-

1973 Rebuild

I’m guessing no one has problems with that then. Maybe the clue is in the name (dust cover) and it’s more about keeping things out than keeping things in.

-

1973 Rebuild

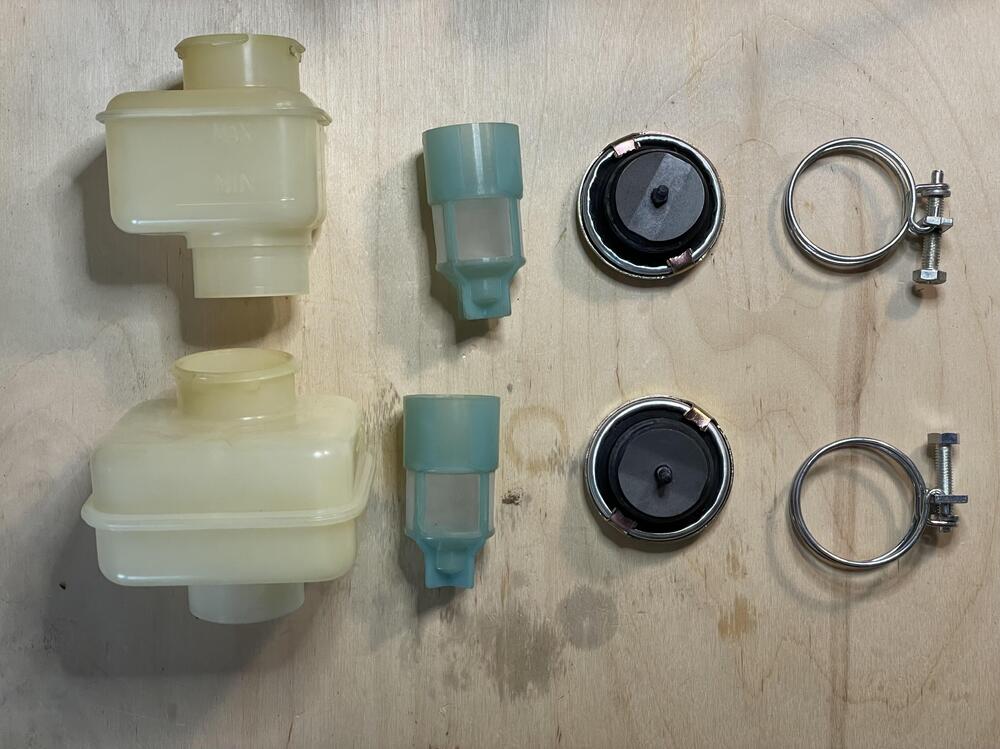

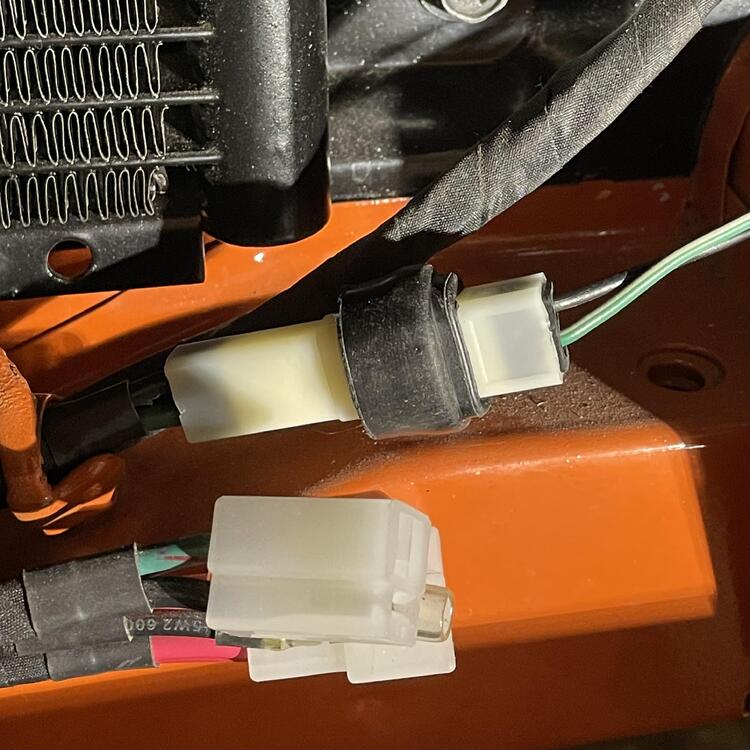

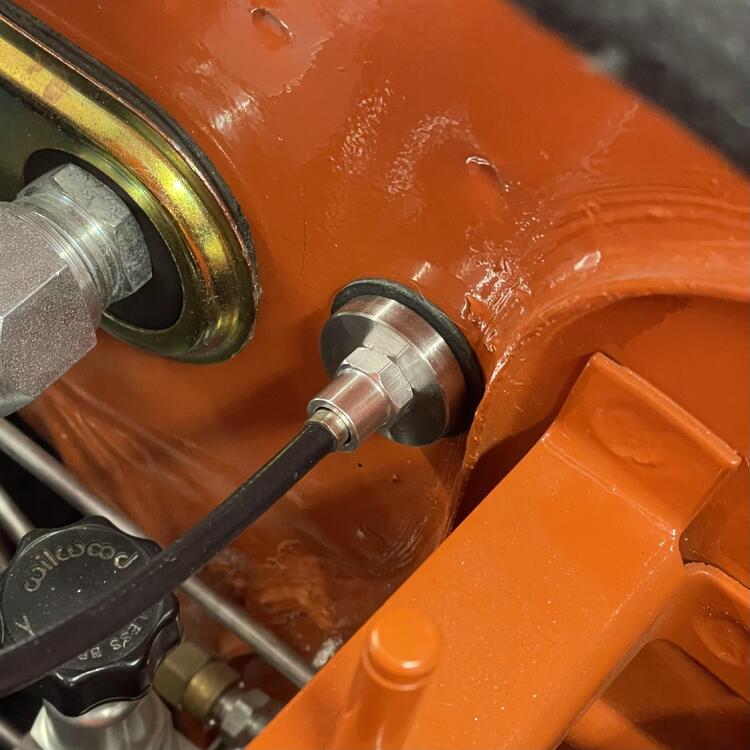

Does anyone know if the 15/16” 280ZX brake master cylinder is supposed to have a dust boot here: That collar is 38mm. The only ones I can find that look right are 26mm. It looks like there’s a groove to hold one on, and there’s clearly a channel for an o-ring, but I can’t find one in the exploded diagram. I have seen a bunch of aftermarket ones that have a dust boot, including the Wilwood 1” MC, but nothing for the factory ones.

-

1973 Rebuild

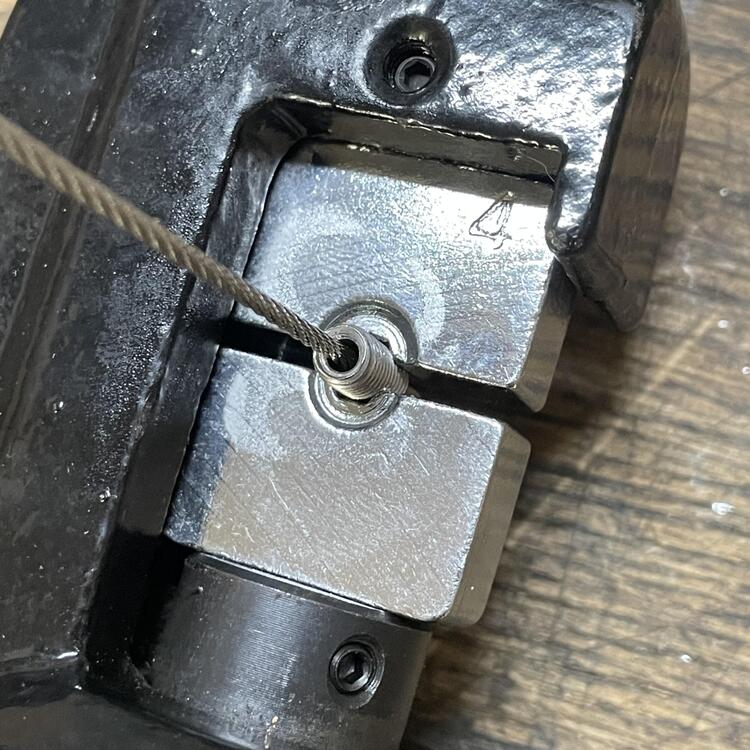

280ZX Brake MC is ready to go! I tore this apart several years ago thinking it would be a short project, but the rebuild kit I had turned out to be for the one made by Tokico (large perforated disc residual valves) and this one is made by Nabco (small rubber duckbill residual valves, see below). I had messed around with trying to rejuvenate the reservoirs. I had read you could cover it in a solution of oxy clean and hydrogen peroxide gel under UV light for 24 hours and it would take the yellow out. It lightened it up, but they’re still clearly yellow. Super clean, though. I also did some chemistry on some of the hardware. The bleeders and reducers for this thing are not common sizes (the reducers are m16x1.0 to