Everything posted by Zed Head

-

Hard to find Redline MT90

I'm using Synchromesh in a Ford transmission and it's good stuff. I've been thinking about using the Friction-modified for a little more. It's a notoriously notchy transmission. The Ford spec. Mercon V was terrible compared to the Synchromesh.

-

L28 Engine For Sale

-

L28 Engine For Sale

I missed that and I was looking right at it. Maybe an E88 head then? The block is still N42. The stamp on the #6 cylinder will tell displacement. Might be an L24 or L26. Sorry AChev, we have confused your sale. The stamp on the #6 cylinder will tell much.

-

Hard to find Redline MT90

One key is to know what you're trying to fix. High RPM synchro problems and notchiness are different things. Many people use plain old 75-90w and do fine, while saving some money. If you want to get fancy use Swepco 201 and ATF at a 3:1 ratio. I use it on my old worn ZX 5 speed and it fixed all of my problems. That's a JMortensen suggestion, except he mixes at 1:1 I think.

-

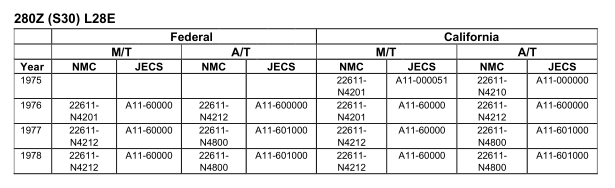

What are the facts about 280z ECU compatibility and differences

Nissan's own ECU document says that the Federal models use the same ECU for the manual transmission cars, even some auto cars. The document is in the Downloads area.

-

L28 Engine For Sale

It has the N42 head and N42 block, so probably dished pistons. 75-76 engine. You might pop the valve cover and get a shot of the camshaft. Probably help your sale. Good luck.

-

Hard to find Redline MT90

Pennzoil Synchromesh is popular. Chickenman and others around the internet say that Friction-Modified Synchromesh is good also.

-

280z dies randomly while driving..

I think that the valve can get stuck open too. That would have an effect. You might just take the bolts out, lift it off and inspect it like 246 says, then make a temporary block-off plate if it's intact inside. Beware, the bolts tend to break.

-

280z dies randomly while driving..

If you know someone else with a 280Z maybe they'll let you put yours in to their car. If the problem follows the ECU there's your answer. People have been known to actually see the defects in their ECU's. Burnt parts or cracked solder joints. Might be worthwhile to remove yours and take it apart. It's very easy to do.

-

280z dies randomly while driving..

One of these - http://datsunforum.com/efi-troubleshooting-kent-moore-j25400-analyzer/

-

280z dies randomly while driving..

This is another sign that something's wrong in the ECU, I think. Most engines will go full rich, maximum temperature-based fuel enrichment, and die immediately if you disconnect the sensor. If you can find a spare ECU it would be worth a try. Maybe you can borrow one.

-

280z dies randomly while driving..

So at 4 minutes it died, then you got out and disconnected the coolant temperature sensor to restart it, then you reconnected the sensor and drove away? This is a stretch but it sounds like it might be related to the ECU, at the coolant temperature circuit. The ECU failures lead to either running rich and dying or just plain immediate dying. Disconnecting the sensor stops current flow through that circuit in the ECU. I wonder if that's the basic reason the ECU's die, the coolant sensor circuit goes bad. I had a 78 ECU go bad, and it would restart also after it died. If you wanted to try a weird experiment that might even keep you going for a little while, put a switch in the coolant sensor circuit. Just run a long wire in to the cabin from each side of the bullet connectors and install a switch. It could even be a momentary push button switch. Then you can break the circuit as soon as it starts to die instead of stopping, getting out, and disconnecting it under the hood. It might help you keep going and offer a clue to the real problem. It sounded pretty good until it crapped out.

-

1978 280z what is this Filter Looking in fuel line?

That one is for fuel. "280" is looking for the vapor line check valve. Actually, I was wrong in my earlier comment. Not any check valve will work. How it works is shown in the FSM drawing. Two way, like CO said. It's kind of redundant as far as the fresh air flow backward to the tank since the gas tank cap has a vent also. If you do change it to a check valve make sure that it lets air out. The filter that's on there is probably the best "fix" until you find a real one. But it's not really going to affect engine performance.

