All Activity

- Past hour

-

andy19422 joined the community

-

1971 HLS30-14938 "Lily" build

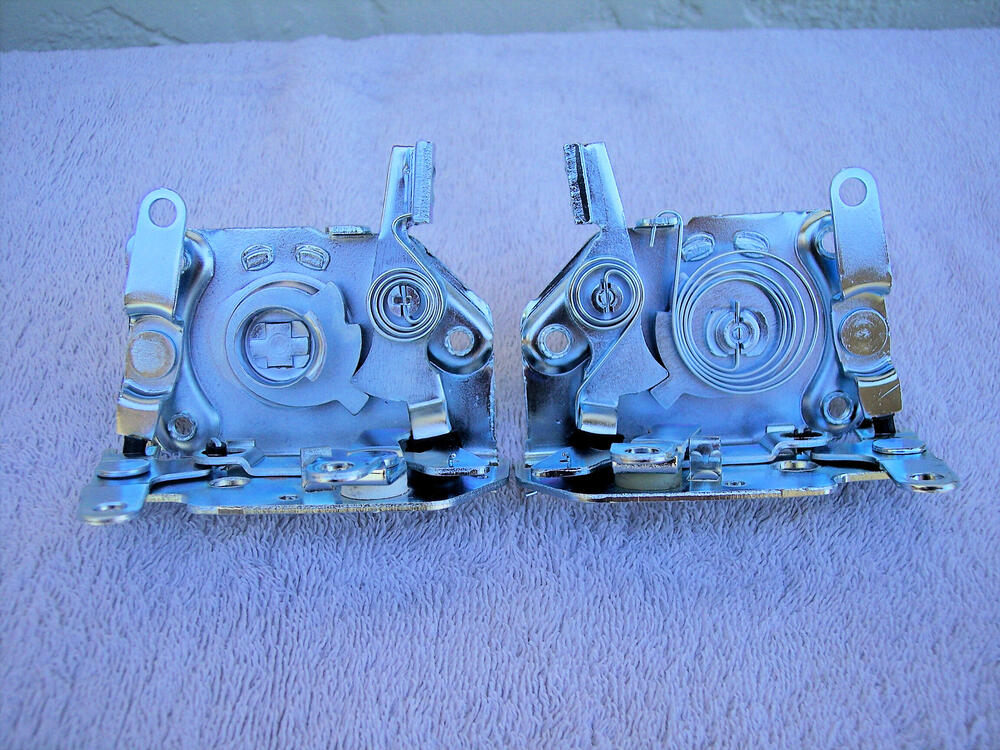

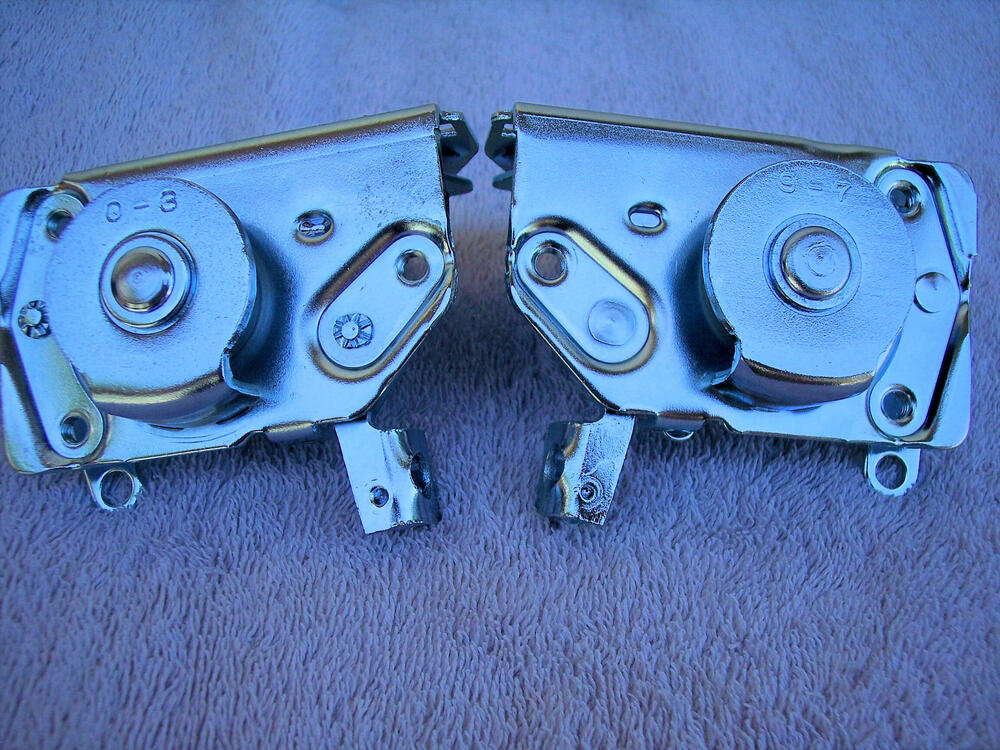

Hey Charles, I found the same difference in the return spring on one of a batch of door locks I picked up a few years ago. The unique one had a date code of 1969. The later style coil spring was not yet installed on the one on the left.

-

Wires Connected To Nothing

Did you download the latest wiring diagram PDF from Captain Obvious? He has resolved a lot of discrepencies in the FSM.

- Today

-

PROPER Electronic Fuel Pump Wiring Under Dash