m10x1.0) and after two weeks of searching for replacements I gave up and decided to try chemically coating them. I didn’t want to do the hardcore hot bluing or zinc methods because of the chemicals, so I used the rust bluing method. Basically, you soak them in white vinegar to strip off the rust, zinc, and anything else on them. Then you paint them with a paracetic acid / salt solution (8 parts hydrogen peroxide:1 part white vinegar + as much salt as it will dissolve). Dry it with a heat gun and throw it into a double boiler. You’ll see the rust turn black, which is when it turns into iron oxide. Buff it with steel wool and repeat until satisfied, then soak for 24 hours in motor oil. They came out okay. I was hoping they would look more like the pistons, but this is what they look like after four rounds of the process, so it’s going to have to be good enough. Fingers crossed that they don’t just immediately corrode. You could also do the phosphoric acid version (cold bluing), but this makes a harder coating of iron oxide. Then I just had to hone the cylinder, flush it with 91% alcohol, wipe it out, and reassemble. I kept the Tokico 240Z reservoir caps since I didn’t wire the car for ZX caps (PN: 46020-U6701) with the fluid level sensors and don’t have the metal (PN: 46020-K2401) or plastic (PN: 46020-N6000) Nabco caps. Maybe later if I can find a set for less than €53.40. It looks pretty good after test fitting it. I’m waiting for a dust cover and O-ring in the mail, then I can install it and bleed the brakes.

