Everything posted by Zed Head

-

280ZX Stalls and Restarts an Hour Later

and post #9. No offense intended. Many of us have found that it's most effective to really dig in to examining and testing the parts first. Just saves time, money and effort in the long run. You can test resistance on the coil and the pickup coil in the distributor while it's in a "no-start" state. You have one of the unique opportunities where the part, whatever it is, stays "bad" for an extended period of time. So, start-die-test-test-test, until it starts again. Then repeat until you find the broken part. It's probably electrical so a multimeter and some time should do it.

-

rear wiper

About a week or two ago I noticed that he was logged in. I remember that he said he was having back problems about a year or more ago. Those can really mess you up. He's up in Seattle. @rossiz

-

All studs or studs and bolts

I bought a ZX motor that had bolts on all of the manifold holes. No studs. I think that it's personal preference. It's much easier to get a nut on the stud from underneath the intake manifold than trying to insert a bolt in to a hole. One argument for studs is that when you put the final torque to it you're spinning steel threads on steel threads. With a bolt it's steel on aluminum. The same when you're removing them. Studs probably help avoid damaged threads. The four big bolts for the intake would probably make life difficult if you replaced them with studs. Never seen big studs used there.

-

New Member - 77 280Z 3-Speed Automatic

Does it have a catalytic converter? They got rid of ZDDP to save the catalytic converters, along with lead in the gas. Might rethink the zinc in the oil. https://www.catalyticconverters.com/damage/

-

New Member - 77 280Z 3-Speed Automatic

There's not much reason to take the pans off and clean them. Extra time and effort and could lead to unexpected problems and leakage. Do you know why it has been sitting? They all "ran when parked" but there must be a reason. Some simple things that you can do are to open the fuel line between the fuel filter and the rail and see if there's liquid fuel in it. See if it smells like gasoline or sweet kerosene. Or Pine Sol. If it's dry or the fuel is orange-red and smells funny the injectors could be gummed up. If it smells like gasoline they'll probably be okay. After you check the fuel tank for rust and old fuel, refill it with fresh gasoline then run the fuel pump to push the old fuel out of the rail and injectors and get it diluted with good new fuel. Or break the return line back by the tank and push the old fuel out. Check that the breaker plate in the distributor isn't rusted. If it is the bearing cage will probably break when vacuum is applied on the first engine start. Lube it up before starting. Pop the valve cover and see how much rust is under there. Condensation can produce a lot of moisture over time. If there's rust then one of the oils with zinc additive might be a good idea. Many people don't use it after break-in but better to be safe. Valvoline VR-1 is popular. I think that NAPA carries it. Check the air filter housing and intake tubing for mice nests. It's one of their favorite spots, besides the air vents in the cabin. Squirt some oil in the cylinders through the plug holes and let it coat the rings before spinning the engine. Some of the valves are always open when the engine is stopped so there will be at least two cylinders with some surface rust on the bores.

-

Pulling the rear drum brakes off my 1977 280Z

The Nissan studs are still available. You can even get them from Amazon. #18 http://www.carpartsmanual.com/datsuns30/Datsun-Z-Index/Axle/Front-Axle

-

'75 280z made it out of the garage.. briefly

I think it's mostly the volume. There was a thread very recently showing the inside of one of the water c ocks and you can see that it's a very small orifice, compared to the size of the water hose. The volume through the heater core is small. Connecting the hoses lets a large volume of coolant pass through the block then right back to the pump inlet. Big hoses. It would be like running a smaller water pump. Plus the coolant is hot from absorbing block heat but doesn't pass through the radiator or the heater core. So you end up with a large portion of the pump volume absorbing heat but not releasing it to the radiator. Somebody actually did some dyno runs with temperature measurements to show the effect. The infamous Tony D. The engine got much hotter with the hoses connected, than with them blocked.

-

Pulling the rear drum brakes off my 1977 280Z

If you're going to replace the shoes you might as well spray some WD-40 or squirt some oil inside and spin the wheel to get things lubed up. Even after you get them started they'll be hard to keep coming.

- 78 280z Severe Driving Problems

-

Reverse backup light switch for 280z 5 speed tranny

The NILES part might be a good part. It's a Japanese company, so not your typical aftermarket supplier. https://www.autopartsway.com/brand.cfm?brandname=niles

-

alternator swap

I've found that my old Nissan factory ZX alternator is better at low RPM than a "new" reman alternator. It's fun to modify but if you're just looking for an improvement that might be an option, if you see one on your wanderings.

-

alternator swap

I think that J30 alt is similar to the Maxima alternator. I think it uses a ribbed belt too, not a V-belt. I modified a 90 amp Maxima alt but it's still sitting in my garage waiting for my old ZX alt to die. The hardest part is getting the nut off of the pulley shaft, and getting a pulley that will fit and be centered after messing around with it. The Maxima alternator is a bolt-on as far as brackets go. I think. I should go out and refit mine to be sure.

