Everything posted by Zed Head

-

Water pump comparison

Did you check the "weep" hole? That's where the shaft seal leakage comes out on the water pumps.

-

Bringing a 1977 Z back life

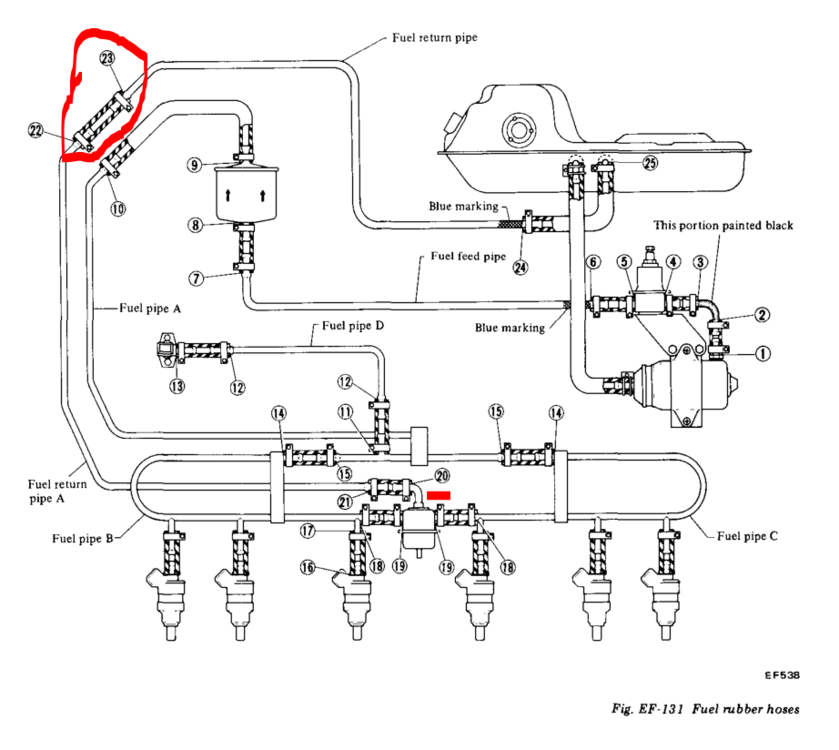

Disconnect the line by the filter that heads back to the tank. Run a line from it to a small tank. Power your pump and see what the pressure does. If pressure drops to ~37 psi then you have a blockage either at the tank or in the lines that return to the tank. It could be something as simple as a kinked line. It could also be a failed fuel hose. They can swell and come apart internally. Especially if somebody used a non fuel-rated hose. Your pictures don't show the bottom of the FPR. The fuel passes through the rail then the FPR before it heads back to the tank.

-

Bringing a 1977 Z back life

I'll sound like an arse here but if you can't figure out the factory rail an aftermarket rail won't be easier. They're the same basic thing, just a different shape. Follow the hose from the bottom of the FPR back toward the filter. It should not be connected to the filter, it should connect to a line that heads back toward the tank. Sounding like an arse again, but you'll have the same types of problems with carbs.

