Everything posted by zKars

-

New Product Idea. Distributor Timing Plate Re-Design

Send me the email or PM me with your shipping details, we’ll get one on the way.

-

New Product Idea. Distributor Timing Plate Re-Design

Did any specific machines catch your eye and not your wallet?

-

New Product Idea. Distributor Timing Plate Re-Design

Send me an email to z240@shaw.ca and we’ll exchange contact info. I’ll only ask for the cost of postage to for a proto type Obliges you to test, feed back, send some pics, maybe some good press if you like it.

-

New Product Idea. Distributor Timing Plate Re-Design

Jim Shim. Nice ring to it. Add it to the list. “About Time” is leading in my book. Quite an advanced concept really. The onesix has it’s own base, this thing won’t help.

-

New Product Idea. Distributor Timing Plate Re-Design

I like that idea. A quick browse of laser engravers that can do steel are out of the price range of practicality and $$. I may be able to find a service that does it that makes the per item cost reasonable. I know! I’ll hand engrave and sign each one. Harder to knock off. I have one of these.

-

New Product Idea. Distributor Timing Plate Re-Design

The danger is in the advance getting too high, retard is not an issue. Even things like spark plug wire tension might affect which way it would tend to wander. Maybe an addition “Stop” of some sort (small bolt and nut) to add to the slot CW of the main hold down bolt to prevent it wandering in that direction?

-

New Product Idea. Distributor Timing Plate Re-Design

Since it works on the L4 as well, would have to include 1342 as well. Maybe not a bad idea to inscribe both. It does add considerable expense to have them engraved however. The laser cutter cannot be used to do both cut and engrave. I suppose I should engrave a trade mark as well. Trying hard to make this cheap and easy, not get rich or make so expensive that it won’t do all the good I hope it does. I understand the danger of feature creep. Add this, add that, make it shinier, etc etc.

-

New Product Idea. Distributor Timing Plate Re-Design

Interesting point. If the main bolt comes loose, I wonder which the dizzy body would naturally tend to rotate? At least a good point to include in the instructions.

-

New Product Idea. Distributor Timing Plate Re-Design

It’s laser cut. And it does need a way to indicate top and bottom. The “A” is still an “A” when it’s upside down.... Maybe it should be “R” . Maybe time to buy that desktop Laser engraver I keep getting badgered about on FaceBook. Name Possibilities: Time It! Dizzy Disk TimeBase TimeSlot AnyTime! AnyTooth That thing with the slots.....

-

New Product Idea. Distributor Timing Plate Re-Design

Cool! I hoped it would meet with general approval. Seems that is the case. I sent some out for Yellow Zinc plating, hope they get back before Alberta closes all non-essential services. I can powder coat gloss black, Cast Aluminum, blue, red here in the shop, or supply them “naked” and let you do the sanding, prep and final finish. But first, of course, we need to run a contest for the best name for this thing. Free timing plate to the best three suggestions.

-

New Product Idea. Distributor Timing Plate Re-Design

Could be plated, powder coated, Mac Tac’ed, carbon fibre wrapped, sponge painted, you name it. Questions, comments, etc appreciated. I can send a few of you a “test” part and you can tell me what you think if that works. I’ve been installing them on local cars, no issues so far. You can literally put the bolt in anywhere on the circumference. If the “right” spot is on a bridge, you just adjust the small bolt location to move it around enough. The only fly in the ointment so far is that there are two sizes needed. The dang distributors with points have a smaller inner and outer bolt circle than the later electronic styles. So I have a SMALL and LARGE version of this plate. Fits all the L4 and L6 distributors I’ve tried so far. Just have to have the right one. I have been thinking about a way to make one plate for both, but it means large width slots and washers to span the gaps. Works, but..... Anyway first things first.

