Everything posted by Zed Head

-

Build Thread - New Turbo-Swapped 280z from WA

Very clean. You mentioned CV's but you should have the stock u-joint half-shafts in the back. Unless he did that swap also. Worn u-joints can cause vibration, and clunking.

-

'75 280z can't get spark

EuroChas might have uncovered one problem with test method. The electrode is not grounded in the spark test video. Any part of the metal body of the plug needs to be touching a ground point. The valve cover usually woks well. If you re-run the test and find that you have spark that will narrow things down. You could also put everything back together and try starting fluid. If it starts for a few seconds then you'll know you have a fuel issue.

-

'75 280z can't get spark

No start, or no spark and no start? With the new distributor you should certainly get spark. Unless it's not turning. People have had the distributor drive shaft gear slip. You might remove the distributor cap and make sure that the rotor is spinning. (Also make sure that you installed a rotor on the new distributor. People have forgotten.).

-

'75 280z can't get spark

This part would be normal.. The + and the - have the same voltage if no current is flowing. The two things most likely to be the source of the problem are the ignition module and the pickup coils in the distributor. The pickup coils are pretty easy, check resistance, and air gap. The ignition module is a little bit harder. Might also be that something broke inside the distributor. When you check air gap, you'll see if that's the case.

-

1981 280zx will not start

You can test the ignition system very easily, just by checking for spark. You can get a good idea of cam and ignition timing by using starting fluid to start the engine. Devise a way to test each system independently. If the engine is flooding, disconnect power to the fuel pump so it won't flood. Start the engine using starting fluid. If it runs well with starting fluid then you'll know that timing is correct, so you won't have to worry about that anymore. You're doing too many things at the same time.

-

1978 280z will not start without ether

Alrighty. I didn't really get a firm impression of that. If that's the case, then a situation I had a while ago might apply. I damaged my ignition module when I forgot to put two spark plug wires on and started the engine. I shut it off right away but after that the spark was too weak to fire the gasoline. It would only start with fluid. And that was a warm engine. I know he said amazing spark, but who knows. Not sure how spark was measured either. Maybe the Start ignition wire is disconnected, and it's catching on the one spark when the key is let go, using ether. Maybe the fuel pump control is screwed up. Test that by removing the oil pressure sensor wire. The pump should run when the key is On. Then you'll know you have fuel pressure. Also, pull a spark plug after it doesn't start. See if it's wet or dry. Maybe you're flooding and the ether is enough to catch a wet spark. Finally - when you say "won't start" do you mean it tries to go but won't catch and run or you get nothing at all? Couldn't tell from cranks and cranks. Finally #2 - describe the work you did. Maybe, somehow, you've lowered the compression ratio so much that it won't fire a gas-air mixture at low RPM. Maybe you have a vacuum leak. Maybe your valves aren't closing completely (you run the risk of burning them if that's the case). Measure cylinder pressure if you can. It's a good clue. Spitballing...

-

1978 280z will not start without ether

This is normal. It's an oddity of the fuel pump control system. Actually a defect, safety-wise. You said that you did a ton of work. I'm going to guess that somehow you disconnected the blue wire to Pin #1, the one from the coil, to the ECU. It's what the ECU counts to determine when to open the injectors. If you added an MSD ignition or did some other igntion or tachometer mod, the EFI system might not work properly. The tachometer is a branch off of that same circuit. Make a list of the ton and maybe somebody will see something else.

- 1981 280zx will not start

-

240z Auto trans and torque converter-free in Detroit

Seems feasible. A picture of a removed bell housing would be interesting.

-

electrical issues on 77 280Z

Must not be much current. It will kill the battery but the circuit has enough resistance that there's not enough current for a test lamp? Seems odd. How fast does it die? Has the alternator been converted to the internally regulated type? There is a problem with some of the conversion procedures that are out there on the internet.

- 1981 280zx will not start

-

1981 280zx will not start

"I have the fuel rail removed right now with everything else connected and I'm going to switch the key just so it starts priming, got the idea from Dave WM. " That's a good idea. Is the CSV out too? Watch all seven. There's no prime pulse on 1981 I think. That came later and even then it often doesn't work. Disconnect the starter solenoid wire, and turn the key to Start. The engine won't turn but the pump will get power.

-

1981 280zx will not start

The injectors get power as soon as you turn the key On. So any short to ground on the wires going back to the ECU would open them. A pinched or abraded wire for example. But a short should show up in your testing at the ECU, as a voltage drop, less than battery voltage measured at the injector pins. You might also hear them click when your turn the key on although the BCDD clicks also. The CSV should only get power when the key is at Start. So it's possible that it would flood the engine, but the odds of pumping a quart of gas in to the engine through shorted injectors, by sitting with the key On, thinking, seems more likely. I filled a chevy crankcase with gasoline after I put a friend's carb on the car and tried to start it. Turns out he had got it from someone else and they had removed the float valve.