Here's a good read on installation for a '72. Dave's 1972 Datsun 240z: Electri...Electric Fuel Pump InstallationIn an effort to make the 240z more reliable, I've decided to upgrade to an electric fuel pump and then retire the mechanical pump. By using...

-

Yarb started following PROPER Electronic Fuel Pump Wiring Under Dash

-

PROPER Electronic Fuel Pump Wiring Under Dash

The oil pressure switch on the 78 280 was the only model that had that configuration.

-

Wires Connected To Nothing

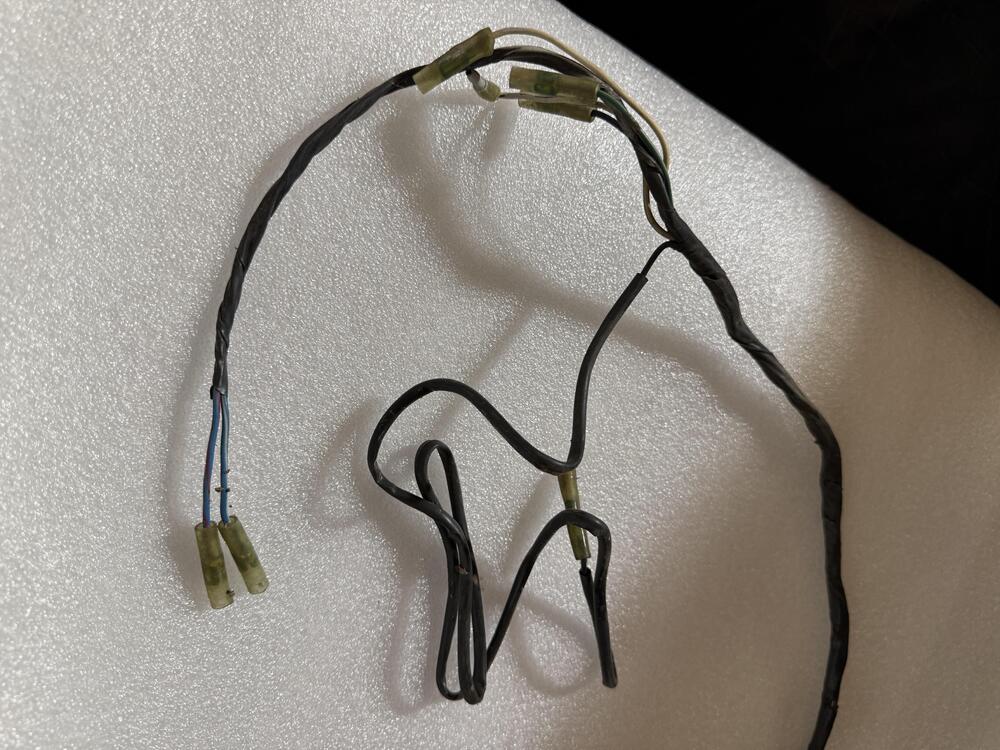

I figured at least some of them were for the radio. Are they all radio related? There is no radio in the car. I'll install one so I will need to know what wires are for what please.

