Everything posted by Zed Head

-

R180 half shaft dislodged from differential.

Edit - the R200's are. Maybe the R180's aren't. The diff axles are different length, left to right side. If you had two short ones in your diff, one of them won't lock in. Shouldn't be any difference in axle length by year. Looks like you have spare parts. Maybe you got some mixed up.

-

Cody's Goon

What does "baulky" mean? I had an old transmission that took a little while to wear itself back in. The first few drives were tough. The "cones" are steel and can rust. Also, for old transmissions, Redline MT90 is great stuff. Makes a difference worth the extra cost.

-

R180 half shaft dislodged from differential.

I think that it's called a "circlip". Circular clip. If you didn't seat the clip in the groove the last time that you installed the half-shafts (that's what we tend to call the u-joint "drive " shafts [which is what Nissan called them back then] then the axle might have been loose and worked it's way out. Or, as grannyknot said maybe it's just worn out. Usually it takes some serious effort to remove the axle from its clip. I use an oiled chisel face myself to wedge it out. They should be very tight. The clip is in the diff.

-

280z dies randomly while driving..

Begin here -

-

Relay Testing and Fuel pump help

Shiny. Apply power, wiggle things. The loose connection will show itself.

-

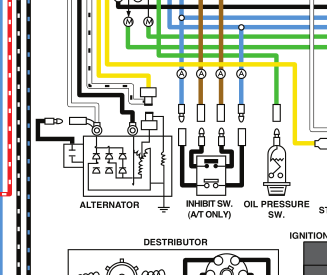

Alternator condensor?

I think it's white/black one. Bottom of the T. But the bad connection could also be at the regulator. Could also be in the regulator. The alternator supplies the ground for the light and energizes the windings so that charging can happen. If it happens again you could check for voltage at various points on the circuit. Follow it from the lamp or back from the alternator. All I'm really saying is that the light should have been on. The fact that it wasn't is a clue.

-

L28 Bare block N42 for sale

Mmmmm...cosmoline. What does "preped" mean, and "good"? Good for immediate reassembly or good for machine work? Looks like they removed all of the core plugs. Probably hot-tanked it. Was any machine work done? You said engine but just show a block. Are there more parts? Just trying to help out. @Mr. A

-

Alternator condensor?

Was the red Charge light on? It should have been. If it was not on then you might have just lost connection with the L wire at the T-plug. I've had that happen at the alternator and at the starter solenoid. Take it off clean it up, give it a little extra crimp with a pair of pliers. And, by "no charging", do you mean it showed some voltage but less than 12? If it showed zero volts then you have a different problem.

-

Relay Testing and Fuel pump help

No. Soldering abilities at the Nissan factory weren't very good back then. Broken solder joints and loose connections happen. Some connections are soldered and some are staked. Time to pry those tabs back and take the cover off.

-

1976 280Z Restoration Project

Funny, I just popped one of those out the other day. They tend to be difficult. A pair of Channelocks over a few layers of cloth will get it spinning to loosen it up. A big screwdriver in the hold-down slot, with a piece of wood under it for a lever that doesn't damage anything, helps pry it out. But, to confirm what you probably already were thinking - it's awkward and difficult, and they tend to stick. Hard to avoid getting plier marks on it. Most are scarred.

-

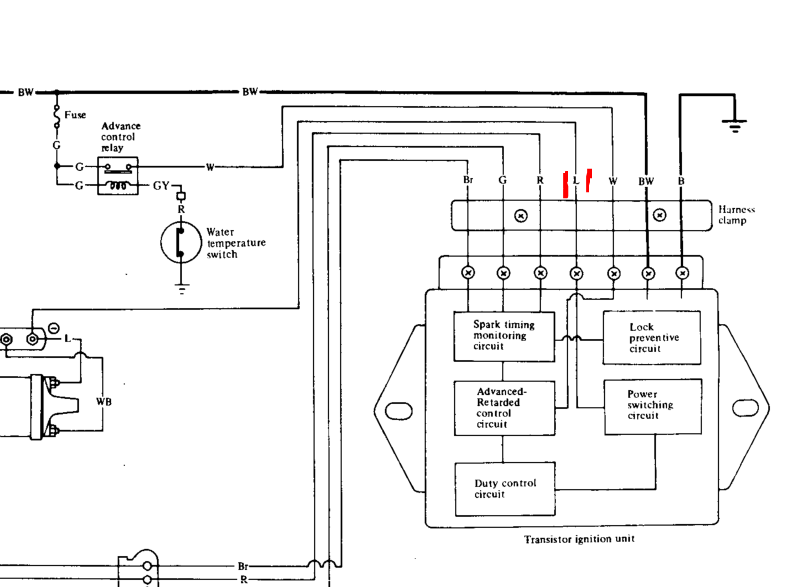

Crane XR 700 does it increase performance

They're right here. The tachs seem sensitive to the voltage pulse. People often have problems with the MSD ignition systems too. I had problems with a GM HEI module. The XR700 is about exactly like what you replaced. No real benefit. You could put the old stuff back and keep the Crane as an emergency spare.