-

Rear wheel bearing install issue

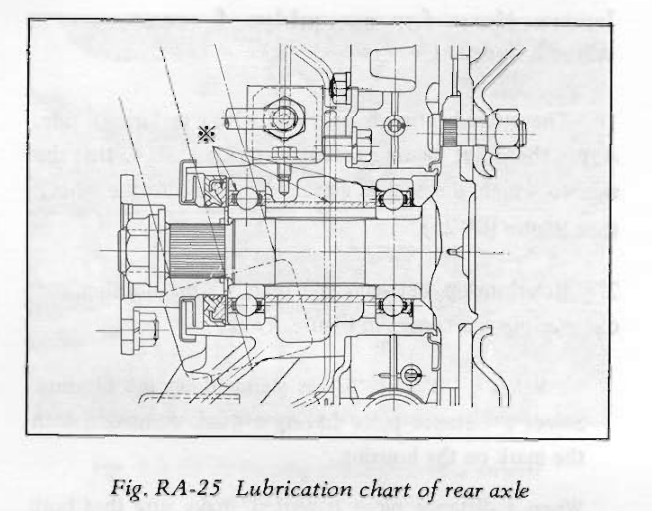

The front bearings and back bearings are completely different. Shape, "races", cages, principle of how they work, how to adjust them, everything. The main similarity is that they roll and need lubrication. If the wheel rolls with weight on it you could probably drive slowly to a shop that knows. Any auto shop should be fine. There's nothing special about the Z bearing assemblies. You could buy a new set of bearings and try again too.

-

Bringing a 1977 Z back life

Forgot to say, check your AFM numbers and post them up. There are differences between the years.

-

orig steel rims and hubcaps

You might try a Wanted ad. Except that I exposed what new costs. I can delete all of mine if you want to reset your bargaining position. Somebody has to have some old steelies that they swapped for mags. Nobody loves the 280Z's either so they'll just look like scrap iron in the garage.

-

orig steel rims and hubcaps

They're out there. Old stock, getting dusty. Maybe your local dealer has some on a back shelf. https://parts.bayridgenissan.com/p/Nissan__/ASSY-ROAD-WHEEL/53885515/40300N3100.html https://www.nissanpartsdeal.com/parts/nissan-assy-road-wheel~40300-n3100.html http://www.carpartsmanual.com/datsun/Z-1969-1978/axle/front-axle

-

Bringing a 1977 Z back life

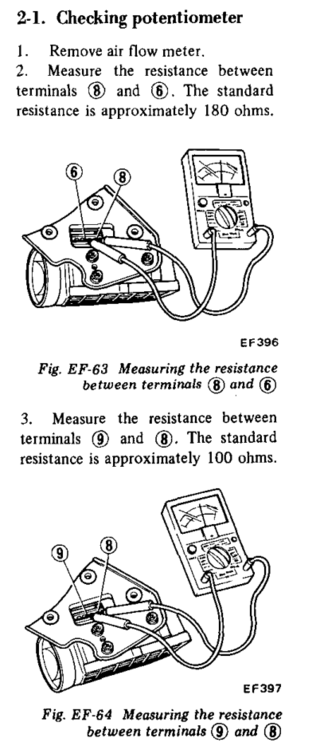

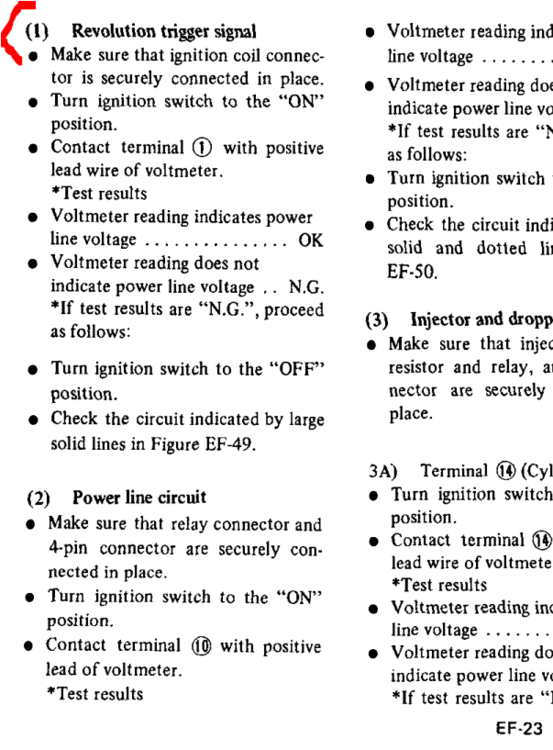

If "over pressure" means above 37 psi then you either have a blockage on the return line or your hoses are connected backward at the fuel filter. You're pumping in to the back end of the FPR. Added the second test on Pin 1, the signal to the ECU to open the injectors. About the AFM - The pin numbers are molded in to the connector on the AFM. Here's a picture of the test with resistance readings. EF-51 in the 76 manual, will be close in 77. Test your other two AFM's first and if one is good you'll know you have a suitable replacement. You can't piece-meal the EFI system testing. Make a list, sit down with your meter, get all of the numbers. The EFI guide is better for that than the FSM. It's more focused. I linked to the 1980 book, which covers all years up to 1980. Good luck.

