Thanks Steve

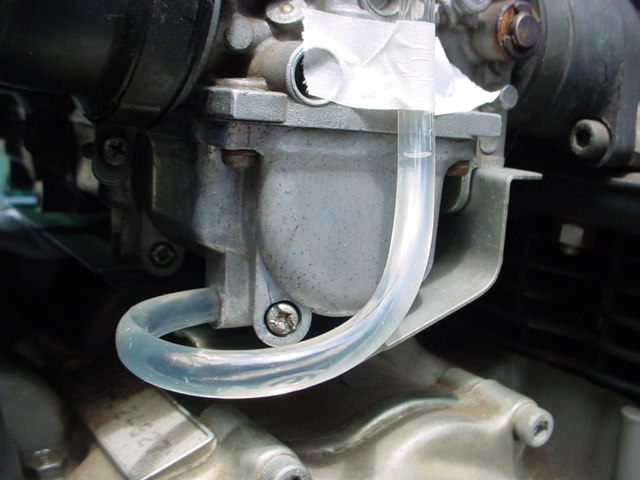

mudkip777, Basically, the process goes like this... Put the carbs together and put them on the car. Everything connected per normal. Then pull the black rubber tube off the nipple on the bottom of the float bowl and temporarily connect up a length of clear plastic tubing in it's place. Position the clear tube like the pics in that thread and then run the fuel pump. In your case, that probably means cranking the engine to make the mechanical pump deliver fuel. The fuel level the develops in the bowl (and hence the clear tube) should meet the spec in the service manual.

I would suggest pulling the plugs and make sure you have a fully charged battery. It could take some cranking to get fuel to the bowls.

That's the clear tube method in a nutshell. Details left to the studied reader.

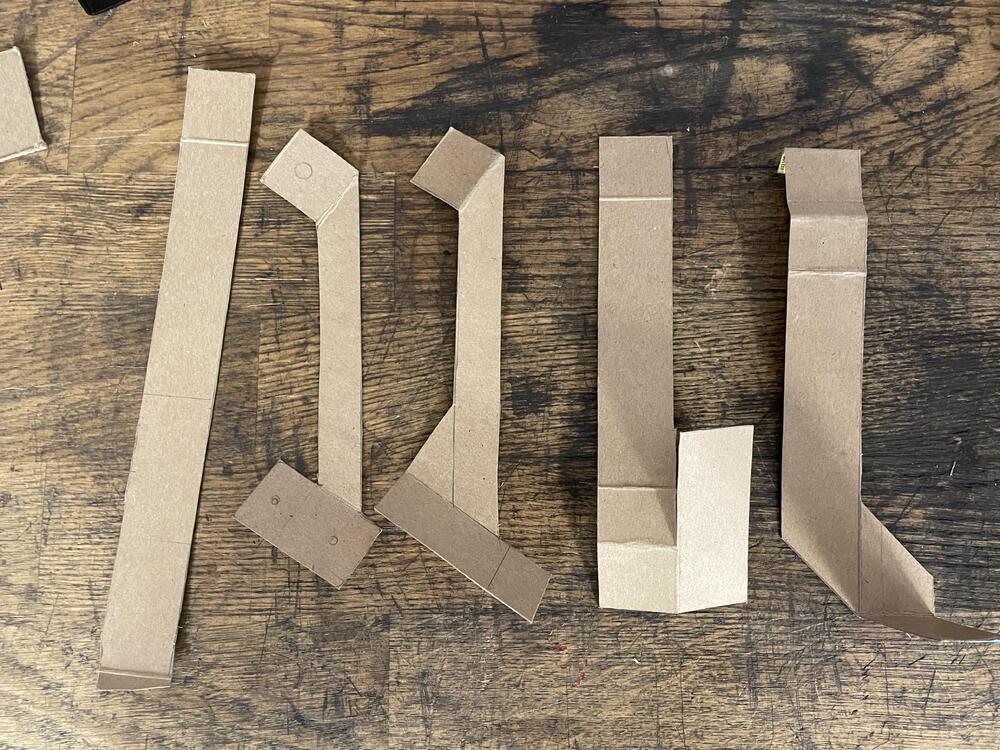

Here's a couple related pics that might help Separated from the rest of the carb, but here's a 240 bowl:

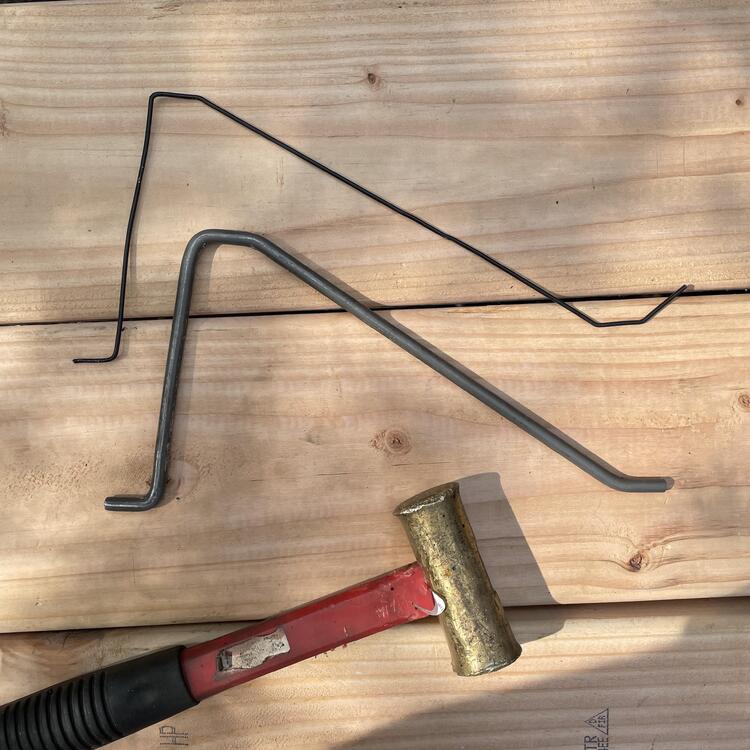

And here's a different carb, but the concept is the same: