't know what the ratio is. He has the other parts too, apparently.

-

1976 280Z Restoration Project

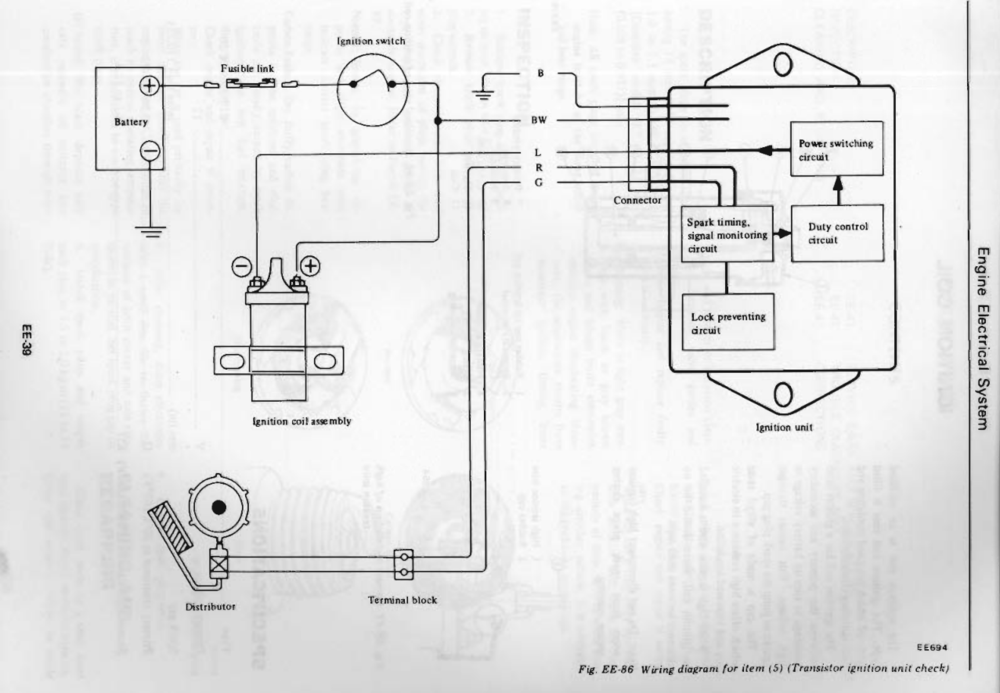

Not trying to one-up, just clarifying. Even though it doesn't really matter much for this case. Took me a while to logic out the second pickup. Sometimes it's called an Emissions function but it's described in Engine Mechanical. Attached a picture. Also attached a picture showing the wire that is common to both pickups. Actually, Green is the common wire and Red or Brown are the separated wires. The key is just to make sure that the two wires to G and W on the HEI module actually pass through a pickup in the distributor. Green goes to G on the HEI module (for proper polarity) so Red or Brown could go to W. It seems complex but once you get in there it's just G to G, coil negative to C, battery power to B, and the other side of the pickup coil (not G, either Red or Brown) to W. And make sure the module is grounded well. I had a 5 wire Nissan module in my car for a while and I just left the unused wires disconnected, and sealed the ends.

-

1976 280Z Restoration Project

The two extra wires are for the extra pickup coil in the distributor. You'll lose one if you convert to the GM HEI module. It will only cause a low idle during warm-up, in between the time that the engine gets fully warm and the AAR closes. The extra pickup coil advances the timing when the engine is cold, increasing idle RPM. The FSM has great diagrams of the TEI's, and Saridout's wiring diagram has the colors, if they're not in the FSM.

-

Brand new owner - need help w/ Christmas gift ideas for my kid

Can't really go wrong any or all three of these - https://www.amazon.com/Rebuild-Your-Nissan-Datsun-Engine/dp/1931128030 https://www.amazon.com/Modify-Your-Nissan-Datsun-Engine/dp/1931128049 https://www.amazon.com/How-Restore-Your-Datsun-Z-Car/dp/1931128022

-

worth saving? VIN:HLS3003595

Looks like two compression rods are serviceable. With bushings. The firewall VIN patch might be intact. The car can be saved! (That's a troll comment. Couldn't resist.)

-

77 280z rust free original unmolested parting out in Las Vegas

Just tired of zag's attempts to get people to join him in his "found' money club. He's the guy that throws the ID away and keeps the money when he finds a wallet. Hoping that that's not acceptable on this site. You can't have a discussion with him because he ignores your posts when they destroy his point, or he comes up with nonsense like at the top of this page.

-

77 280z rust free original unmolested parting out in Las Vegas

I would add, that the basic issue here is that most of us don't want to hear about these kinds of things. It's not what the forum is about. We know they happen, but some things are best kept to yourself. If you shoplifted some parts from the auto parts store, don't come on to the forum to tell people about your "score". It dirties up the good stuff on the forum. And don't try to argue that the parts store sold you some bad parts so they got what they deserved, or everybody does it, or some other justification. Just enjoy your ill-gotten gains, alone. That's about it. You and your friends might have a "culture" where this is acceptable, it's just not acceptable here. Sorry to the members who might have joined in with their own stories. I'm not a saint myself, and could tell some stories from way back when but I don't do those things any more and don't talk about them either. Let's get back to the basics, and stop talking about how to scam the system.

-

In need of a 83 280zx n/a vacuum advance

Don't forget the Parts Wanted sub-forum - http://www.classiczcars.com/forum/21-wanted/