-

Rear wheel bearing install issue

Is the bearing still inserted in the casting on the inside? Check for a gap on the outer race, where it should be seated. There are so many different, conflicting, opinions about what the problem could be that you're probably just going to have to learn the basics and figure it out your self. That link I provided is pretty educational. If you focus on how the bearings work and what the purpose of the "distance piece" is, and think about how the balls ride in the races, it will probably click for you. This caliper is cheap but works well. I have one. Take some measurements. https://www.oreillyauto.com/detail/performance-tool-4601/tools---equipment-16488/tools-17919/measuring-tools-16659/measuring-calipers-19579/caliper/w80152/4614478

-

Alternator question

You'd need a soldering iron. And you'll probably find that the brushes are worn when you take it apart. I only suggested just to show that the parts are available. You can get the other parts on Rockauto too. Probably find a complete kit on eBay. Or, if you have a shop in your neighborhood they might be able to get the parts and do the work. Just saying, it might be a better option than taking a chance on a parts store reman. You'd have a real professional taking the time to do it right. The parts are available and that's usually the only limitation. http://www.rockauto.com/en/catalog/nissan,1987,d21+pickup,2.4l+l4,1210857,electrical

-

Water pump comparison

So many ways to get variation in what you're measuring. Cold weather, cold metal, where the point of the thermometer is sitting, etc. I think that the only test for that new style of blade is a hot day, a long drive, and attempts to make it overheat. That's just for cooling capacity. You'll have to wait 10 - 20 years to test durability.

-

Rear wheel bearing install issue

A cocked/kocked/carked/caulked race will cause problems. http://www.skf.com/binary/tcm:12-114679/140-710 BIMG 11_2012_tcm_12-114679.pdf Edit - I didn't think that "****" would make it through. Edit 2 - But, apparently, "cocked" will.

-

differential half shaft seal. does it require special tools?

Many people have issues with oil vapor coming from the breather, when the diff gets hot. Worth a check. Another source.

-

Alternator question

Hope you get a good replacement on the first try. Apparently, maybe, the internal regulator can be replaced. Might be worthwhile to just have yours rebuilt. I bought a rebuild kit for a 2003 Ford alternator. Just for fun. Bearings, brushes, and regulator. Haven't done it yet, it's a future project. $30. Here's the Rockauto VR for yours - http://www.rockauto.com/en/catalog/nissan,1987,d21+pickup,2.4l+l4,1210857,electrical,voltage+regulator,4884

-

Rear wheel bearing install issue

Food for thought, and discussion - when the nut is fully torqued to spec. it basically turns the axle, the distance piece and the two inner races in to one solid piece. Like it was machined out of one solid piece of steel. The outer races are just along for the ride, moved only by the force of the balls. It seems to me that the companion flange bearing's outer race is not seating, causing the inner race of the wheel side to pull in to try to meet the distance piece. Already said this, just wanted it all in one post. Also, a tape measure is not the proper tool for that measurement.

-

Rear wheel bearing install issue

Can you tell if the outer race on the inside bearing was seated fully in the casting? Like 246 said, a bearing fitment problem might be the cause. The blue bearing on his illustration. That outer race has to seated completely, otherwise the balls take all of the final torquing force. Actually, it seems odd that one of the axles is still covered in grease where that bearing's inner race should have wiped it clean.

-

Rear wheel bearing install issue

I was trying to figure out what that would do, earlier. It would leave the outer outer (yes, double outer) race unseated, so maybe that allows the whole axle, flange, and distance piece assembly to move inward, without the outer race stopping it. That could cause the rubbing. That's the most hopeful cause, easy to fix. Edit - That would leave the inner outer race unseated also. So a hit with a heavy mallet on the inner flange should push the three parts back outward and relieve the rubbing.