-

1973 240z Custom Wiring From Scratch

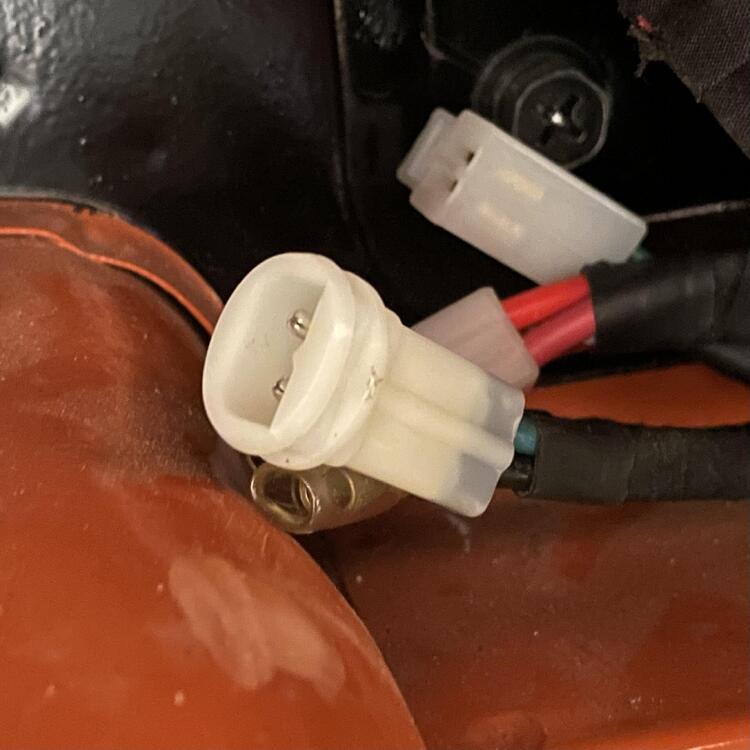

Quick one today. After working out some kinks in the wiring (thanks @SteveJ) I’m nearly done with it. I refurbished the wiring for the tail lights this week. I’ve always planned to rework the arrangement to be more like (but not exactly like) the euro tail lights. I’ve read a ton of stuff about these cars getting rear ended, so I wanted to make it as clear as possible that I’m braking. I still plan to add a third brake light, but I think this is substantially better than the original US tail light configuration. Driving lights are the outside top lights only. IMG_4744.mov IMG_4745.movTurn signals are the outside bottom lights only (thanks to @w3wilkes for the flasher recommendation). Brakes all of the top lights. Now I have to figure out what I’m going to do with the front turn signals. These LEDs are so bright that when the driving lights are on you can’t tell they flashing from more than a couple feet away. I’m wondering if there’s a way to make it cut power to the driving light wire only when the turn signal is working.

-

1973 240z Custom Wiring From Scratch

I just switched to OEM flasher relays and tried it with the LEDs still installed. No change. The lights come on but don’t flash. Then I pulled the LEDs and put incandescent bulbs in, which totally fixed it. So it’s the flashers and/or the LEDs and not the wiring. I am going to try swapping the wires over the weekend and putting the LEDs back in (no time right now. Work deadlines). If that fixes it I’ll just leave it like that until I get around to buying new relays.