-

280ZX aftermarket ignition?

Not sure where this is going... Do loop... Good luck.

-

280ZX aftermarket ignition?

Good luck with it. You really gotta be very specific and notice the fine details to solve these sporadic problems. The answer is in the fine observations. When and what. "Jumps around" and "occasionally" don't tell much. No offense. The system is essentially two parts - the "trigger" and the current control. You could buy an MSD unit and run it with your distributor trigger. But if the trigger is the problem it won't help. You could also convert to points for a test. Mechanical system. No electronics to confuse things.

-

Relay Testing and Fuel pump help

I would just set up your volt meter, remove your oil pump sender connection and turn the key to On. The pump will start running. Watch, listen, wait. It should sit at 36-37 psi for hours. That's what it does when you're driving, it just sits back their and spins. Watch the gauge, listen to the pump, and wait for something to happen. If nothing happens and fuel pressure holds steady, you're problem is probably not related to fuel pressure. Break the problem in to small pieces.

-

1978 280z what is this Filter Looking in fuel line?

You don't need it for engine operation. It's an emissions device. Edit - the following statement is wrong >>> Any check valve will work. Cool. I've discovered a new trick.

-

280ZX aftermarket ignition?

The GM HEI modules are pretty robust once set up right, and cheap. $25. You can use the red and green wires from inside the ZX distributors to drive them. Or get a 280Z distributor and use that. Your tachometer needle is the best clue to what's happening with spark. If it starts jittering or dropping and rising, or doesn't match engine best-guess engine RPM that's a clue. If it rises smoothly and follows RPM then spark is probably not your issue.

-

Relay Testing and Fuel pump help

The pumps do wear out or get damaged. I had one that I picked up from a wrecking yard that worked great for about 5 minutes then slowly lost pressure and started making noise. FastWoman has posted about one that she had in her car that did similar. This might also explain the drop in voltage that you mentioned early on, as the motor gets loaded up and pulls more current. Might be worth your time to remove the fuel pump and bench test it. Or crawl under the car, set your meter up on the pump terminals measuring voltage, and have somebody actuate the pump for you. You'll hear it and see what voltage is doing. If it looks great with a low voltage drop for a minute or two but slowly drops voltage and runs slower, that's a clue.

-

Engine Building?

I would start with money and convenience on engine builds. If you live down the street from a shop that knows how to work on these old engines, and has a machine shop with a guy that knows what he's doing, for a good rate, you're probably in good shape. Most of us these days have trouble finding anybody who knows much about them and won't charge a ton for simple operations. I had problems finding somebody that would turn a flywheel for a reasonable cost.

-

280ZX aftermarket ignition?

The factory 280Zx distributor and electronic ignition module is pretty good. What improvements are you looking for? Black Gold's HEI suggestion is probably the cheapest, and biggest bang for the buck.

-

Cody's Goon

Shifting in to reverse is the clutch disengagement test. These transmissions don't have synchros on reverse.

-

Relay Testing and Fuel pump help

I did ponder the measurement of resistance on a circuit that had voltage. My reasoning didn't give me an answer. A test light to represent the pump circuit might be a better test. I thought that somebody had found a flaw in Nissan's overall test procedure for the pump control. Maybe that was it. The test results don't fit the original problem very well. As SteveJ noted in post #11. I just tried to move things along. Might have extended the barking instead. Sorry.

-

Fuel Pump Relays rewire

What is your idle speed? And did you rev the engine up a little bit when you were checking for charging? Have you checked for voltage at the T plug wires? They both should show battery voltage with the key on and the engine off. One senses battery voltage, the other supplies current to the windings. Your 78 came with an internally regulated alternator. Might be that somebody cut your L wire, the one that supplies current to the windings. Does the red Charge light on the voltmeter light up when you turn the key on and go off when the engine starts? It's supposed to.

-

L28 Bare block N42 for sale

They make nice coffee tables.