-

Spark Plug, Compression, Gearing, and Power Feedback

Some of us were trying to make the point that the chain might not be worn. In other words, replacing it won't change anything. Just reiterating... But, once you take things apart, clarity will ensue. What engine does that Benz have in it? Is it one of those that looks like a Datsun engine?

-

Rear wheel bearing install issue

You said you used the FSM. It's in there, with a big picture. Dimensions for the distance piece also. It's all in there. I'd measure it even if you find the letter. Which bearing part numbers did you get? Maybe you got the wrong bearings. Did you compare old to new to see if they match? It looks like Nissan went with high precision on that assembly. The axle rides very close to the casting. A short distance piece might allow the inner race to pull in at high torque. If it did though, you might have damaged the races. The torque is supposed to clamp the two inner races against the distance piece. You're putting all of the load on the balls and races.

-

Alternator question

I should have added - disconnect the alternator electrically with the engine not running. Should be a quick easy check. I thought my Nissan with 260,000 miles on a VG30E and no major work was a big deal. Which engine does the 87 use?

-

Alternator question

I think that Steve might have meant that the VR is shorted, partially/high resistance, drawing the battery down with the engine not running. He meant disconnecting the alternator electrically, to stop the draw. You would probably see a change in voltage with a good meter. Connect the meter, measure voltage, remove the alternator plug with the meter still connected, see if voltage pops upward. Might even see or hear a small spark when you remove the plug. Edit - Oops. thought you were gone SteveJ...

-

Water pump comparison

Never thought about the open back of the impellers on the stamped blade. It is like a water wheel. It probably does push less coolant but might not be a factor for a typical street car. It would be neat to set two up pushing water against each and see which one wins. Those cast impellers are so purty though. I'm surprised people don't polish or chrome them before installation. Transparent plastic housing with a polished impeller inside. A few LEDS... Nice.

-

WTB 280ZX distributor E12-80

Like dutchzguy said, any reman Datsun distributor will probably be of low quality. And stronger spark won't fix your timing/backfiring issue, although a new/reman distributor might. You could spend some important money and time and end up with the same problem. If you have some electrical knowledge or know somebody who does you could probably devise a way to use your points to trigger an electronic module, such as the GM HEI module. Like a home-built MSD unit, but much less expensive. The HEI module trigger circuit is described as monitoring polarity of the voltage (zero crossing) but people have used it on the zero and five volt trigger from 280ZX turbo ECU's. You could run the points circuit through the G and W terminals, with a resistor, if necessary. Based on the ZX turbo ECU usage, it should be possible, I think. That's just a way to get electronic ignition on a modest budget. Have you had your points distributor out and examined it? The breaker plates tend to all apart. There are other problems you can have with points also, like bad condensers.

-

differential half shaft seal. does it require special tools?

I think that that is an R180. The bolts in a circle on the side are the clue. Visible in your picture. There should be a bolt behind the u-joint that you need to remove before yanking. Most seals can be pulled easily by punching a small hole in them with an awl or small sharp punch then running a wood or sheet metal screw in to the hole to use as a puller.

-

Water pump comparison

As I recall, people have identified three potential issues with the stamped impeller, but there's not a lot of evidence supporting the theories. One is just having the stamped steel rust and wear away, Another is cavitation, causing damage and wear to the impeller. And the other is lower flow. I've not seen solid evidence that the stamped is worse than the cast. Some new engines use stamped impellers in the factory water pumps, I think. But they were probably designed in conjunction with the housing design. I think that the stamped GBM impeller is designed to fit in to a housing designed for a cast impeller. Who knows if it matters. On the other hand, here's a 2016 Camaro V6 water pump. 2016 and still cast curved blades. http://www.rockauto.com/en/moreinfo.php?pk=7204964&cc=3353479&jsn=520