-

1973 240z Custom Wiring From Scratch

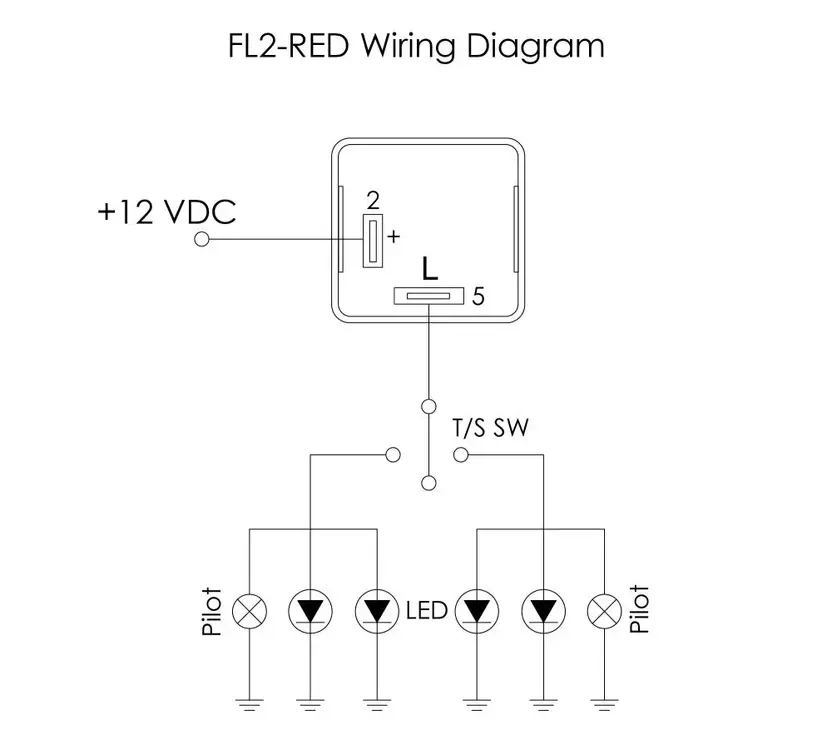

Okay, found my first error. The flashers aren’t flashing. I had replaced both the TS flasher and the hazard flasher with one of these LED-specific flasher relays. When the switch is thrown the lights come on, but they are just on, no flashing. Unplug the flasher and there are no lights, which makes sense because the circuit is broken in that scenario. I swapped an aftermarket replacement for the stock one into the spot for the turn signals, but there was no change. I haven’t had a chance to get to the one for the hazards yet. Any thoughts? Edit: After looking at the spec diagram on the red relays and comparing the marking on the original relays, I’ve found that the polarity is backwards. This flasher relay has the pins flipped from the one I am using and is the one I should have bought. Maybe if I swap the wires in the connector it will fix it. I just blanked on checking this.

-

1973 240z Custom Wiring From Scratch

I have lights. No one is going to not see this thing. These LEDs are significantly brighter than the lights on my Subaru. Unfortunately, somewhere between testing it on the bench and installing the dash, the speedo and tach illumination stopped working. I think the main branch of wiring coming out of the dimmer is messed up. I also don’t have any blinkers for some reason. That one is going to be harder to figure out. Worst case scenario is that I made a mistake in the engine harness.

-

Nabco vs Tokico 15/16 Brake MC Pistons

The stop screw catches the rear (left in photo below) piston in the narrower part between the seals, right? I noticed that space on the Tokico kit (bottom) is longer than the Nabco version (top). There’s also more fluid in that area because the piston is narrower there. The front (right in photo) piston is also narrower on the Tokico, but otherwise those are really similar in length. Virtually the same. I wonder if the Tokico works in the Nabco but not the other way around.

-

Matthew Abate started following Nabco vs Tokico 15/16 Brake MC Pistons

-

Nabco vs Tokico 15/16 Brake MC Pistons

I considered putting this in the ZX section but I thought the brake specific section would be better due to all the upgrade threads. I was wondering if anyone has tried or knows what happens if you try to use the pistons from a Tokico master cylinder rebuild kit in a Nabco MC. looking at them side by side they are clearly different, but only just. It make be hard to see in the photo but there are small differences in the measurements between them (dirty is Nabco, shiny/bagged is Tokico). The overall length looks the same. I haven’t measured them yet so can’t give you precise numbers.

-

1973 Rebuild

I was able to get these out with a small hook. I think the corrosion was holding them in. Once I got it open I found out I have the wrong rebuild kit. I have 46020-C6126, which is for the Tokico . This is a Nabco, which uses totally different residual valves. I think the kit part number is 46011-P6525.

-

1973 Rebuild

The 7-piece kit, black 80/20 loop. When I spoke to them they said that was better feel than “OEM” and better wearing that cut pile. It does have good feel.

-

1973 Rebuild

They only showed two kit options when I looked for 240zs. There are several fabric and color options though. https://newarkauto.com/pages/search?Make/Datsun/Model/240Z/Year/1973 ••• By the way, does anyone know how to pull the residual valves (the black cones) out of a 15/16 Nabco master cylinder? The ones in the rebuild kit are not threaded. I’m assuming it’s some kind of press fit situation.

-

1973 Rebuild

They have this kit and one with several more pieces, which I assumed was for 280zs.