-

L24 compression question

Before you button it up, just rotate each lobe to the base circle (the part where there's no lifting force on the rcoker arm) and measure lash. No need to turn any wrenches, just get a number. That will tell you a lot. If you had excess wear you'd be able to feel it on the lobe, by running a finger nail across the lobe and feeling for a ridge. The deeper the worser. There's two easy things that will give you something to ponder over the cold weather. grannyknot mentioned rings. If you re-run your pressure measurements, but with oil in the cylinders, that will give an indication of rings versus valves. Oil tends to affect the rings sealing more than the valves.

-

1981 280zx will not start

Might be flooding due to disconnected or broken coolant temperature sensor. And somebody parked it beside the barn for a reason. The 1980 EFI Manual is probably about the same for 1981. Might use it to at least get familiar with the parts. http://www.classiczcars.com/files/category/14-280zx/ http://www.classiczcars.com/files/category/4-manuals/ 1980 "EFI Book"

-

WTB:Manual transmission rear case

That was my conclusion too. You can see the reverse lockout mechanism inside.

-

WTB:Manual transmission rear case

I'll put the pictures here. More interesting. It's from a mystery 5 speed that Itook a chance on. Ended up using the case to build a 71C swap. The insides had broken synchros and the adapter plate bearing was bad. Looked like somebody got angry and tried to blow it up. But the cases were in good shape.

-

280z from 1977: startup and idle problem

Sounds like it's running very lean. You probably have a leak in to the crankcase from one of the PCV hoses. Examine all of them, including the one in to the block under the intake manifold. Make sure all of the hoses in this picture actually go somewhere important. All of the air that goes in to the intake manifold needs to go through the AFM. So check the hoses from the AFM to the manifold also. If you can, confirm that your fuel pressure is correct also. Pumps get noisy when they have to push hard through something like a kinked line or blocked filter, or when they have to pull the fuel against a restriction. You could have fuel starvation.

-

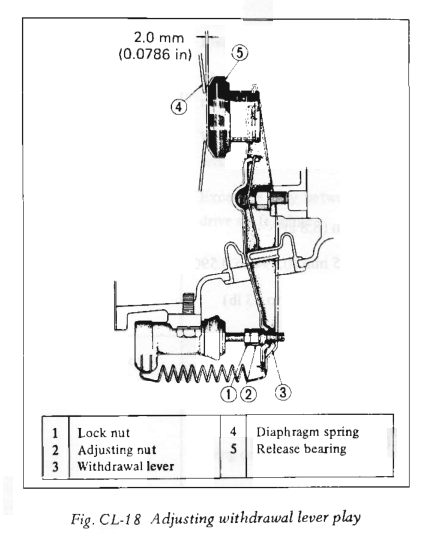

Clutch help in 71 with 5 speed please.

Hope I wasn't too blunt earlier. The clutch control is actually very simple once you dig in to it. The reason that the same measurement works for all combinations of engine, clutch and transmission is because the slave cylinder bolts to the tranmssion in the smae spot on all transmissions, and the fork pivot is the same height, and the flywheel surface is usually the same distance from the mating surface of engine and transmission. Here's a diagram from the 1972 FSM showing the relationship of all of the parts, with the adjustable rod. You can see how the angle of the fork needs to be the same (edit - unless you have the adjustable rod. But Nissan got rid of that, probably to hold the best angle for the slave cylinder travel) because the slave cylinder and fork pivot can't move. They're fixed. So the fork at the collar is always starting in the same spot. so you have to adjust the collar to make everything work right. It's all about where the end of the fork starts its movement. p.s. Found that the new software allows CTRL V pasting of snipped images right in to the post. Sweet.

-

L24 compression question

The oil from the oiler also oils the valve stems and their seals, and some slips past for the guides. Oil draining and flying everywhere when it works right. When a piece of the system fell off the rest of the holes didn't get any pressure. The front cylinders might have got some timing chain sprocket and chain splash, while the back was drier. I'm just conjecturing. I'd guess things got dry, some valve stems and guides and cam lobes and rocker arms got very hot, and this affected the seals and the valves themselves. Basically most of the valve train overheated. Might also be that there was some lobe wear and the valves aren't opening at the correct time. #4 might be dying. Did you check valve lash when you replaced the oiler section? Just one possibility.

-

Coolant temperature

If it doesn't keep rising, past the M, on th highway, you don't really have a problem. Ranges have a high and a low.

-

Clutch help in 71 with 5 speed please.

We already said that your measurements look right. Confirm that the hydraulics do what they're supposed to do. Measure the distance that the slave cylinder extends out of its bore when the pedal is pushed. Hydraulics can fool a person.

-

Clutch help in 71 with 5 speed please.

Nobody mentioned diameter. Maybe "thickness" is a better word. Stole this from EuroDat's past post. Post #33.

-

280z parts for sale

That would be the pinion shaft flange. There are different styles out there. Beware. Specify the drive (propeller shaft) that you'll be using. The Z's up through the 280ZX's all used the same bolt pattern and bolt size, except for 1975. Might be easiest just to get an old open 240 - 280Z open diff (except 1975) and steal the pinion flange.

-

280z parts for sale

I have a complete 240Z driveshaft. Two actually. Both the short style though, for the offset diff. But the flange would be removable.