-

Logybeara joined the community

-

w3wilkes started following PROPER Electronic Fuel Pump Wiring Under Dash

-

PROPER Electronic Fuel Pump Wiring Under Dash

You could do an inertia switch in the jumper loop on that plug. Duralast Fuel Pump Inertia Switch SW1771

-

jimmyd joined the community

-

1971 HLS30-14938 "Lily" build

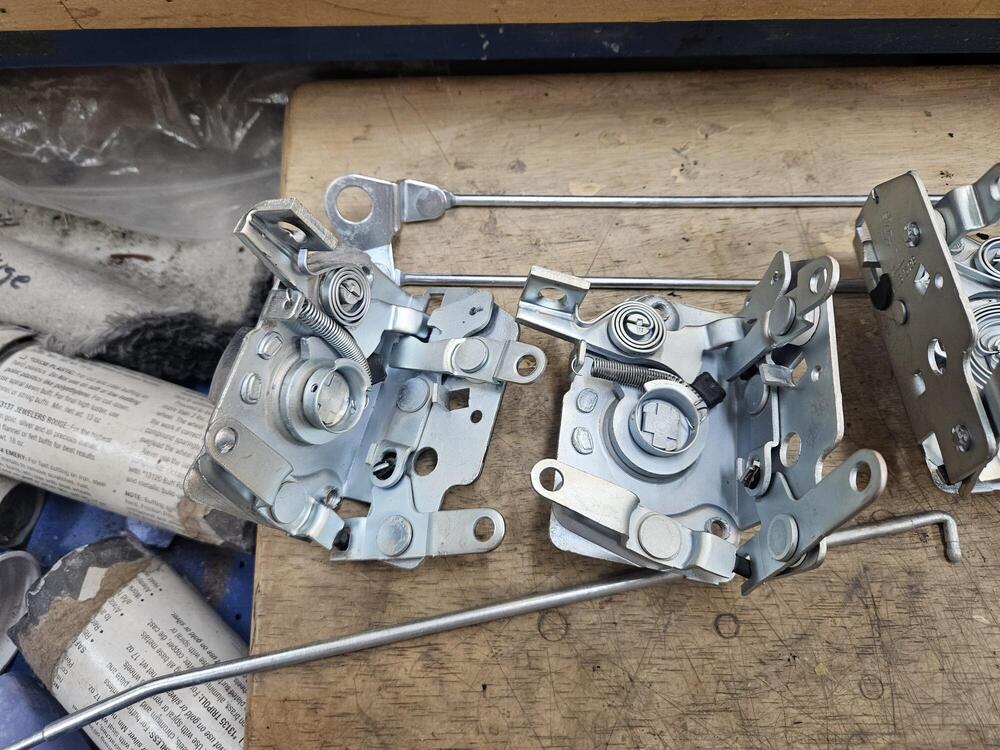

When installing the door latches, make sure you use the correct length flathead. The lowest screw that attaches the latch is shorter than the others. If you put in the longer one in that position, the latch will hang up. Again, ask me how I know 🤣😝

-

1971 HLS30-14938 "Lily" build

Yeah, I went socket head because I was thinking that getting in there with a hex driver would be easier than a phillips screw driver. And now that I've done it, I think I made the right call. T-handle allen driver for the win. Oh, and they're stainless. Seemed like the right material for the application.

-

1971 HLS30-14938 "Lily" build

Yeah i know thát feeling.. it was only yesterday that i took a look at a combination of a drill/lathe and millingmachine.. but not really to buy one because it's all Chinese junk and i don't have really room for it/that! (And a bridgeport is a machine that needs a stable floor!)

-

Zpenman started following Wires Connected To Nothing

-

Wires Connected To Nothing

They look like the radio power and lighting connections. Does you car have a radio installed?