-

1973 Rebuild

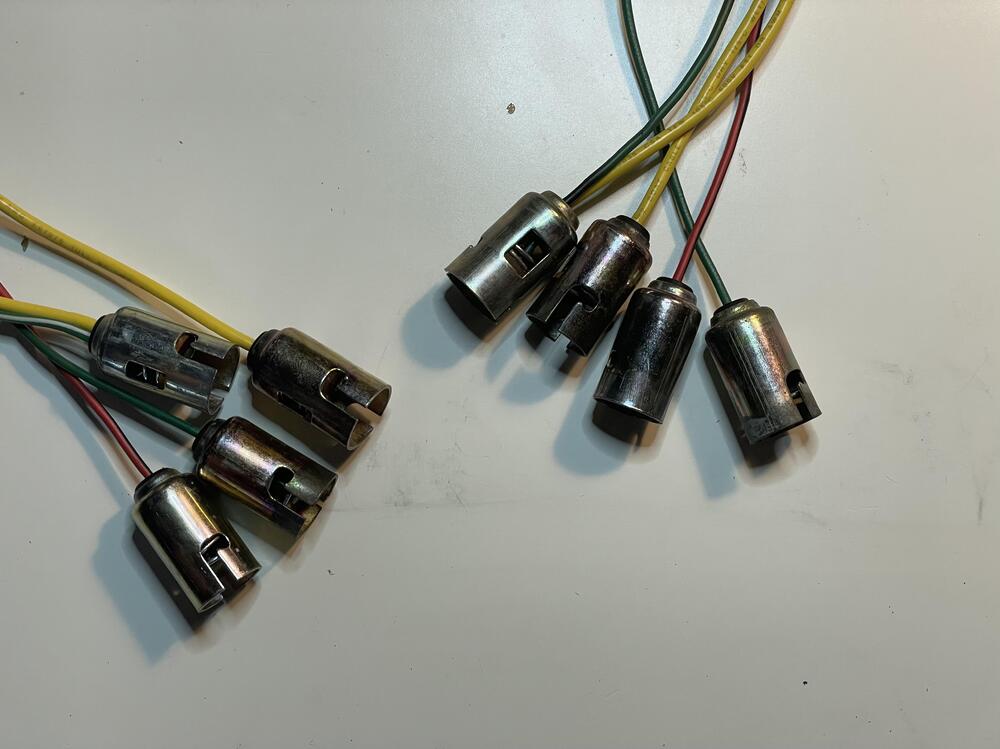

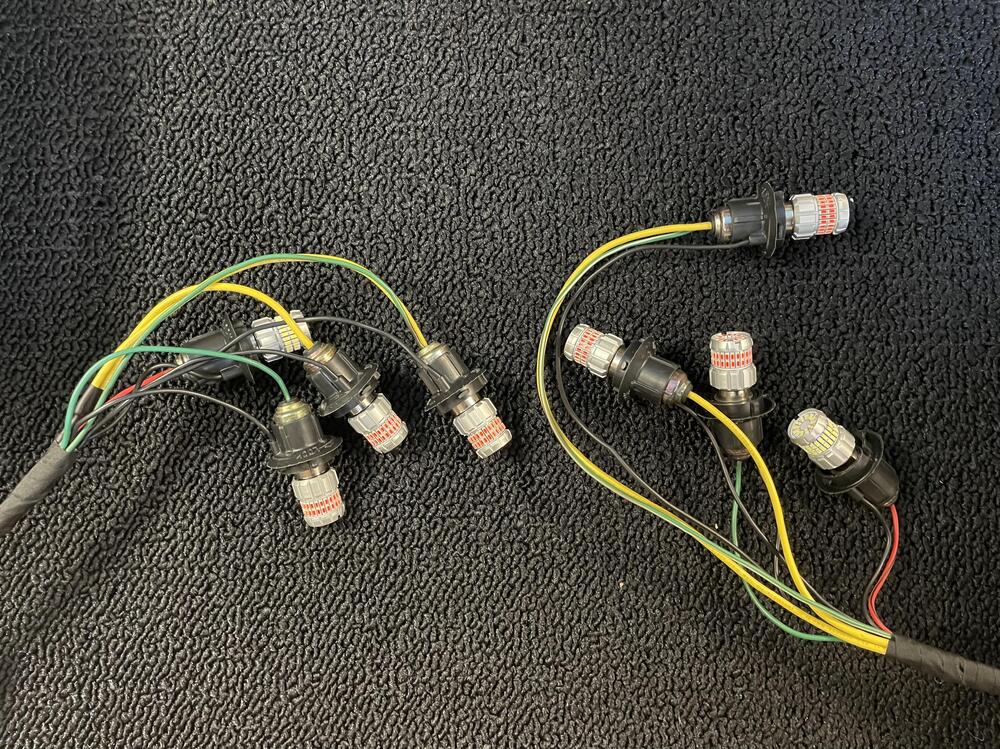

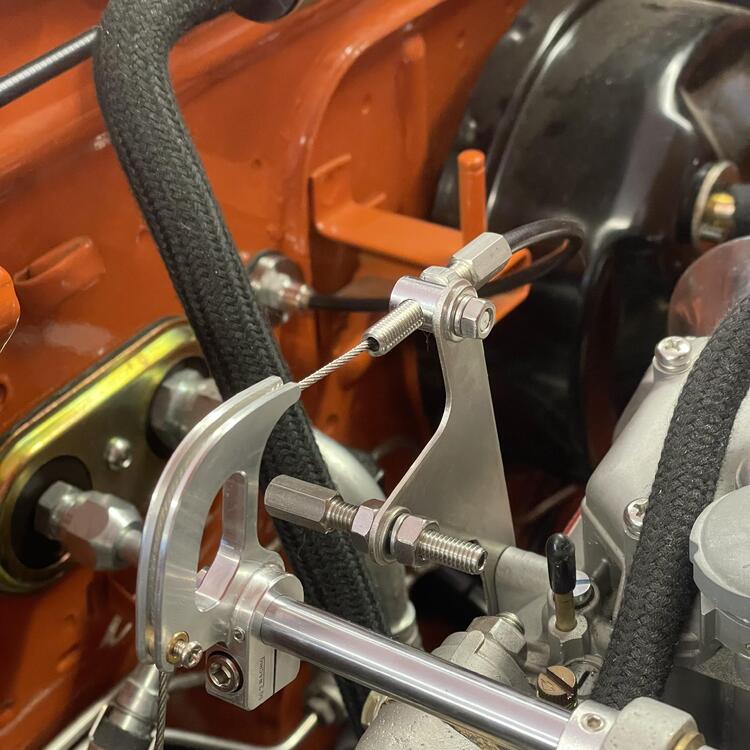

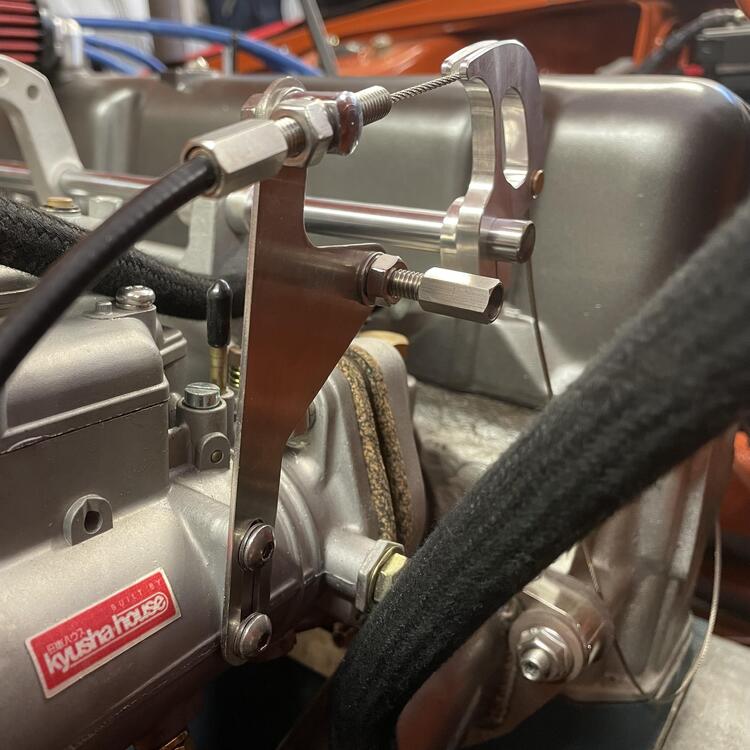

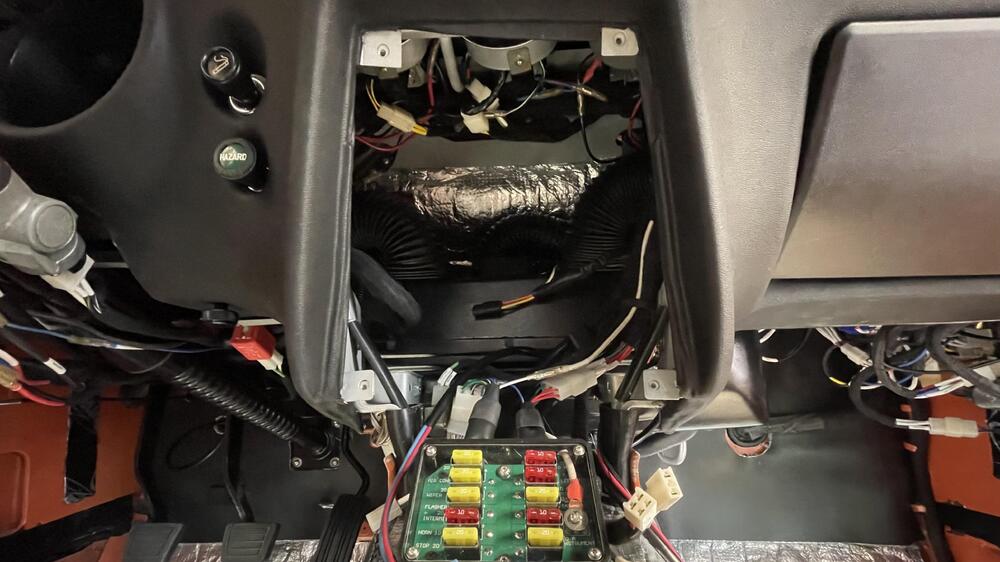

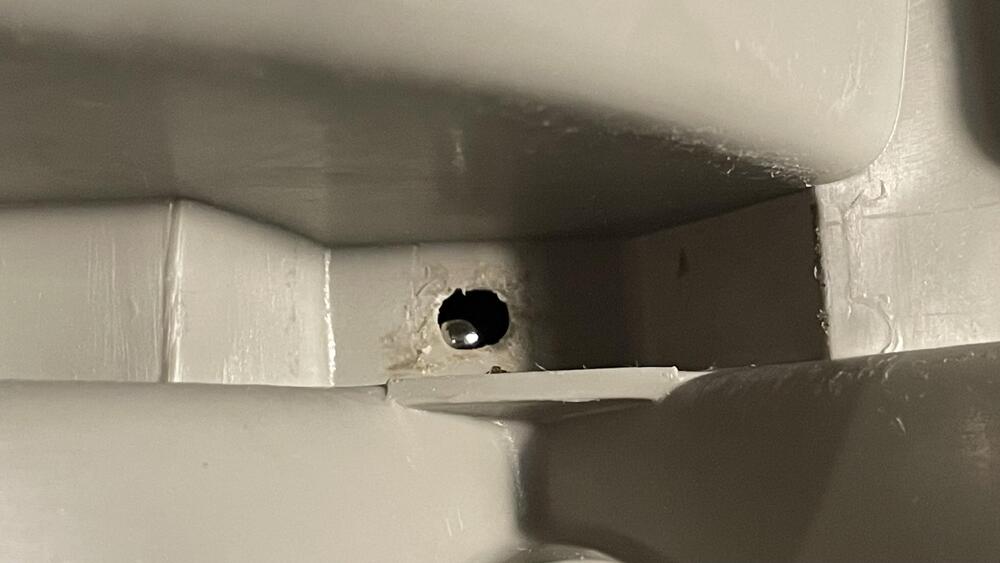

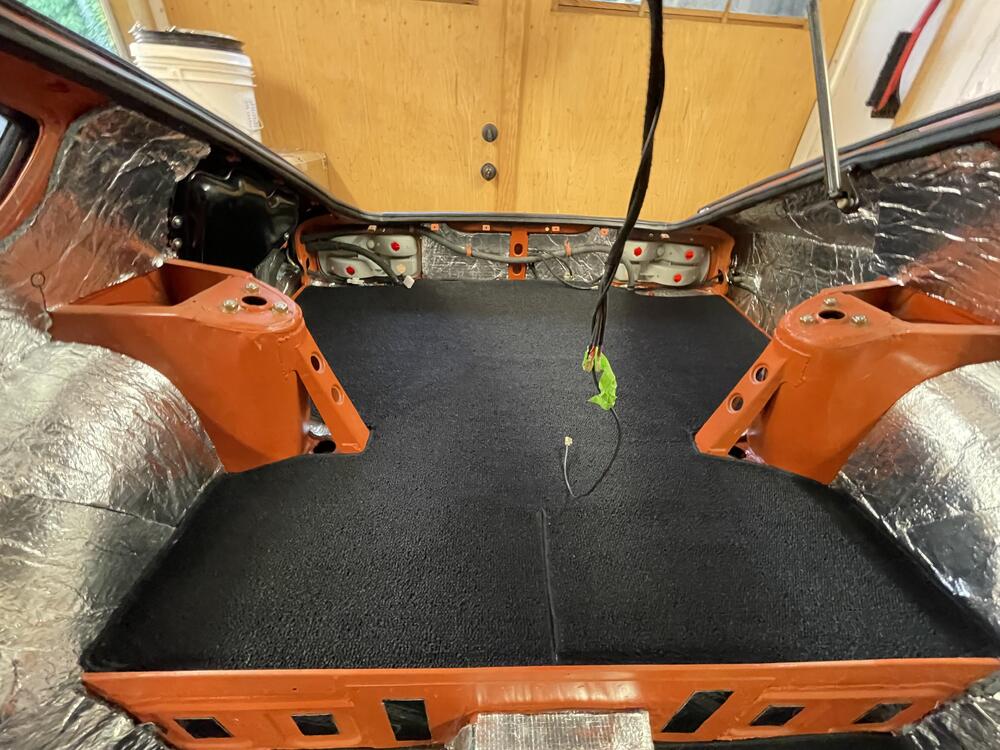

Okay, it’s been a minute so this post will be all over the place… I’m going to start with baby steps that feel like giant steps. I was able to install the left side headlight bucket. It seems small, but I hadn’t been able to get to all of the weatherstripping that goes under the fender so I put it off. This was the first time I’d seen it together (on one side) since it came back from the painter. I found there was a sizable gap between the bucket and the fiberglass air dam and I didn’t know how far the dam was going to flex. It ended up working out when I got the blinkers on, but it’s not a crisp clean fit. More on that later. ••• I didn’t do a great job documenting this, but I did a complete refurb of my marker lights and turn signals, inside and out. Left side is before, right side is stage 2 of the 3 step polish. The left front TS and three of the marker lights were pretty beat up. The white plastic was nearly brown inside and the mirror of the fronts and metal housings of the marker lights were all rusted. I stripped these pieces and painted the metal parts with highly reflective silver spray paint. The plastic housing I sprayed white inside and left the outside raw, painting the mirror the same as the marker lights housings. The lenses were sanded with 400 grit wet/dry paper, then up through 5,000 grit, and finally polished with Novus plastic polish. Surprisingly, I was able to reuse all of the OEM rubber parts. They just needed scrubbing with a green scotch bright pad. I decided to replace all of the hardware with stainless bolts instead of sheet metal screws because the right rear screws are uncomfortably close to the fuel vapor hoses. I wasn’t able to get JIS screws quickly enough so I just went with generic M5 cap head bolts, with fender washers and lock nuts on the inside. The ones in back got rubber caps on the bolts, too, just to be safe. All of the wiring and connectors for these were replaced. The OEM sockets and rubber boots were refurbished. I ran out of bullet connectors so I used Yamaha sealed connectors for the front marker lights. I’m a bit bummed that the rubber covers from Vintage Connectors for the turn signals are so short. I’m wondering