Everything posted by Zed Head

-

Can you use 79-83 280zx pistons in a 75 280z?

.040" over flat tops. https://www.ebay.com/itm/165387446201?fits=Model%3A280ZX|Make%3ADatsun&epid=75271992&_trkparms=ispr%3D1&hash=item2681dc27b9:g:8OMAAOSwvkJiMhTi&amdata=enc%3AAQAGAAABIKiiCdDNms8s1aN21U%2Bmm7wiO1Yzt1v6lTAirumB82Fef3JCgqY6kRipL4DKdXgD0FAq7G4lB4Z1PC9drVf527H8gPvzl6v6C%2BMUGWburvcIMlBPo59ZzQ4aq61o5WqQa%2Fw0Qs324QvLl4dptZyuitjGtNYhI3m2nNzBGdSccVhTMZ3fCXLQekspzg9XfkQ3on4sShcbRXe9trCxUy%2BMgjbVkA9czun4vcV%2BD%2FY1rSRju4gT8T50LkSkcSpHOoeP3e9KYDMOU%2FrQwQrvlIkqIH6V9JHYb54tFE5ExVHvU41Ss5S0qVSH6hJioh0OZsJpfCF4T0CARtU9rFKWm3pDVSHvfCN0Mf8zaWbTxWukvgCJsSSTApzPTx79KySUALI%2BFA%3D%3D|tkp%3ABFBMutDWz_Zf

-

Can you use 79-83 280zx pistons in a 75 280z?

Here are standard pistons for what you have. https://www.ebay.com/itm/172502490849?fits=Make%3ADatsun&epid=77048862&hash=item2829f31ee1:g:FxEAAOSw9KNiFsAL

-

Can you use 79-83 280zx pistons in a 75 280z?

1980 (maybe 1981) to 1983 were flat tops. That was the range of the P79 heads, approximately. 1979 was definitely the N47 head and dished pistons. Check your information source, there is a lot of bad information out there. eBay shows that those are dished. So they would be like your stock pistons. If the picture is correct. Those are turbo pistons though so the top ring is set farther down the piston, I think, to protect it from excess heat. They would work but not be exactly the same. https://www.ebay.com/itm/283805353930 eBay has a bunch but the seller sites are hard to search.

-

77 280z Restoration

-

77 280z Restoration

I thought that it was for looks.

-

Can you use 79-83 280zx pistons in a 75 280z?

ZX pistons are flat top pistons and your 75 pistons are dished. But many people use the flat tops to raise the compression ratio for a bit more power. I think it would end up about 10:1. So yes they would work, you'll just end up with a higher CR.

-

Help - Adding ground locations

You can have more than one ground point. There is a ground wire from the alternator body to the harness which must be attached to battery negative. And the alternator body is attached to the engine block through its mounting bolts. And battery negative is attached to the body grounds. Plus the battery negative is attached to the engine block through the starter mounting bolt. Many distributors use the mounting screws as grounds through the distributor body, but also have a separate grounding wire to the body. You can learn a lot with a meter. Posting before I look at SteveJ's reply...

-

New build, engine wants more ignition timing, but I'm scared of knock....