-

Distinct clunk when accelerating in first gear

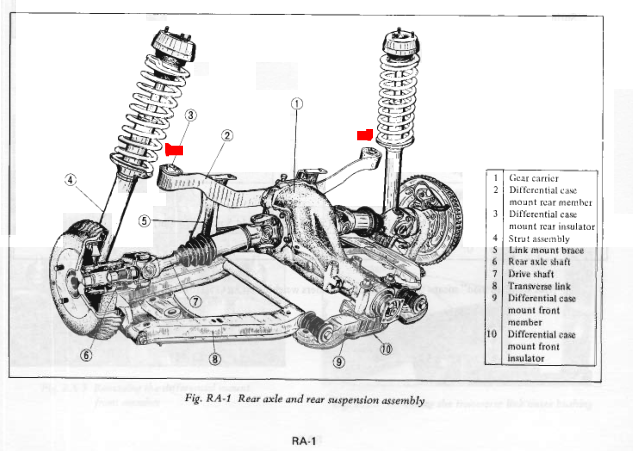

This is a nice looking undercarriage though. Very clean. No leaks. Wish mine looked like that. But, you should get some soft pads for your mechanic to use on the lift arms. He's denting things and lifting in the wrong spots. Each lift probably adds a little bit more damage.

-

Reverse backup light switch for 280z 5 speed tranny

You've been using the illicit side of the free market?

-

Reverse backup light switch for 280z 5 speed tranny

Free market economic principles.

-

'75 280z made it out of the garage.. briefly

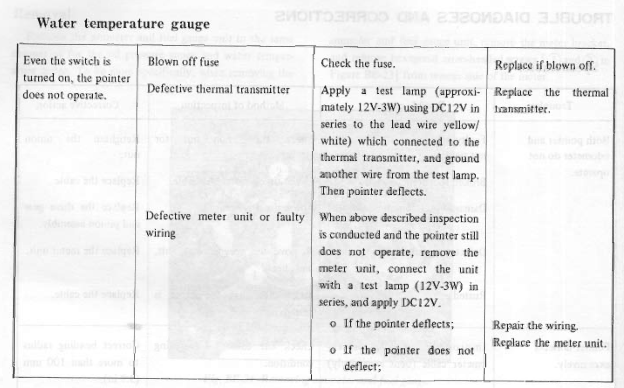

I think that you can test the gauge itself by grounding the harness wire at the sender to the block through a small resistance. You can also measure resistance through the sender prong to the block to see if it's good. The sender ground through its threads I think. Sometimes people use Teflon tape and don't get the ground. Found a procedure in the 1972 FSM -

-

Distinct clunk when accelerating in first gear

Good times man...good times. You can get thumping from the ends of the mustache bar also. The diff twists when you apply power, or torque from deceleration. If the mustache bar bushings are loose you'll be able to lift the end of the bar up by hand.

-

l24 blocked engine build - Few Questions

Here's something beyond quench... (For thought only. It's voodoo.). https://www.google.com/search?client=opera&q=Somender+Singh+Grooves&sourceid=opera&ie=UTF-8&oe=UTF-8 http://www.herningg.com/projects/groovyheads.html https://somender-singh.com/index.html

-

l24 blocked engine build - Few Questions

Sorry, I think I blended two threads together in my head, or assumed that the head they built was designed with "squish". Actually, I can't be sure, the details aren't in the thread. Here's the thread I was thinking of and another I found when I was looking. Sounds like he used an open chamber N42 head. http://forums.hybridz.org/topic/51825-scratchbuilt-l6-efi-intake-manifold/ Here's some squish stuff. I've found a lot of inconsistency in what people write abut quench/squish. For example, you'll find people taking about how the piston has to be within a certain distance to the head or you'll actually create a detonation hot spot. But then when you do the math on their engines you find that it doesn't fit, they have no quench. http://forums.hybridz.org/topic/63444-l6-squish-discussion-the-battle-against-detonation/ BRAAP has a post out there somewhere about getting the piston so close to the head's quench pad that the piston number transferred to the head, in the carbon residue. Sounds neat but not clear if an actual benefit was measured. That's the basic problem. Showing that it works.

-

l24 blocked engine build - Few Questions

It's one of those engine building concepts, to create the best combustion process, I believe. The "squish" is supposed to propel the gases in the squish area out across the combustion chamber for more complete combustion. There is also a cooling effect on the top of the piston that some people propose happens as it gets so close to the head. What's not really clear though is how the rest of the chamber design comes in to play. Valve and port orientation and the way the gases flow in to the cylinder, spark plug location, things like that, all come in to play, I think. The OP has put together a set of "perfect" concepts, but it's unknown how all of the perfection will work together. There's a good thread on Hybridz by BRAAP and Ron Tyler, where they took all of the "known" ideal concepts, including quench and porting and a new intake manifold design to build an engine. When they dyon'ed it, they couldn't get much power out of it without major detonation problems. They used Megasquirt and knew how to tune but the parts just wouldn't work together.

