Everything posted by Zed Head

-

123 Ignition plasma ball

Be careful with disconnecting your plug wires. And sparks in general. My experience has been that electronic ignition modules do not like stray electricity. I fried a GM HEI module by leaving two wires disconnected by accident. http://newautoaa.blogspot.com/p/secondary-circuit-of-ignition-system.html

-

LS1 Coil packs

"coil packs" usually refers to wasted spark systems. The LS engine coils are "coil on plug" or COP. www.hybridz.org has a bunch about them. @madkaw has commented about them. Wasn't that you that started a thread in the recent past about this?

-

123 Ignition plasma ball

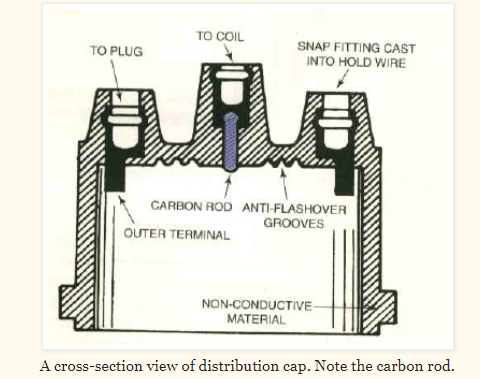

The spark would have to pass through the cap material, or along the surface of the cap, to get from the electrodes to the outside. A thin layer of nail polish is not likely to stop that. Is there carbon tracking inside the cap? Follow the path of the spark from the coil's center electrode, through the wire to the cap's center electrode, and then through the "button" inside and out the rotor to each spark plug electrode. The lowest resistance path will be used by the electricity, of course. It seems like bad cap material just based on the video. There are conductive paths on the outside of the cap, probably on the inside too.

-

Rockets from Iran hitting US bases in Iraq now

Nobody can say what's likely or unlikely these days. Not even worth trying to guess, just assume that somebody will suffer somewhere.

-

"The Orange"

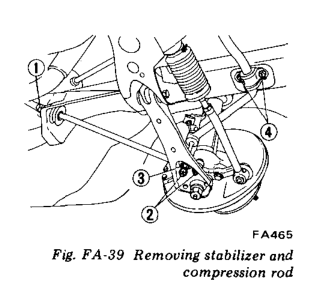

If you move the T/C rod through its normal motion while the suspension moves up and down you'll see that the rod pivots through the mounting hole where the bushings are. The end of the rod needs room to move up and down as the front of the rod moves. The PU bushings are solid and fill up the space that the rod end needs, putting a side load on the rod end. It fatigues and breaks off eventually. I think that it's also where the squeaking and groaning comes from.

-

Pitch of l28 280z motor

Looks like a long lever arm. Interesting but potentially problematic. A broader view would be neat but if you want to keep it secret that's cool. Still, leave the engine alone and work on the back end, I'd say.

-

280z 78 Wont idle, Running Rich, out of ideas.

Your coil should be matched to the ignition module, or points. What are you using?

-

280z 78 Wont idle, Running Rich, out of ideas.

Does "position 5" mean 5 degrees advanced? Not sure what you're looking at or doing. Timing should be set at about 10 - 15 degrees advanced, normally.

-

280z 78 Wont idle, Running Rich, out of ideas.

I think that the mark is actually in between new and worn out enough to move. It's normal wear. If he move's it it will be too far advanced. It's on #1.

-

Pitch of l28 280z motor

Who made it? Sounds like you're using the mustache bar and crossmember mounts. Four points of contact. Never heard of anybody doing this. Kind of on your own, except for general expertise here. Mounting holes, generally, are only used for the bolts to pass through, friction and clamping force should hold the metal in place. The hole edges should not see any side forces, in a good design. Still need a picture. Where's your phone?

-

Pitch of l28 280z motor

He might have one of the aftermarket R230 mounts. Some of them have problems, it would be interesting to see it. If so, doing all of the realignment at the diff mount would be best, probably. The engines should be fine. If the engine is moved it will affect other things, like the throttle linkage, the shiftier angle., cooling fan orientation, etc.

-

2 to 3 clicks when cold starting.

The most common problem that I've seen is dirty/corroded battery connections. Clean them up and try again before buying anything.

-

Pitch of l28 280z motor

You should have mentioned this from the beginning. Side to side, the engine is fine. Front to back is your concern and, as grannyknot said, your driveline angle is important, although it's not the driveshaft angle that matters the most. It's the match between the rear diff pinion shaft and the engine's crankshaft, they need to be parallel. You can jack the ends of the car up to get the oil to drain, if that's a problem. There are how-to's all over the internet. Here's some examples from the past. jmortenen's link to the hybriz site has a bunch, in detail. https://forums.hybridz.org/topic/43993-differential-laser-alignment-tool/

-

Pitch of l28 280z motor

The L28 engine is the same as the the L24 engine, except internally. It's a direct bolt-in swap. There should no change at all in any angles, or degrees of level. It's the same block, essentially.

-

Pitch of l28 280z motor

The oil pan is. The cylinder bores are not perpendicular to the ground, they are tilted. There are no "level" surfaces on the top of the engine. Except maybe the intake manifold heat shields.

-

Pitch of l28 280z motor

Use the oil pan mounting surface and/or the back/bottom of the engine where the transmission bolts up. Underneath.

-

280z AFM lead?

I'd like to see where that black wire is connected also. Looks like somebody in the past either made a bad guess or used some bad logic. Wouldn't be surprised if it was just connected to the cover screw. Ground to ground.

-

FS5W71B Rebuild Thread - Tips tricks and discoveries!

And side forces on the bearing will cause more movement. The indicator probe isn't putting much push on the outer race. Stuff like this is why good machinists make good money and bad ones go out of business. No offense intended, just trying to point out how important the numbers are and how difficult it can be to get them, then use them.

- Air in fuel lines and sputtering at high and now low speeds

- Air in fuel lines and sputtering at high and now low speeds

- Air in fuel lines and sputtering at high and now low speeds

-

FS5W71B Rebuild Thread - Tips tricks and discoveries!

Convenient and easy. Maybe not ideal though. Can't really say without numbers. Grab an input shaft of an assembled transmission and wiggle it. That will give you an idea of how much play there is in the bearings. Probably doesn't matter much though, people have taken apart working transmissions and found that the adapter plate bearings were shot.

- Air in fuel lines and sputtering at high and now low speeds

-

FS5W71B Rebuild Thread - Tips tricks and discoveries!

Did you measure "slop" in the bearing? Just curious. I'm not a machinist but I took a GDT calls years ago. You could end up with a hole bigger than your cutter edges or one offset to one side. From slop in your alignment tool/bearing.

-

FS5W71B Rebuild Thread - Tips tricks and discoveries!

EuroDat and Dave WM had a discussion going about the insert orientation and how the FSM was wrong, quite a while ago. For the record. It's out there somewhere. Found it -