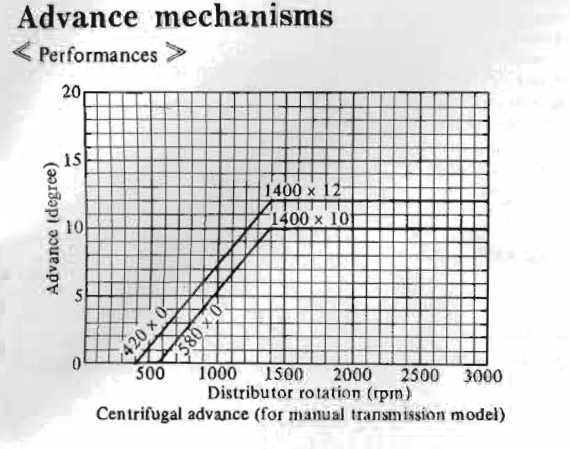

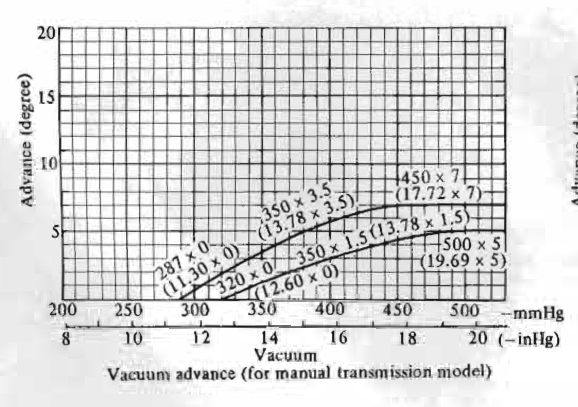

Have you studied the factory curves? Vacuum advance disappears pretty quickly, and it's only vacuum (pressure based). Does the software allow you to change units? It will make things easier. There are conversion charts. I'd match a factory setup and then tune from there. https://www.vacuum-guide.com/english/equipment/conversion_pascal_bar.htm https://www.engineeringtoolbox.com/vacuum-converter-d_460.html

-

77 280z Restoration

Can you point that out in the text? Maybe you read in to it subconsciously, with "driveshaft angularity"? I can't find anything specific about getting noise from a top mount. Quite a few people running a top mount only. It works well. Although I did make mine to match driveshaft angularity. RTz built his for a V8 application, originally, so changed the angle slightly. p.s. they call it a mount but it is actually a strap replacement when used with a snubber. Pedantic... https://www.technoversions.com/DiffMount.html

-

77 280z Restoration

I had the clunk and made my own mount, based on the RTz design. I am pretty certain that the noise comes from the diff nose rising up then dropping back down on to the crossmember. The clunk is when it hits. There is a video or two out there showing that. So, the use of a snubber on top is really just stopping the initial rise. It works, just pointing out the why. One nice thing about hanging the diff nose from the top is that you can mess around with your rear suspension without having to deal with the hanging diff nose. But, really, a new diff mount will probably get rid of the clunk. It's really hard to tell that the mount rubber is worn unless you stick a pry bar in there and lever it up, with force. It is surprising how far it will move. I made a new mount because I bought the car for something to work on, a reason to be in the garage. It was a challenge. But today I might just buy a new diff mount if it was available.

-

Name Those Springs

I found some yellow ones in Australia. https://www.ebay.com.au/b/Coil-Springs-for-Nissan-Datsun-240-Z/33582/bn_7019833571 and Summit, but they aren't specific on vehicle. https://www.summitracing.com/parts/afc-25225-3?seid=srese1&gclid=CjwKCAjwoduRBhA4EiwACL5RP1FKAFgrHQZEuWSVT8JZyqMnHkertyDdfGfUFJhOg00yDEjZ945UjxoCWMgQAvD_BwE

-

L28 Timing chain

Here's a Hybridz link with a youtube video. The guys that posted in it are some of the smart engine building guys. Might give you some ideas and the video has good images of the marks and the links. He has dark links. https://forums.hybridz.org/topic/129303-matching-cam-crank-timing/ Time-stamped the video.

-

L28 Timing chain

There's probably a cam lobe at a certain point when things are right that you could use instead of the marks. Just about to get on the ramp or straight up, or something.

-

L28 Timing chain

Everything seems pretty well installed, but it's just hard to tell if the cam is oriented correctly. Weird that the aftermarket companies have removed all of the marks needed to ensure proper installation. Is there a mark on the lower sprocket? I looked at the images on Rockauto and couldn't tell. They might be showing the backside. Edit - I think I see it now.

-

saturday night music thread

- saturday night music thread

Is that Hank Jr.? I didn't cheat, but I will now. I was close -- saturday night music thread

- saturday night music thread

- I'd rather save this oil pump, but...