-

New Product Idea. Distributor Timing Plate Re-Design

For years, literally years and years, I have been frustrated over and over again when setting up timing on our L series engines. Whether it’s a fresh engine setup, or after removing and replacing the distributor drive shaft after routine maintenance, I’m very often off by one tooth. “So what” I proclaim, I’ll just adjust the timing by rotating the distributor a bit more. But nope, the slots in the plate are never long enough to allow that. Or I have a custom setup and need to put the distributor in a specific orientation, but can’t because the timing plate won’t line up as needed. I’ve had many customer cars in for various work, and often find the drive gear alignment is out have to sort out their timing issues. They may have been running crazy retarded for a long time and didn’t know how to fix it. I’ve often resorted to cutting and welding on extensions to the plate to give me more rotation. Ugly, but it worked. Whatever the reason, being too lazy to drop that sway bar one more time to get the oil pump off, or having a custom setup, or needing to get just the right base to suit the upgraded ZX E12-80 distributor you just bought but now can’t use, wouldn’t it be nice to just have a distributor timing plate that allows more adjustment? Maybe even cover any all possible Nissan distributor replacement options no matter your specific situation? No need to find the “right” base? Heck, just not caring if you have the drive shaft alignment EXACTLY right when you put the oil pump back on, would be worth at least 6 rolls of toilet paper, right? Maybe even a BIG jar of hand sanitizer! Not a week goes by when someone has been begging for help with getting the timing right here or on any of the forums or facebook. How often have each of us posted the famous picture looking down the dizzy hole with the correct tang orientation? You know the one. Well, I’ve had enough. I “Fixed” it. Even put an “A” and and arrow to show you which way is “Advance”. So what say you experts? Is is this worth making more of? Suggestions?

-

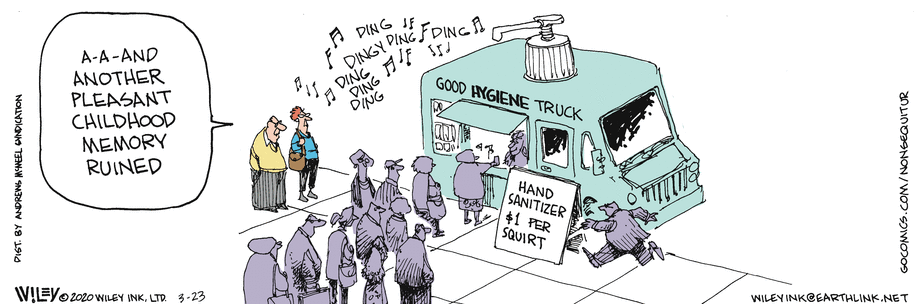

Isolation Videos/Content to Keep Spirits High: Post Something (Non-Virus) for Entertainment of Others

- Isolation Videos/Content to Keep Spirits High: Post Something (Non-Virus) for Entertainment of Others

Very short video. One frame. Thank you Berkeley Breathed/Bloom Country Pretty much describes how many feel I think.- 1975 blower housing differences