if I need to do something like wrap them in tape to keep the water out. The bulbs are color matched LEDs from Super Bright LEDs, which I think look nicer than using white ones under the colored lenses. The color is much richer while still being… uh, super bright. The gaps around the air dam closed up a bit after I got all of the hardware on, but the curves of each piece (headlight bucket, air dam, and blinker housing) don’t match, which is irritating. I’m hoping it will disappear once the bumper is on. ••• I FINALLY finished my throttle cable setup. I looked at a bunch of off the shelf options and a few specifically for Z cars, but the prices and not quite being what I wanted pushed me into making my own. The two challenging pieces were the bulkhead and the bracket. I made the bulkhead out of a stainless steel drain plug that a friend drilled out and tapped for me on his lathe. We broke a tap and probably dulled a second to the point of not being usable any more. If I did it again I would use aluminum. It’s held on with an M18 nut and has the cable adjuster for a triumph motorcycle brake lever screwed into it for the cable sleeve. That’s probably also unnecessary as I could have made the bulkhead so it acted as the cable sleeve seat on its own. The bracket was another Send Cut Send job. I had to wait until everything else was figured out to design and order it, but I made four versions with the hole for the throttle cable adjuster at various heights. I opted for the second tallest, but I’ll change it if this ends up feeling wrong. I’m definitely going to have to ad a bend along the long edge to reduce flexing. I went with a progressive cam from @duffymahoney and had to make sure there is no interference when all said and done. The shortest bracket looked the best but was uncomfortably close to the cam at full throttle. All of the cable bits and pieces I got from Venhill Engineering for a song. The reason there are two adjusters in the photo is so the bracket can also hold the choke cable, which I am repurposing to operate the starter valves on the Mikunis. I doubt I’ll ever use them but I don’t like having inoperable parts in the car. The cable is affixed to the ball socket by a m5 lamp bolt that was decapitated, crimped to the cable, rethreaded, and soldered. So yeah, the throttle half of this project is done for now. I just need to change the screw holding the cable to the cam to be a set crew, cut the excess cable, and cap it off so it won’t fray. The