Funny, I saw the cartoon and thought the right words to search to be sure, (Edit, deleted stuff - never mind. I see that the caption fits what he said. Oh well.) Would Heisenberg be more appropriate? Not the Breaking Bad one.- Name Those Springs

There might be numbers and/or letters under the dirt. Tokico puts a number on theirs.- I'd rather save this oil pump, but...

But integrity is undefined until it's off and disassembled. The dilemma.- I'd rather save this oil pump, but...

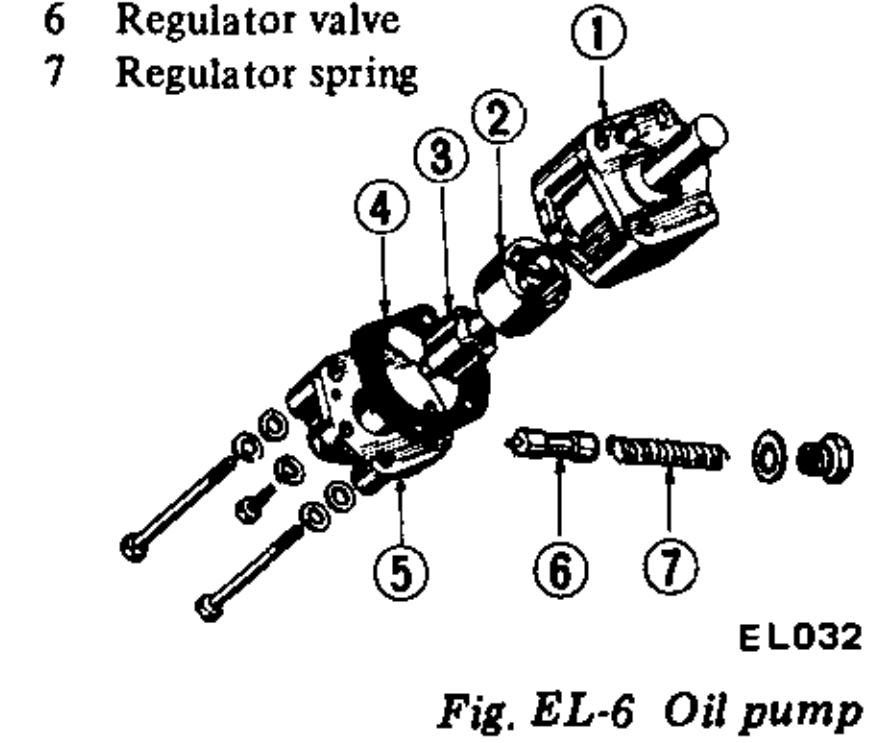

Try splitting the cover off of the pump body, 5 and 1. That's probably where the stuck bolt is stuck.- New build, engine wants more ignition timing, but I'm scared of knock....

An N42 on flat tops will be up there, higher, in CR. But, usually, full timing is in by 2500 RPM, so you might be a little bit cautious. Your MAP curve (vacuum advance) seems a bit odd also, you might look at some examples from the FSM to see what Nissan does. @madkaw has done some tuning on performance engines, as well as @Diseazd and other that I can't remember right now. These are for 1973- What is this part?

I have seen descriptions of it being done. You have to put the number one cylinder in a certain spot so that you can get the pan past the counterweight. But rod bearings don't go bad quickly on these engines. If you have rod bearing problems there's probably a lot more wrong that needs fixing. You didn't say what car you're working on. Good luck.- Z's on BAT and other places collection

Looks like somebody put a lot of work in to it. Why not the last piece though? Makes no sense! "400ci Chevrolet V8 is equipped with a Holley Stealth Ram intake and throttle body, sequential-port fuel injection, an electric cooling fan, an engine-compartment fuel pressure gauge, a Harwood plastic fuel cell, and a remote battery mounted in the trunk.......Power is sent to the rear wheels through a Ram clutch and a Tremec six-speed manual transmission." and an R180. - saturday night music thread

Important Information

By using this site, you agree to our Privacy Policy and Guidelines. We have placed cookies on your device to help make this website better. You can adjust your cookie settings, otherwise we'll assume you're okay to continue.