Everything posted by Zed Head

-

Oil pan help??

Thanks for replying. From out here, the post reader, the sigh sure does look like a comment. Just couldn't tell what the comment was about.

-

Types of oil used for Strut Tower tube

The original struts used special oil. Aftermarket strut insert replacements don't need any oil. Not sure what you're working on. p.s. if you click Signature, put stuff in the box, and save it, it will show up at the bottom of your posts. https://www.classiczcars.com/settings/

-

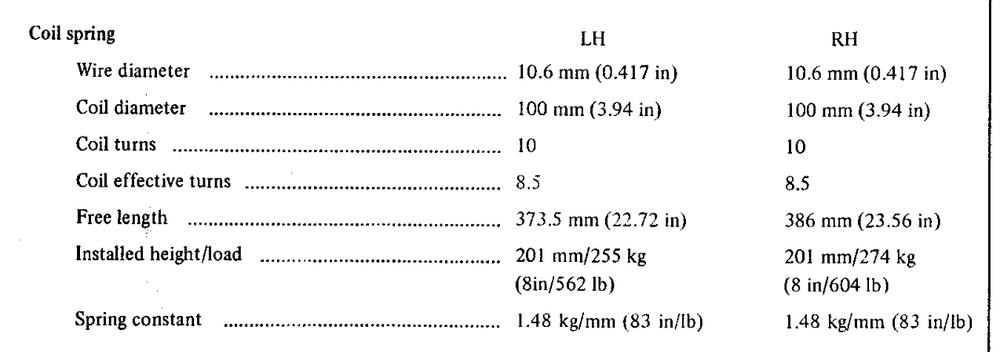

Frot coil spring length

I suppose it depends on what the worry would be. Worry about them failing? Spring sag with age is not uncommon. Did you notice any variance in corner height when they were installed? The thing about aftermarket springs is you don't really know how they'll sit until you get them installed. You can find reports of weirdness with the Eibach progressive rate springs. Don't know if that problem ever got solved. It's a conundrum.

-

Frot coil spring length

Seems to be normal and as Nissan intended. Maybe to offset an imbalance in the car's weight, maybe from the engine tilt. Not clear, although it might be described somewhere. I don't think that the aftermarket considered it.

-

Oil pan help??

It's just snark if you don't follow it with something useful. Are you sighing the pan question or the build details?

-

Oil pan help??

I have a vague memory that the ZX pan works in a Z. But, since you have both why not measure to be sure? How much "building" will you be doing on the turbo engine? You know that it has a lower CR than an NA engine, right?

-

A Nissan (NISMO) DOHC Kit for the L Series is Officially Available

So close. I almost went for it. You even left an ellipsis to draw people in. Well done, again. You are a master at baiting people... p.s. proper grammar would use the word "directly", I believe, not direct.

-

A Nissan (NISMO) DOHC Kit for the L Series is Officially Available

That's 24 degrees of rotation of the transmission, putting the shifter in the driver's lap. Can't remember which way the VG30 engine is rotated. It uses a different transmission. I wonder if it's a better option. Maybe it's been considered. Derek is mentioned in one of the articles. I assume that his engine is not rotated? Seems like poor timing on Nissan's part, waiting so long to introduce their head, when there were already two out there. Besides the fact that block supply is diminishing. Slim market. OS Giken Releases L Series Head - The Gentleman RacerOS Giken was born in the early 1960s; Osamu Okazaki wanted to build a true high-performance Japanese race car to compete against the sports cars from Europe dominating the sport at the time. Like many

-

saturday night music thread

I had their greatest hits album when I was a kid. In retro my parents were probably concerned.