-

1971 HLS30-14938 "Lily" build

Socket heads might be nice there. One day I might have room for a lathe... and a bridgeport...and... 😁

-

Carb flats on float chambers

I don't know if it's the ONLY reason for it's existence (seems unlikely), but that is where they printed the identifying markings:

-

SN 00042 Restoration; The Older Twin

Here's mine. A little embarrassing to post after your clean and shiny stuff, but it's what I got. They'll work fine, but aren't as pretty. You can see the washers under the springs:

-

SN 00042 Restoration; The Older Twin

Much better. One follow up question though... Are there metal washers between the hold down springs and the shoes? I can't tell for sure from the pics, but I just want to make sure the springs are not riding directly on the shoes.

-

1971 HLS30-14938 "Lily" build

Sigh. Of course you did. Right after I did this: Yes... Before you ask. Yes, I made the little plastic washers.

- Z Parts For Sale.

-

1971 HLS30-14938 "Lily" build

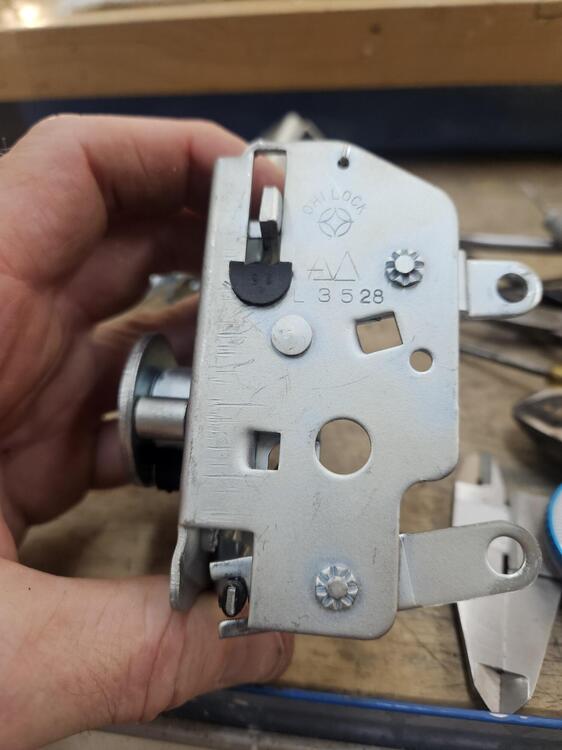

I made it back into the shop again, finally. I got a batch of clear zinc back from the platers and went through and reworked some door latches. I used the kits that Steve Nixon sells for the rubber bits inside the latch. I also bought a couple of spring assortments because one of the latches was missing the return spring Interestingly I have two different styles of latch. I have the style with the coiled return spring and then I have one latch that has the two flat springs in it. The one with two flat springs has a small notch on either side of the latch arm slot. Steve's rubber parts are designed for this style of lock. On the other locks I had to take a little rubber out of the semi circular pieces to make them fit properly and I glued them in place with some black super glue There are also three squarish rubber pieces that fit over the ends of the arms to cushion them The hardest ones to get on are the one that go on the door striker. There is very little little clearance to get the one side in Here are my two styles side by side. Maybe someone else can add some info on when these parts changed? Even the flat spring on the latch pawl is a different design between the two... I also put the dovetail on the edges of the doors and the spring loaded door poppers into the door jambs. Minimal progress but something. Now that I have the latches back, I can work on assembling the rest of the doors and glass

-

SN 00042 Restoration; The Older Twin

Checking on my vin 740 shows the same apparently un-used black wire…… Looks clean as a whistle inside the protective sleeve…. Like the above mentioned previous picture Was folded for extended time …..

