Everything posted by kmack

-

240Z Body Dimensions

This file is to be opened in Adobe Acrobat. This is a copy of the overall body dimensions for the 240Z from the factory shop manual. All dimensions are in millimeters. To convert (mm) to (in) multiply by .03937. chassisfrommanual8bmpwocomp.zip

-

floor jack and jack stans

The Owner's Manual says to place the jack under the seam where the rocker panels meet the floor panels. There is a vertical strip of metal there that has a "half-moon" cut-out and those are the exact jacking locations for the stock jack supplied with the car when new. If you're using a regular floor jack, you can still lift using these points, but I'd suggest using a block of wood in between so you don't damage the metal any more than neccessary. I always place my floor jack under various points of the suspension. I lift the back by placing the jack under the diffirential, and the front using the front cross memeber.

-

Homemade paint booth

From the album: '71 before shots

This was done while I was sand blasting the body. Just used 7 mil foundation plastic that you can get at Lowe's or Home Depot. -

Toon Town

Jerry, Rest assured that the "I spend more time waxing my Trailer Queen than taking a bath" Purists, would end up eating cones if the rules of the show insisted that the cars be driven on a road course to evaluate their road-worthy ability! Anytime my local club holds a car show and we get to vote for viewer's choice, I always - ALWAYS - vote for a car that has at least a little road grime on it! Cars are meant to be driven, not stored away in an oversized closet and taken out in the sunshine on special occasions. "Controlled chaos on asphalt" I love it! Drive 'em the way they were intended to drive, I say.

-

Fuel tank problem

Both EScanlon and myself gave a pretty good description of replaceing the lines for the vent tank. Follow this link: http://www.240z.org/forums/showthread.php?s=&threadid=1309 We've both been down this road before as have others. It's not too hard to do, but it does required dropping the tank a little.

-

Converting Interior (White to Black)

I saw that....blew my mind to. And we both said pretty much the same thing. Just wait, 2ManyZs will come on and be jealous that we beat him to it. Then he won't be able to up his number of posts some more!

-

Converting Interior (White to Black)

All of the panels should fit without any problems. (Although all my knowledge is with 240's) You also have the option of repainting your interior panels. I believe the best product is SEM. (someone else help me out with the product info) It may come out cheaper than buying an whole parts car, especially if your panels are in good shape other than being discolored.

-

Fuel tank problem

Have you checked the condition of your tank vent lines? These are the large fuel lines that run behind the tail light panel, through the floor and into the gas tank. Over time they get hard and brittle and crack. If so, then when you fill your tank over half full they will leak gas out of the tank. Particularly the long one on the driver's side of the car. It joins into the gas tank right at the tank seam.

-

Help me build a new exhaust system :)

So I should try and cram a "turbo-type" muffler in the tunnel along w/ the trans. and drive shaft? That sounds a little crowded. My "original" exhaust had a "glasspack" type installed there, that's the only reason I mentioned it. I know the pre-muffler is supposed to quite the resonating, but are you saying I should do w/o it? I hate to be picky here on this, but I'm getting close to to needing this.

-

A horrible weekend for me

Glad to hear you were ok.... As for the car.....ever want to do a convertible project?

-

Help me build a new exhaust system :)

Marty, I know the factory system came w/ a "pre-muffler" in it. At some point, a PO had installed what looked like a glasspack in the middle of my otherwise stock system. I need a total rebuild of mine, and will go to the 2-1/4" system. What do you recommend for this middle muffler or one at all? As for the Turbo muffler, what brand(s) do you recommend? I want something that is rather subdued, but will growl when driven hard. Looking for suggestions also.....

-

Blatant (*) kissing

EScanlon's on to something here....maybe T-shirts w/ the site logo. Then everytime a site member went to a Z function, they could wear their shirt and the site would get free advertising.

-

Strut bar????

I've heard that a 1" sway bar up front can eventually lead to metal fatigue of the frame rails and cause cracking. Suggested fix was to weld on a plate underneath the bar mounts to help overcome the fatigue and strengthen the area.

-

What year is mine & what badges?

Alfadog, the "L" in HLS stands for "left-hand drive". Your's is right hand drive am I correct? Joe71, I'll have to check and see if I still have the vents that came off the parts hatch I bought. I have new vents so I"m not sure what I did w/ the old ones. They weren't in the greatest shape, but were still in one piece. If I can find them, I'll let you know.