-

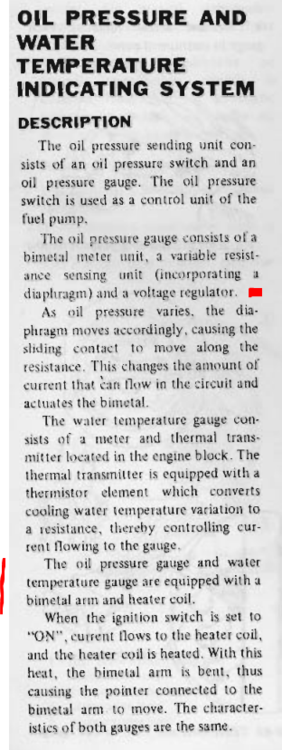

Oil pressure sensor 1983 280zx NT

Might be the gauge itself, not the sender. There is some voodoo there also. This is from 1978. They stopped describing it in later FSM's. It's not a great description they don't really tell where the voltage regulator part is. They blend the sensor and dash gauge all in to one. But, it might be the gauge.

-

Crane XR 700 does it increase performance

The XR700 is the "low energy" version of their electronic ignition. It keeps the ballast resistor and is basically just a points replacement. The XR3000 has current-limiting technology and is designed to use a lower resistance coil so that you can use a larger plug gap. SteveJ is asking about the ignition module that your 260Z came with. It's the finned aluminum thing by the fuse box. The blue wire needs to be disconnected from it, at least. Might as well disconnect all of them. I've posted this before but sometimes a capacitor/condenser on the negative side can suck up some voltage spikes. I'm not sure how Crane's adapter works, it needs an external power supply. Your tach is the voltage sensing type, not the Smith. http://www.triumphspitfire.com/images/cranemanual.pdf

-

Crane XR 700 does it increase performance

Might be easier to just fix the tach problem. What is it doing? Higher energy spark generally helps for leaner mixtures (emissions), richer mixtures like you might find with a high performance cam at times, turbo engines with high cylinder pressures, stuff like that. It reduces the number of misfires. Once the spark starts a fire, performance is on its way. For general driving around in the car, probably not much difference.

-

Look what I found.

-

Relay Testing and Fuel pump help

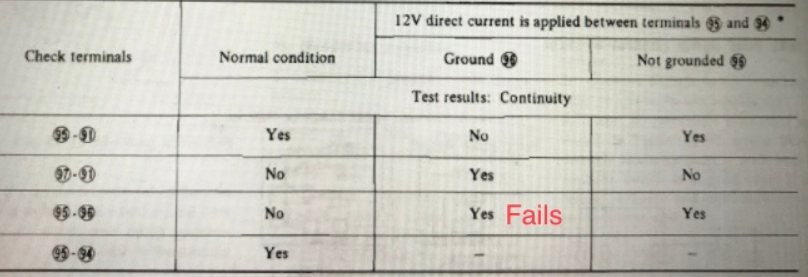

The odd part is that you did get continuity in the "Not grounded" test, but not on the "Grounded" test. Doesn't make sense that the contact would open just by grounding 96. Unless it's a sporadic problem.

-

Relay Testing and Fuel pump help

Sometimes a spec of dirt can get between the contacts in the relay. I would take apart the pump control relay and apply power, then just watch to see if the 95-96 contacts close. If they do close but there's no continuity then there's something in the way. You won't get shocked with just 12 volts. Take it apart, check the contacts, hook up some power.

-

Relay Testing and Fuel pump help

I converted your numbers in to yeses. Everything looks right except for the fail. That must mean that you had an open circuit on 95-96, meaning that the fuel pump relay would not get power. I reread your first post and can't really tell what the problem is that you're trying to fix. You said that you have a weird problem where the "new fuel pump was working". no power 95-91 Yes (yes) No (no) Yes (yes) 97-91 No (no) Yes (yes) No (no) 95-96 No (no) Yes (???) Yes (yes) 95-94 Yes (yes)

-

Relay Testing and Fuel pump help

Not really clear what you're saying here. "my readings were very different between the 2 tests". Are you saying that two different meters gave different results? Or that the same meter gave different results? And when you write "FAIL" you should still give the value of no or yes, or, better, the resistance reading. You have no, FAIL, and resistance readings all blended together.

-

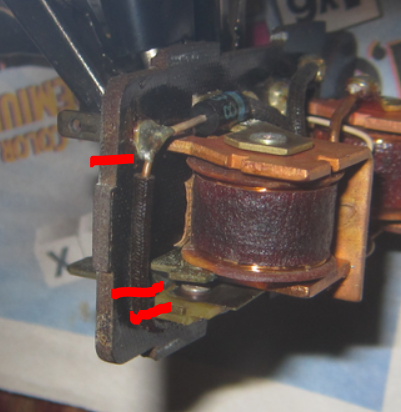

Repair distributor vacuum advance pot?

