Everything posted by Zed Head

-

COVID-19

Lots of interesting ways to think about death.

-

COVID-19

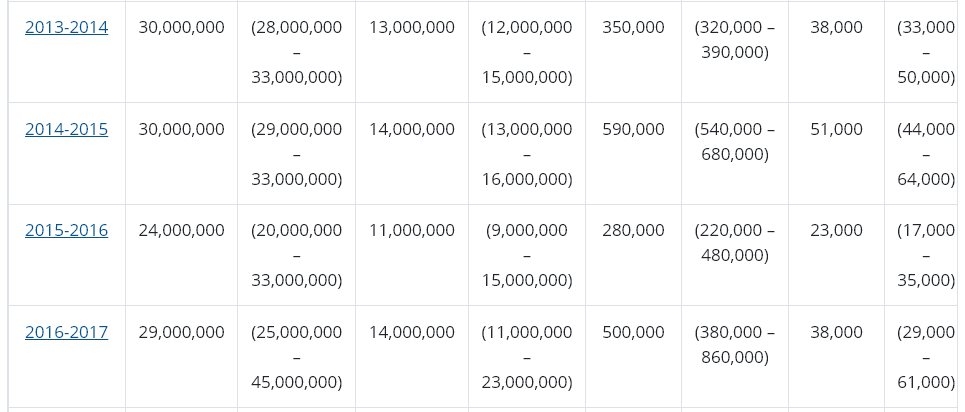

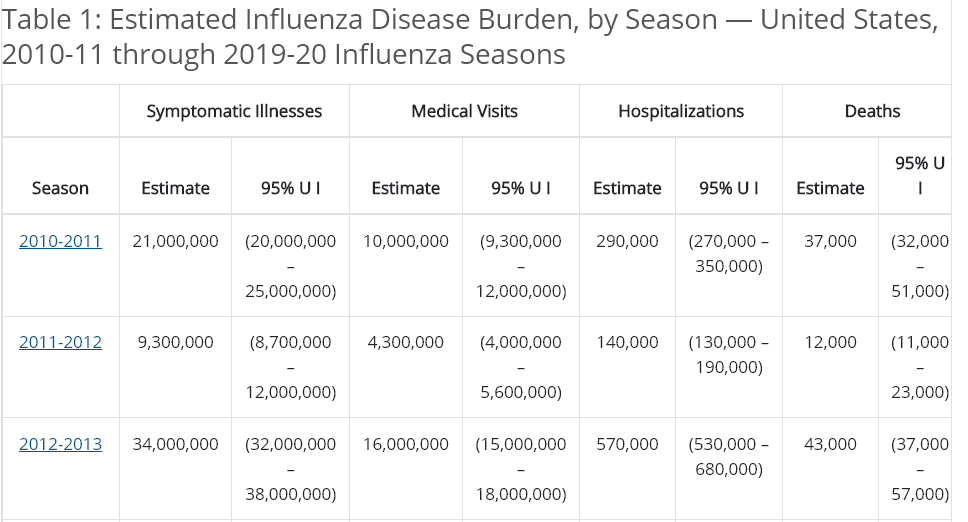

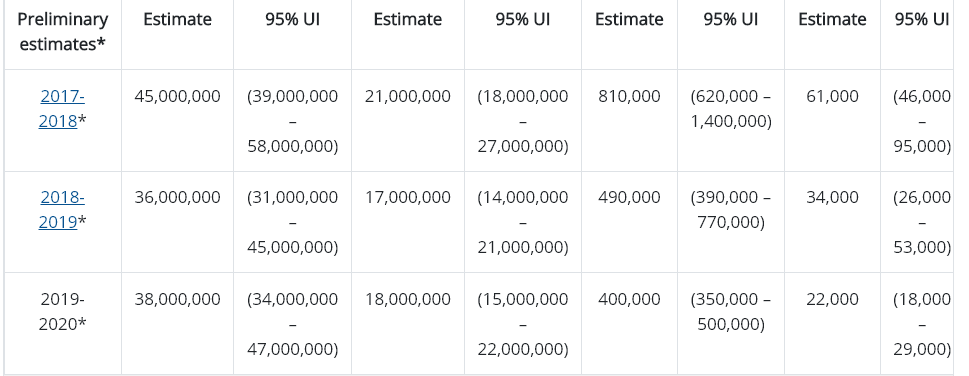

Sorry CO, I left out some middle years just to make the size of the post smaller. 13, 14, 15, and 16 add up to 150,000 so 359,000 is the correct ten year number.

-

280z plenum

Never heard of them. Only found them when they popped up on a Google search of that part number.

-

Starter motor engages then slips out

Is it an automatic or manual? Might not matter but good to know. If I had your problem I'd probably try to lever the starter away from the ring gear while I tightened the starter bolts. Crude, but it seems like the starter gear teeth aren't fully engaging with the ring gear. Maybe the wear on the ring gear teeth is enough to finally cause binding, from what was a tight tolerance. Actually, an even simpler quicker test is to loosen the starter bolts slightly so that the starter can move away when actuated and let the teeth mesh. It should be fine for a few starts as a test. If it works you'll know that you have gear meshing problem. Edit - do you still have the old starter? Take a close look at the teeth on the drive gear. You might find that they've not been fully engaging in the past. Might be a clue.