- 78 280z Severe Driving Problems

-

'75 280z made it out of the garage.. briefly

The radiator cap is just a pressure relief valve. If the pressure is exceeded the coolant is purged through that tube. Could be that you got the wrong cap or that you just didn't have it inserted right. Check that cap closely, make sure it's seated so that it can hold pressure. If it's not seated the coolant will just flow out as it expands. The heater cores are best if they are blocked, not connected. By connecting them you're creating a short circuit for the coolant and it doesn't pass through the head. It just circles around in that useless loop. It reduces the overall flow through the engine. Where'd you get that cool looking "FUSIBLE LINKS" cover? Is that what they used in 1975?

-

78 280z Severe Driving Problems

I forgot that you had the rail out when I suggested just starting the engine. In my test, I wired the injectors in series so total circuit resistance was 6 x 2.5 ohms...15 ohms. I was more concerned that they might not open. But the key is that it's not voltage that is the concern, it's current. Overheating. If you connect 12 volts to a dry injector I think that it might heat up enough to do some damage, over time. Maybe. But in your case with the dropping resistors in place, and fuel passing through, there shouldn't be any problem. The injectors see 12 volts as soon as you turn on the key. They're opened by grounding that voltage at the ECU.

-

78 280z Severe Driving Problems

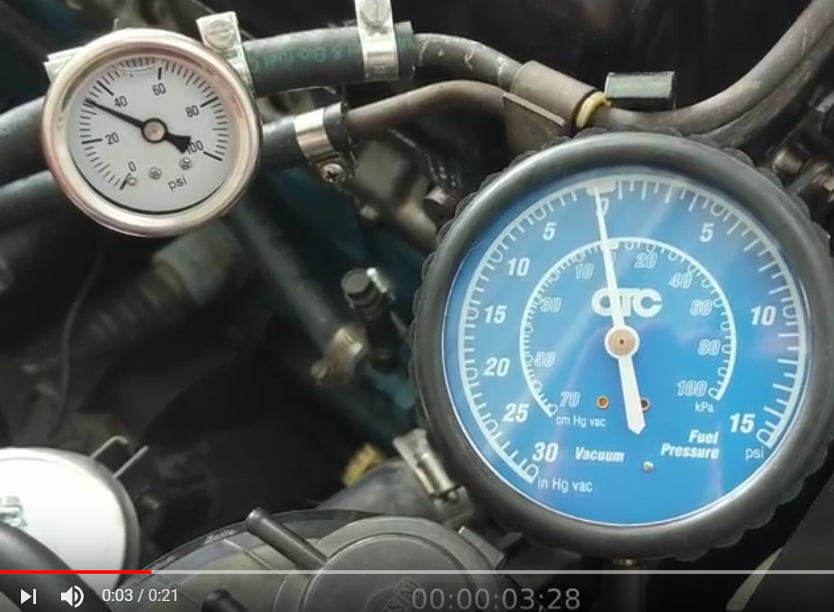

Just realized that you might have run your vacuum port FPR test using residual pressure. Fuel pressure tests are generally done with the pump on. There are many ways to run the fuel pump without the engine running. A simple one for 1978 is to remove the oil pressure sender wire. Then turn the key to On. The pump should run continuously. It's a flaw in the system. The pump will be fine also, it's cooled by fuel too. It runs full time when the engine is running. You can also remove the starter solenoid wire and turn the key to Start. Or prop open the AFM vane and turn the key to On.

-

78 280z Severe Driving Problems

In the picture I grabbed from your video, copied again below, if you've ever seen 40 psi then you should have seen it at zero vacuum, as shown in the picture. Unless the extra 2 volts from alternator power pushed the Walbro up in to the excess volume zone. Who knows. Fire up the engine, remove the vacuum reference hose from the FPR, and see what the fuel pressure gauge says. Give the engine some RPM to be sure you're at maximum alternator output. The pump is just pushing against the FPR spring to get the seat open. Maybe you've got some particles holding the FPR seat open and that's why pressure is low and doesn't respond to vacuum. Ponder that FPR drawing that you posted earlier and you'll get some ideas. The vacuum just relieves atmospheric pressure from the spring cavity. You could probably blow on the reference port and get pressure to rise. These EFI systems are just a collection of really simple concepts. So, unless your helper was pulling vacuum in the picture below and it didn't show on the vacuum gauge I'd say your fuel pressure gauge is sticky. Pulsing the injectors adds extra information, but if your inlet screens are clogged it won't show that, directly. I filled those bottles at wide open injectors with my own tester. Injectors wired in series. The injector solenoids are cooled by the fuel passing over them and the current is low. They'll be fine. Pressure should be at maximum with no vacuum...