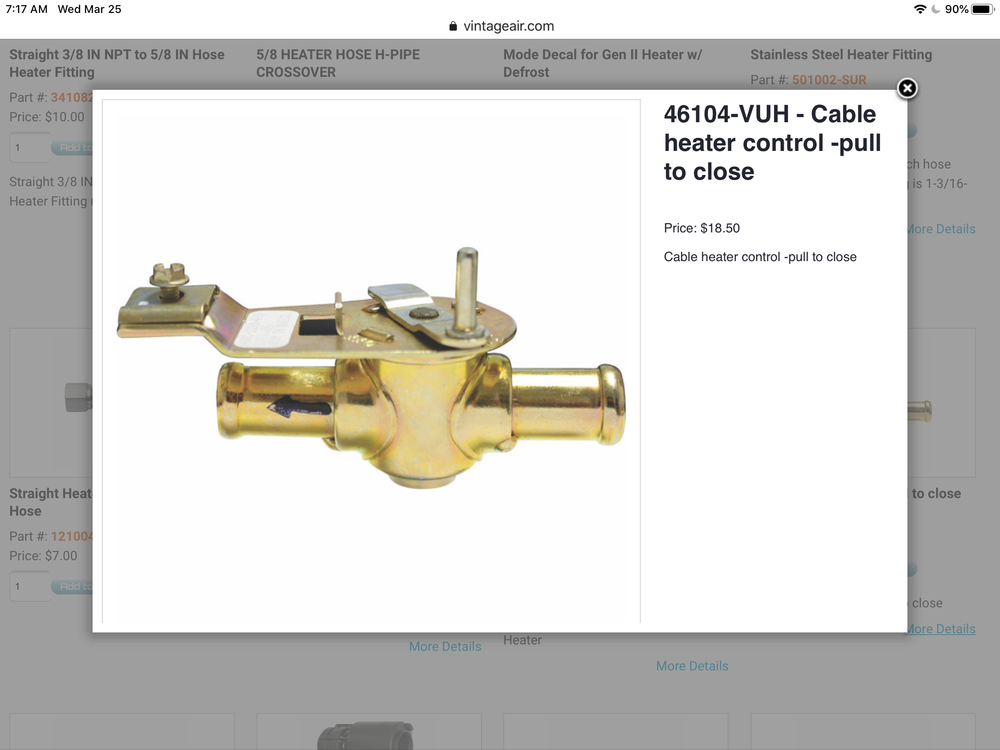

Vintage Air makes a generic powered heater control valve. It can be controlled by any rotary or linear potentiometer (0-10 kohm IRRC) you care to use. $90USD. 50507-VUA - Servo Heater Valve Re-fit Kit with Control Knob and Pod https://www.vintageair.com/instructions_pdf/50507-VUA.pdf They also sell generic cable operated heater control valves.- 240z Fuse Box Replacement - Feedback Request - MSA, ST, Etc.

Time and corrosion that slowly builds on the contacts, creating ever increasing resistance at the fuse/clip contacts and even within the wire crimps at the connectors. This creates increasing heat. Which accelerates the corrosion, which accelerates the heat, etc. That particular circuit operates at a fairly high current level that makes it the first go. BTW the fuse selection itself does nothing to limit current, it is just a switch that blows when the current in the circuit exceeds its melt point. Voltage and resistance in the circuit determine the current. V=IR- Door spacer

That little padded ring is glued to the back of the door panel over the window crank hole. Definitely "optional" More window crank clips are here. https://www.clipsandfasteners.com/Nissan-Window-Crank-Handle-Retaining-Clip-p/a16340.htm I see the price is no longer the $5.39 I paid in 2013. Now $11.39, but still cheap for a 100. I think I still have 50 of the box I bought back then. And they are a perfect fit BTW- Quiz Of The Day

Great set of shots. Not easy either. Oh, I’m old. Can you post bigger pictures?- Quiz Of The Day

I'm actually quite impressed. All were identified more or less correctly, but no one got them all right. 1- Hatch luggage strap loose end keeper loop-thing. Zup 3- Spring clips that keep the under front fender seal in place. Very similar to choke cable clip, just bigger. Granny, Blue 4- Coat hook from early 240. Coat button really. . Blue 5- 2+2 door release handle, on rear upper portion of the door so rear seat passenger can open the door. . Blue, almost... 6- Throttle linkage spring, ZUP 7- Loch ness snowman caught making waves in Lake Ontario. Or door interior light push button switch, not sure which. Granny 8- Blower fan dropping resistor. 240z, 3 speed. Blue, Granny almost, 9- Turn signal bulb shroud in 280z Tach. 240 likely same. Blue Granny 10- E-brake cable adjusting nut. Granny 11- Un-snapped off ignition switch bracket mount security screw. Zup 12- Ash tray retainer clip. Granny And then there is the mysterious missing #2 that NOBODY mentioned. I was hoping someone would fill in their list and take a WAG at #2 anyway. Alas, it was not to be. Honorable mention goes to Zed Head for most inventive guesses. My job is done here. Next!- Datsun 240Z chrome taillight bars

The one set I purchased was very impressive. And they stayed looking great on my very well used 73.- Quiz Of The Day

No judging, just a way to pass some time. After a few take their guesses and stew for a while, I’ll reveal the answers.- Quiz Of The Day

Making some progress. Lack of scale is hurting some perceptions... BTW, nothing is ZX or 510, just S30. I was VERY tempted to slip in a 510 thing but I resisted the urge.- Quiz Of The Day

- Quiz Of The Day

I’ll dig through my pile-o-stuff and see if I can find a few obscure parts and get you to guess what they are. Maybe some pictures taken super close up to distort the view.- Quiz Of The Day

Thank you. I can go back to washing my hands. We are of course expecting someone to do one of these quizzes every day now, right? - Isolation Videos/Content to Keep Spirits High: Post Something (Non-Virus) for Entertainment of Others

Important Information

By using this site, you agree to our Privacy Policy and Guidelines. We have placed cookies on your device to help make this website better. You can adjust your cookie settings, otherwise we'll assume you're okay to continue.

Subscriber

Subscriber