-

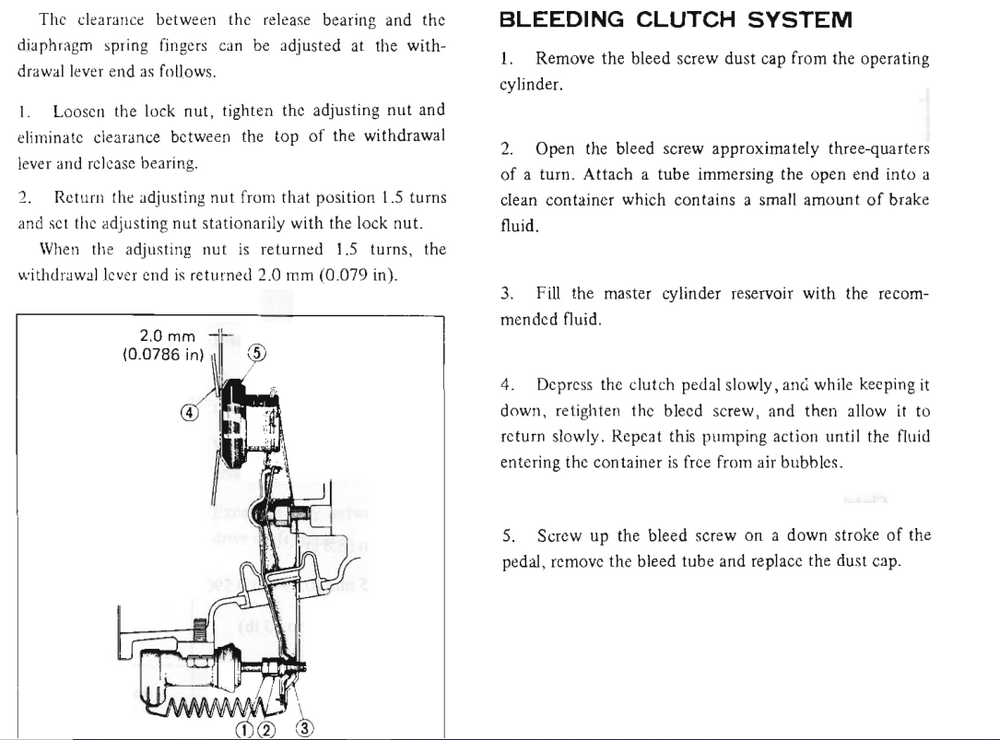

240z 4 speed manual

If it was mine I'd watch the play at the adjusting nut on the rod. Press the fork against the pressure plate fingers using one hand and run the nut in until you have contact with the fork with the other one. That would be zero play. Then back it off 1.5 turns. Easier to do the adjustment without the spring attached, since you'll be able to feel when you're on the pressure plate fingers. I've never done one but I think I understand what they're trying to accomplish. 2 mm of play between bearing and pressure plate when the slave clyinder is at the start of its stroke. Don't forget to check the pedal adjustment at the MC also. I've adjusted play there in the same way. Just max out the adjustment rod, being careful not to press the piston in to the MC bore, then back it off a bit. Another feel by finger job. And you don't need to remove the clevis you can turn the rod with a pair of pliers or a strong grip while everything is assembled.

-

240z 4 speed manual

Did you follow the instructions? Don't know why they show the measurement since most people will just tighten until play is gone and loosen 1.5 turns. Nobody's going to stick a feeler gauge in that hole. Don't forget to bleed.

-

Z's on BAT and other places collection

-

Odd Bolts in Balance Tube

dzcg might be having seller's regret. 🤢 Everyone knows about ad blockers. They work. Good luck.

-

A Nissan (NISMO) DOHC Kit for the L Series is Officially Available

@Derek makes something similar. https://forums.hybridz.org/topic/119641-twin-cam-head-for-the-l6-from-derek-at-datsunworks/?do=findComment&comment=1249401

-

CAR STALLS WHILE DRIVING!!!

This was a clue that it was an electrical problem. If the engine was still spinning because it was in gear then spark will still move the tachometer needle.