-

How to repair paint chips

Would a well machined metal block work? Say something along the lines like a meatl lathe cutting bit? These are high strength steel and are typically rectangular in shape. I have quite a few ranging from less than an inch to over 3" in length.

-

getting ready for undercoating

From the album: '71 before shots

Here's a shot on the rotisserie. Notice the clean shiney metal waiting for epoxy sealer and final undercoating. The primered section on pass. side is the section of floor that had to be replaced along with battery/firewall repair. -

battery repair

From the album: '71 before shots

This how my battery, firewall repair looked before final paint. Not the best, but definitely better than before! -

In the beginning...

From the album: '71 before shots

This is basically what I started with...and hopefully somewhat of an idea what I'll end up with. The paint in this picture is totally shot, but you can't tell. -

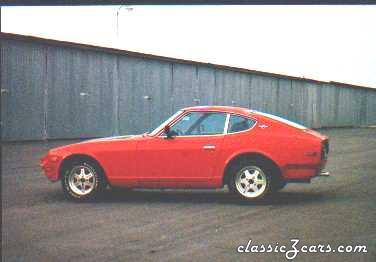

Paint Color

I agree w/ 2ManyZs, the paint code sticker was on the drivers side on my car. It's not there anymore because you almost couldn't read it so I just peeled it off. My color code is 905, sort of a Cherry Red. An unmistakable red!

-

How to repair paint chips

I found this info on a Mercedes Benz site. Lots of good stuff there. Ken Taken from Scott Grundfor Co. – Ideas for Collectors (www.scottgrundfor.com) A friend in the auto detailing business suggested a way to repair the chips quickly and economically. He proposed brush-touching the chips with a dab of paint. I thought the paint would look as if it had been brushed, but he described the process of building up the paint just above the original level then gently sanding it down. We tried it, and we could see that unless you knew exactly where the chip was, you could never see the repair. The process works best with solid colors; metallic colors may come out blotchy. A Better Way First, get the right touch-up paint for your car. For a recent model with original factory paint, a Mercedes-Benz dealer can sell you a small bottle of touch-up paint with an integral brush. If you don't know the name of the color, if it has faded, or if the car has been repainted, your local automotive paint store can match a paint sample and sell you a pint or so. Your car has a code used to determine the formula for mixing the color. Clean the chipped area. Paint will not stick to a surface with wax, grease, or silicone on it. Dilute a liquid detergent, and use a sponge or soft rag to clean the area around the chip, especially the chip itself. Clean off any accumulated residue. Let it dry. If you see bare metal, dry it immediately to prevent rusting. This works well for a small chip, perhaps caused by a rock, but a long scratch takes more skill and patience; it can be repaired, but rarely. Practice on a small, out of-the-way area so that if you make a mistake, it will be hidden. This process is not recommended for a car with a lot of chips. If that's the case, consider repainting the panel. For one or two chips, this alternative saves the difficulty and expense of spot-painting a larger area or repainting an entire panel. If you spot-paint an entire area and blend new into existing paint, you have two dissimilar paints: the new paint and the original underneath. When you spot-paint an area then finish it, you might get an exact color match then, but in time the two paints applied at different times age differently, and a ring or spot will appear. Applying Paint With the area clean and dry, you'll need a good brush with a very fine point. A large brush will slop paint over the edge of the chip. To keep the paint inside the chip, you need a very small brush with just a few bristles. Mix the paint thoroughly. Liquid paint settles as it stands, so mix in all the pigment at the bottom of the container, or the color will be off. If the paint is too thick to go on the brush and be applied in a light coat, it will need to be reduced to a thinner consistency. If you're using lacquer, you'll need lacquer thinner; if you are using acrylic enamel, use acrylic reducer. To get the desired consistency, paint should be thinned approximately one part thinner to one part paint or one half thinner to one part paint. With the brush, build successive light layers of paint into the chip. Paint shrinks as it dries, so build the layers gradually. If you put one big glob of paint into the chip, it will continue to dry for months, shrinking as it does so. Even if you finish it flat, a few months later a crater will develop where the repair was made. Allow drying time of at least an hour or two between paint layers. The longer you wait, the better the finish you'll get, so let the paint dry thoroughly. Two to four layers of paint will be needed to fill the crater. Because the paint will shrink, build the final layers a little above the crater surface. It should be fairly close but slightly above the surrounding paint. Let this dry for several weeks. In the meantime, your car won't look awful. It will look like you simply brush-touched that area, which will certainly look better than the chip. The key to this entire process is that the paint must dry thoroughly. Finishing Learning the skill of finishing is another key to success. You'll need a cube about an inch square that is perfectly flat on at least one side to use as a small wet sanding block. If you don't have something flat of this size, cut a block of hardwood. Before sanding, you might mask off the area by putting tape about an inch away all the way around. Then if you get a little aggressive in your sanding, you won't sand and scuff the surrounding area. Use 1,000-grit or 1,200 grit ultrafine wet sandpaper. You need very little; a sheet will cost about a dollar at an automotive paint store. Tear off a tiny square, enough to wrap around the block, then use a sponge to wet the area as you sand. Use the sandpaper and block to level the paint mound down to the surrounding original paint. Use the lightest possible pressure on the block, and gently wear down the little mound. Sand a little and very lightly—this can take mere seconds—then dry the area and inspect it. When you see that the mound has disappeared, you've gone far enough. Avoid sanding too much. If the paint is old or thin, or if you sand too hard, you'll go right through the finish. If you very carefully let the block float with just the gentlest pressure over the little mound of paint built up over the chip, you'll wear off the top of the new surface without removing much if any of the surrounding paint. Ideally, you'll scuff it just a bit. Next, use magnesium polish, Mother's or Blue Magic, available at most automotive stores. Magnesium is the finest abrasive I've found for compounding paint. Use a soft cloth in the area scuffed by the sandpaper and rub until the scratches are gone. Rubbing in one direction works best. After polishing, wipe the area dry and inspect it. If you see deeper scratches, do a little more polishing with the mag polish. Finally, wipe the surface clean and use wax or automotive polish (carnauba wax or similar), to finish the area around the chip. Done right, you've filled the chip and finished the top so that it blends in nicely. If you look very closely, you may see the spot. If you notice bubbles trapped in the paint (they produce white specks in the center of the chip) your paint was probably too dry, too thick. As you grow more skillful in applying wetter, thinner layers, the surface will not bubble. This method can effectively repair a chip without painting an entire panel. I've used it on show cars, where it even held up to the scrutiny of judges.