-

1971 HLS30-14938 "Lily" build

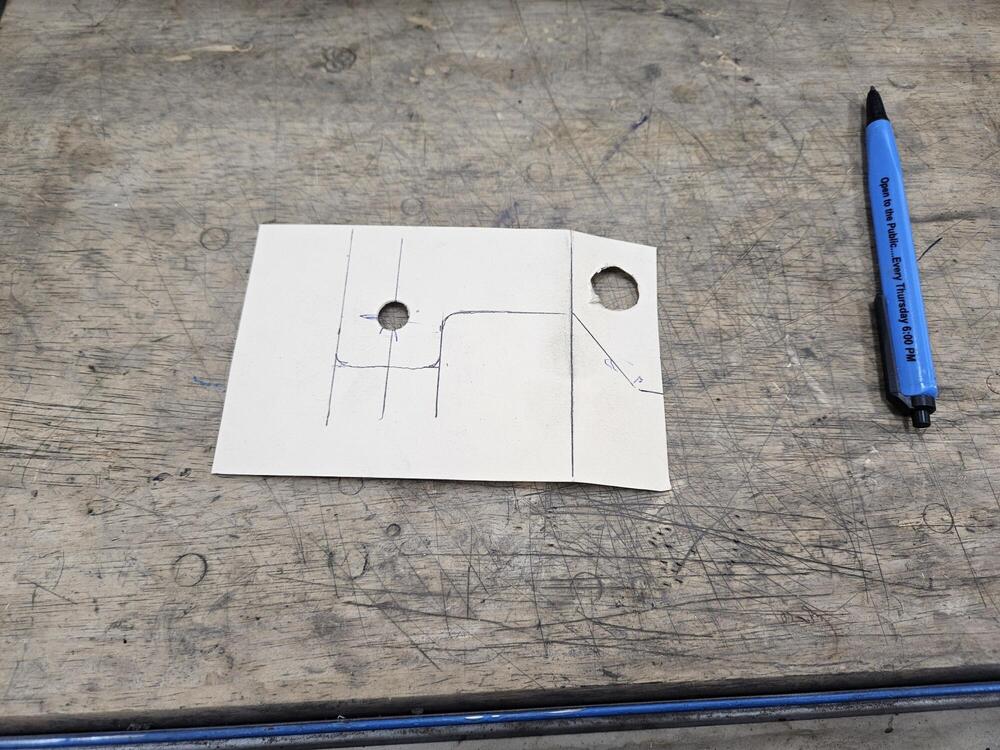

I thought I posted this up already but I didn't see them over the last few pages... I had to trim the ears on the R200 diff for a little more clearance on the new SS exhaust This is an untrimmed side Trimmed I made a bracket to connect to the mid span support on the top of the new exhaust. It will attached under the diff arrestor strap nut Template Under the car Finished

- Yesterday

-

1971 HLS30-14938 "Lily" build

- L20b Cody's Goon

-

texasz started following PROPER Electronic Fuel Pump Wiring Under Dash and Wires Connected To Nothing

-

Wires Connected To Nothing

I have a bunch of wires in the center, right above the tranny tunnel, that are connected to nothing. Can someone help with identifying what each of these should be connected to? Here are several pictures I just took. https://photos.app.goo.gl/AtbSgkaMo9Fm5uT8A

-

PROPER Electronic Fuel Pump Wiring Under Dash

Does anyone have the PROPER way to connect the under dash electronic fuel pump wiring in a 240Z? For testing purposes the connection in this picture (green and black/white wires) was jumpered and it worked. Being that there is a molex plug here there must be more to wiring it up properly. I've been told that the factory had it wired to the oil pressure gauge so that if the car lost oil pressure it would stop the fuel pump.

-

SN 00042 Restoration; The Older Twin

-

RCR Z started following Z Parts For Sale.

-

Z Parts For Sale.

RESTORATION PROJECT DONE & CLEARING OUT THE SHED. NO REASONABLE CASH OFFER REFUSED. L26 Motor with E88 Head- 074185 4 Speed Transmission - Likely L4W71B Aluminum Radiator Door Window Frames (L & R) Fiberglass Headlight Scoops (L&R) R-200 Differential 4:11 R180 Differential 3:36 2-Hitachi 3 screw Carburetors (HJG46W?) Mounted to N36 Intakes NEW - 2 each 12" Electric Fans with Controller Set of 4 - 280ZX Wheels Front Bumper with Valence Panel - Good Condition Rear Bumper - Bumper Ends Good Center Poor Full Sets of Windshield and Rear Deck Glass Stainless Trim Grille Front Valence Pieces New Rubber Weatherstrip - Window Glass Run, Rear Deck Glass, 1/4 Window, Cowl to Hood Windshield Passenger Window Glass 1970 Deck Glass with Vertical Defroster Wires TOO MANY MORE VARIOUS PARTS TO LIST!!