-

Z's on BAT and other places collection

Another VRP car. Already sold once for $101,240. https://bringatrailer.com/listing/1972-datsun-240z-380/ https://bringatrailer.com/listing/1972-datsun-240z-93/

- 280zx 1979 2+2 slick roof restauration

-

Z's on BAT and other places collection

It looks bent around the exhaust pipe. Maybe backed the pipe in to something and it caused some damage. Good Not so good, but not terrible. The bumper looks a bit dinged up on the bottom too.

-

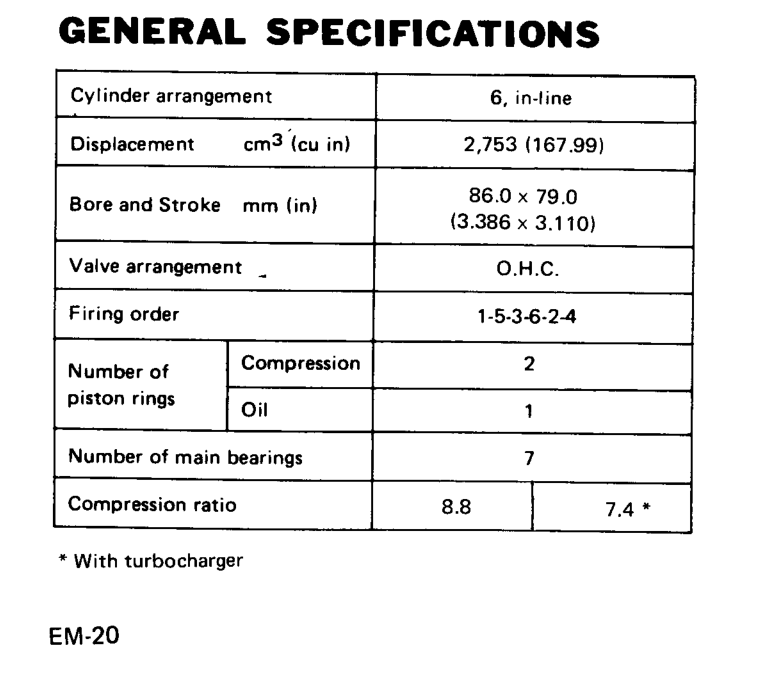

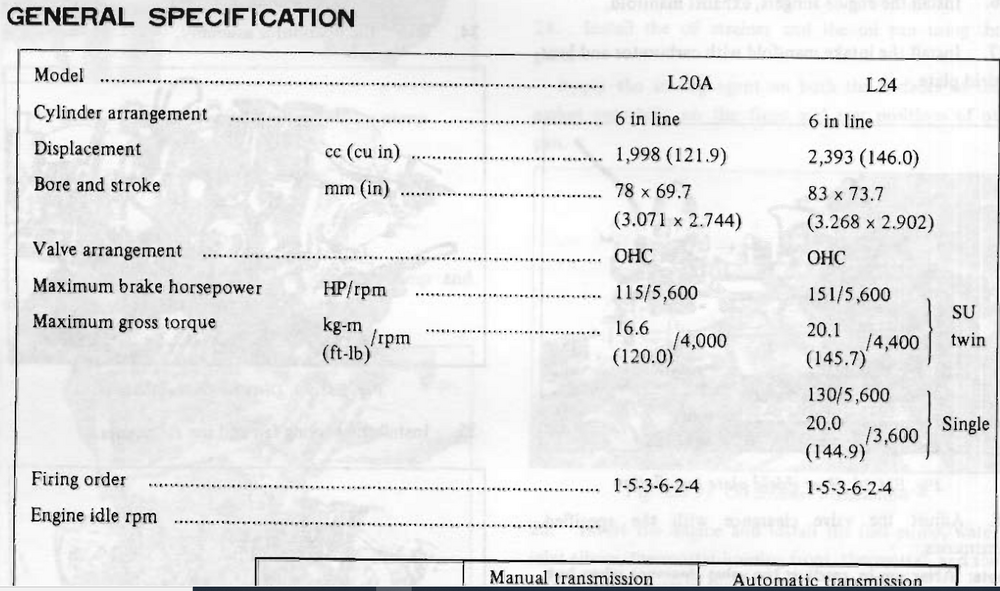

L20a Engine Help

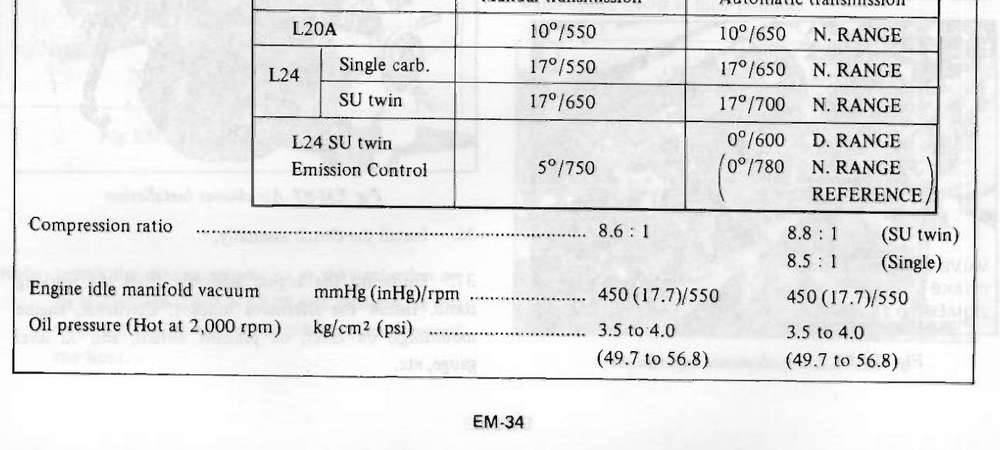

I'd see if you can work out a deal for the proper head if you're looking to be close to a restoration. I don't want to hurt zKars' position but he did say "never been able to sell". Seems like he's been waiting for you... Good luck. I redid the math for what should be the E31 head and got 7.7. Didn't add your millimeter overbore though. Also found that some of the engine calculators out on the internet seem to have the wrong chamber volumes. I used the dimensions and reported CR from the FSM to calculate volume. Just for fun.

-

L20a Engine Help

Is there a specific reason that you're trying to save the L20?

-

L20a Engine Help

I got 7.5 for the CR of an L24 head on an L20 block, assuming the L24 head is the dual SU head. Probably want to get with zKars on that L20 head. Realized that I used the E88 L24 head for the calculations. 8.6 CR instead of 9.0. I'll redo them later. Probably still under 8 CR.

-

1971 HLS30-14938 "Lily" build

Disconnect at the manifold/header exit and run your borescope up that way. That distributor looks like just a magnetic pickup distributor, that uses an external ignition module. But your exhaust blockage sounds reasonable. Good luck. Post pictures.

-

1971 HLS30-14938 "Lily" build

I ruined a GM HEI module by running the engine with two spark plugs disconnected. I assume that a stray high voltage discharge, or some sort of "flyback" (it's a thing), made its way through the module. After I turned the engine off and reconnected the wires the engine wouldn't start. I checked spark and got a weak orange spark. The engine would start with starting fluid but would not without. Put a spare new module in and it fired right up. How about some details, just for fun, on the new electronic? Is it a ZX type or Pertronix or something else?

-

1971 HLS30-14938 "Lily" build

I've also seen old plug wires crossfire or short to ground. Waaayyy back in high school working with old worn out car parts. Used to have to arrange the wires to avoid problems. Also seen that visible weak spark does not always spark under cylinder pressures. Had a weak ignition module once. You're probably running points though?

-

L20a Engine Help

You can back out combustion chamber volume using compression ratio and displacement. The 1972 FSM has the numbers. And if you have the head and block in hand you can take some measurements.