-

M/C for sale (Z funding...)

I know this isn't really Z related, but all proceeds go directly to my Z project. So in a way, it kind of is related... Anyway, what I have is an '89 Suzuki GS500 w/ 16k miles for sale. It has new brakes, Vance & Hines Exhaust, Stage 1 jet kit. Minor scratches and one small dent on the side of the gas tank. I'm asking $900 as is. This bike runs great and has never failed to start or run excellant in the last 4 years I have had it. I'm located in San Antonio, Tx and can arrange delivery to as far away as Dallas or Houston. Any inquires can be either emailed to me or call the house @ 210-699-6436. Thanks, Ken.

-

Thoughts for those who take life too seriously

....and the one I like: Everyone has a photographic memory, some just don't have film. I have a few more at work that are really good....

-

Comprehending Engineers

I used to work at a non-profit research facility and some of the engineers there were way off in left field. If you had a question about design or something chemical, they'd rattle your brain with facts, theories, etc., but ask them to show you how to change a tire or something like that and they were stumped! No amount of "book smarts" can make up for a good set of "street smarts" and common sense. I worked along side another technician on a "Torque-loss" testing program on various production engines. We essentially took out individual parts and spun the engine to measure the amount of torque. When we got down to nothing more than the crank, we had to have some way to simulate piston/rod weight. The project engineer suggested using lead semi-circles held on by regular hose clamps. :eek: We tried to plead with him that this would not work, since the clamps would be out of balance. Didn't work. We slung the weights at about 4500 rpm and I've never seen another 8000 lb test stand jump in the air like that! Talk about having to change your shorts!!! The only response we got from the engineer when we had to go buy another engine and start over was: "I thought it would work?"