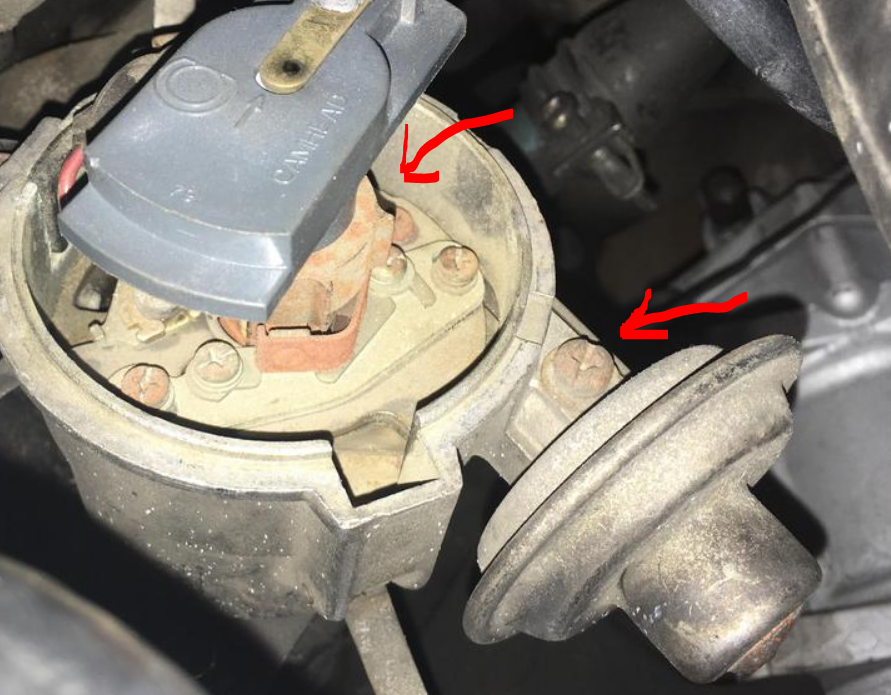

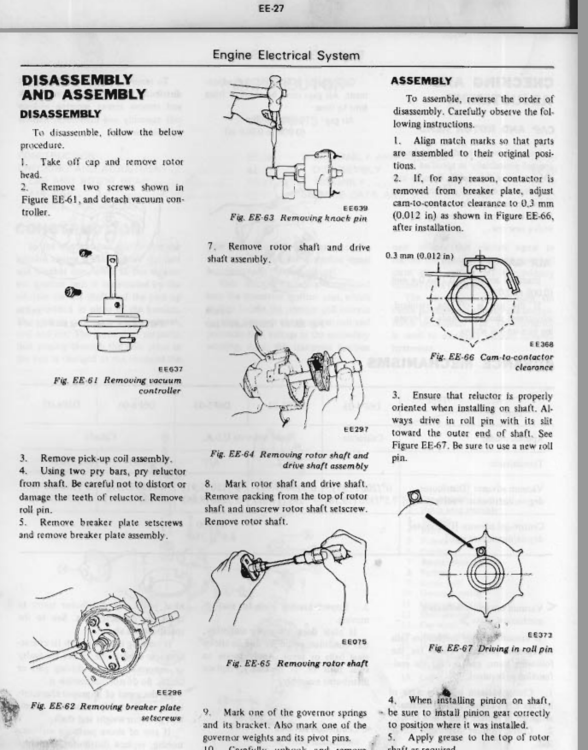

If you remove the big screw you should be able to carefully wiggle the canister free and very carefully pull it out slightly. As you move it the plate with all of the screws in it should rotate. Be very careful, if it doesn't move easily don't force it. The bearings are in a plastic cage that often breaks. OR. You can twist the pate with all of the screws in it in the direction of the vacuum canister. The rod should goin to the canister as the plate moves. OR. You can remove the tiny screw that holds the end of the rod on to the plate, then the big screw that holds the canister, and just remove the whole canister. Then twist the plate by hand. OR. You can do the above, then remove the whole distributor and remove the breaker plate, and look through the sides for rust. Loosen the big screw first, it's usually very tight. Sometimes so tight it takes drastic measures. BUT. There's a lot of rust visible there. I'd be surprised if your bearings aren't already rusty. They might be salvageable. You probably haven't had vacuum advance for a while. If I had that in front of me, I'd loosen the big screw while it's mounted then take the distributor out and go through it. Take the breaker plate out, check the mechanical advance, and the breaker plate bearings. Disassembly is shown in the FSM.

-

Repair distributor vacuum advance pot?

I must have been thinking of the 240Z cans. I know I was keeping my eyes open for spares since they're hard to find.

-

Repair distributor vacuum advance pot?

My mistake. I might have been thinking of breaker plates. Did you check that the arm attaches to the same spot on the breaker plate?

-

Repair distributor vacuum advance pot?

I happen to have my box of distributor parts down. I'll dig around and confirm.

-

Repair distributor vacuum advance pot?

The round part that fits in to the distributor is smaller and the arm is a different length. If I recall right. Always worth double checking.

-

Repair distributor vacuum advance pot?

Since you're working on yours, check the breaker plate for rotation. If the bearings are rusted up or have fallen out, it might be time to just get a replacement distributor. The vacuum unit moves the breaker plate so if it won't move anyway it's a pointless fix. You should be able to rotate it by hand. The vacuum unit pulls on it.