-

280z plenum

It's a 75 280Z. I wonder if the rest of the car is similar. That is not a typical rust area, to that degree. Might be best off to find a new shell and move all of the good parts over. https://www.classiczcars.com/profile/35466-ennisdavis/

-

Starter motor engages then slips out

Has it ever worked for you or did you just buy someone else's problem?

-

COVID-19

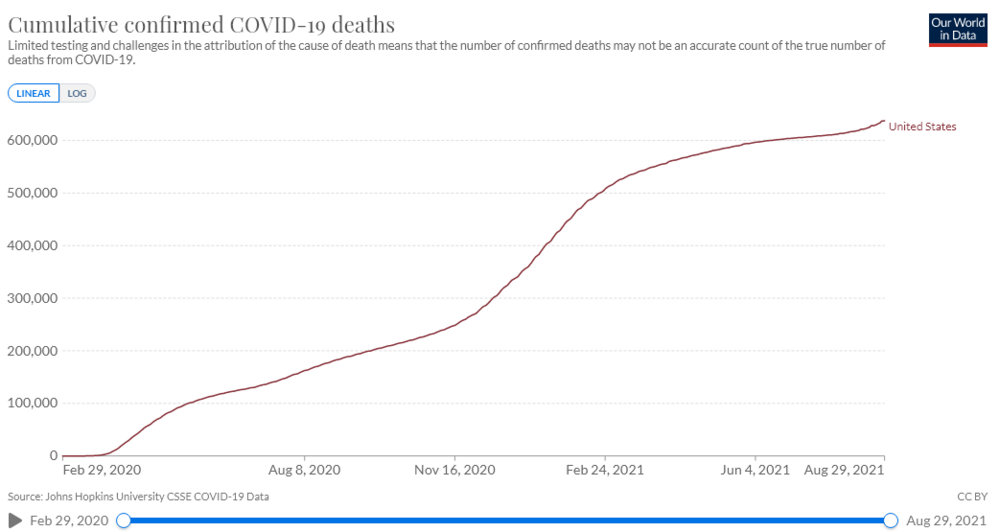

Facts only mean so much but here are some. https://www.cdc.gov/flu/about/burden/past-seasons.html Looks like 510,000 for the first full year of COVID-19. We're at 127,000 already at about 6 months in to the second year. https://ourworldindata.org/covid-cases

-

280z plenum

Found a web site. Who knows? 436 Euros for the top piece. http://www.autospares.eu/search.html?search=search&article=66300-N4700&term=0&sort___search_results_by=final_price&chk_smode=on&smode=A http://www.autospares.eu/price-lists/nissan/2568/

-

280z plenum

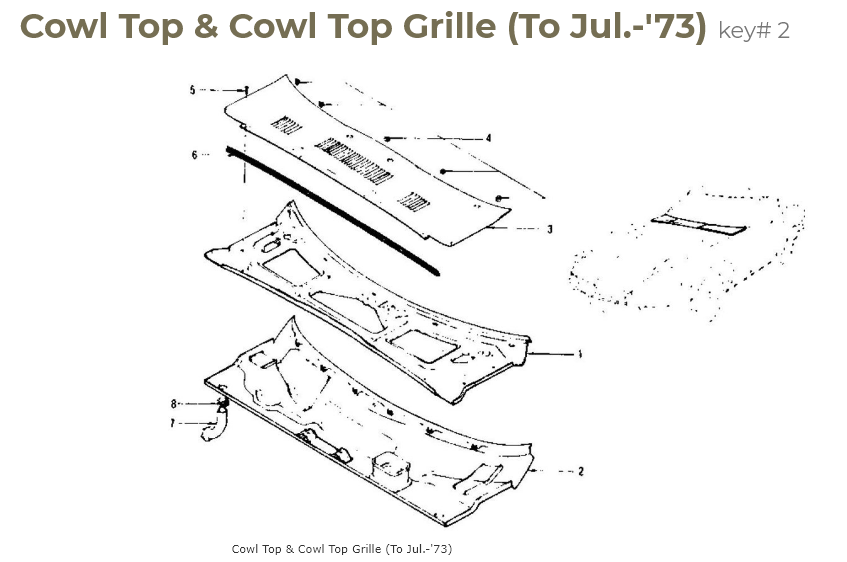

I didn't narrow it down, just found the part shown and posted a starting point. But, since you brought it up... http://www.carpartsmanual.com/datsun/Z-1969-1978/body-260z-280z/2-seater/cowl-top-grille

-

280z plenum

Use this to figure out which wrecking yard cars to chop up. http://www.carpartsmanual.com/datsun/Z-1969-1978/body-240z/cowl-top-grille

-

Barefootdan's 280z Build

If you go with ground control then any short circuit in the wire between the device and the control relay will power the device. If you have power supply control a short will blow the circuit's fuse instead.