bracket will definitely need to be stiffer, but that’s for later. ••• Unfortunately I keep forgetting to take pictures, but I can show you how I ran the AC drain so it minimizes the size of the lump when I install the transmission hump upholstery. The Vintage Air evaporator came with a black hose, but I swapped it out for some hose with a thicker side wall, which should keep it from compressing under the upholstery and inhibiting the flow of condensation. A nozzle connects to the hose with a 1/2” barbed splice fitting. The black piece is from sun roof drains on GM and other vehicles and its X-shaped aperture should create a Venturi effect when mounted perpendicular to air flow to pull water out and prevent anything from traveling back up the hose. Pretty generic and available on Amazon for a few bucks. I cut the insulation to make a channel for the hose to rest in. A 5/8” hole and some RTV to make sure it doesn’t pop out and I’m good to go. I also finished the passenger side door window and the rest of the interior firewall work the same day. Now to check the refrigerant plumbing for air leaks. 👍🏻 ••• After I was finally able to get all of the firewall work done, I put the dash in and plugged it all together. Nothing major to report since I’ve discussed the details in previous posts. This time I took more care to tuck the wiring away nicely. The few loose ends are wire for a set of foot well lights that are switched at the doors, a feed for a USB plug I intend to put in the center console, and the power/ground and control wires for the evaporator. The biggest challenge was getting it back in with the air ducts installed. This corrugated tubing from Vintage Air is nice but it’s not flattened/ovular like the OEM stuff so it requires some persuading. I still think it’s better, though. It’s tough to see in the center but it’s really well fit to the evaporator without any clamps, which keeps it clean and free of things to chafe of the hose or wiring looms. I’m hoping a harness cover will clean up the mess around the relays, but I’m going to zip tie some of this up tight before any cowls or covers go on. ••• And here it’s starting to feel like a car! Or, at least I am staring to get some storage space back. 