-

Comprehending Engineers

Comprehending Engineers - Take One Two engineering students were walking across campus when one said, "Where did you get such a great bike?" The second engineer replied, "Well, I was walking along yesterday minding my own business when a beautiful woman rode up on this bike. She threw the bike to the ground, took off all her clothes and said, "Take what you want." "The second engineer nodded approvingly, "Good choice; the clothes probably wouldn't have fit." Comprehending Engineers - Take Two To the optimist, the glass is half full. To the pessimist, the glass is half empty. To the engineer, the glass is twice as big as it needs to be. Comprehending Engineers - Take Three A pastor, a doctor and an engineer were waiting one morning for a particularly slow group of golfers. The engineer fumed, "What's with these guys? We must have been waiting for 15 minutes!" The doctor chimed in, "I don't know, but I've never seen such ineptitude! "The pastor said, "Hey, here comes the greens keeper. Let's have a word with him." [dramatic pause] "Hi George. Say, what's with that group ahead of us? They're rather slow, aren't they?" The greens keeper replied, "Oh, yes, that's a group of blind fire-fighters. They lost their sight saving our clubhouse from a fire last year, so we always let them play for free anytime." The group was silent for a moment. The pastor said, "That's so sad. I think I will say a special prayer for them tonight." The doctor said, "Good idea. And I'm going to contact my ophthalmologist buddy and see if there's anything he can do for them." The engineer said, "Why can't these guys play at night?" Comprehending Engineers - Take Four (No doubt a Teamster engineer) There was an engineer who had an exceptional gift for fixing all things mechanical. After serving his company loyally for over 30 years, he happily retired. Several years later the company contacted him regarding a seemingly impossible problem they were having with one of their multimillion dollar machines. They had tried everything and everyone else to get the machine to work but to no avail. In desperation, they called on the retired engineer who had solved so many of their problems in the past. The engineer reluctantly took the challenge. He spent a day studying the huge machine. At the end of the day, he marked a small "x" in chalk on a particular component of the machine and stated, "This is where your problem is". The part was replaced and the machine worked perfectly again. The company received a bill for $50,000 from the engineer for his service. They demanded an itemized accounting of his charges. The engineer responded briefly: One chalk mark $1, Knowing where to put it $49,999. It was paid in full and the engineer retired again in peace. Comprehending Engineers - Take Five What is the difference between Mechanical Engineers and Civil Engineers? Mechanical Engineers build weapons, Civil Engineers build targets. Comprehending Engineers - Take Six Three engineering students were gathered together discussing the possible designers of the human body. One said, "It was a mechanical engineer. Just look at all the joints." Another said, "No, it was an electrical engineer. The nervous system has many thousands of electrical connections." The last said, "Actually it was a civil engineer. Who else would run a toxic waste pipeline through a recreational area?" Comprehending Engineers - Take Seven “Normal people ... believe that if it ain't broke, don't fix it. Engineers believe that if it ain't broke, it doesn't have enough features yet." Scott Adams, The Dilbert Principle Comprehending Engineers - Take Eight An architect, an artist and an engineer were discussing whether it was better to spend time with the wife or a mistress. The architect said he enjoyed time with his wife, building a solid foundation for an enduring relationship. The artist said he enjoyed time with his mistress, because of the passion and mystery he found there. The engineer said, "I like both." "Both?" Engineer: "Yeah. If you have a wife and a mistress, they will each assume you are spending time with the other woman, and you can go to the lab and get some work done."

-

Non-modification camber kits (MSA)

I got the new Motorsport Auto Auto News the other day. On page 18 they list a new "Performance Camber kit" for the front and rear. They are listed at $99.95 for a pair. "...our camber kit is a direct bolt-in allowing simple camber changes while requiring no sheet metal modification. Allows for 1.5 degrees of camber change. Maintains original ride height in Z's built up to 8/74...." At some later point down the road, I'd like to lower my Z a little, no more than an inch. I've heard/been told that lowering affects your camber, hence the need for adjustment. If this little gadget works, then it would make things a lot easier. Question: Has anybody heard/seen/used or otherwise have any additional info on this type of product? Is 1.5 degrees of change enough for a Z that has been lowered 1"? I know I could adjust my camber just by slotting the strut mounting holes, but I'd hate to do that sort of thing and then later want to go back to stock. Also, I'm looking at using this car for some autocross duty.