-

Transmission Noise in 3rd Gear - F4W71A

Type A definitely looks different than type B. I really don't know much about either. I did find your part number under the Sports pages though. You probably did too. You might see if there's another old Datsun forum out there somewhere. Your idea of trying a 1.0 mm shim makes sense. Can't hurt. Might be the guy before you was in a hurry or just didn't have the tools to do it right. https://www.carpartsmanual.com/datsun/sports-1965-1970/power-train/transmission-shaft-gear/5-speed-(warner)/20 Here's the link that you copied the numbers from. http://www.carpartsmanual.com/datsun/Z-1969-1978/power-train/transmission-gears/4-speed/to-aug-71 And for those who want to see the change... http://www.carpartsmanual.com/datsun/Z-1969-1978/power-train/transmission-gears/4-speed

-

So many problems , Don't know where to start ....

I've wondered if the broken magnet was a show stopper. Apparently not. Make sure the blue wire is connected to the negative terminal. It's Pin 1 trigger to the ECU for the injectors. Counts sparks then opens them up.

-

What spline lug lock is this??

- 1983 280zx project

Lots of good stuff on this page, linked below. Menu down and to the right. Not many ZX's here. @dutchzcarguy has one. https://www.classiczcars.com/files/- So many problems , Don't know where to start ....

What are the issues? Might just be the module. You can wire in a GM HEI module for about $25. Or buy a ZX module for $134 (ouch). The HEI module will work as well or better. You could also convert to a 280Z distributor if you happen to find one. https://www.rockauto.com/en/catalog/nissan,1981,280zx,2.8l+l6,1209338,ignition,ignition+control+module+(icm),7172 Here's a detailed, make-it-look-right example, but you can also just extend the wires out to the fenderwell.- COVID-19

https://www.theguardian.com/world/2021/aug/28/unvaccinated-teacher-infected-half-her-students-covid-california-cdc- 1975 ujoints

Here is that recent thread.- 1975 ujoints

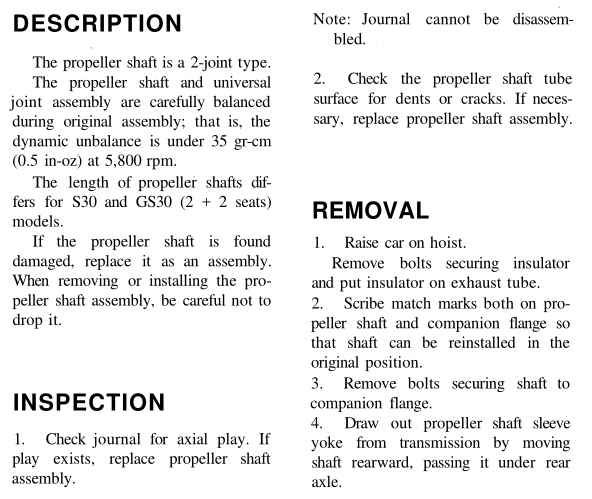

Which ones? There are six. Here is the info from the Nissan Factory Service Manual book. There are shops that know how to make the propeller shaft joints replaceable but it's not standard practice. somebody just posted about it.- Putting in a replacement L-28

Really seems like the guy is just having general problems running his business. All signs say avoid Whitehead Performance. It's been going on for a few months. Go to April 10 in this thread if the link doesn't get you there. https://forums.hybridz.org/topic/113706-whitehead-performance/?do=findComment&comment=1228704- Ignition coil specs for 240Z

This would make a good addition to the Wiring Diagrams Downloads page, and a few other places. Documents can exist in more than one place, I assume.- air cleaner housing connections

Bad bleeders bud. Bummer. New MC maybe? Yours seems oddly shaped. Where did it come from? Looks it might even have ports, or the bosses for ports, on the other side. Are they drilled and tapped? Maybe just swap them.- air cleaner housing connections

Any chance you have a motor mount problem? I like to browse around the BAT site to compare to other cars. They take a lot of pictures. I took a few looks and it does seem like they have more room than you do. Here's a 71. https://bringatrailer.com/listing/1971-datsun-240z-187/ https://bringatrailer.com/datsun/240z/?q=240z- Where connections go to

- battery drain

Sounds like your L wire is not providing power to the windings. Check for voltage at the L wire with the key on. A good alternator with no L power will not charge. Actually with an external alternator, it's the F terminal. No F power, No F'ing charging. Check inside the plug with the key on. sometimes the connection canget loose too, so if you find power make usre it's a solid connection to the F terminal. Check your grounds also. The alternator case should have a ground through the monuts but it also has a dedicated ground wire. No ground no charge. - 1983 280zx project

Important Information

By using this site, you agree to our Privacy Policy and Guidelines. We have placed cookies on your device to help make this website better. You can adjust your cookie settings, otherwise we'll assume you're okay to continue.