🤣 I’m really pleased with how the Vintage Dashes dashboard looks. The glove box door needs adjusting, but after hitting the finisher with some Landau Black SEM Color Coat it all came together. It seems the internet was correct about that being the right color. I’d heard these aftermarket windshield gaskets leave a bit to be desired compared to OEM, and it’s true, but I think you can finesse it into shape. The gaps in the corners were really bad until I put the steel trim in. That stretched them out a bit, but it’s not perfect. I’ll let it settle for a while and then might just pump the gaps full of weather strip adhesive until it’s filled in. Speaking of steel trim, that’s a fun chore. 🙄 ••• My spare tire cover was FILTHY. Luckily it cleaned up well and didn’t pucker or warp. The orange flecks in the fiber board are a nice touch. ••• Lights! No before pictures but here’s everything put together. I used the same process on the lenses as the blinkers. The housings were scrubbed and then wiped lightly with acetone to get the last of the adhesive off. Thankfully I didn’t need to recondition the mirrors. The center lug on the replacement chrome trim is too short to function as the only fastener holding everything together. I used a M5 threaded socket left over from installing the blinkers along with a rubber washer. It worked fabulously, but I think it would be really easy to screw up if over tightened. No wiring yet. I just wanted to close up the cabin for the next step. ••• Looking clean figuratively and literally. I picked up the basic carpet set from Newark Auto in black 80/20 loop. It’s really nicely made, but I don’t think it’s meant to go with an insulation kit like the one I have. There are a few places where it would have fit better if there was no insulation, and there are a few places where it is just straight up wrong. Overall give it a 89 or 91 out of 100. Worth it but could be improved. I’ll be using the vinyl kit from MSA on the sides. I’m going to cross my fingers and hope my original interior pieces clean up nicely. I just put them straight into storage without unpacking them when I bought the car, so who knows what shape their in. If they suck I’ll be new replacements. But yeah, the car is starting to feel like a car.

-

1973 Rebuild

That’s the idea! I was given one of theirs jump starters as a joke/gift a while ago. It is kind of amazing. I picked this up with their Genius 10 trickle charger, which will work through the cigar lighter in cars where it’s not switched.

Important Information

By using this site, you agree to our Privacy Policy and Guidelines. We have placed cookies on your device to help make this website better. You can adjust your cookie settings, otherwise we'll assume you're okay to continue.